Heraeus CRYOFUGE 6000i User manual

CRYOFUGE 6000i

CRYOFUGE 8500i Operating Instructions

How to use these instructions

With the help of these operating instructions, familiarise yourself with your centrifuge and its accessories.

The operating instructions help you to avoid improper operation. Therefore always keep the instructions

close to the centrifuge.

Operating instructions which are not accessible cannot prevent improper use and therefore injury

or damage to property.

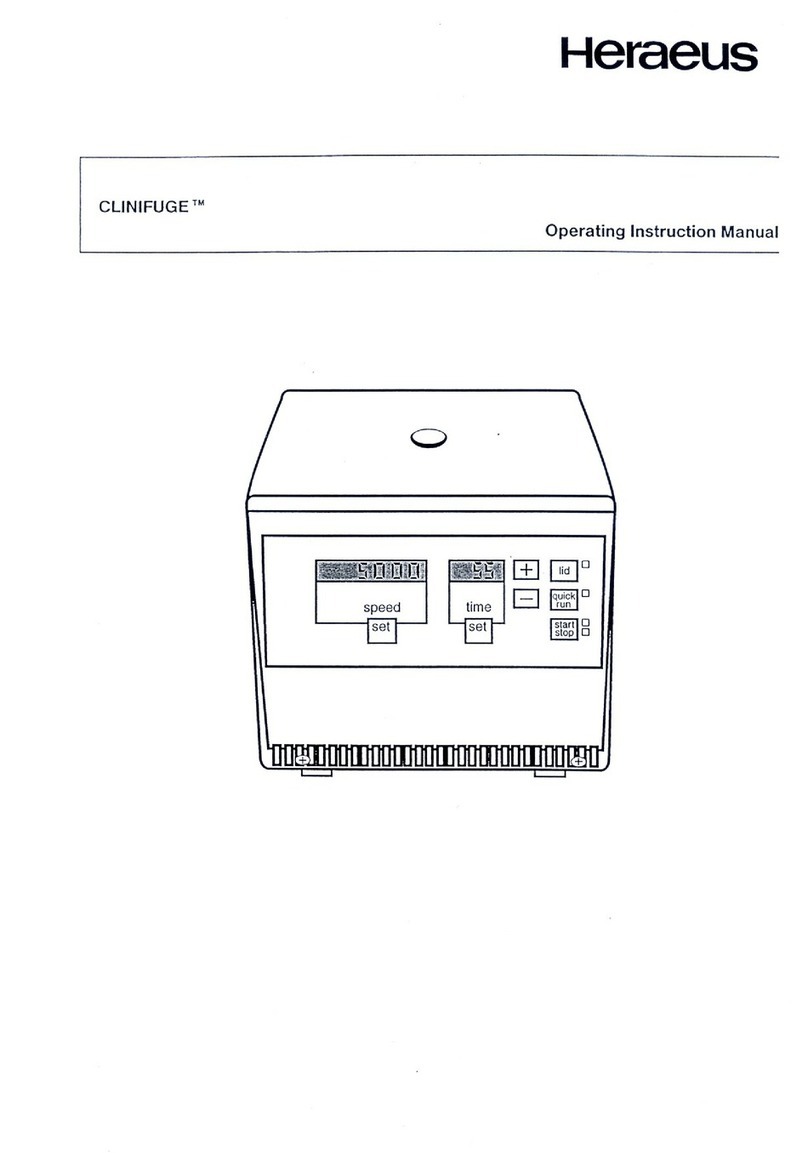

Please open out

On the back of this page, you will find an

illustration of the operating field with a

compilation of the most important func-

tions

1.Key switch

Diagnosis display

2.Lid open

3.Imbalance

4.System check

5.Programming error

6.Excess temperature

Program field

7.Program display

8.Key to activate program memory

9.Key to end saving process

10.Direction keys for choosing program number

Functional fields

Curve field

11.Display of curve numbers

12.Reference LED: Acceleration curve

13.Selection key for acceleration and deceleration

curve

14.Reference LED: Deceleration curve

4- function field

15.Display for multi-functional indication

16.Reference LED: Speed

17.Reference LED: RZB value

18.Selection key for speed, RZB, rotor/bucket or

radius

19.Reference LED: Rotor/bucket type (order no.)

20.Reference LED: Radius

Time field

21.Time display

22.Reference LED: Running time

23.Selection key for running time or start delay

24.Reference LED: Start delay

Temperature field

25.Temperature display

26.Reference LED: Temperature display

27.Selection key for set temperature or excess

temperature control

28.Reference LED: Excess temperature

Adjustment key field

29.Key for set value display and adjustment

30.Direction keys for pre-setting the display positi-

ons

31."+" and "-" keys for set value adjustment

32.Key for saving the adjusted set values

Control key field

33.Release LED to open the lid

34.Lid key

35.Release LED for "quick stop"

(rapid deceleration)

36."quick stop" key

37.Release LED to start ("start" function)

38.Release LED to decelerate

("stop" function)

39.Double function key to start or stop

speed time temp

set

rcf delay ∆t

rotor

radius

accel

system check

progr. error

overtemp.

decel

select

store

mode

execute select select select enter start

stop

imbalance

progr. mode

check lid

program

BA

C

69 9 125050

1278

10 14 13

12 11

18

16

17 20 24

15 21 25 29 30 34 33

36 35

37

38

39

30

31

32

19 22 26

23 27

28

3

4

5

69

6(3$&21752/7DEOHRINH\VDQGGLVSOD\V

Contents

1

Contents

Contents .......................................................................................................................... 1

Safety Measures and Hazards....................................................................................... 3

Description of Appliance................................................................................................ 5

Classification ............................................................................................................................................... 5

Definition...................................................................................................................................................... 5

Safety Equipment........................................................................................................................................ 5

Rotor chamber armouring........................................................................................................................ 5

Lid lock..................................................................................................................................................... 5

Thermal motor and electronic protection ................................................................................................. 5

Imbalance switch ..................................................................................................................................... 5

Protection against excess temperature.................................................................................................... 6

Lid emergency opening............................................................................................................................ 6

Accessories................................................................................................................................................. 6

Conformity with standards and regulations ................................................................................................. 7

Guarantee conditions .................................................................................................................................. 7

Instructions for Rapid Start-up...................................................................................... 9

Technical Information................................................................................................... 11

Common performance features................................................................................................................. 11

Special information for Cryofuge 6000i / 8500i.......................................................................................... 11

"SEPACONTROL" features....................................................................................................................... 12

Transport and Installation............................................................................................ 13

Transport and Storage............................................................................................................................... 13

Unpacking the CRYOFUGE...................................................................................................................... 13

Unpacking the Rotor.................................................................................................................................. 15

Installation place........................................................................................................................................ 17

Connection requirements .......................................................................................................................... 17

Start-up...................................................................................................................................................... 17

Opening the lid .......................................................................................................................................... 17

Installing and Removing the Rotor .............................................................................19

Handling the wind protection boiler rotor................................................................................................... 19

Installing the rotor...................................................................................................................................... 19

Lubricating the swing bearing bolts........................................................................................................... 19

Rotor hood................................................................................................................................................. 20

Rotor removal............................................................................................................................................ 20

Loading the Rotor......................................................................................................... 21

General instructions................................................................................................................................... 21

Bucket positions ........................................................................................................................................ 21

Symmetrical loading.................................................................................................................................. 21

Filling the vessels ...................................................................................................................................... 22

Permitted imbalance.................................................................................................................................. 22

Maximum load........................................................................................................................................... 22

Special Features for Working with Blood Bags ......................................................................................... 23

Inserting blood bags............................................................................................................................... 23

Centrifuging blood bags......................................................................................................................... 24

"SEPACONTROL" Programming................................................................................. 25

Design ....................................................................................................................................................... 25

Memory variants .................................................................................................................................... 26

Key switch.............................................................................................................................................. 26

Display (set and actual values).............................................................................................................. 26

Sequential control...................................................................................................................................... 27

Opening the lid....................................................................................................................................... 27

Starting .................................................................................................................................................. 27

Stopping................................................................................................................................................. 27

Quick stop.............................................................................................................................................. 27

This manual suits for next models

1

Table of contents

Other Heraeus Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual