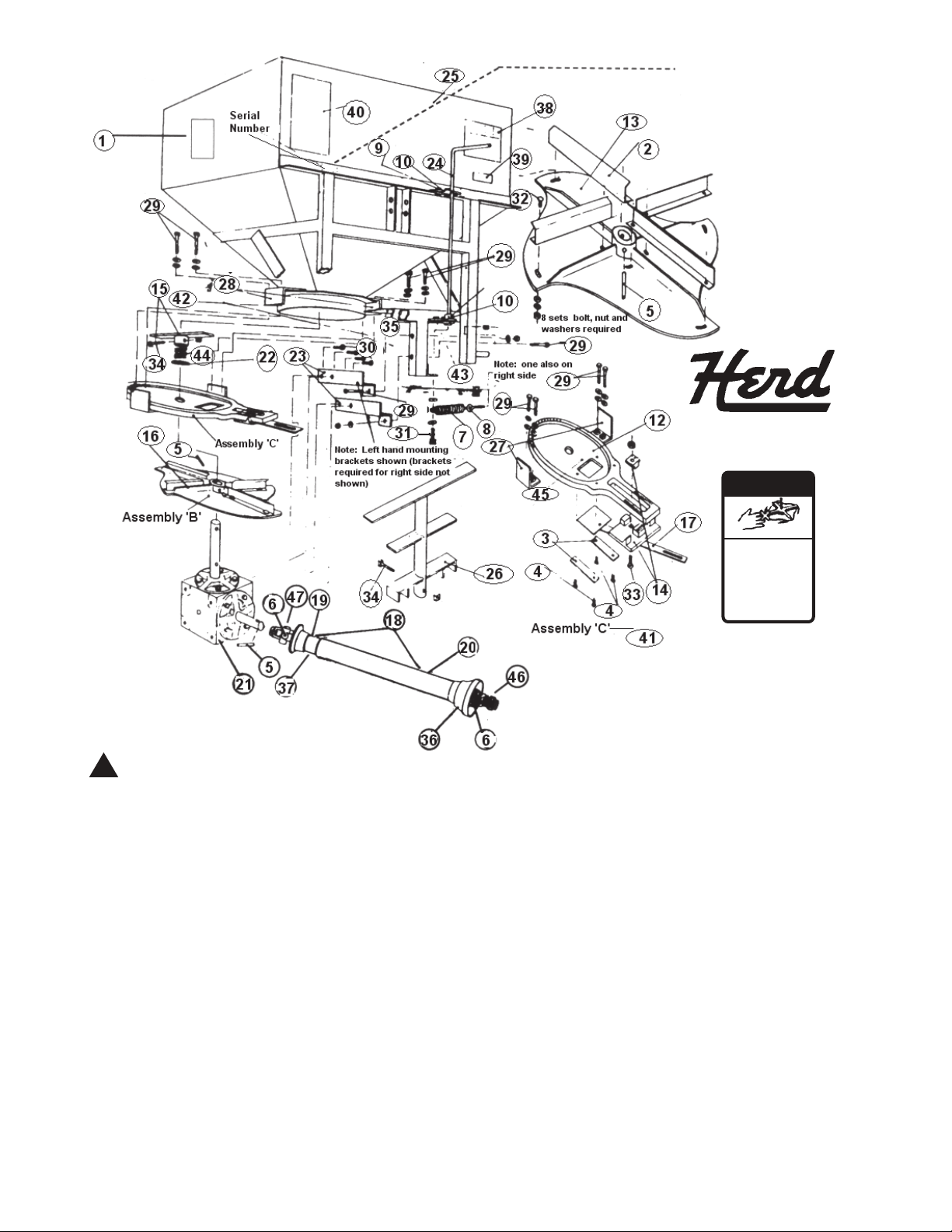

14. 146 SEED OPENING GAUGE, WITH BOLT (COMPLETE)................................................................................. 1

146B BOTTOM PART ONLY OF 146 SEED GAUGE ............................................................................................. 1

146U UPPER PART ONLY OF 146 SEED GAUGE................................................................................................ 1

15. 147 REGULAR AGITATOR WITH BOLT & NUT ................................................................................................... 1

16. 148 FAN, COMPLETE WITH SPRING PIN .......................................................................................................... 1

17. 149 OPENING CONTROL PLATE, WITH LINKAGE............................................................................................ 1

18. 150P* 25-1/4" SHIELDED POWER TAKE-OFF SHAFT FOR 1-3/8" PTO WITH 1" DRIVEN END...................... 1

19. 150FP BROADCASTER END OF 25-1/4" POWER TAKE-OFF SHAFT.................................................................. 1

20. 150MP TRACTOR END OF 25-1/4" POWER TAKE-OFF SHAFT ............................................................................ 1

21. 2000 GEAR BOX, COMPLETE - FOR 540 RPM (SEE CUT ON GEAR BOX FOR PARTS) (SAME AS 151)... 1

2000M GEAR BOX, COMPLETE - FOR 1,000 RPM (SAME AS 151M) (OPTIONAL) ........................................... 1

22. 152 WASHER - 1" BORE, USED ON FAN SHAFT IN HOPPER ........................................................................ 1

23. 154 "Z" ANGLES USED TO CARRY GEAR BOX - LEFT SIDE .......................................................................... 2

153 "Z" ANGLES USED TO CARRY GEAR BOX - RIGHT SIDE (NOT SHOWN IN DRAWING) ..................... 2

24. 212 HANDLE ASSEMBLY FOR 750 ..................................................................................................................... 1

25. 211 HOPPER FOR MODEL 750 (11-1/2 CU. FT. CAPACITY)............................................................................. 1

214 FRAME, LESS CONTROL HANDLE (PRICE ON REQUEST) ....................................................................

26. 158 LIME AGITATOR W/BOLT, USED WITH DEHYDRATED LIME OR DOLOMITE (OPTIONAL)................... 1

27. 159 "L" BASE CLAMP - LOWER........................................................................................................................... 2

28. 160 "L" BASE CLAMP - UPPER (WELDED TO HOPPER) ................................................................................. 2

29. 418 1/2" x 3" BOLT WITH NUTS AND FLAT WASHERS.................................................................................... 8

30. 419 3/8" x 1" BOLT WITH LOCK WASHERS........................................................................................................ 8

31. 407A 5/16" x 1" BOLT WITH NUT AND WASHER.................................................................................................. 2

32. 420 5/16" x 3/4" CARRIAGE BOLT WITH NUT AND LOCK WASHER............................................................... 8

33. 421 5/16" x 1-1/4" CARRIAGE BOLT WITH NUT................................................................................................. 1

34. 422 5/16" x 1-3/4" BOLT WITH NUT (USED IN AGITATOR 147) ........................................................................ 1

35. 1093 DEFLECTOR - 22" LONG (NOT SHOWN IN DRAWING)............................................................................ 1

36. 92P PLASTIC SHIELD FOR TRACTOR HALF OF WEASLER P.T.O. SHAFT (INCLUDES #79P & 80P) ........ 1

95 PLASTIC SHIELD FOR TRACTOR HALF OF G & G P.T.O. SHAFT (INCLUDES #46 & 47) ..................... 1

37. 93P PLASTIC SHIELD FOR SEEDER HALF OF WEASLER P.T.O. SHAFT (INCLUDES #79P & 80P)........... 1

94 PLASTIC SHIELD FOR SEEDER HALF OF G & G P.T.O. SHAFT (INCLUDES #46 & 47) ....................... 1

38. 215 FERTILIZER INSTRUCTION DECAL FOR MODEL 750.............................................................................. 1

39. 216 MODEL NUMBER DECAL - FOR 750........................................................................................................... 1

40. 989C SEEDING CHART DECAL ............................................................................................................................. 1

41. 222 ASSEMBLY "C" COMPLETE, OF BASE PLATE 144 AND PARTS.............................................................. 1

42. 223 HOPPER BASE RING (MUST BE WELDED TO HOPPER) ........................................................................ 1

43. 86A 5/16" x 1" CAP SCREW WITH 2 NUTS AND FLAT WASHER..................................................................... 1

44. 1123 STAINLESS STEEL COMPRESSION SPRING - USED BETWEEN AGITATOR AND WASHER ............ 1

45. 1126 1/4" x 3/8" HEX HEAD CAP SCREW ............................................................................................................ 1

46. 96 YOKE ONLY, FOR TRACTOR HALF OF WEASLER P.T.O. SHAFT............................................................. 1

101 YOKE ONLY, FOR TRACTOR OF G & G P.T.O. SHAFT............................................................................... 1

47. 97 YOKE ONLY, FOR BROADCASTER HALF OF WEASLER P.T.O. SHAFT .................................................. 1

103 YOKE ONLY, FOR BROADCASTER HALF OF G & G P.T.O. SHAFT.......................................................... 1

P

ARTS FOR 2000 (OR 151 GEARBOX WITH 1" SHAFTS:"

FOR MODEL 750

1. 2017 HOUSING.................................................... 1

2. 2016 CAP ............................................................. 2

3. 2018 SHORT SHAFT, DRIVE.............................. 1

4. 2013 BEARING CONE - LARGE (L44643) ........ 2

5. 2012 BEARING CUP - LARGE (L44610) ........... 2

6. 2011 BEARING CONE - SMALL (LM11749)...... 2

7. 2010 BEARING CUP - SMALL (LM11710)......... 2

8. 2014 GEAR, STEEL, 14-TOOTH ........................ 1

9. 2019 GEAR, STEEL, 19-TOOTH ........................ 1

12. 2009 OIL SEAL..................................................... 2

13. 2005 ROLL PIN .................................................... 2

14. 2008 KEY.............................................................. 2

15. 2006 GASKET - .014 ........................................... VAR.

16. 2007 GASKET - .005 ........................................... VAR.

17. 2002 5/16" x 1" HEX HEAD CAP SCREW ......... 8

19. 2003 VENTED PIPE PLUG ................................. 1

20. 2001 5/16" LOCK WASHER ................................ 8

21. 2015 LONG SHAFT - VERTICAL DRIVEN......... 1

2020 SHIM............................................................ VAR.

DESIGNS SUBJECT TO CHANGE WITHOUT NOTICE.