Heraeus MEGAFUGE 1.0 User manual

MEGAFUGE

1.0

MEGAFUGE

2.0

MEGAFUGE

1.0

R

MEGAFUGE

2.0

R

MEGAFUGE

3.0

R

Megafuge 1.0

r.eraeus

Operating Instructions

~~rnsr

- G &

Megafuge 2.0

-=

~

-=

11

~~~&]~

- -

El§'

Megafuge 1.

0R

- -

(;l:

"°"'!!!!.

LJ

~~~~~~~~~~~~~~~~~~~~~~~~

,II

~~~~~

- -

El~

Megaluge 2.0R - -

~

-=

LJ

~~~~~~~~~~~~~~~~~~~~~~~~

11

~~~~IT

- -

El§'

Megafuge 3.0R

-=

-

§:

"°"'!!!!.

LJ

,,

...

Ji!H

~~~~~~~

LJ

L_J

LJ

QUEST 1054

PRECAUTIONS AND HAZARDS

Please read this manual very carefully before attemptingto operate the centrifuge!

The centrifuge must not be operated by unqualified personnel1 Avoid causing damage to the

un

it

or

its

accessories through incorrect operation!

In

the

event oferrors, proceed exactly according to

the

instructions1

Nevertransportthe centrifuge with a rotor installed on its shaft!

Use

only original spare parts!

ATTENTION -DANGER!

Never

open

the lid manually while

the

rotor

is

spinning!

It

is forbidden

to

program a rotor or buckettype,

which

is

not physically installed (see

7.2.1

).

The following rules must

be

strictly observed:

-Neveroperate

the

centrifuge if the rotor is

not

correctly

installed

(see

5.1).

-Do not operate

the

centrifuge with any parts

or

covers

removed.

-Never run

the

centrifuge when

the

electrical or mechanical equipment have been tampered wi

th

by

unauthorized

or

unskilled personnel.

-Never attempt

to

run the centrifuge with an incompatible rotor (see 2.4 -

It

is forbidden

to

use the rotor

#8155with any buckets

in

the Megafuge

1.0

or

1.0R).

-Do not operate

the

centrifuge with incorrectly installed buckets.

-The maximum rotor load

and

speed

must

be

observed.

-Do not spin corrosive samples which may impair the material strength

of

the rotors and buckets without

taking all necessary precautions (e.g. sealed rotors

or

buckets).

-Never use accessories (rotors

or

buckets) which

show

noticeable traces

of

corrosion

or

mechanical

damage.

-Do not spin samples which can create flammable or explosive mixtures when exposed

to

air, unless

adequate safety precautions have been taken (e.g. shel

ter).

-Do not operate

the

centrifuge

in

explosion-hazardous locations. The Megafuges are neither explosion-

proof norinert gas shielded.

-Do not use accessories which

are

not approved

by

Heraeus, except commercially available centrifuge

tubes

of

glass

or

plastic.

The manufacturer is only responsible for the security, reliability

and

performance

of

the unit, if

-

the

unit is operated

in

accordance with the operating instructions

-installations, expansions, new adjustments, changes or repairs are performed by Heraeus authorized

personel

NOTE:

When performing centrifugation and other functions which may expose workers to splashed blood

or

body

fluids, all laboratory personel must follow universal laboratory precautions including wearing gloves, facial

protection, gowns or laboratory coats, and plastic aprons. For further details, consult your local laboratory

safety director.

FAST START

UP

REFERENCE GUIDE

Setting up

the

MEGAFUGE

1.

Set unit

on

a flat sturdy, resonance-free table (or lorrywith lockable wheel

s)

in a well vent

il

ated area (without

exposion to direct su

nl

igh

t)

and

mark

a

safety

zone

of

30

cm

around

it (details

in

Section

4.

1

).

2.

Insure tho

ma

ins supplyavailable isequal with t

t1e

required on identification plate (see Electrical

Connec

tion,

Section 4.2).

3. After plugging into the adequatewall socket, turn

on

the main power loca.ted on the rear panel (left

hand

side).

4.

Wail for the illumination of the yellow L

ED

n

ex

t to the

LID

key.

Open the lid by pressing the

LID

keypad

and

remove all

pack

i

ng

materials and accessories.

5.

Remove the rotor packaging

and

mount it on the

dr

i

ve

shaft (see Secti

on

5.1

+ 5.2).

6.

Rot

or

must move freely, when installing the swing-out rotor a

ll

four

buckets

must

be

occupied!

7.

Load a

ll

adap

tors

and

lubes

mak

ing sure the rotor is symmetrically balanced (see Symmetrical Charge,

Section 6.1).

WARNING!

Do

not

centrifugate

dangerous

material without

taking

all

necessary

precautions

(see PRECAUTIONS

AND HAZARDS)I

8.

Close the l

id

firmly, bul

do

not slam

it.

The "Open" message will disappear from the displ

ay,

if

th

e lid is

closed correctly.

Programming

the

First Run

9.

To set the Cat. No. of lhe installed rotor press the SET key of the

TI

ME field

once

and

then pressagain

and

keep pressed for the whole

se

tting procedure. The rotor sign "r

o"

will appear

and

the flash

ing

Cat. No.

shown in

th

e SPEED/RCF field can

now

be changed

by

using the yellow

"+"

or "-" keys. If the flashing

Cat. No.is

eq

ualwith the insta

ll

ed

one,release the pressedSET key (seeProgramming ofRotor,Section

7.2.1

).

WARNING!

On

using the swing-out rotor, always program the Cat. No. of the really installed buckets, otherwise the

maximum allowed bucket speed can

be

overwritten and damageto persons

or

propertymay result.

10

.To

se

t time, press the

SET

keypad of the TIME

fi

el

d.

Cha

n

ge

time

by

press

in

g

the"+"

or

"-

" keyp

ads

(see

Programming of Tim

e,

Section 7.2.5).

11.

To set speed for a timed run, press the SET keypad in t

he

SPEED

field. Change speed setting

by

pressing

"+"

or

"

-"

keypad (for setting RCF i

ns

t

ea

d of SPEED values see 7.2.2).

12

. For timed runs, press the START keypad. Slow

and

fast

acce

leration can

be

togg

led with the BRAKE key

(see

Smoo

th

Acc

eleration and Deceleration, Secti

on

7.1.5). After termination of the programmed time, unit

will shut off automatically.

Preparing

the

next run

13.

Wait for release of

LID

key (yellow

LED

indicates

end

of cycl

e),

open the lid

and

remove all

tub

es from

the rotor.

14.

Ch

eck

for broken glass or leakage into roto

r,

bucketsand

/o

r

chambe

r (see

10.1

and for disinfecting see10.2).

ATTENTION!

In

case

of

contamination,

the

user

is

obligated

to

disinfect

the

unit

and

its

accessories.

15.

To remove roto

r,

unscrew

and

grasp it

on op

po

s

in

g points and detach from the shaft by pul

li

ng

vertically

to the top.

Caution!

Remove

the

rotor

only

in vertical

position

otherwise

the

drive

shaft

will

be

damaged

.

To

pre

pa

re the next run, foll

ow

the routine cleaning procedures (of Section 10), if necessary,then repeal steps

5 to 15. For

more

detailed informa

ti

on

abo

ut

the

M

EG

AFUGE feature

s,

operati

on

and

gu

idelines, consult other

sections of

th

is manual.

3

TABLE

OF

CONTENTS

Page

PRECAUTIONS

AND

HAZARDS 2

FAST

START

UP

REFERENCE GUIDE 3

1.

DESCRIPTION 6

1.1

Classification

6

1.2

Definition

6

1.3

Safety

Inspections,

Standards

and

Regulations

6

1.4

Standard

Accessories

6

1.5

Warranty

7

2.

TECHNICALDATA 8

2.1

Performance

Features 8

2.1

.1

Com

mon

Features

8

2.1.2

Special

Features

of

the

standard

MEGAFUGES 8

2.1

.3

Special

Features

of

the

refrigerated

MEGAFUGES

9

2.2

"M

EGACONTROL"-Features 9

2.3

Mains

Supply

10

2.4

Rotor

Tables 10

2.4

.1

MEGAFUGE

1.0 Rotors 10

2.4.2 MEGAFUGE

2.0

Rotors 10

2.4.3 MEGAFUGE 1.0R Rotors

11

2.4.4

MEGAFUGE

2.0 R Rotors

11

2.4.5

MEGAFUGE

3.0

R Rotors

11

3. SAFETYSYSTEMS

12

3.1

Rotor

Chamber

12

3.2

Lid

Lock

12

3.3

Thermal

Motor

Protection

12

3.4

Imbalance

Switch

12

3.5

Check

of

Acceleration

Rate

(only MEGAFUGE 1.0R/2.0R) 12

3.6

Emergency

Lid

Release

13

3.7

Overtemperature

Protection

(only MEGAFUGE 1.0R/2.0R/3.0R) 13

4.

INSTALLATION 14

4.1

Location

14

4.2

Electrical

Requirements

14

4.3

Main

Power

Switch

14

4.4

Opening

the

lid

14

5.

ROTOR EXCHANGE

15

5.1

Use

of

Collet

Chuck

15

5.2

Mounting

16

5.3

Removing

16

6. ROTOR LOADING 17

6.1

Swing-out

Rotors

17

6.2

Symmetrical

Charge

17

6.3

Distribution

of

Racks 18

6.4

Tube

Filling

18

6.5

Partial

Load

18

6.6

Loading

limits

19

6.7

Sealed

Rotors

#

3360/

#

5315

19

4

TABLE OF CONTENTS

7. "MEGACONTROL" PROGRAMMING INSTRUCTIONS

7.1

Co

ntrol Keys

7.1.1 Lid

7.1.2 Start

7.1.3

Stop

7.1.4

Quick

Run

7.1.5 Smooth Acceleration and Deceleration (brake)

7.2 Programming

7.2.1

RotorSelection

7.2.2

Speed

Selection

7.2.3 RCF Selection

7.2.4 Brake Cut-out Speed Selection

7.2.5 Time Selection

7.2.6 Temperature Selection

(o

nly MEGAF

UGE

1.0R/2.0R/3

.0R

)

7.3 D

is

pl

ay

7.3.1

Speed

7.3.2 RCF

7.3.3 Time

7.3.4 Rotor

7.3.5

Standby

7.3.6 Temperature (only

MEG

AF

UGE

1.0R

/2.0R/3.0

R)

8. ACCELERATION AND BRAKING PROFILES

8

.1

Profile Principles

8.2 Sel

ec

tion

of

Profiles

8.3 Turbule

nce

During Deceleration (Swing-out Rotors)

8

.4

Brake Setting for DelicateSamples

9. TEMPERATUREFEATURES

9.1 MEGAFUGE

1.0/2

.0 with Air Circulation Cooli

ng

9.1.1 Pr

epa

ring a Speed-Temperature Ch

art

9.1.2 Thermo-Deli

cate

Sa

mples

9.2

MEGAFUGE 1.

0R/2.0R/3.0R

Cooling Unit -Temperature Control

9.2.1 Pre-cooling

or

pr

e-

h

ea

ting

of

Empty Rotors

and

Buckets

9.2.2 Pre-cooling

or

pre

-heating

of

Samp

l

es

10.

MAINTENANCE AND CARE

10

.1 Cleaning

10

.2 Disinfection

10

.3 Collet Chuck

10.4

Grea

sing

10

.5 Glass Breakage

10

.6 Condensed Water

10.7 Servicing Schedule

11. TROUBLE SHOOTING

11.1 Measures

to

Do-it-yourself

11.2 Servicing

Page

20

21

21

21

21

21

21

21

21

21

22

22

22

22

22

22

22

22

22

22

22

23

23

23

23

23

24

24

24

24

25

25

25

26

26

26

26

26

27

27

27

28

28

30

5

1. DESCRIPTION

1.1 Classification

Tt1e

MEGAFUGES are technically hi

gh

ly developed microprocessor controlled laboratory cen

tr

ifuges with

frequency controlled and maintenance-free induction rnolor.

The MEGAFUGES are bench-top

mode

ls

with an ext

ensivG

range of accessories.

1.2 Definition

The centrifuges have low vibra

ti

on solid polymer

bo

tt

om

plat

es.

The housing is built of sheel steel. Tt1e front

panel is

made

of plastic. Housing and front panel are fixed tightly to

th

e bottorn plate.

The rotors are staned directly with a frequency controlled induction d

ri

ve (brushlcss) with high acceler

a1

ion

power. Ihis drive ensures quiet, low vibration runr1ing at high speed wi

th

hi

gh

reliabili

ty.

The drive is mounted

with shock absorbers

to

the bottom plate and sealed wi

th

a rubber flange

to

the rot

or

chamber. The main

microprocess

or

controls the functions

fo

r speed measuring and regulation, the temperature measuring

and

regulation (MEGAFUGE 1.0R/2.

0R/3

.0R) program storage, safety control

and

error coding. An addilional

microprocessor

is

responsible

fo

r the key and di

sp

l

ay

!unc

ti

ons. The centrifuge

is

controlled

by

the

"Megacontrol" system (see section

7.)

MEGAFUGE 1.0/2.0

The air, drawn through the rear hole of the lid during

ope

ration of the motor, cools the rotor, motor

and

electroni

cs

and

is discharged

fro

m the centrifuge via louvers in

th

e housing (see fig

.1

).

MEGAFUGE 1.0R/2.0R/3.0R

These

mode

ls are equipped with a compressor plant

ro

r temperature control (see section 9.

2).

1.3

Safety Inspections, Standards

and

Regulations

Safety inspections accordi

ng

to

GS,

CSA, CLA, U

L,

VOE

and

SEV.

-

Acc

ident prevention regulations for ce

n1

rifuges,

UVV

VBG

7z.

-

Acc

ident prevention regulations

fo

r e

le

c

tr

ical plants and supplies U

VV

VBG

4.

-Electrical safety according to

IEC

1010-1and I

EC

1010-2-D

- Electrical noise suppression according to

VOE

0871 grade 8

-DIN

58

970, part 2 for laboratory centrifuges

-MEGAFUGE 1.0R/2.0R/3.0R:Acciden1 preventation regulations for

coo

ling units,

UVV

VBG

20.

1.4

Standard Accessories

The centrifu

ges

are supplied with a collet chuck and a special socket wrench to fasten the rotors. (Spare

Pan N

o's

see below).

Centrifuge

MEGAFUGE 1.0/2.0R/1.0R/2.0R

MEGAFUGE 3.0R

Collet ct1uck

/

/70003100

,,?70904041

Socket wrench

//2036

0047

//

20005492

50

ml of anti-corrosive o

il

(Spare

Part

No.

#7

00

098

24) to

pro

tect the metall

ic

surface of rotors and buckets

and a small vial of special grease (Spare

Part

No.

#70006692) to coat the trun

ni

ons or sw

in

g out rotors are

su

pp

lied as well.

Printed documentation supplied are:

- a prospectus with all avail

ab

le accessories

- the operating instruc

ti

ons

- a notice card fort

he

correct fas

te

ning ofrotors

- a warranty registration form

- a pl

as

tic case for keeping all documentation (should t)e fastened aside the centrifuge)

6

1.5

Warranty

The vvarranty

pe

ri

od

starts

wi

th

me

day of delivery. Within lhe

wa

rranty

pe

r

iod

lhe cen

tr

ifuge is repaired or

re

placed t

ree

of cost if

tt1ere

are clernonstrable faults

in

ma

terials or workmanship.

0

(!)

0

Fig.

1 MEGAFUGE

1.012.0-

lidshowing

the

holes

for

integrated

air

circulation

7

2. TECHNICAL DATA

2.1 Performance Features

2.1.1

Common

Features

Base construction:

Housing:

Front panel:

Operation:

Drive:

Lid opening:

Closing:

Locking at run:

Starting/Stopping:

Re-starting:

Ouick-run/-stop:

Imbalancestop:

Range ofambient temp.:

-during operation

-

in

case ofstorage

or

shipping

solid polymer bottom plate ensures l

ow

vibration centrifugal runnings

motorand back panel

made

of sheet steel covered wi

th

annealing color

synthetic resin for incorporation

of

key and displayelementscovered with cleanable

membrane.

By

programming ofMEGACONTROL (features see

2.2)

frequency controlled, maintenance-free induction motor

key button, !he lid pops

up

and opens by the

gas

lid stay(s)

press the lid down and push on

top

of the lid locks.

doub

le safety circuit (hard- and software controlled)

dualfunction key button indicated by LED's (start at green, stop at red)

at anytime during braking phase

wi

th

quick-run press-and-hold key/quick stop on release

automatic

dur

ing acceleration, if allowed imbalance is exceeded

4°C -

35

°C (39° F-

95

°

F)

-10°C

-

50°C

(14°F

-

122°F)

2.1

.2

Specia

l features of the standard MEGAFUGES

MEGAFUGE

1.0

MEGAFUGE 2.0

max. speed:

6000

rpm

6000

rpm

w

it

h rotor:

1/3

360

//33

60

max. RCF:

6240

X g

6240

X g

with rotor:

/1

3360

1/

3360

max. power

in

put:

700W

700W

max.capacity: 4 x 220 ml 4 x 500

ml

with rotor/bucket:

#2704/#2706

#

81

55/# 8160

max. kin. energy:

26

.0 kNm

29

.8

kNm

max. sample overtemp.: 15 K 15 K

(above ambient temp.)

rotor

chamber

-material:

ename

lled steel ename

ll

ed steel

- si

ze(¢

x H): (430x210)

mm

(430x210)mm

(1

7"

X

8¼")

(17" X8¼")

dimension

(HxWxD):

(41

x46x54)cm

(41

x46x54)cm

(16¼" X 18

¼"

21¼") (16¼" X

18¼"

X

211/4'')

weight:

52

kg

55

kg

115

pounds 1

22

pounds

noise level:

~

70

dB(A)

~

70 dB(A)

8 I

2.1

.3

Special

features

of

the

refrigerated MEGAFUGES

-MEGAFUGE 1

.OR

MEGAFUGE 2.0 R MEGAFUGE 3.0 R

max. speed:

15000

rpm

15000

rpm 4 700 rpm

with rotor: #

1379/

#30

41

#

1379/

//304

1

/1

5315

max. RCF: 20120 X Q

20120

X g 4 790

xg

with

rotor:

II 1379 /11379

11

5315

max. power input: 1100W 1100 W

1450W

max. capacity: 4 X 220 ml 4 X 500 ml 4 x 750

ml

with rotor/bucke

t:

,¥

2704/#2706

#8

155/

#8160

118074/11

8080

max. kin. energy: 26.0 kNm 29.8 kNm 40.6 kNm

rotor chamber -material: fine steel fine steel fine steel

-

size(¢

x H): (430x210)

mm

(430x210)

mm

(460x230)

mm

(17"

X 8¼")

(17"

X

8¼")

(18"

X 9")

dimension

(H

xWxD):

(41

x71

x58)cm

(41

x71

x58)cm

(44x

73

x60)

cm

(16¼" X

28"

23") (16¼" X 28"X 23")

(171/2''

X

29"

X 24'')

weight: 104 kg 109kg

128

kg

230 pounds 240 pounds 282 pounds

noise level:

~

64

dB(A)

~64

dB(A)

~

64 dB(A)

2.2

"MEGACONTROL"-Features

Parameter storage:

Data memory:

Diagnostic indications:

Digital parameter display:

Acceleration:

Deceleration:

Speed

selection:

RCF

se

l

ect

ion:

Brake

cut

-out point:

Rotor selection:

Time selection in 2 modes:

"hd" mode:

min

mode:

Time display by Quick-Run:

sec mode:

MEGAFUGE 1.0R/2.0R/3.0R

Temperature selection:

for speed,

RCF

value, rotor type, brake cut-out point, running time

MEGAFUGE 1.0R/2.0R/3.0R: alsotemperature

with NV

-R

AM's (non -volatile random -access-memory)

-lid open

-imbalanced loading

-general troubles in the unit

-data transmitting errors

-rotor over temperature (MEGAFUGE 1.0R/2.0R/3.0R)

speed,

RCF,

rotor, time MEGAFUGE 1.0R/2.0R/3.0R: alsotemperature

2 stepped reproducable profiles: smooth start and fast, can be switched over

at any time using the brake key

1reproducable profile

and

unbraked deceleration, can be switched

over

at

anytime using the brake key

adjustable

in

stages

of

100

rpm

up

to

max.

rotor

or bucket speed

adjustable to max. ref value (see

2.4)

converted into stages

of

100 rpm

adjustable

in

stagesof 1

00

rpm

up

to the preselected speed

preprogrammed menu, arranged in ascending rotor

or

bucketCat. Numbers

continuous operation

adJustable

in

minutes from 1 min to

99

min

1 s -

99

s

0°c

-

40°c

9

2.3 Mains Supply

Centrifuge Cat. No.

Voltage/

Frequency

MEGAFUGE 1.0

//

3490

230V

/50Hz

--

MEGAFUGE 1.0

#349

1

120V/60Hz

MEGAFUGE 1.0

//3

495

100V

50/60Hz

MEGAFUGE 1.0

//

3496

240V

50

Hz

MEGAFUGE 2.0

#3482

230V

/50Hz

MEGAFUGE 2.0

//3

485

120V

/60

Hz

MEGAFUGE 1.0R

//3060

230V

/50Hz

MEGAFUGE 1.0R

#3

06

1

120V

/6

0

Hz

MEGAFUGE 1.0R #

3066

1

00V

/50Hz

MEGAFUGE 1.0R

//306

7

100V

/60Hz

MEGAFUGE 2.0R

#30

80

230V

/50Hz

MEGAFUGE 2.0R

//

3085

120V

/60Hz

MEGAFUGE 3.0R

#8

100

230V/50Hz

MEGAFUGE 3.0R

#8

107

208/240

1) V

/60

Hz

ATTTENTION!

') Voltage for use: see identification label.

2.4

Rotor-Tables

2.4.1

MEGAFUGE

1.0

Rotors

Rotors

with

Swing-out Buckets

rotor/bucket max.

Cat.-No. capacity

[# ] [ml]

2705

+

2252

48

X

15

2705

+

2706

1) 4 X

220

2705

+27083) 8 plates

33604)

48

X 15

2704

+

8030

5)

48

X 15

2.4.2 MEGAFUGE 2.0

Rotors

Rotors

with

Swing-out Buckets

rotor/bucket max.

Cat.-No. capacity

[#]

[ml]

33604)

48

X 15

8155

+8082 2 carriers

8155

+

8160

4 X

500

1) round buckel with her

me

tically tight lid

•) vacutain

cr

(tubes up to 1

32

mm

length)

3) 4 microtiter carriers w,th 2 plates in each

max.

speed

[rpm]

4000

4300

2800

6000

4000

max.

speed

[rpm]

6000

3300

3500

ATTENTION -DANGER!

The

maximum

speed

of

2800

rpm

must

never

be

exceeded!

4) sealed rotor -ATTENTION! Instructions

in

Section 6.7

must

be

observed

absolutely!

5) rectangle bucket with her

me

tically sealedl

id

max.

RCF

[xg]

2890

3490

1280

6240

3220

max.

RCF

(xg]

6240

1850

2570

-

Power input Main Fusing

700W

16A

700W

15A

700W

15A

700W

16A

700W

16A

700W

15A

1100W

16A

1100W

15A

1100W

15A

-

1100W

15A

1100W

16A

-

1100W

15

A

1450W

16A

1450W

15A

max. max. load

radius

per

position

[cm] [g]

16.2 510

16.9

425

14.6

360

15.5

510

18.1

510

max. max. load

radius

per

position

[cm]

(g]

15.5 510

15.2 260

18.8

800

ATTENTION-DANGER! Hermeticalsealing

is

only

guaranteed

by

troublefree

operation

of

the

centrifuge

and

its accessories!

10

2.4.3 MEGAFUGE 1.0R Rotors

Rotors

with

Swing-out

Buckets

and Angle Rotors

rotor/bucket max.

max

.

Cat.-N

o.

capacity speed

[//

] [ml] [rpm]

1379

24

X 1

.5

15000

2705

+

2252

48 X 15

4000

2705

+

2706

1) 4 X 220

4300

2705

+

2708

3) 8 plates 2800

3041

18

X 2.0 15000

33604)

48

X 15 6000

2705 + 80305) 48 X 15

4000

2.4.4 MEGAFUGE 2.0R Rotors

Rotors with

Swing-out

Buckets

and

Angle

Rotors

---

---

rotor/bucket max.

Cat.-No. capacity

[

tf

] [ml]

1379

24

X 1.5

3041

18

X 2.0

3360

4) 48 X

15

8155

+

8082

2 carriers

8155+8160

4 X 500

1) rou

nd

bucket with hermetically tight l

id

2) vacutainer (

tu

bes

up

to

1

32

rn

m le

ng

th)

J)

4 microt1ter carriers

witt1

2 plates in each

max.

speed

[rpm]

15000

15000

6000

3300

4000

---

ATTENTION -DANGERI The maximum

speed

of

2800

rpm

must

never

be

exceeded!

')

sealedrotor -ATTENTION! Instructions

in

Section6.7

must

be

observed

absolutely!

5)

rectangle

bu

cketwith h

erm

etica

ll

y sealed

li

d

max. max.

RCF radius

[x

g] [cm]

20120 8.0

2890

16.2

3490 16.9

1280

14

.6

17860

7.1

6240 15.5

3220

18.1

max. max.

RCF radius

(xg] [cm]

20120 8.0

17860

7.1

6240 15.5

1850 15.2

3360 18.8

--

max. Ioad

sit

io

nper

po

[g]

3

5"10

425

360

4.9

510

510

-

max. load

per position

[g]

-3

4.9

510

260

800

ATTENTION -DANGER! Hermetical sealing

is

only

guaranteed

by

troublefree operation

of

the centrifuge

and

its

accessories!

Notice! The minimum reachable sample temperatures in MEGAFUGE 1.0R/2.0R/3.0R are equal

to

or

towerthan

4°C

for

all rotors at maximum speed.

2.4.5 MEGAFUGE 3.0R Rotors

Rotors with

Swing-out

Buckets

rotor/bucket max. max.

Cat-No. capacity speed

[//]

[ml]

[rpm]

5315

1)

8X12X15

4700

80702) 4 carriers

2800

807

4 +

8078

3) 4 X

24

X

15

3500

807

4 +

8080

4) 4 X

750

3500

8074 +

8082

2 carriers

3300

1) sealed rotor -ATTENTION! Observe instructions

in

Section6.7!

') rotor for mineral oil glasses (up to

200

mm

length)

max. max. max. load

RCF radius per position

[xg]

[cm

)

[g)

4790 19.4

510

1910 21.8

260

2510 18.3

1020

2890

21

.1

1100

1960

16.1

260

ATTENTION -DANGER! When using the standard glasses

#3

1

10

, #

311

1

and#

3112, the speed must

be

r

ed

uced

to

1800rpm

3) double-rectangular

bu

ck

et

4) r

ou

nd

bucket with hermetically sealed lid

ATTENTION -DANGER! Hermetical sealing

is

only

guaranteed

by

troublefree operation

of

the

centrifuge

and

its

accessories!

Notice! The minimum reachable sample temperatures

in

MEGAFUGE 1.0R/2.0R/3.0Rare equal to

or

lowerthan

4°C

for

all rotors

at

maximum speed.

11

3. SAFETY

SYSTEMS

3.1 Rotor

Chamber

MEGAFUGE 1.0/2.0

The rotor chamber consists ofa solid steel armor coated with enamel.

MEGAFUGE 1.0R/2.0R/3.0R

The stainlesssteel rotor

chambe

r is surrounded

by

a sol

id

armored vessel.

3.2

Lid Lock

The cabinet lid can only be opened when the rotor speed

is

at zero and the mains power on. The centr·ifuge

can only be started when the lid is correct

ly

locked and the "open" message has turned off.

3.3

Thermal

Motor

Protection

The power

to

the motor

is

switched off

in

the eventof motorovertemperalure to protect

th

e drive system.

MEGAFUGE 1.0R/2.0R/3.0R

An additional motor temperature switch turns on cooli

ng

fans to keep the temperature inside the

un

it a

suitable range.

3.4 ImbalanceSwitch

Al

l MEGAFUGES are equipped with an imbalance switch.

If the all

owab

le imbalance is exceeded, the message

"ba

l" will alternate with

th

e speed display and the drive

brakes to standstill automatically (see

11.1).

3.5

Check

of

Acceleration Rate (only MEGAFUGE

1.0R/2.0R)

Whenever the rotor # 1379 or

#304

1

is

set, the microprocessor will check the acceleration rate to protect

the drive system

or

other rotor types from damagein the event

of

false programming (see

11.1,

E-18).

12

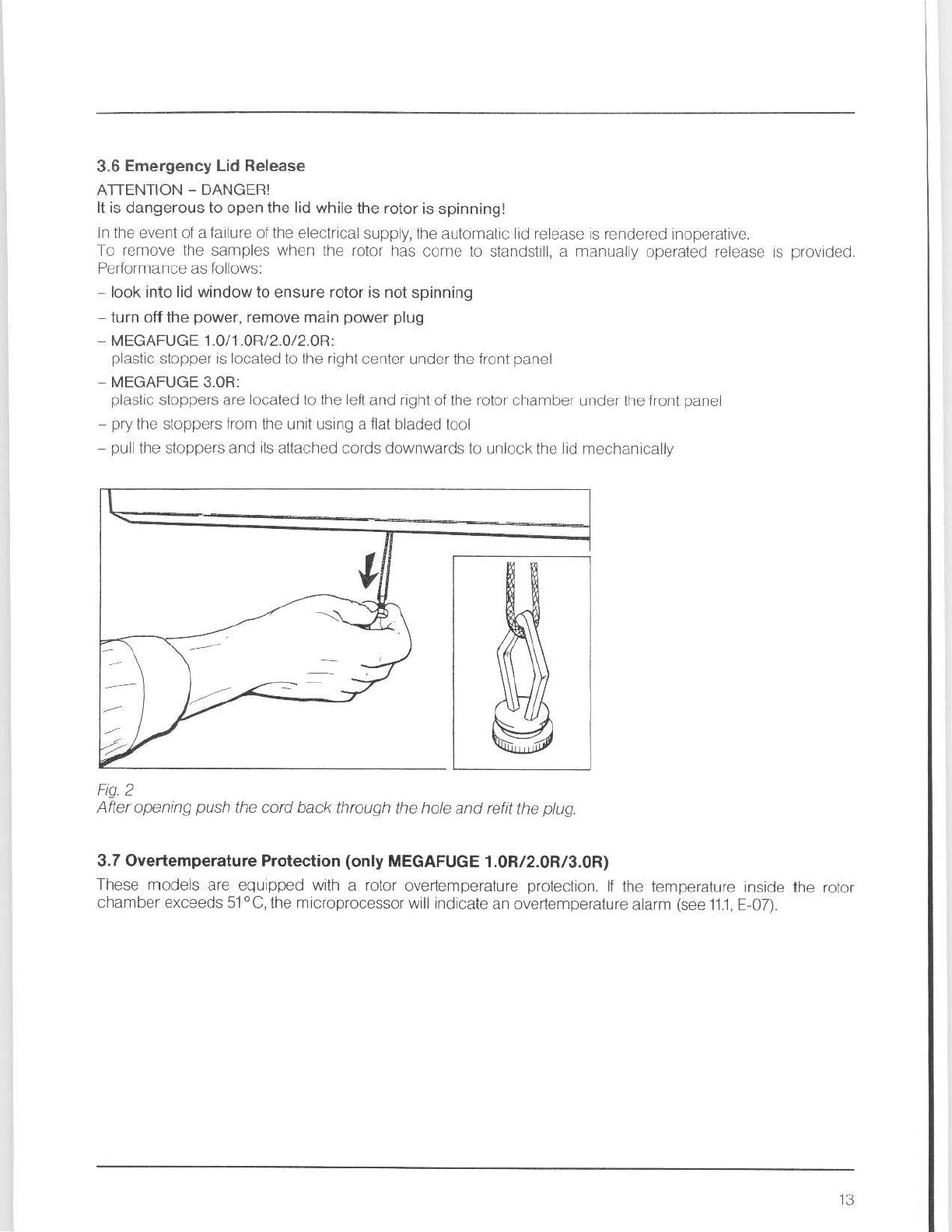

3.6 Emergency Lid Release

ATTENTION -DANGER!

It

is dangerous to open the lid while the rotor

is

spinning!

In the event ofa

fa

il

ure of the electrical supply,the automatic lid release is rendered inoperative.

To remove the samples when the rotor has

come

to standsti

ll,

a manually operated

re

lease is provided.

Perfo

rmance as

fo

llow

s:

-look into lid window to ensure rotor is not spinning

-turn off

the

power, remove main power plug

-MEGAFUGE 1.0/1.0R/2.0/2.0R:

plastic stopper is localed to the rightcenter underthe front panel

-MEGAFUGE 3.0R:

plastic stoppers are located to the left and right of the rotor chamber under the front panel

-pry the stoppers fr

om

the

un

it using a flat bladed tool

-pu

ll

t

he

stoppers and

it

s attached cords downwards to unlock

th

e lid

mec

ha

nical

ly

Fig.

2

After

openingpush the

co

rd

back

through the

ho

le

and

refit the plug.

3.7 Overtemperature Protection (only MEGAFUGE

1.0R/2.0R

/3

.0R)

These models are equipped with a rotor overtemperature protection.

If

th

e temperature inside the rotor

chamber exceeds

51

°C,

tt1e

microprocessor will indicate an overtemperature alarm (see

11.1,

E-07).

13

4. INSTALLATION

4.1 Location

The centrifuges are delivered in a special cardboard or wooden box.

Op

en the

box

carefull

y,

remove

th

e

transportprotec

ti

on

parts (foam) and put the

un

itm

its

location.

The unit must be set up on a sturdy,

le

vel laboratory t

ab

le

or

a suitable carriage with lockable wheels.

WARNING!

Do

not

place

the unitnext

to

a heat emitting element

or

instrument!

There must

be

a minimum clearance

to

the

wall

and

any

adjacent

equipment

of

10

cm

to

ensure

unrestricted

air

circulation.

The international european regulations for centrifuges require a safety zone

of

30

cm

around

the

centrifuge.

We

recommend

to

mark

this area

to

keep

away

persons

or

dangerous

goods

(e.g.

comprising

inflammable

or

infectious liquids}

during

centrifugation.

4.2 Electrical Requirements

Bef

or

e connecting

th

e Megafuge to the mains suppl

y,

make certain

th

at:

1.

the line voltage imprinted on

th

e identification plate is equal wi

th th

e one available (see 2.3 Mains Supply}

2.

th

e line voltage circuit breaker is a

13,

15 or

16

A

mp

type with a slow release feature commonly used for

instruments.

4.3 Main Power Switch

Connect the line cord plug

to

the

app

r

op

riate wall socket. Turn on the main power sw

it

ch located on the back

left hand side.

All

displaysand diodeswill light

up

tor two seconds (system check).

ATTENTION!

The main power switch should not be

us

ed (except in case of emergency)

to

interrupt the centrifuga

ti

on

.

Fo

r

t

hat,

the STOP key is provided.

Note: When powered

off,

all parameters of the last run a

re

main

ta

ined.

4.4

Opening

the

lid

The lid can only be opened with

tr1c

lid key when

the

yellow

LED

is li

t.

This is only possible when the rotor is

not turn

in

g and no er

ro

r messages

arc

displayed.

WARNING -DANGER!

The mechanical lid unlocking mechanism (see 3.6}

must

not

be

used

to

interrupt centrifugation.

It

is

absolutely

necessary

to

wait until the drive

has

come

to

standstill (can

be

checked

through the

window

in the

center

of

the lid).

14

5. ROTOR EXCHANGE

CAUTION!

Before inserting the rotor, make sure

that

the

rotor

chamber

is

free

of

contaminations (dust,

debris

etc.).

Condensate

or

residual sample

liquid

must

be

removed before centrifugation.

When clamping

on

the rotor

to

the drive shaft, the temperature

of

the rotor, the drive shaft

and

the collet

chuck

must all be in the range

of

10-30

°C

to

avoid loosening

of

the collet

chuck

by

temperature

imbalance.

WARNING!

The rotor

must

be

removed before transporting

the

centrifuge! Damage

to

the rotor and centrifuge may

result ifthe rotor

is

not

removed prior

to

transporting.

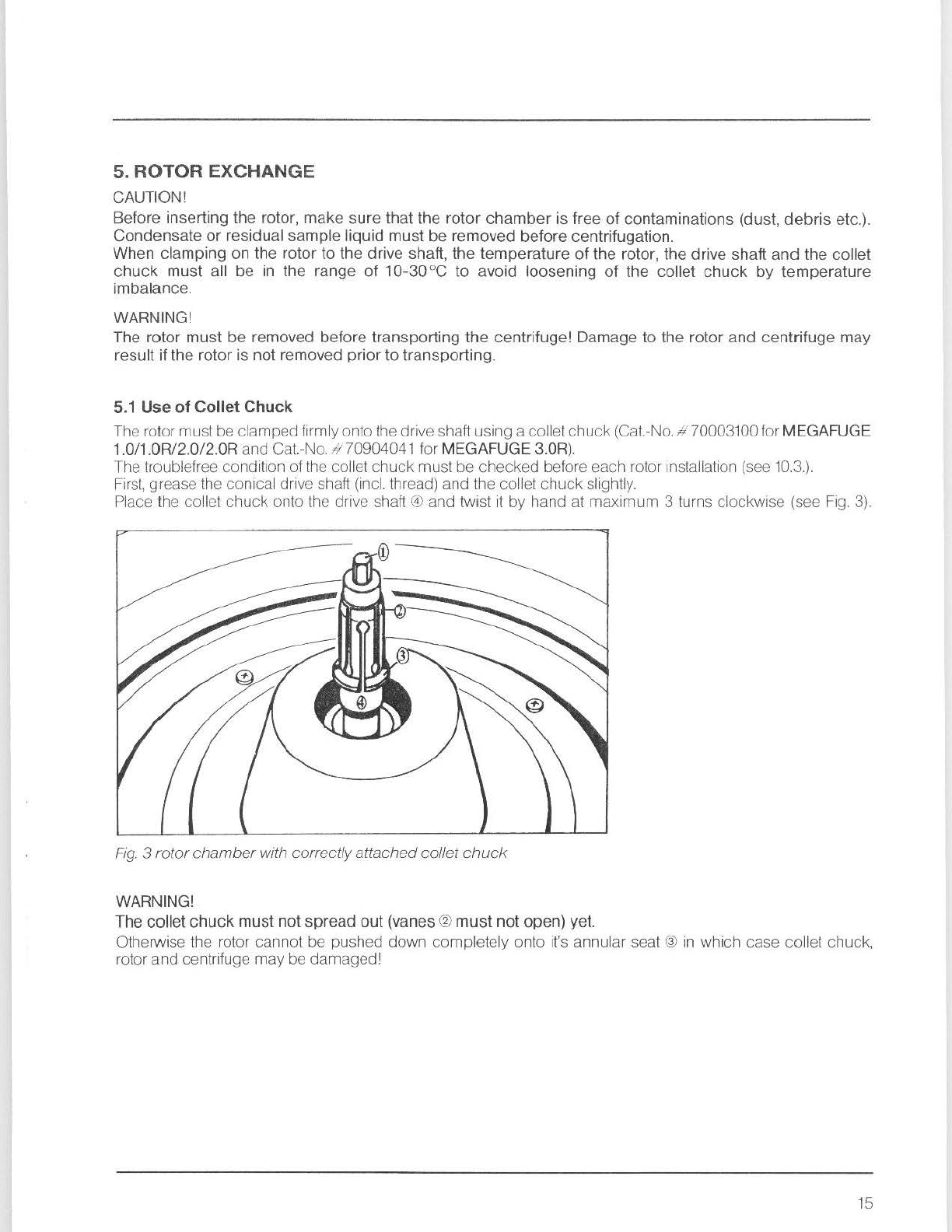

5.1

Use

of

Collet Chuck

The rotor mustbe clampedfirmlyontothe drive shaft using a collet chuck (Cat.-No.4"70003100for MEGAFUGE

1.0/1.0R/2.0/2.0R and Cat.-No.

//

70904041 for MEGAFUGE 3.0R).

The troublefree condition ofthe collet chuck must be checked before each rotor installation (see

10.3.).

Fi

rs

!,

grease

th

e conical drive shaft (incl.

th

read) and the collet chuck slightly.

Place the collet chuck onto the drive shaft

Ci>

and twist

it

by

hand at maxi

mum

3 turns clockwise (see

Fig.

3).

Fig.

3

rotor

cham

ber

with correctlyattachedcol/et

chuck

WARNING!

The collet

chuck

mustnotspread out (vanes ®

must

not

open) yet.

Otherwise the rotor cannot be pushed down completely onto it's annular seat @

in

which case

co

llet chuck,

rotor and centrifuge

may

be damaged!

15

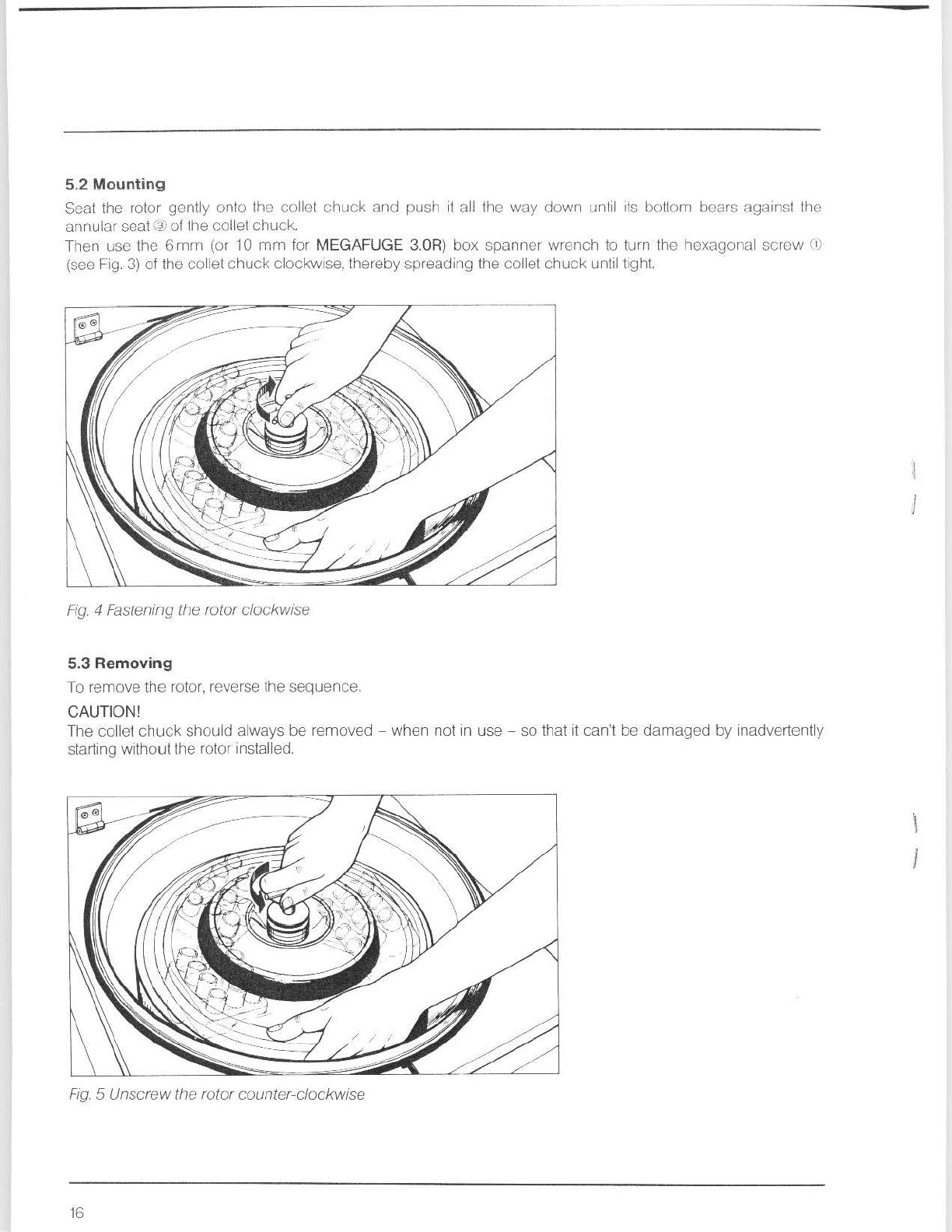

5.2 Mounting

Seat the rotor gently onto the collet

chuck

and push

it

a

ll

the

way

down un

til

i

ts

bottom bears against the

annular seat@ofthe collet chuck.

Then use the 6

mm

(or 10

mm

for

MEGAFUGE

3.0R)

box

spanner wrench to turn the hexagonal screw Ci)

(see Fig.

3)

of the

co

llet chuck clockwise,thereby spreading the collet chuck untiltight.

Fi

g.

4 Fastening the rotorclockwise

5.3

Removing

To remove the rotor, reverse the sequence.

CAUTION!

The collet ct1uck should always

be

removed -when not

in

use -so that it can't be damaged

by

inadve

rt

ently

starting without

the

rotor installed.

Fig.

5 Unscrewthe rotor counter-clockwise

16

}

6. ROTOR LOADING

WARNING!

The following instructions must

be

observed

exactly

to

avoid damage!

When using the sealed

rotor

#

3360

or

#

5315

,

the

loading instructi

ons

in

Sec

tion 6.7

must

be

obs

erved

in

every

det

ai

l.

All

adapters

must

only be loaded with t

ubes

whi

ch

have the right

shape

,

siz

e

and

material

(observe

tub

e manufacturer recommendations).

6.1

Swing-out

Rotors

WARNING!

In

swing

-

ou

t

rotors

all positions

mus

t be

occupied

with swinging

bucke

ts. The buckets

may

have an

ide

nt

i

fi

ca

ti

on letter which sta

te

s

H1e

weight class.

(e.

g. "E" or "D"). Only equal weight classes may be inserted

in opposi

ng

place

s.

Make

sure

that the

tubes

or

adapters

in

opposing

buckets

are identica

l.

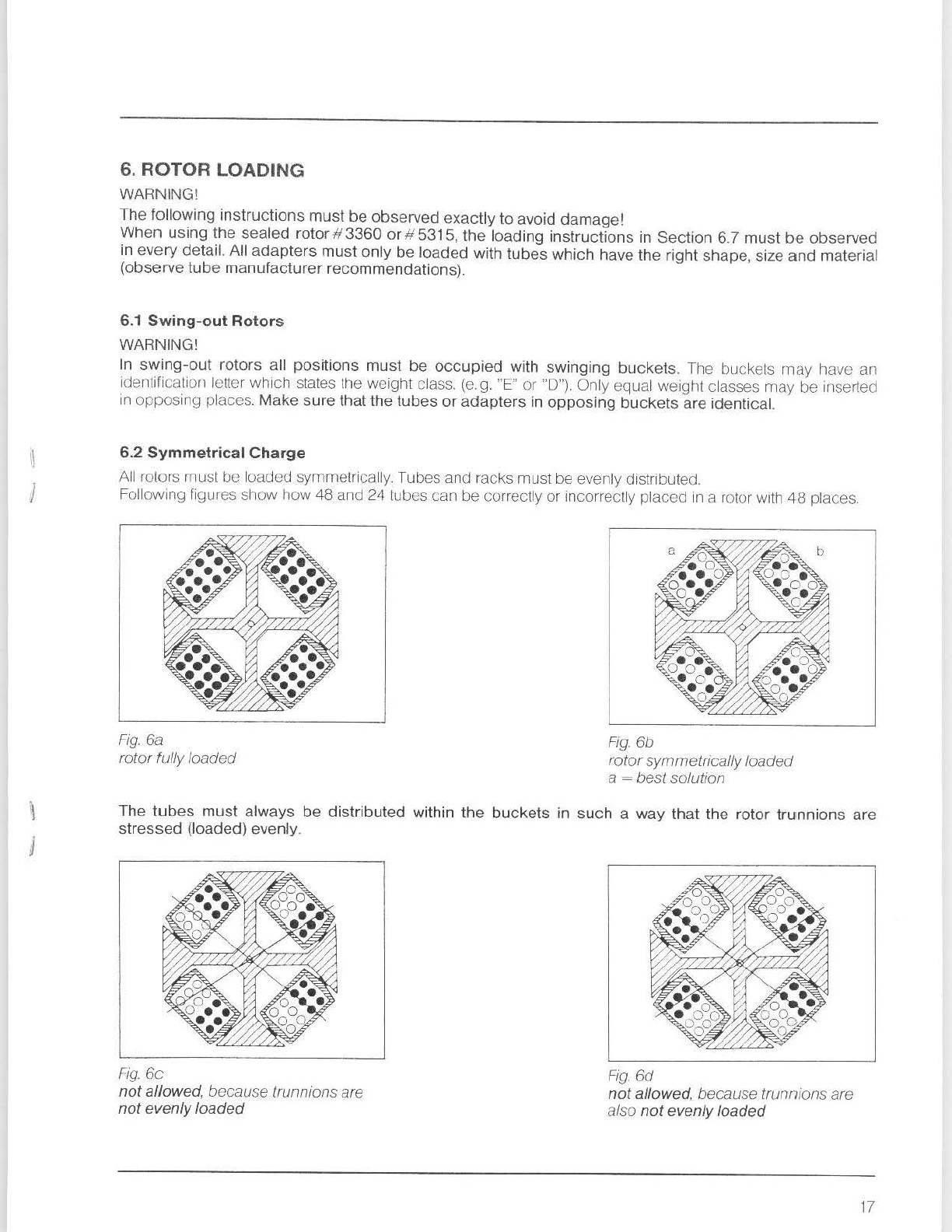

6.2

Symmetrical

Charge

All rotors must be loaded symme

tr

ically.Tubesand racks must be evenly distributed.

Following figures sh

ow

how 48 and 24 tubes can be correctly or in

co

rr

ectly placed in a rotor wi

th

48

places.

Fig.

6a

rotor fully loaded F

ig

.

6b

ro

tor

sy

mme

tr

ically loaded

a = be

st

solution

The

tubes

must

always be distributed within

the

buckets

in

such

a

way

that

the

roto

r

trnnnions

are

stressed

(loaded) evenly.

Fig.

6c

not

allowed

, because

tr

unni

ons

are

notevenly

loaded

Fig

.

6d

not

allowed

, because trunnions are

also

not

evenlyloaded

17

6.3

Distribution

of

Racks

In

order

to

avoid rotor wobble which might cause damage

to

both lhe centrifuge and the sample,

opposing

places

must

be

provided with identically loaded adapters, multiple carriers, tubes, bottles

etc

.

to

obtain

the

best

possible

balance.

Imbalance causes running

no

ises and produces a negative effect on

th

e

cJrive

system (excessive wear

out

of

the motorsupport).

The

permiss

i

ble

difference in total weight (or load) between

opposing

buckets

is

rotor

dependent

(see

RotorTables

2.4).

Todetermine the buc

ket

weights, any laboratory scale

is

suitable but a taring balance

is

best.

6.4 Tube Filling

Centrifuge tubes

up

to

approx. 30 mrn

in

diameter may

be

fil

led evenly

by

eye (up

to

5-10

mm

below the

rim,

depending upon size).

NOTE!

Using an angle

rot

or

and tubes without caps, only partial filling is possible (about

60%

and

75%

of the

maximum capacity). The actual amount of

fil

ling depends

on

the rotor's angle.

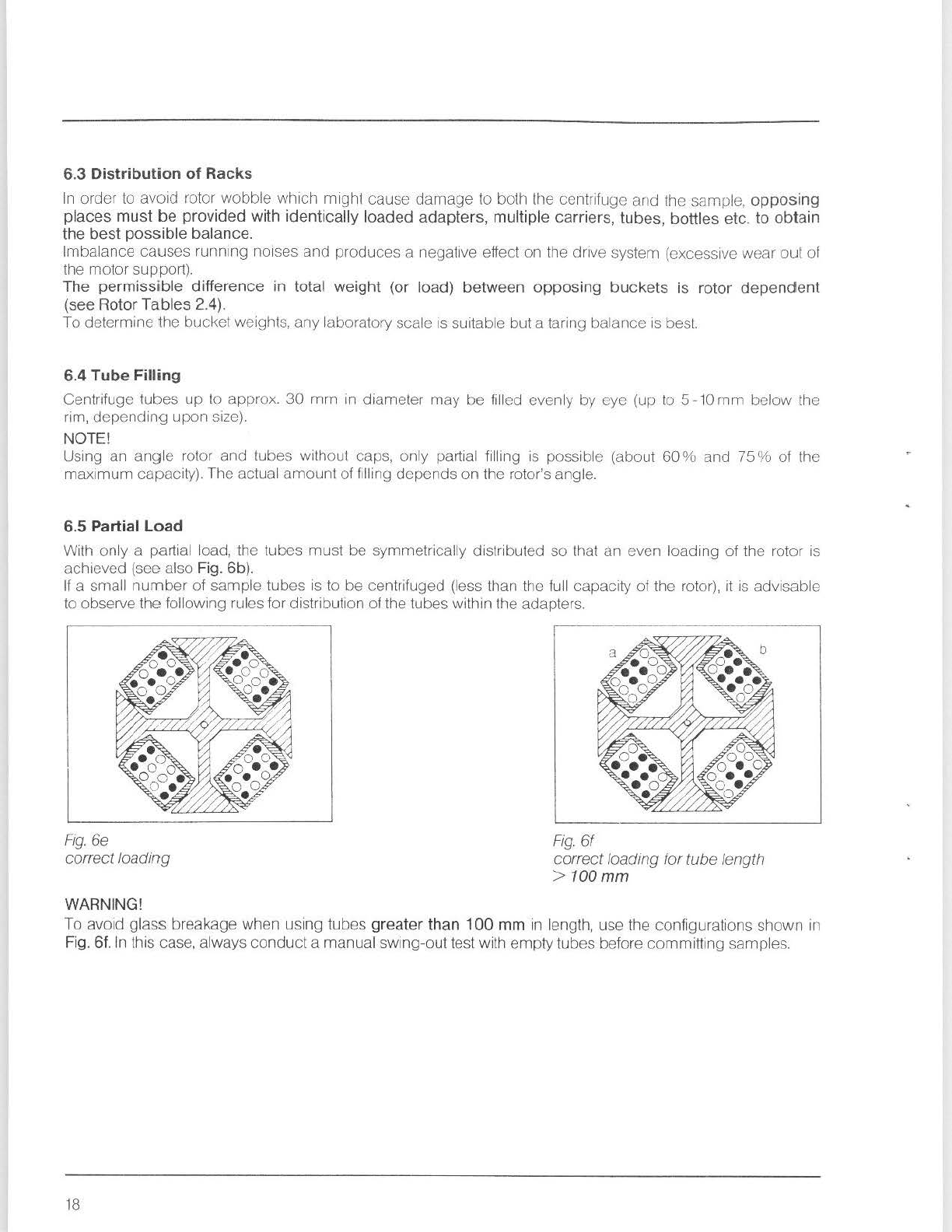

6.5

Partial

Load

Wi

th

only a partial load, the tubes must be symmetrically distributed so that an even loading of the rotor is

achieved (see also Fig. 6b).

If

a small number of sample tubes

is

to be centrifuged (less than the

ful

l capacity of the rotor), it is advisable

to

obseNe the following rules for distribution ofthe tubes within the adapters.

Fig.

6e

correct loading

WARNING!

Fig.

6f

correctloading for tube length

>

100mm

To

avoid

glass

brea

kage

wt1en

using

tubes

greater than 100 mm

in

l

ength,

use

the

configurations shown

in

Fig. 6f. In this case, always conducta manual swing-out test with emptytubes before committing samples.

18

6.6

Loading limits

rne material strength

of

every rotor

Is

limited with regmd to

1he

mass and speed-dependent forces actrng on its

yoke a

nd

other c

om

ponents du

ri

ng centrifuge operation.

HERAEUS rotors are designed

In

such a way that they still possess high strength reserves at the

maximum

perm1ss1ble

load and speed. Still

th

e maximum

permissible

limi

ts

must

not be

exc

ee

ded

.

It

is

the

operator's

responsibility

to

avoid overloa

ding

the rotor.

The max. permitted load

is

reached when all tubes are filled with a fluid of 1.2 g •

cm-

3 density. When the

density is higher th;rn

1.2

the tubes

may

only be partly filled. The total weight of a bucket

msy

not exceed the

value corresµonding

to to

tal fi

ll

ing with a liquid of 1.2

dens

i

ty.

As an alternative in such cases,

11

is possible

to

reduce the maximum perrrntted speed nm;:ix in accordance

with

the

following formula:

✓

To:ai

wc,y",I or

ltw

t•IIC:<ets

rul

s~m:il••

nadm =

nmax

w,tro

a ,i,,ns,1y

o:

1.2 9

cm

-

---

l

otdl

vvei<Jht

c:

tt1H

tJuckcts

11

c1

samp1t.?

w1

t

ll

h1ghnr c!e

ns1

N

6.7 Sealed Rotors

3360/5315

ATTENTION!

Sp

ecial

lo

ading instructions must be

observed

when

us

i

ng

the Seated Rotors#

3360

or

# 5315!

The operating instructions which are supplied with the sealed rotors must al

so

be read and observed exactly!

The Sealed Rotor is a swing-out rotor with a sealing lid designed for applications involving infectious

or

pathogenic samples. The centrifugal force of the buckets

,n

this rotor

Is

absorbed by an exterior ring of

fiberglass-reinforced pla

sti

c.

The lid reduces air friction whict1 a

ll

ows

th

is rotor to roach a high

er

max

i

mum

speed

th

an without lid.

Lock the rotor lid correctly to protect against spills due to broken glass or damaged tubes that may result

1n

aerosol cont

am

i

na

tion.

The buckets or

rotor"

3360

or

"'

5315 should be loaded wtlh Centn-Lab racks

or

inserts of identical exterior

dimensions and weight.

The rotor is intended to accomodato tubes 1

00

mm

in

length. However, shorter or longer tubes can be used.

Under certain circumstances, only the middle positions of the tube rack (sec

fig.

6Q

may

be occupied

by

the

longer tubes

to

prevent them from being knocked against the rotor yoke. Check

th

at

th

e buckets swing out

fr

eely.

Do not run the centrifuge with emptyglasstubes. Glass tubes

of

equal weight

may

exhibitverydifferent centers

ofgravity resulting in substan

ti

al

im

balance. This effect is reduced by filling

th

e tubes.

The unique

co

nstruction

of

the

Sealed Rotor requires special precautions when operating. The following

rules

must

be

absolutely

observed

in every detail.

WARNING!

It

is

esse

nt

ial thatthese rules are

prec

isely followed

in

order

to

preventdamage

to

the

rotor

or

ce

ntrifuge

resulting in a potential hazard

to

nearby

equipment

and

personnel.

1) Attach the rotor

co

rrectly

2) Ensure each counter-weightis

In

itsownposition 1-4 (only for rotor~ 3360being balanced

by

theseweights)

3) Insert

all

buckets and all tube rack

s.

All

buckets

must

be loaded.

4)

Load bucketsevenly and symmetrically

5)

Do not exceed permitted weight differences:

adjacent buckets: 100g

opposing buckets:

10

g

6) Do not exceed maximum sample load (

51

0g per bucket)

7) Check troublcfree operation

of

th

e rotor lid and observe expiration date (5 years laterthan imprinted date)

8) Lockrotor lid correctly

9) Do not exceed the speed limitof

th

e rotor (see RotorTables

2.4)

19

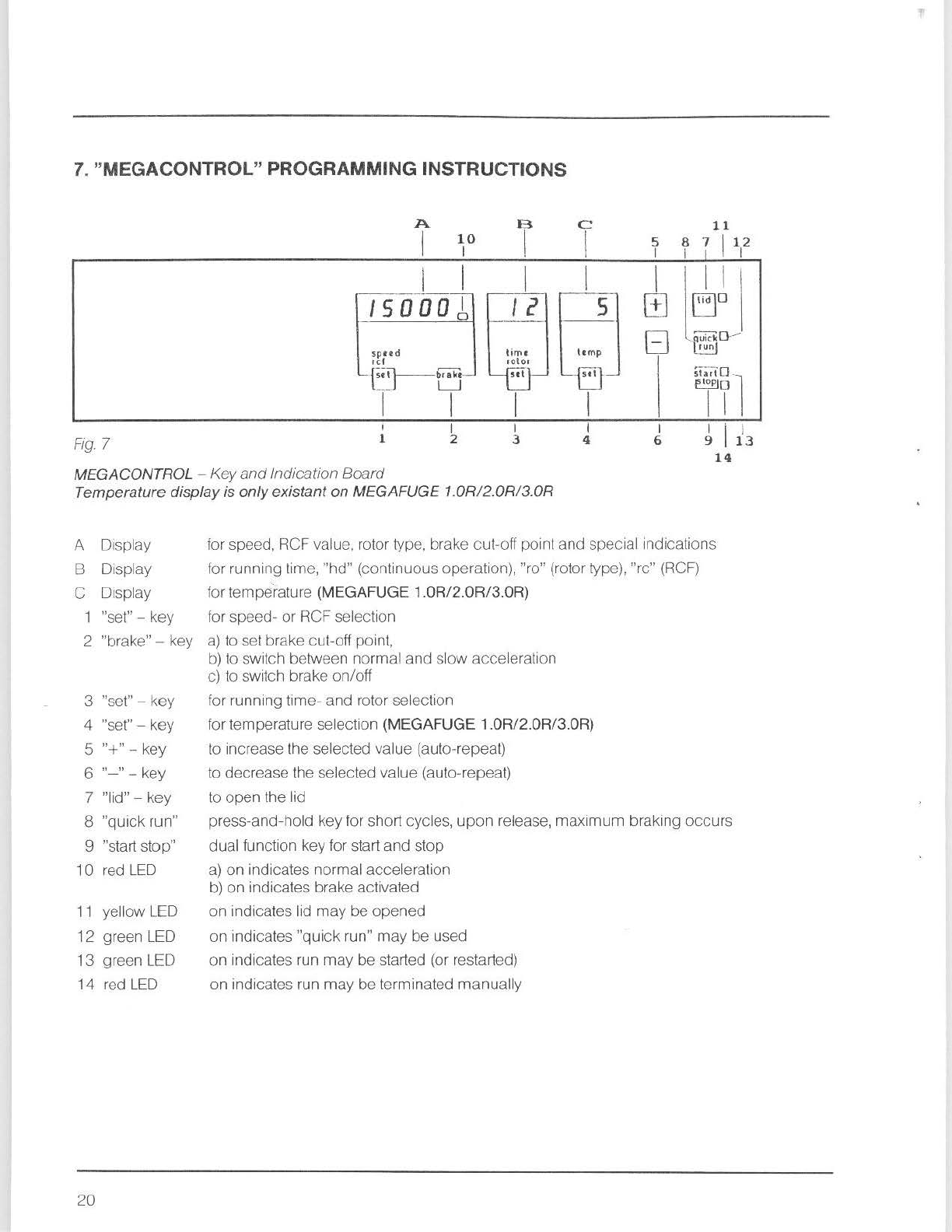

7. "MEGACONTROL" PROGRAMMING INSTRUCTIONS

A B C

11

I

10

I I 5 8 7 1

1i2

I I I

I I I I

~~:

/SOOD!

, 2 s

spud

ltm

p

,er

-e~b<al<r

-

starl·

□

-

1

--

L_J

~o

I I I I

I I I I I I .

Fig.

7 1 2 3 4 6 9 I1\

14

MEGACONTROL -

Key

and

Indication

Board

Temperature displayis onlyexistanton MEGAFUGE 1

.0R/2

.0R

/3.0R

A Display

B Display

C Display

1 "set" -key

2 "brake" -key

3 "set" -key

4 "set" -key

5 "+" -key

6 "-" -key

7 "lid" -key

8

"quick

run"

9 "start stop"

10

red

LED

11 yellow LED

12

green LED

13

green LED

14 red

LED

20

for speed, RCF value, rotor type, brake

cut

-offpoint

and

special indications

for running tirne,

"hd"

(conti

nuous

opera

ti

on), "ro" (rotor type), "re" (RCF)

for temperature (MEGAFUGE 1.0R/2.0R/3.0R)

for speed-

or

RCFselecti

on

a)

toset brakecut-off point,

b)

to switch between normal

and

sl

ow

acce

leration

c) to

sw

i

tch

brake on/off

for running

tim

e- and rotor selection

for

temperature sele

ct

ion (MEGAFUGE 1.0R/2.0R/3.0R)

to increase the selected value (auto-repeal)

to decrease the selected value (auto-repeat)

to

open

the lid

press-and-hold key for short

cyc

les,

upon

release,

maximum

braking

occ

u

rs

dual functi

on

key for start

and

stop

a)

on

indicates normal

acce

leration

b)

on

indicates brake activated

on

indicates lid

may

be

opened

on

indicates

"quick

run"

may

be used

on

indicates run

may

be

started (or restarted)

on

indicatesrun

may

be

terminated

manual

ly

This manual suits for next models

4

Table of contents

Other Heraeus Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual