Heraeus CLINIFUGE Instruction Manual

Heraeus

CLINIFUGE

™

Operating

Instruction

Manual

Kr

LL

READ

ME

FIRST

The

Clinifuge

centrifuge

is

designed

to

perform

a

variety

of

separation

tasks

in

small-scale

laboratories.

Before

operating,

follow

these

few

simple

cautions

and

guidelines.

A

FEW

DO'S

AND

DON'Ts

Read

all

parts

of

this

manual

carefully

before

attempting

to

operate

the

unit,

to

insure

smooth

operation

and

avoid

damage

to

the

unit

or

its

accessories.

If

a

malfunction

occurs, consult

the

Troubleshooting

Guide

at

the

end

of

this

manual.

If

problems

persist,

call

Heraeus

Instruments

at

1-800-441-2554

or

FAX

information

about

the

problem

to

Heraeus

at

1-908-754-9494.

Never

attempt

to

open

the

lid

manually

while

the

rotor

is

spinning!

Always

use tube

adaptors

when

loading

5

ml.

and

7

ml.

tubes

(see

Section

3.6).

10-,

12-

and

15-ml.

tubes

are

loaded

without

adaptors.

Complete

the

warranty

card

shipped

with

your

unit

and

return

to

the

manufacturer.

FOR

SAFETY,

NEVER

OPERATE

THE

CENTRIFUGE

IF:

-

the

lid

is

open

—

the

rotor

is

not

properly

installed

(see

Section

3.5)

-

the

expiration

date

stamped

on

the

rotor

has

passed

(see

Section

6.3)

or

the

rotor

has

been

used

more

than

10,000

cycles

(see

Section

6.2)

—

the

maximum

weight

of

a

tube

including

sample

exceeds

24

grams

or

the

density

of

the

sample

material

exceeds

1.2 g

-

cm~3

for

top

speed

operation

—

the

rotor

is

not

loaded

symmetrically

(see

Section

4.1)

Never

operate

the

Clinifuge

if

you

have

not

checked

the

maximum

centrifugal

speed

recommended

by

the

tube

manufacturer.

WARNING!

In

case

of

imbalance

(e.g.

tube

breakage

or

non-symmetrical

loading),

shut

off

power

to

the

unit

immediately.

To

accomplish

this:

1.

press

the

STOP

key

on

the

front

of

the

unit

immediately

2.

less

preferably,

pull

the

power

plug.

NOTE:

When

performing

centrifugation

and

other

functions

which

may

expose

workers

to

splashed

blood

or

body

fluids,

all

laboratory

personnel

must

follow

universal

laboratory

precautions.

For

details,

contact

your

local

laboratory

safety

officer.

Clinifuge

Centrifuge

Operation

Manual

(Revision

05/93)

READ

ME FIRST

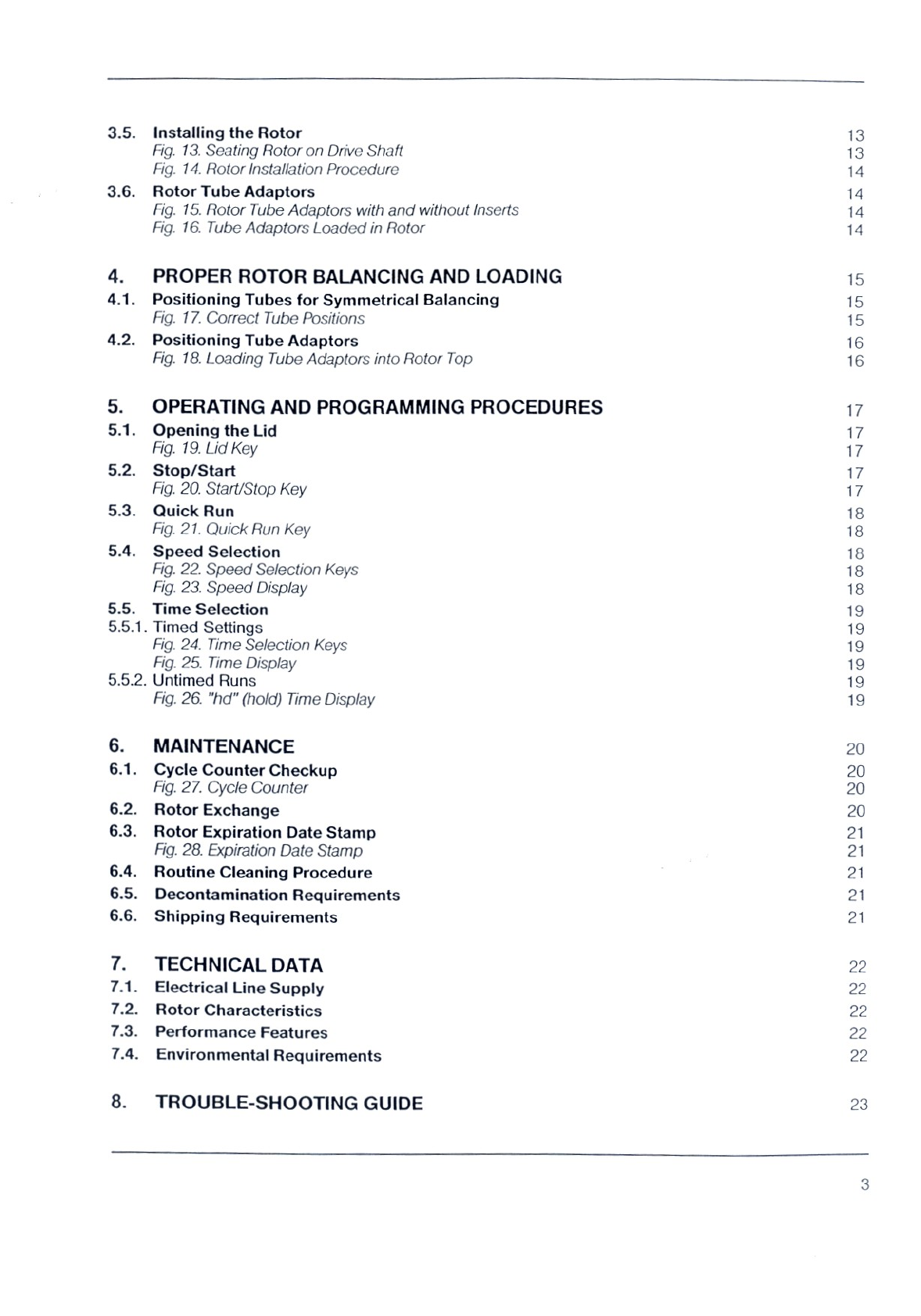

Table

of

Contents

FAST

STARTUP

REFERENCE

GUIDE

Fig.

1.

Clinifuge

Control

Panel

Fig.

2.

Closed

Clinifuge

Fig.

3.

Opened

Clinifuge

Fig.

4.

Locking

Nut

and

Assembled

Rotor

Fig.

5.

Tube

Adaptors

and

Inserts

(optional)

ユー

ュー

ユーーーー

pre

Npnabra*

mama

Wu

그

PNRNNNNNNN

の

の

mA

よら

一

3.2.

3.3.

3.4.

DESCRIPTION

OF

UNIT

Definition

Standard

Parts

Optional

Equipment

Mechanical

Construction

Electrical

Construction

Warranty

Operating

Controls

Fig.

6.

Clinifuge

Operating

Controls

and

Control

Panel

Display

Features

.

Speed

.

Time

.

Standby

Mode

Light

SETTING

UP

THE

CLINIFUGE

Location

Electrical

Requirements

Self

Check

Cycle

Standby

Mode

Automatic

Lid

Lock

Opening

the

Lid

Emergency

Lid

Opening

Accidental

Lid

Opening

during

Run

Fig.

7.

Emergency

Lid

Opening

ROTOR

REMOVAL

AND

INSTALLATION

Rotor

Parts

Fig.

8.

Fully

Assembled

Rotor

Fig.

9.

Correct

Rotor

Installation

Fig.

10.

Disassembled

Rotor

Removing

the

Rotor

Taking

the

Rotor Apart

Fig.

11.

Rotor

Disassembly

-

Top

View

Assembling

the

Rotor

Fig.

12.

Assembling

the

Rotor

ooooums

oo oo

oo

oo

D

D

NN

NI

NN

NI

NI

3.5.

3.6.

5.2.

5.3.

5.4.

5.5.

5.5.1.

5.5.2.

6.1.

6.2.

6.3.

6.4.

6.5.

6.6.

7.

7.1.

7.2.

7.8.

7.4.

Installing

the

Rotor

Fig.

13.

Seating

Rotor

on

Drive

Shaft

Fig.

14.

Rotor

Installation

Procedure

Rotor

Tube

Adaptors

Fig.

15.

Rotor

Tube

Adaptors

with

and

without

Inserts

Fig.

16.

Tube

Adaptors

Loaded

in

Rotor

PROPER

ROTOR

BALANCING

AND

LOADING

Positioning

Tubes

for

Symmetrical

Balancing

Fig.

17.

Correct

Tube

Positions

Positioning

Tube

Adaptors

Fig.

18.

Loading

Tube

Adaptors

into

Rotor

Top

OPERATING

AND

PROGRAMMING

PROCEDURES

Opening

the

Lid

Fig.

19.

Lid

Key

Stop/Start

Fig.

20.

Start/Stop

Key

Quick Run

Fig.

21.

Quick Run

Key

Speed

Selection

Fig.

22.

Speed

Selection

Keys

Fig.

23.

Speed

Display

Time

Selection

Timed

Settings

Fig.

24.

Time

Selection

Keys

Fig.

25.

Time

Display

Untimed

Runs

Fig.

26.

"hd"

(hold)

Time

Display

MAINTENANCE

Cycle

Counter

Checkup

Fig.

27.

Cycle

Counter

Rotor

Exchange

Rotor

Expiration

Date

Stamp

Fig.

28.

Expiration

Date

Stamp

Routine

Cleaning

Procedure

Decontamination

Requirements

Shipping

Requirements

TECHNICAL

DATA

Electrical

Line

Supply

Rotor

Characteristics

Performance

Features

Environmental

Requirements

TROUBLE-SHOOTING

GUIDE

15

15

16

16

17

17

17

17

18

18

18

18

18

19

19

19

19

19

19

20

20

20

20

21

21

21

21

21

22

22

22

22

22

23

FAST

STARTUP

REFERENCE

GUIDE

Setting

Up

the

Clinifuge

1.

Set

unit

on

a

flat,

sturdy,

resonance-free

surface

in

a

well

ventilated

area.

2.

After

plugging

into

power

supply,

turn

on

the

main

power

switch

located

under

the

left

side

of

the

unit

(See

Electrical

Requirements,

Section

2.2.)

3.

Open

the

lid

by

pressing

the

LID

keypad.

4.

Remove

all

packing

materials.

Rotor

must

move

freely.

5.

If

adaptors

are

required,

remove

the

rotor

(See

Section

3.6, Fig. 15),

and

insert

adaptors

(See

Section

3.6,

Fig.

16)

6.

Mount

the

rotor

on

the

drive

shaft,

aligning

the

groove

on

the

underside

of

the

rotor

base

with

the

cross-pin

in

the

drive

shaft.

Screw

locking

nut

in

place.

(See

Section

3.5,

Figures

13

and

14

for

full

rotor

installation

instructions)

WARNING!

If

the

locking

nut

does

not

easily

engage

the

threaded

portion

of

the

drive

shaft,

do

not

try

to

force

the

rotor

further

onto

the

drive

shaft.

Instead,

remove

the

rotor

and

re-install,

making

sure

the rotor

is

correctly

seated

on

the

drive

shaft

cross

pin.

7.

Load

tubes

making

sure

the

rotor

is

symmetrically

balanced.

(See

Section

4.1,

Fig.

17

on

Positioning

Tubes.)

8.

Close

lid

making

sure both

lid

locks

are

engaged.

Display

will

read

"OPEN”

and

centrifuge

will

not

operate

if

both

locks

are

not

fully

engaged.

Programming

the

First

Run

9.

To

set

time,

press

the

SET

keypad

in

the

TIME

field.

Change

time

by

pressing

"+"

or

"~"

keypads.

10.

To

set

speed

for

a

timed

run,

press

the

SET

keypad

in

the

SPEED

field.

Change

speed

setting

by

pressing

"+"

or

"-"

keypad.

11.

For

timed

runs,

press

START

keypad.

Unit

will

shut

off

automatically.

For

untimed

runs,

press

QUICK

START

keypad

and

hold

for

desired

time.

Preparing

the

Next

Run

12.

At

end

of

cycle,

remove

all

tubes

from

rotor.

13.

Check

for

broken

glass

or

leakage

into

rotor

and/or

chamber.

14.

To

remove

rotor,

remove

locking

nut

by

turning

counter-clockwise.

Insert

index

fingers

into

opposite

tube

holes

and

lift

rotor

straight

up.

To

prevent

damage

to

drive

shaft,

do

not

lift

rotor

at

an

angle.

To

prepare

the

next

run,

follow

the

routine

cleaning

procedure

(Section

6.4),

if

necessary,

then

repeat

Steps

3to

14.

For

more

detailed

information

about

Clinifuge

features,

operation and

guidelines,

consult

other

sections

of

this

manual.

i

+]

[ia

[©

ー

|

[quick]

0

speed

time

=

set

set

sano

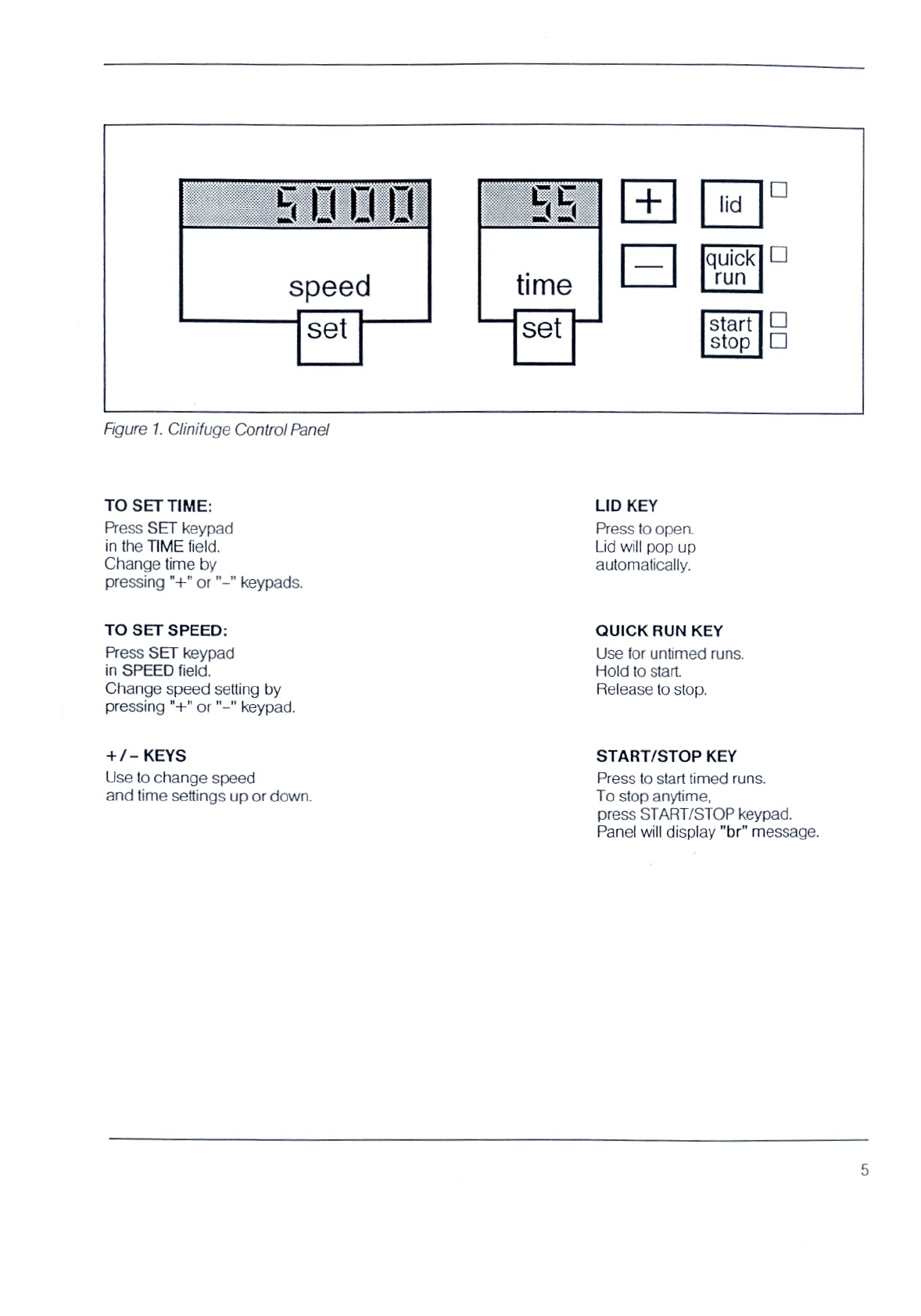

Figure

1.

Clinifuge

Control

Panel

TO

SET

TIME:

Press

SET

keypad

in

the

TIME

field.

Change

time

by

pressing

"+"

or

"-"

keypads.

TO

SET

SPEED:

Press

SET

keypad

in

SPEED

field.

Change

speed

ing

by

pressing

"+"

or

"-"

keypad.

+/-

KEYS

Use

to

change

speed

and

time

settings

up

or

down.

LID

KEY

Press

to

open

Lid

will

pop

up

automatically.

QUICK

RUN

KEY

Use

for

untimed

runs.

Hold

to

start.

Release

to

stop.

START/STOP

KEY

Press

to

start

timed

runs.

To

stop

anytime,

press

START/STOP

keypad.

Panel

will

display

"br"

message.

Figure

2.

Closed

Clinifuge

(Control

Panel)

Figure

3.

Open

Clinifuge

(down

view

w/rotor

mounted)

=

==

O

Figure

4.

Locking

Nut

&

Assembled

Rotor

Alla

Figure

5.

Tube

Adaptors

&

Inserts

(optional)

6

1.

DESCRIPTION

OF

UNIT

1.1.

Definition

The

Clinifuge

is

a

laboratory

centrifuge

used

for

a

variety

of

separation

tasks

in

small-scale

laboratories.

The

following

features

provide

easy,

efficient

operation:

—

maintenance-free

induction

drive

motor

—

microprocessor

controlled

—

no

carbon

dust

build-up

due

to

elimination

of

carbon

brushes

—

membrane

touch

pads

for

easy

cleaning

—

CSA

listed

(Canadian

Standards

Association)

-

angle

rotor

designed

to

carry

10-,

12-

and

15-ml.

tubes

(tube

adaptors

available

as

optional

equipment

for

5

ml.

and

7

ml.

tubes)

1.2.

Standard

Parts

The

Clinifuge

you

have

been

shipped

comes

with

the

following

parts:

1.

Two-part

rotor

(Figure

4)

2.

Locking

Nut

(Figure

4)

1.3

Optional

Equipment

Tube

adaptors

and

inserts

(See

Figure

5.)

1.4

Mechanical

Construction

The

Clinifuge

frame

is

constructed

of

solid steel

with

an

armor

chamber

and

a

suspension

for

the

drive

and

lid

mechanics

which

provide

extra

security

in

the

event

of

rotor

malfunction.

The

impact-resistant

plastic

casing

is

mounted

to

the

frame

to

reduce

noise

and

vibration.

Digital

displays

(LED's

-

light

emitting

diodes)

indicate

speed,

time

and

operating

conditions.

1.5

Electrical

Construction

The

Clinifuge

operates

on

one

circuit

board

using

microprocessor-controlled

digital

LED

displays

and

key

pads

on

the

face

of

the

unit

to

control

program

settings.

CAUTION:

The

microprocessor

board

is

located

directly

behind

the

front

panel.

To

avoid

electric

shock

or

damage,

only

a

factory

trained

technician

may

service

this

area.

1.6

Warranty

The

Clinifuge

is

warranted

against

defects

in

materials

and

workmanship

for

a

period

of

one

year

after

shipment

to

the

customer.

The

Clinifuge

rotor

is

warranted

against defects

in

materials

and

workmanship

for

the

period

of

10,000

cycles

or

the

expiration

date

stamped

on

the

rotor,

whichever

occurs

first.

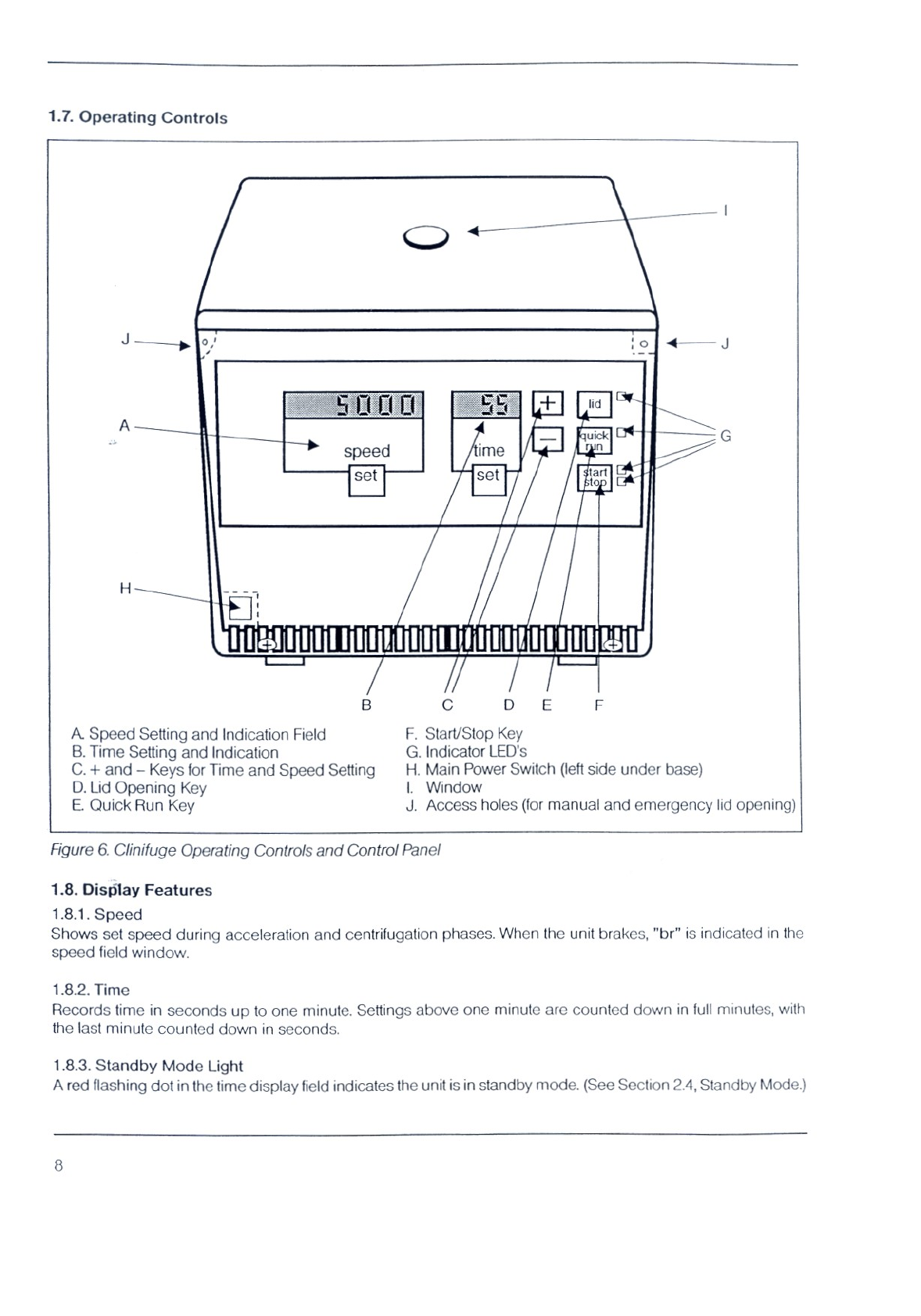

1.7.

Operating

Controls

B

ο D

E Е

A.

Speed

Setting

and

Indication

Field

F.

Start/Stop

Key

B.

Time

Setting

and

Indication

G.

Indicator

LED's

C. +

and

—

Keys

for

Time

and

Speed

Setting

H.

Main

Power

Switch

(left

side

under

base)

D.

Lid

Opening

Key

L

Window

E.

Quick Run

Key

J.

Access

holes

(for

manual

and

emergency

lid

opening)

Figure

6.

Clinifuge

Operating

Controls

and

Control

Panel

1.8.

Display

Features

1.8.1.

Speed

Shows

set

speed

during

acceleration

and

centrifugation

phases.

When

the

unit

brakes,

"br"

is

indicated

in

the

speed

field

window.

1.8.2.

Time

Records

time

in

seconds

up

to

one

minute.

Settings

above

one

minute

are

counted

down

in

full

minutes,

with

the

last

minute

counted

down

in

seconds,

1.8.3.

Standby

Mode

Light

A

red

flashing

dot

in

the

time

display

field

indicates

the

unit

is

in

standby

mode.

(See

Section

2.4,

Standby

Mode.)

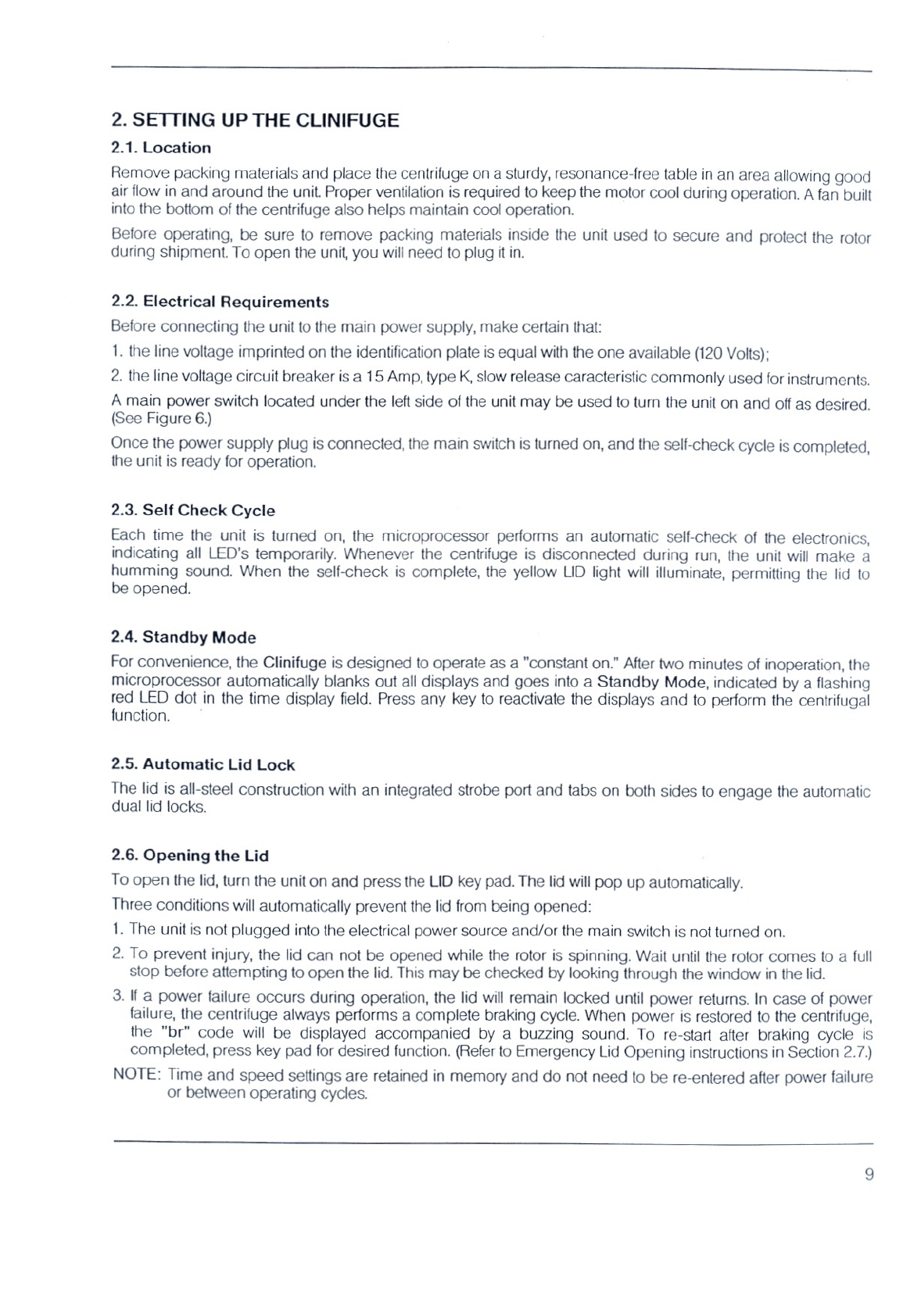

2.

SETTING

UP

THE

CLINIFUGE

2.1.

Location

Remove

packing

materials

and

place

the

centrifuge

on

a

sturdy,

resonance-free

table

in

an

area

allowing

good

air

flow

in

and

around

the

unit.

Proper

ventilation

is

required

to

keep

the

motor

cool

during

operation.

A

fan

built

into

the

bottom

of

the

centrifuge

also

helps

maintain

cool

operation.

Before

operating,

be

sure

to

remove

packing

materials

inside

the

unit

used

to

secure

and

protect

the

rotor

during

shipment.

To

open

the

unit,

you

will

need

to

plug

it

in.

2.2.

Electrical

Requirements

Before

connecting

the

unit

to

the

main

power

supply,

make

certain

that:

1.

the

line

voltage

imprinted

on

the

identification

plate

is

equal

with

the

one

available

(120

Volts);

2.

the

line

voltage

circuit

breaker

is

a

15

Amp,

type

K,

slow

release

caracteristic

commonly

used

for

instruments.

A

main

power

switch

located

under

the

left

side

of

the

unit

may

be

used

to

turn

the

unit

on

and

off

as

desired.

(See

Figure

6.)

Once

the

power

supply

plug

is

connected,

the

main

switch

is

turned

on,

and

the

self-check

cycle

is

completed,

the

unit

is

ready

for

operation.

2.3.

Self

Check

Cycle

Each

time

the

unit

is

turned

on,

the

microprocessor

performs

an

automatic

self-check

of

the

electronics,

indicating

all

LED's

temporarily.

Whenever

the

centrifuge

is

disconnected

during

run,

the

unit

will

make

a

humming

sound.

When

the

self-check

is

complete,

the

yellow

LID

light

will

illuminate,

permitting

the

lid

to

be

opened.

2.4.

Standby

Mode

For

convenience,

the

Clinifuge

is

designed

to

operate

as

a

"constant

on.”

After

two

minutes

of

inoperation,

the

microprocessor

automatically

blanks

out

all

displays

and

goes

into

a

Standby

Mode,

indicated

by

a

flashing

red

LED

dot

in

the

time

display

field.

Press

any

key

to

reactivate

the

displays

and

to

perform

the

centrifugal

function.

2.5.

Automatic

Lid

Lock

The

lid

is

all-steel

construction

with

an

integrated

strobe

port

and

tabs

on

both

sides

to

engage

the

automatic

dual

lid

locks.

2.6.

Opening

the

Lid

To

open

the

lid,

turn

the

unit

on

and

press

the

LID key

pad.

The

lid

will

pop

up

automatically.

Three

conditions

will

automatically

prevent

the

lid

from

being

opened:

1.

The

unit

is

not

plugged

into

the

electrical

power

source

and/or

the

main

switch

is

not

turned

on.

2.

To

prevent

injury,

the

lid

can

not

be

opened

while

the

rotor

is

spinning.

Wait

until

the rotor

comes

to

a

full

stop

before

attempting

to

open

the

lid.

This

may

be

checked

by

looking

through

the

window

in

the

lid.

3.

If

a

power

failure

occurs

during

operation,

the

lid

will

remain

locked

until

power

returns.

In

case

of

power

failure,

the

centrifuge

always

performs

a

complete

braking

cycle.

When

power

is

restored

to

the

centrifuge,

the

“br”

code

will

be

displayed

accompanied

by

a

buzzing

sound.

To

re-start

after

braking

cycle

is

completed,

press

key

pad

for

desired

function.

(Refer

to

Emergency

Lid

Opening

instructions

in

Section

2.7.)

NOTE:

Time

and

speed

settings

are

retained

in

memory

and

do

not

need

to

be

re-entered

after

power

failure

or

between

operating

cycles.

2.7.

Emergency

Lid

Opening

WARNING!

Never

attempt

to

open

the

lid

manually

while

the

rotor

is

still

spinning.

Confirm

that

rotor

has

stopped

spinning

by

looking

through

the

round

window

in

the

middle

of

the

lid.

Disconnect

power

cord

before

using

the

following

Emergency

Lid

Opening

Procedure.

2.8.

Accidental

Lid

Opening

during

Run

If

the

lid

opens

during

a

run,

the

microprocessor

will

flash

the

LID

error

message.

Before

lifting

the

lid,

confirm

that

the

rotor

has

come

to

a

full

stop

by

looking

through

the

round

window

in

the

middle

of

the

lid.

In

case

of

a

prolonged

power

failure

or

defect,

the

LID

button

can

not

be

used

to

open

the

lid.

The

locked

cabinet

lid

can

be

opened

manually

as

follows:

1.

Disconnect

the

power

cord

before

using

the

emergency

lid

opening

procedure.

2.

Make

sure

the

rotor

is

fully

stopped

by

looking

through

the

round

lid

window.

3.

Insert

two

rods

into

the

access

holes

on

both

side

panels

(See

Figure

7)

and

unlock

the

lid,

one

side

ata

time.

Access

Hole

Access

Hole

Figure

7.

Emergency

Lid

Opening

Not

to

be

used

while

rotor

is still

spinning!

10

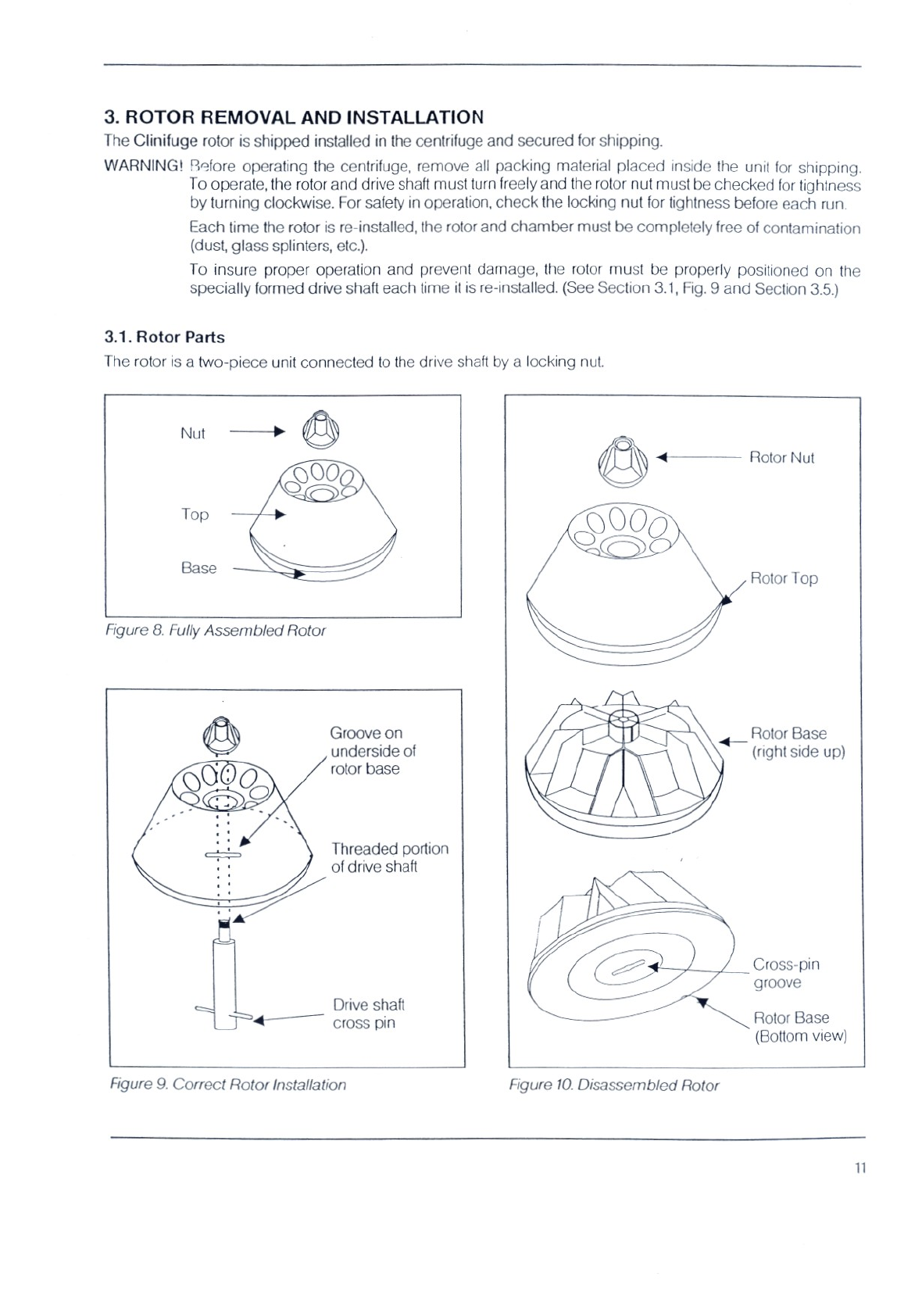

3.

ROTOR

REMOVAL

AND

INSTALLATION

The

Clinifuge

rotor

is

shipped

installed

in

the

centrifuge

and

secured

for

shipping.

WARNING!

Before

operating

the

centrifuge,

remove

all

packing

material

placed

inside

the

unit

for

shipping.

To

operate,

the

rotor

and

drive

shaft

must

turn

freely

and

the

rotor

nut

must

be

checked

for

tightness.

by

turning

clockwise.

For

safety

in

operation,

check

the

locking

nut

for

tightness

before

each

run

Each

time

the

rotor

is

re-installed,

the

rotor

and

chamber

must

be

completely

free

of

contamination

(dust,

glass

splinters,

etc.).

To

insure

proper

operation

and

prevent

damage,

the

rotor

must

be

properly

positioned

on

the

specially

formed

drive

shaft

each

time

it

is

re-installed.

(See

Section

3.1,

Fig.

9

and

Section

3.5.)

3.1.

Rotor

Parts

The

rotor

is

a

two-piece

unit

connected

to

the

drive

shaft

by

a

locking

nut.

Nut

Rotor

Nut

Rotor

Top

Figure

8.

Fully

Assembled

Rotor

É

Groove

on

<

Rotor

Base

underside

of

(right

side

up)

G

O

rotor

base

RC

Threaded

portion

NZ

of

drive

shaft

Cross-pin

groove

Drive

shaft

=

4

cross

pin

Rotor

Base

(Bottom

view)

Figure

9.

Correct

Rotor

Installation

Figure

10.

Disassembled

Rotor

3.2.

Removing

the

Rotor

To

remove

the

rotor

from

the

chamber:

1.

Open

the

lid.

2.

Remove

all

tubes

and

check

for

broken

glass.

3.

Remove

rotor

locking

nut by

turning

counter-clockwise.

4.

To

remove

rotor,

insert

index

fingers

into

holes

in

rotor

and

pull

straight

up.

If

properly

installed,

the

entire

rotor

will

lift

out.

(Before

inserting

fingers,

check

holes

for

broken

glass.)

WARNING!

Never

pull

the

rotor

up

at

an

angle.

Doing

so

could

bend

the

drive

shaft

and

cause

permanent

damage

to

the

motor.

3.3.

Taking

the

Rotor

Apart

To

separate

the

rotor

top

from

the

rotor

base:

1.

Remove

rotor

from

unit

and

place

on

a

flat

surface.

2.

Insert

index

fingers

into

empty

tube

holes

on

opposite

sides

of

the

rotor

top.

3.

Using

thumb,

press

firmly

down

on

centerpiece.

The

two

halves

of

the

rotor

should

separate

easily.

Rotor

Hole

Centerpiece

Press

here

to

separate

Rotor

Base

Figure

11--Rotor

Disassembly

—

Top

View

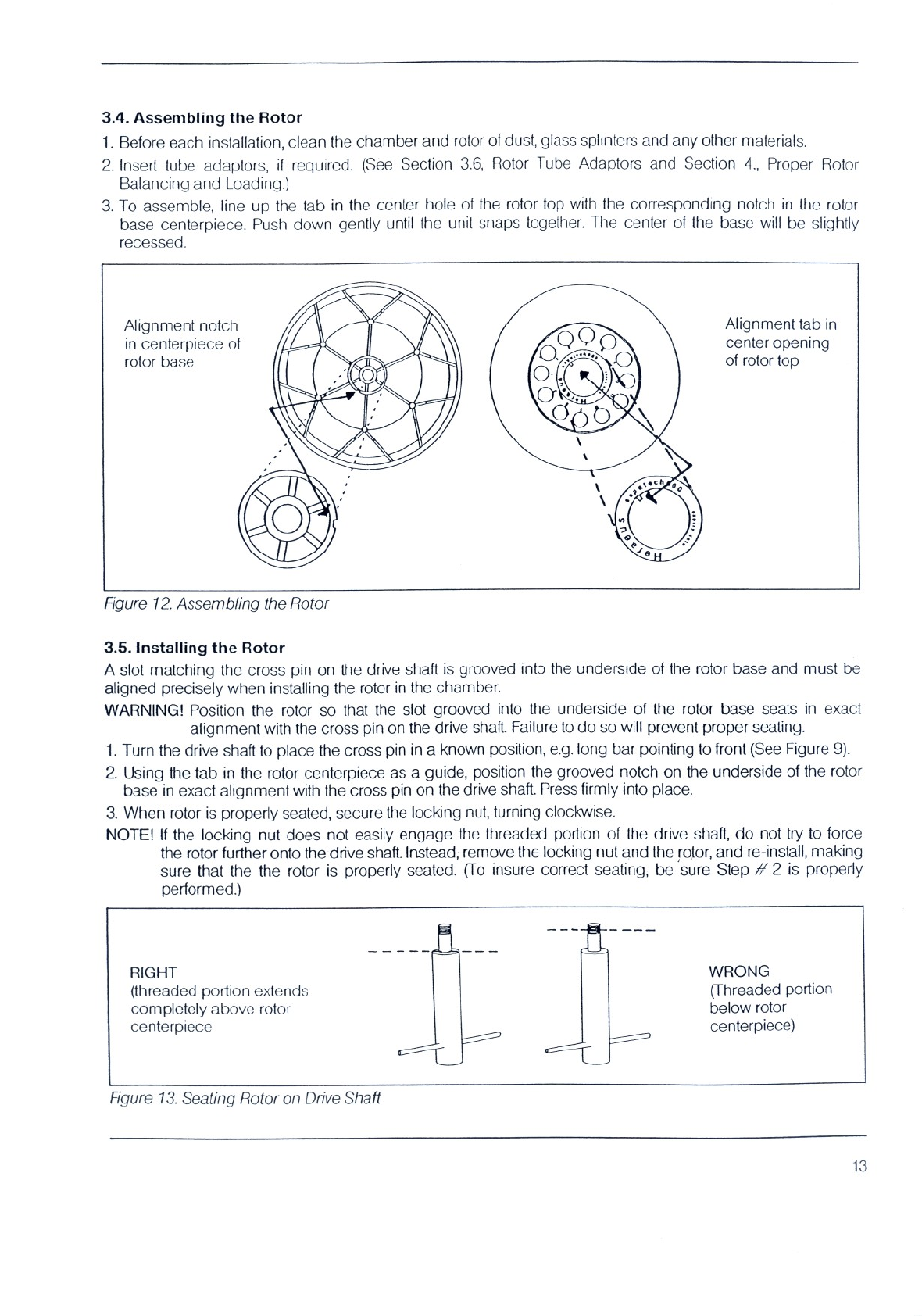

3.4.

Assembling

the

Rotor

1.

Before

each

installation,

clean

the

chamber

and

rotor

of

dust,

glass

splinters

and

any

other

materials.

2.

Insert

tube

adaptors,

if

required.

(See

Section

3.6,

Rotor

Tube

Adaptors

and

Section

4.,

Proper

Rotor

Balancing

and

Loading.)

3.

To

assemble,

line

up

the

tab

in

the

center

hole

of

the

rotor

top

with

the

corresponding

notch

in

the

rotor

base

centerpiece.

Push

down

gently

until

the

unit

snaps

together.

The

center

of

the

base

will

be

slightly

recessed.

Alignment

notch

Alignment

tab

in

in

centerpiece

of

center

opening

rotor

base

of

rotor

top

Figure

12.

Assembling

the

Rotor

3.5.

Installing

the

Rotor

A

slot

matching

the

cross

pin

on

the

drive

shaft

is

grooved

into

the

underside

of

the

rotor

base

and

must

be

aligned

precisely

when

installing

the

rotor

in

the

chamber.

WARNING!

Position

the

rotor

so

that

the

slot

grooved

into

the

underside

of

the

rotor

base

seats

in

exact

alignment

with

the

cross

pin

on

the

drive

shaft.

Failure

to

do so

will

prevent

proper

seating.

1.

Turn

the

drive

shaft

to

place

the

cross

pin

in

a

known

position,

e.g.

long

bar

pointing

to

front

(See Figure

9).

2.

Using

the

tab

in

the

rotor

centerpiece

as

a

guide,

position

the

grooved

notch

on

the

underside

of

the

rotor

base

in

exact

alignment

with the

cross

pin

on

the

drive

shaft.

Press

firmly

into

place.

3.

When

rotor

is

properly

seated,

secure

the

locking

nut,

turning

clockwise.

NOTE!

If

the

locking

nut

does

not

easily

engage

the

threaded

portion

of

the

drive

shaft,

do

not

try

to

force

the

rotor

further

onto

the

drive

shaft.

Instead,

remove

the

locking

nut

and

the

rotor,

and

re-install,

making

sure

that

the the

rotor

is

properly

seated.

(To

insure

correct

seating,

be

sure

Step

4

2

is

properly

performed.)

RIGHT

WRONG

(threaded

portion

extends

(Threaded

portion

completely

above

rotor

below

rotor

centerpiece

centerpiece)

Figure

13.

Seating

Rotor

on Drive

Shaft

13

Figure

14.

Rotor

Installation

Procedure

3.6.

Rotor

Tube

Adaptors

The

Clinifuge-rotor

is

designed

to

hold

5

ml.,

7

ml.,

10

ml.,

12

ml.

and

15

ml.

tubes.

Tube

adaptors

and

inserts

(Section

1.3,

Fig.

5)

are

available

as

optional

equipment

and

tubes

must

be

positioned

as

follows:

-

10,

12

and

15

ml.

tubes

may

be

placed

directly

into

the rotor

without

adaptors

-

7

ml.

tubes

must

be

loaded

into

adaptors

without

inserts

before

being

positioned

in

the

rotor

(See

Figure

16)

- 5

ml.

tubes

must

be

loaded

into

adaptors

which

have

been

fitted

with

inserts

before

being

positioned

into

the

rotor

(See

Figure

15)

Rh

—

Top

|

Tab

Tab

Insert

(7

ml.

tubes)

會

(5

ml

tubes)

Rotor

Tube

Adaptor

without

Insert

Inserts

A

Î

Rotor

Tube

Adaptor

with

Insert

Figure

15.

Rotor

Adaptors

with

and

without

Inserts

Figure

16.

Tube

Adaptors

Loaded

in

Rotor

14

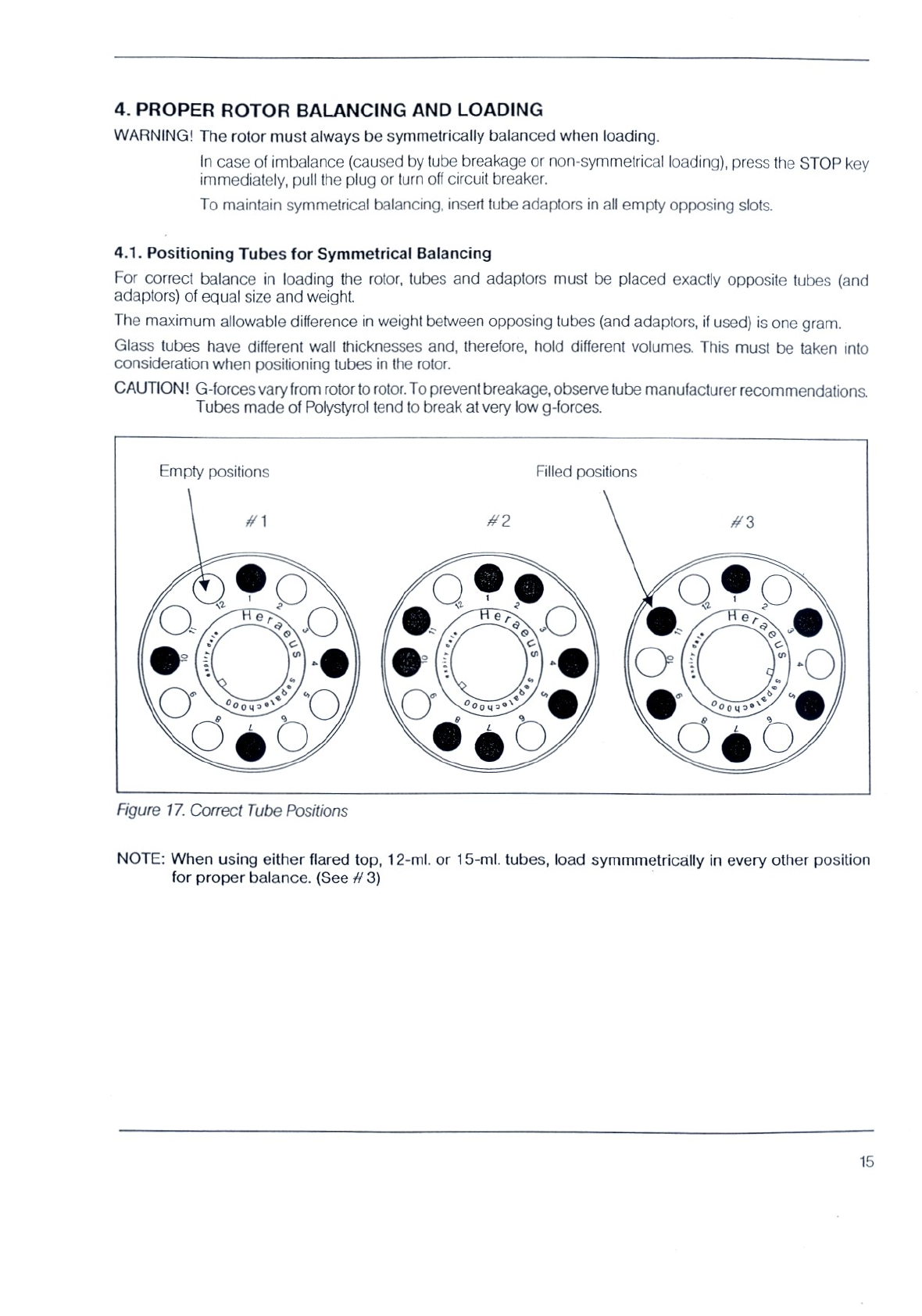

4.

PROPER

ROTOR

BALANCING

AND

LOADING

WARNING!

The

rotor

must

always

be

symmetrically

balanced

when

loading.

In

case

of

imbalance

(caused

by

tube

breakage

or

non-symmetrical

loading),

press

the

STOP

key

immediately,

pull

the

plug

or

turn

off

circuit

breaker.

To

maintain

symmetrical

balancing,

insert

tube

adaptors

in

all

empty

opposing

slots.

4.1.

Positioning

Tubes

for

Symmetrical

Balancing

For

correct

balance

in

loading

the

rotor,

tubes

and

adaptors

must

be

placed

exactly

opposite

tubes

(and

adaptors)

of

equal

size

and

weight.

The

maximum

allowable

difference

in

weight

between

opposing

tubes

(and

adaptors,

if

used)

is

one

gram.

Glass

tubes

have

different

wall

thicknesses

and,

therefore,

hold

different

volumes.

This

must

be

taken

into

consideration

when

positioning tubes

in

the

rotor.

CAUTION!

G-forces

vary

from

rotor

to

rotor.

To

prevent

breakage,

observe

tube

manufacturer

recommendations.

Tubes

made

of

Polystyrol

tend

to

break

at

very

low

g-forces.

Empty

positions

Filled

positions

Figure

17.

Correct

Tube

Positions

NOTE:

When

using

either

flared

top,

12-ml.

or

15-ml.

tubes,

load

symmmetrically

in

every

other

position

for

proper

balance.

(See

#

3)

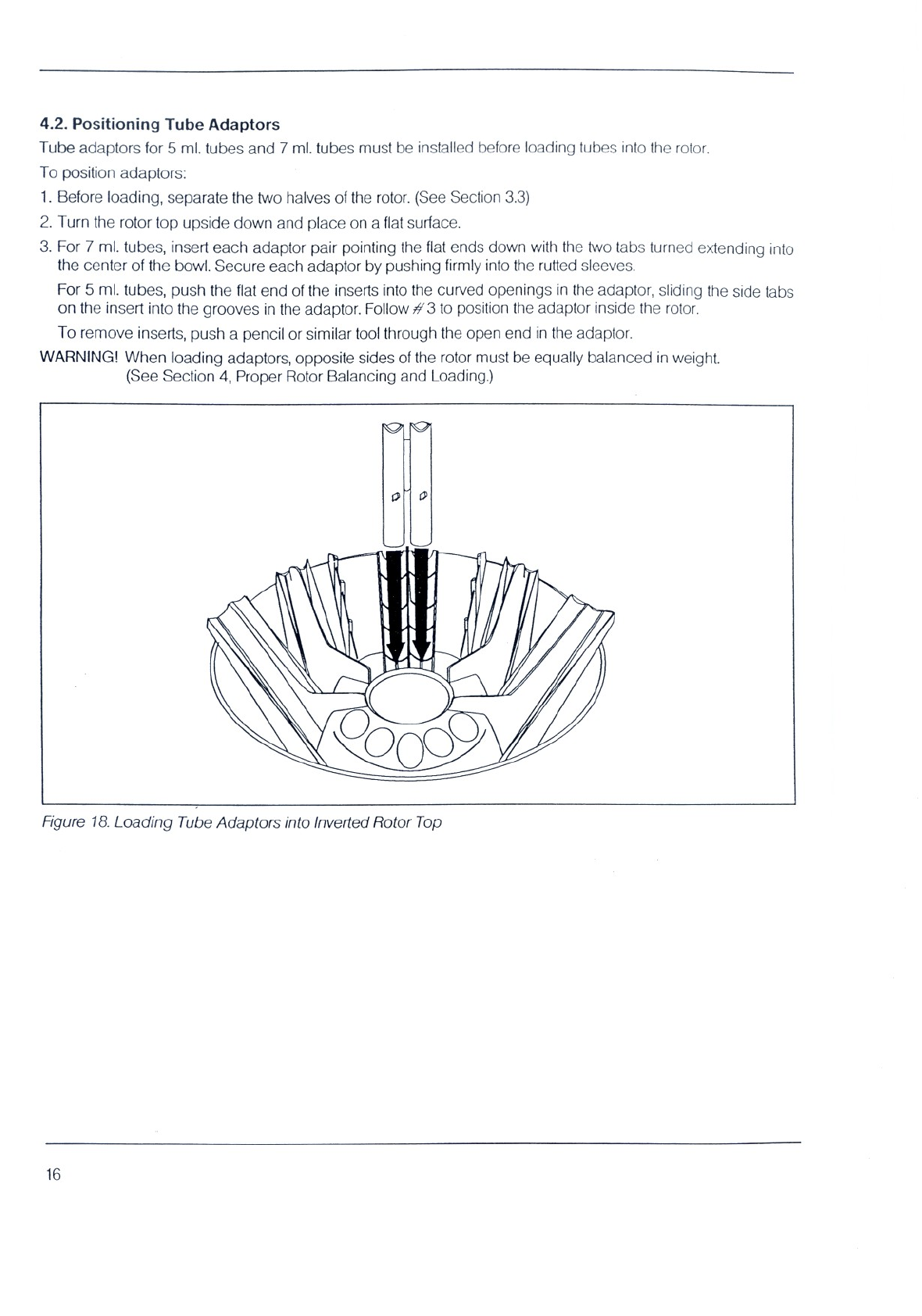

4.2.

Positioning

Tube

Adaptors

Tube

adaptors

for

5

ml.

tubes

and

7

ml.

tubes

must

be

installed

before

loading

tubes

into

the

rotor.

To

position

adaptors:

1.

Before

loading,

separate

the

two

halves

of

the

rotor.

(See

Section

3.3)

2.

Turn

the

rotor

top

upside

down

and

place

on

a

flat

surface.

3.

For

7

ml.

tubes,

insert

each

adaptor

pair

pointing

the

flat

ends

down

with

the

two

tabs

turned

extending

into

the

center

of

the

bowl.

Secure

each

adaptor

by

pushing

firmly

into

the

rutted

sleeves

For

5

ml.

tubes,

push

the

flat

end

of

the

inserts

into

the

curved

openings

in

the

adaptor,

sliding

the

side

tabs

on

the

insert

into

the

grooves

in

the

adaptor.

Follow

#3

to

position

the

adaptor

inside

the

rotor.

To

remove

inserts,

push

a

pencil

or

similar

tool

through

the

open

end

in

the

adaptor.

WARNING!

When

loading

adaptors,

opposite

sides

of

the

rotor

must

be

equally

balanced

in

weight.

(See

Section

4,

Proper

Rotor

Balancing

and

Loading.)

Figure

18.

Loading

Tube

Adaptors

into

Inverted

Rotor

Top

16

5.

OPERATING

AND

PROGRAMMING

PROCEDURES

5.1.

Opening

the

Lid

Figure

19.

LID

Key

5.2

Start/Stop

Figure

20.

START/STOP

Key

The

lid

can

be

opened

only

when

the

braking

process

is

completed

and

the

yellow

LID

LED goes

on.

To

open,

press

the

LID

key

pad.

The

lid

will

pop

up

automatically.

Once

the

unit

starts,

the

LID

key

is

disabled

for

the

entire

operating

cycle.

NEVER

TRY

TO

OPEN

THE

LID

WHILE

ROTOR

IS

TURNING.

(See

Emergency

Lid

Opening

Pro-

cedure.)

NOTE:

In

case

of

power

failure,

the

LID

key

pad

cannot

be

used

to

open

the

lid.

Follow

Emergency

Lid

Opening

Procedure,

Section

2.7,

Fig.

7.

When

the

green

START

LED

is

on,

centrifugation

may

be

started

by

pressing

the

START/STOP

key

pad.

When

the

rotor

starts

turning,

the

green

START/STOP

LED

goes

off

and

the red

LED

goes

on,

indicating

the

STOP

function

is

available.

When

the

cycle

is

completed

and

the

braking

cycle

has

ended,

the

green

START

LED

and

yellow

LID

LED

will

both

illuminate,

indicating

that

the

unit

may

be

opened

or

another

cycle

may

be

started.

To

stop

centrifugation,

press

the

START/STOP

key

pad

when

the

red

LED

is

illuminated.

After

each

stop,

the

green

START

LED

lights

up

again,

indicating

that

the

interrupted

cycle

may

be

continued

at

any

time.

If

START

is

pressed

during

the

braking

cycle

there

will

a

delay

before

the

Clini-

fuge

begins

to

accelerate.

17

5.3.

Quick

Run

Figure

21.

Quick

Run

Key

5.4.

Speed

Selection

IAN

Figure

22.

Speed

Selection

Keys

Figure

23.

Speed

Display

If

the

green

START

LED

is

on,

centrifugation

may

also

be

started

with

the

QUICK

RUN

key.

To

operate

in

QUICK

RUN

mode,

press

and

hold

the

QUICK

RUN

key

for

the

required

length

of

time.

While

the

QUICK

RUN

key

is

pressed,

the

rotor

accelerates

gradually

to

its

highest

speed.

Centrifugation

continues

until

the

key

is

released,

which

causes

the

rotor

to

brake

immediately.

If

QUICK

RUN

is

pressed

again,

acceleration

will

be

re-activated.

The

QUICK

RUN

key

may

be

used

for

runs

requiring

less

than

one

minute.

(Braking

will

still

require

the

same

time.)

The

QUICK

RUN

key

may

also

be

used

to

override

the

speed

set

in

programming)

Speed

is

adjusted

in

gradations

of

100 revolutions

per

minute.

Speed

settings

are

retained

in

the

unit's

memory

during

standby

periods,

and

need

be

entered

only

if

changing

the

previously

set

value.

When

the

centrifuge

is

in

Standby

Mode,

the

display

screens

for

TIME

and

SPEED

are

blank.

To

activate,

press

the

SET

key

pad

in

the

SPEED

field.

The

previously

set

speed

will

appear,

flashing

the

digit

in

the

100ths

position

in

the

speed

display

window.

Set

the

new

speed

up

or

down

using

the

"+"

or

"="

keys.

After

entering

the

new

speed,

press

the

SET

key

pad

in

the

SPEED

field

again

to

replace

the

previously

set

speed

in

memory.

The

speed

setting

mode

is

complete.

18

Table of contents

Other Heraeus Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Biotage

Biotage TurboVap user manual

AFi

AFi KATRINA Maintenance manual

Metkon

Metkon VACUMET 52 Operation & instruction manual

MICROLIT

MICROLIT EASYFILL Operation manual

Thermo Scientific

Thermo Scientific 1310 operating instructions

PerkinElmer

PerkinElmer LED Solutions ACULED Designer Kit Silver user manual

PerkinElmer

PerkinElmer Clarus SQ 8 MS Series Hardware guide

PerkinElmer

PerkinElmer UATR user guide

Tripp Lite

Tripp Lite NPOE-30W-1G owner's manual

New Era Pump Systems

New Era Pump Systems NE-1000 Multi-Phaser manual

Lightwave

Lightwave EasyCheck EC400KD instruction manual

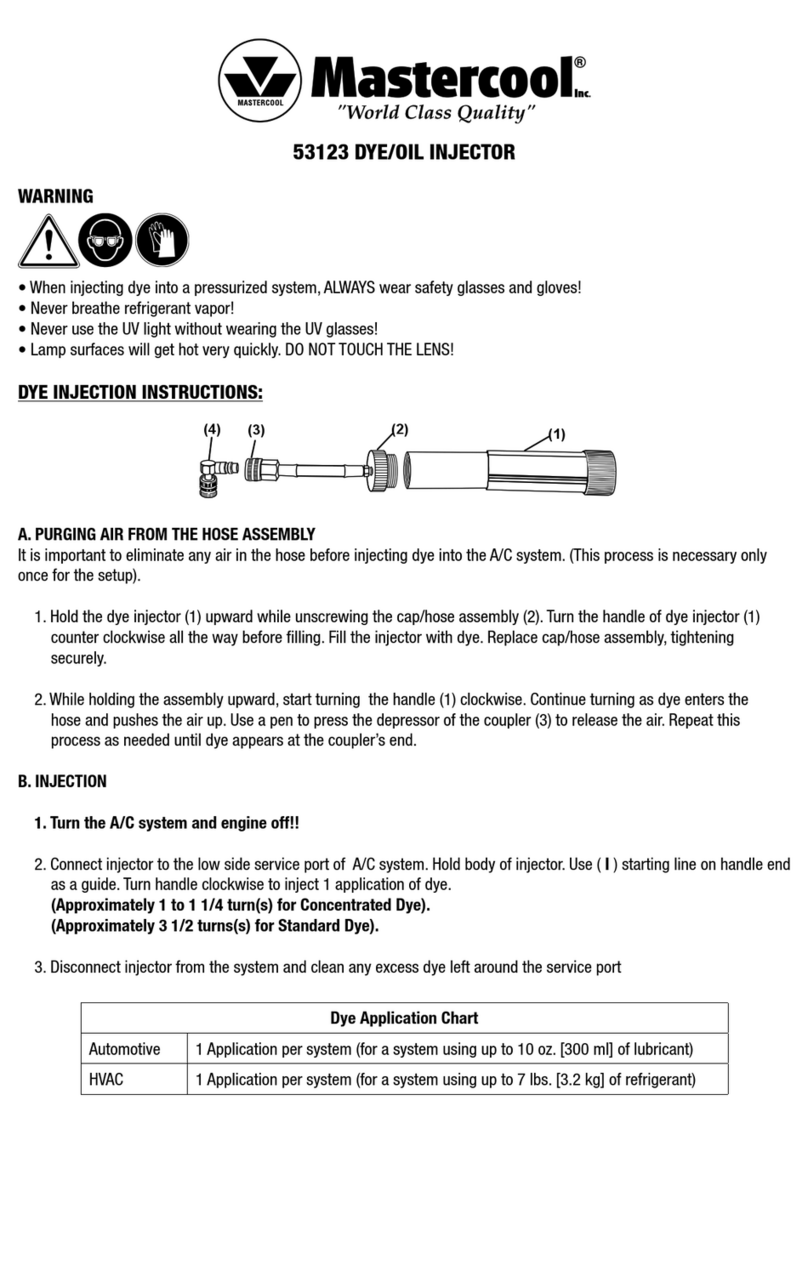

Master cool

Master cool 53123 quick start guide