Contents

i

Table of Contents

Safety......................................................................................................................... iii

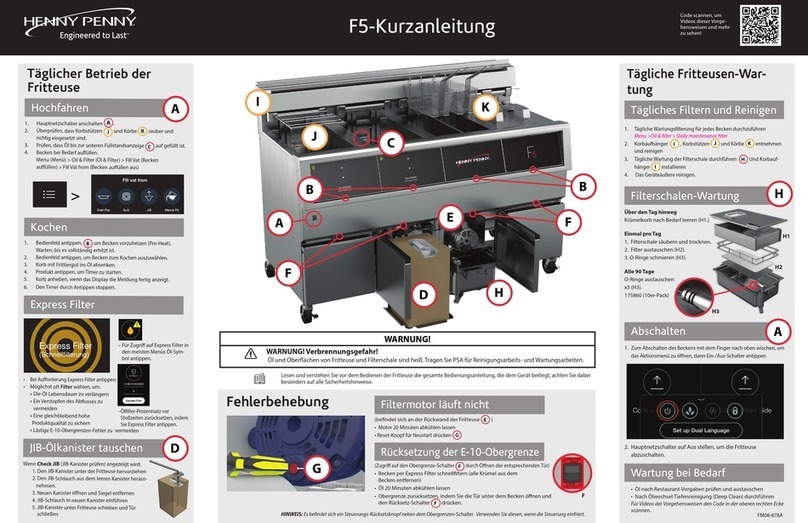

Chapter 1 Troubleshooting ..............................................................................................1

1.1 Introduction ...........................................................................................................1

1.2 Troubleshooting .....................................................................................................1

1.3 Error Codes...........................................................................................................3

Chapter 2 Info & Filter Button Stats ..................................................................................5

2.1 Info & Filter Button Stats .........................................................................................5

2.1.1 Filter Button Stats ............................................................................................5

2.1.2 Info Button Stats ..............................................................................................5

Chapter 3 Information Mode ............................................................................................7

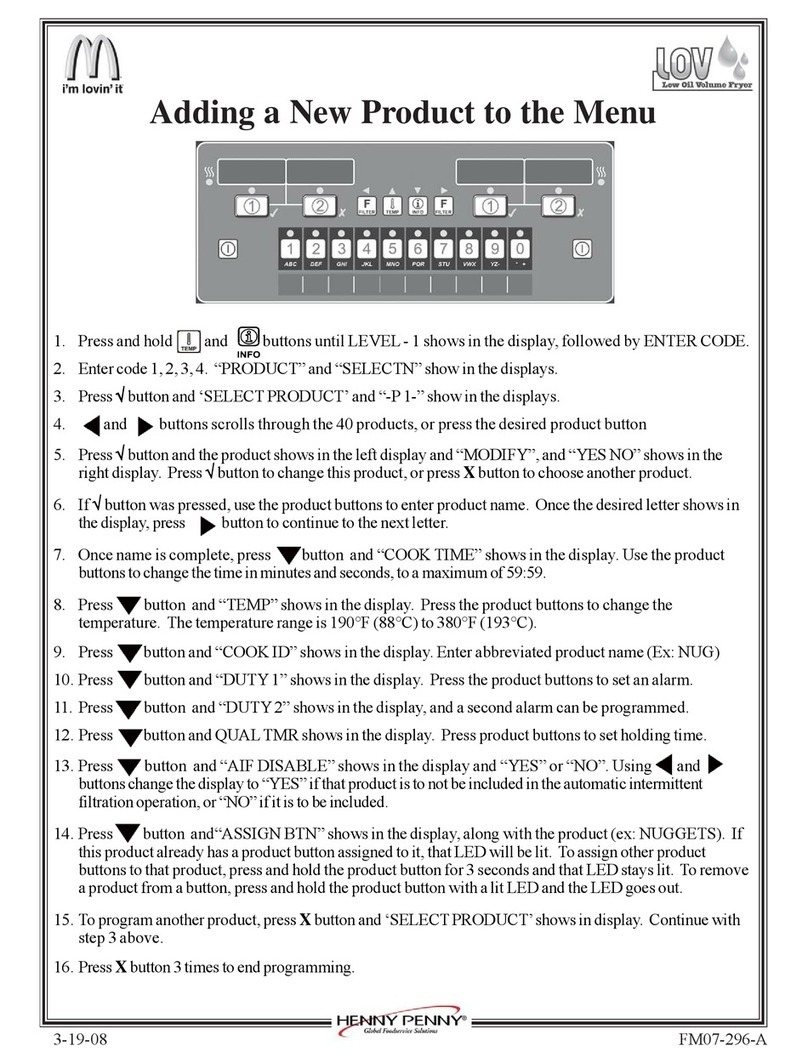

Chapter 4 Product Program Mode..................................................................................15

4.1 Modifying Product Settings ...................................................................................15

Chapter 5 Level 2 Programming.....................................................................................19

5.1 Special Program Mode .........................................................................................19

5.2 Do Not Disturb .....................................................................................................27

5.3 Clock Set.............................................................................................................28

5.4 Data Logging, Heat Control, Tech, Stat, & Filter Control Modes................................28

5.5 Tech Mode...........................................................................................................29

5.6 Stats Mode ..........................................................................................................34

Chapter 6 Maintenance .................................................................................................37

6.1 Introduction .........................................................................................................37

6.2 Maintenance Hints ...............................................................................................37

6.3 Preventative Maintenance ....................................................................................37

6.4 Control Panel & Menu Card Replacement ..............................................................38

6.5 High Temperature Limit Control .............................................................................40

6.5.1 Checkout.......................................................................................................41

6.5.2 Replacement .................................................................................................41

6.6 Breakers .............................................................................................................48

6.6.1 Checking Procedure for Breaker .....................................................................49

6.7 Main Power Switch...............................................................................................49

6.7.1 Checkout.......................................................................................................50

6.8 Temperature Probe Replacement ..........................................................................51

6.8.1 Checkout.......................................................................................................51

6.8.2 Replacement .................................................................................................52

6.9 Oil Channel Clean-Out .........................................................................................55

6.10 Element Safety Switch........................................................................................55

6.10.1 Checkout.....................................................................................................56

6.10.2 Replacement ...............................................................................................56

6.11 Contactors .........................................................................................................58

6.11.1 Checkout .....................................................................................................59

6.11.2 Replacement ...............................................................................................61

6.12 Solenoid Valves .................................................................................................63

6.12.1 Replacement ...............................................................................................64