Assembly Instructions2HermanMiller 1BSSGX rev A

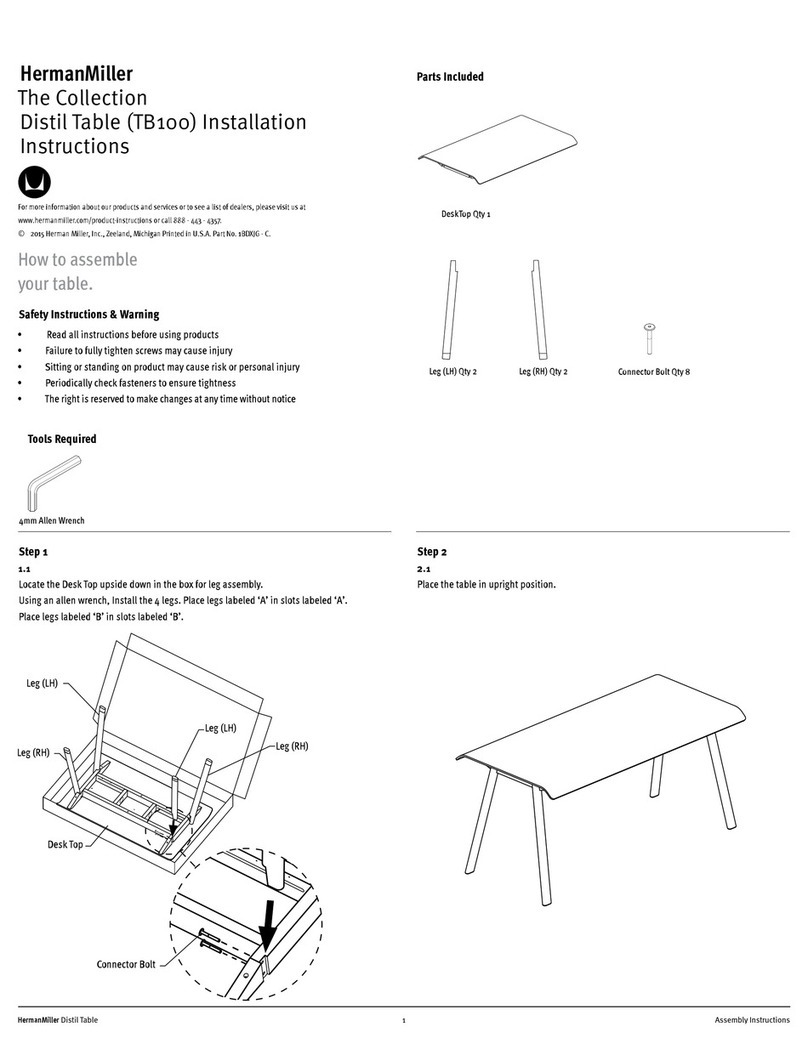

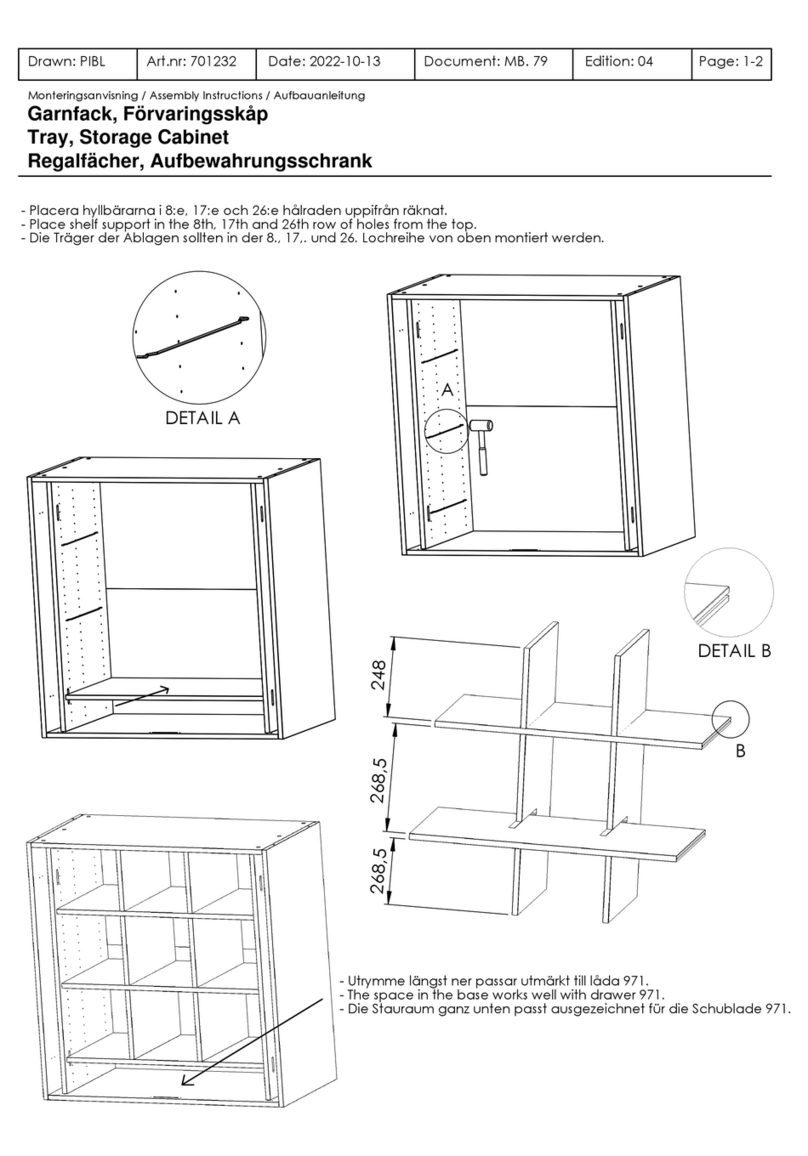

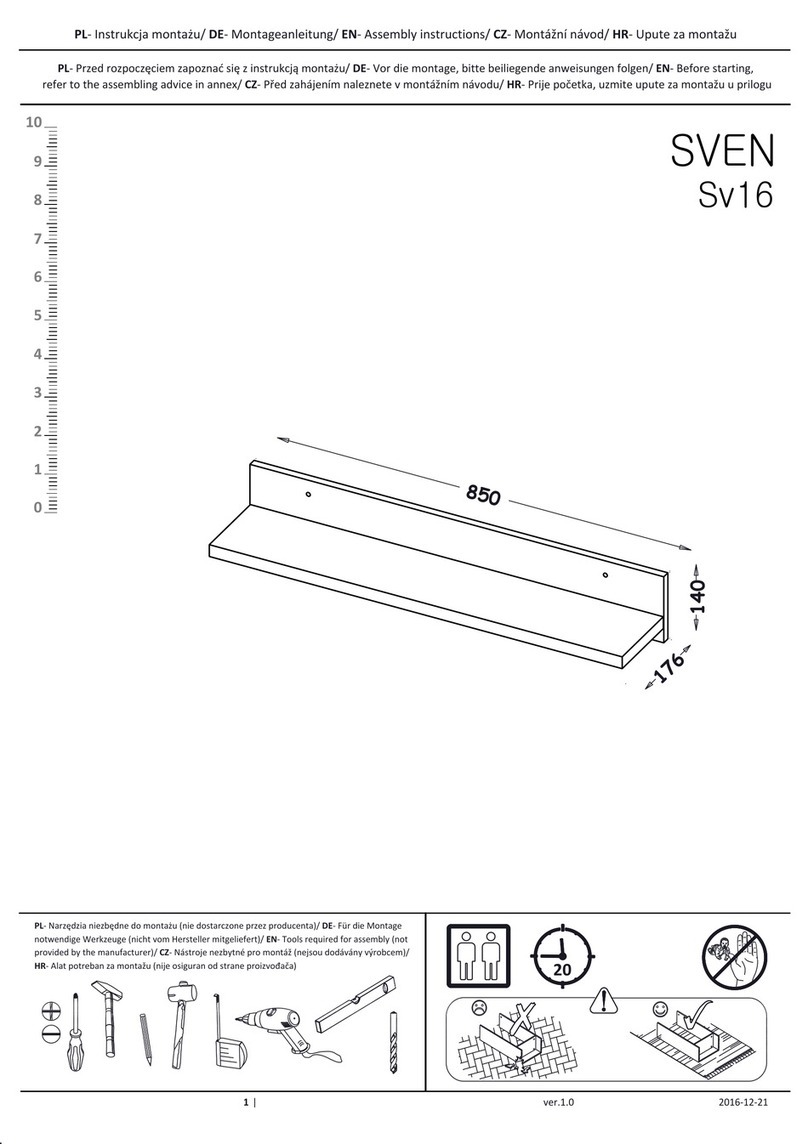

Step 3 (for 1500 wide table only)

To attach the stiffener to worksurface follow the below procedure.

A. Locate stiffener with pilot holes on the ends. Place end cap over

the end holes and install together with pan head screws.

B. Install remaining pan head screws in an alternating pattern.

A

B

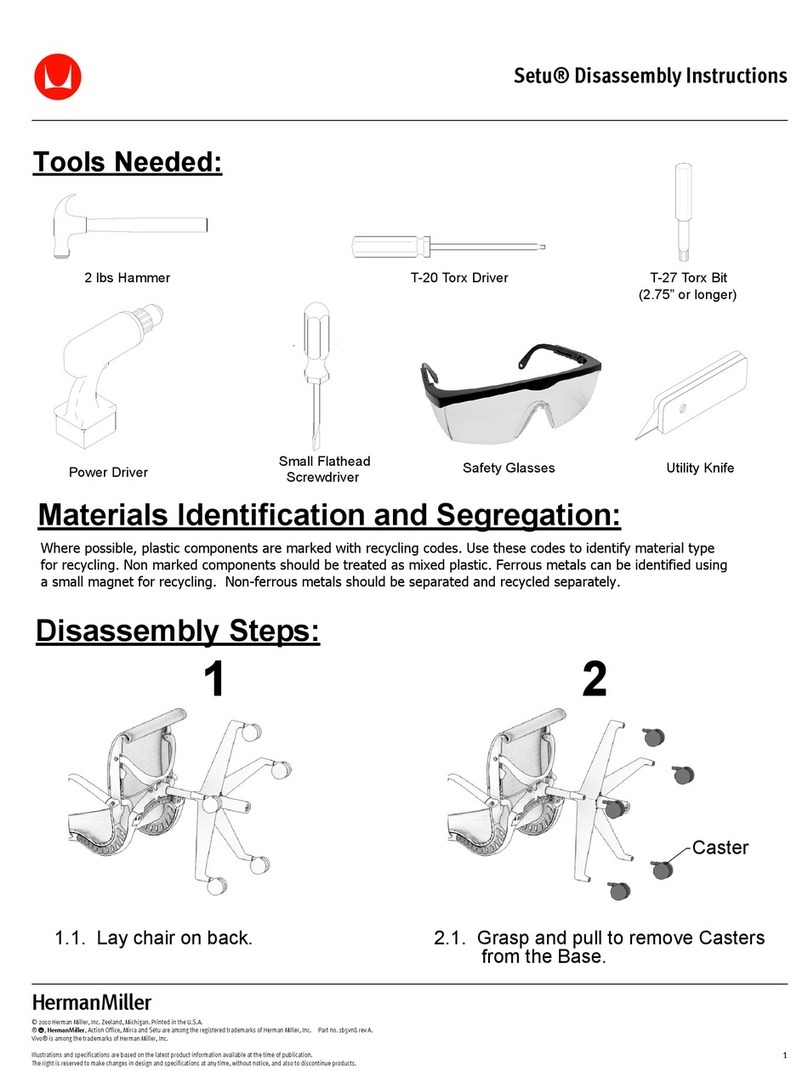

Disassembly for Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling codes. Use these codes to identify

material type for recycling. Non marked components should be treated as mixed plastic. Ferrous

metals can be identied using a small magnet for recycling. Non-ferrous metals should be separated

andrecycled separately. To disassemble product, reverse the above installation steps

© 2009 Herman Miller, Inc., Zeeland, Michigan Printed in U.S.A.

® YHermanMiller, Abak, Action Oce, Avive, Co/Struc, Ethospace, Intersect, Meridian, Passage,

Prospects, Quadrant, Resolve, Scooter, Vivo interiors, Lifework, Teneo, and V-Wall are among the

registered trademarks of Herman Miller Inc.

TM Burdick Group, CLT, Flex-Edge, My Studio Environments, and Q system, are among the trademarks of

Herman Miller Inc.

Illustrations and specications are based on the latest product information available at the time of

publication. The right is reserved to make changes in design and specications at any time, without

notice, and also to discontinue products.

ABB

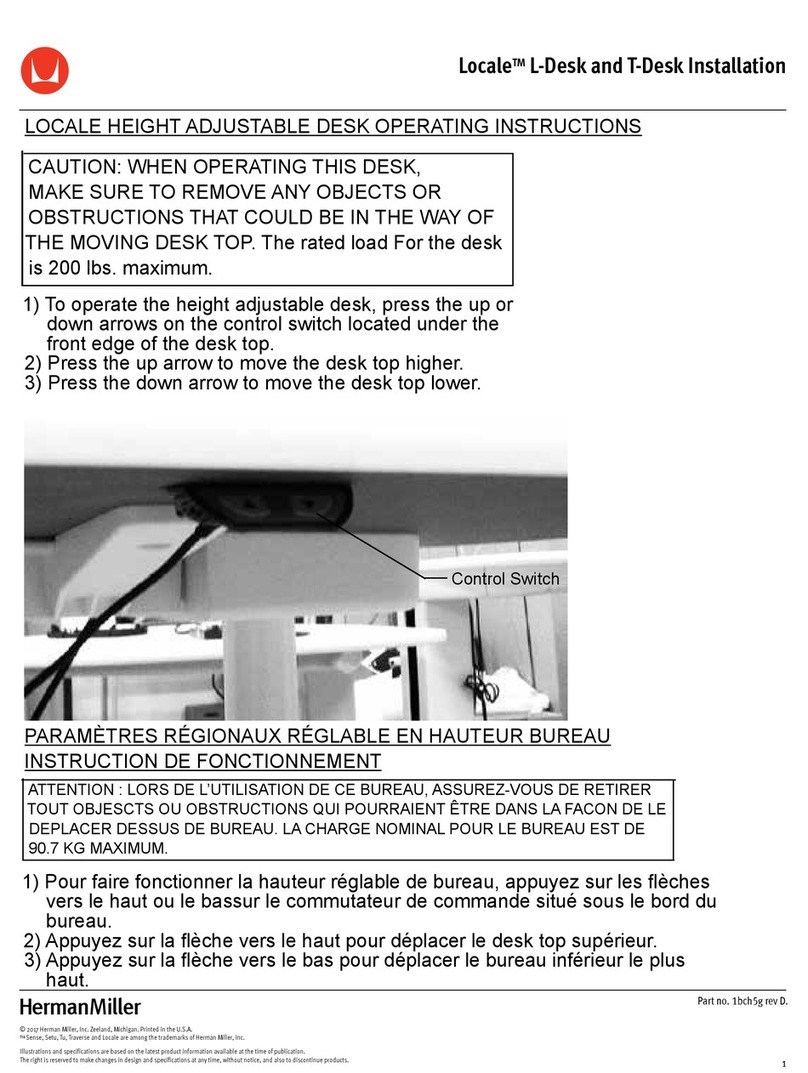

Step 2

To attach legs to the worksurface follow the below procedure.

A. Screw two flat head screws into marked two piloted holes first to locate

the leg.

B. Finish by installing additional flat head screws in marked locations that

are NOT piloted. These screws are field drilled.

Note: Attach legs with worksurface upside down

Assembly Instructions2HermanMiller 1BSSGX rev A

Step 3 (for 1500 wide table only)

To attach the stiffener to worksurface follow the below procedure.

A. Locate stiffener with pilot holes on the ends. Place end cap over

the end holes and install together with pan head screws.

B. Install remaining pan head screws in an alternating pattern.

A

B

Disassembly for Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling codes. Use these codes to identify

material type for recycling. Non marked components should be treated as mixed plastic. Ferrous

metals can be identied using a small magnet for recycling. Non-ferrous metals should be separated

andrecycled separately. To disassemble product, reverse the above installation steps

© 2009 Herman Miller, Inc., Zeeland, Michigan Printed in U.S.A.

® YHermanMiller, Abak, Action Oce, Avive, Co/Struc, Ethospace, Intersect, Meridian, Passage,

Prospects, Quadrant, Resolve, Scooter, Vivo interiors, Lifework, Teneo, and V-Wall are among the

registered trademarks of Herman Miller Inc.

TM Burdick Group, CLT, Flex-Edge, My Studio Environments, and Q system, are among the trademarks of

Herman Miller Inc.

Illustrations and specications are based on the latest product information available at the time of

publication. The right is reserved to make changes in design and specications at any time, without

notice, and also to discontinue products.

ABB

Step 2

To attach legs to the worksurface follow the below procedure.

A. Screw two flat head screws into marked two piloted holes first to locate

the leg.

B. Finish by installing additional flat head screws in marked locations that

are NOT piloted. These screws are field drilled.

Note: Attach legs with worksurface upside down

Assembly Instructions2HermanMiller 1BSSGX rev A

Step 3 (for 1500 wide table only)

To attach the stiffener to worksurface follow the below procedure.

A. Locate stiffener with pilot holes on the ends. Place end cap over

the end holes and install together with pan head screws.

B. Install remaining pan head screws in an alternating pattern.

A

B

Disassembly for Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling codes. Use these codes to identify

material type for recycling. Non marked components should be treated as mixed plastic. Ferrous

metals can be identied using a small magnet for recycling. Non-ferrous metals should be separated

andrecycled separately. To disassemble product, reverse the above installation steps

© 2009 Herman Miller, Inc., Zeeland, Michigan Printed in U.S.A.

® YHermanMiller, Abak, Action Oce, Avive, Co/Struc, Ethospace, Intersect, Meridian, Passage,

Prospects, Quadrant, Resolve, Scooter, Vivo interiors, Lifework, Teneo, and V-Wall are among the

registered trademarks of Herman Miller Inc.

TM Burdick Group, CLT, Flex-Edge, My Studio Environments, and Q system, are among the trademarks of

Herman Miller Inc.

Illustrations and specications are based on the latest product information available at the time of

publication. The right is reserved to make changes in design and specications at any time, without

notice, and also to discontinue products.

ABB

Step 2

To attach legs to the worksurface follow the below procedure.

A. Screw two flat head screws into marked two piloted holes first to locate

the leg.

B. Finish by installing additional flat head screws in marked locations that

are NOT piloted. These screws are field drilled.

Note: Attach legs with worksurface upside down

1BSSGX rev A

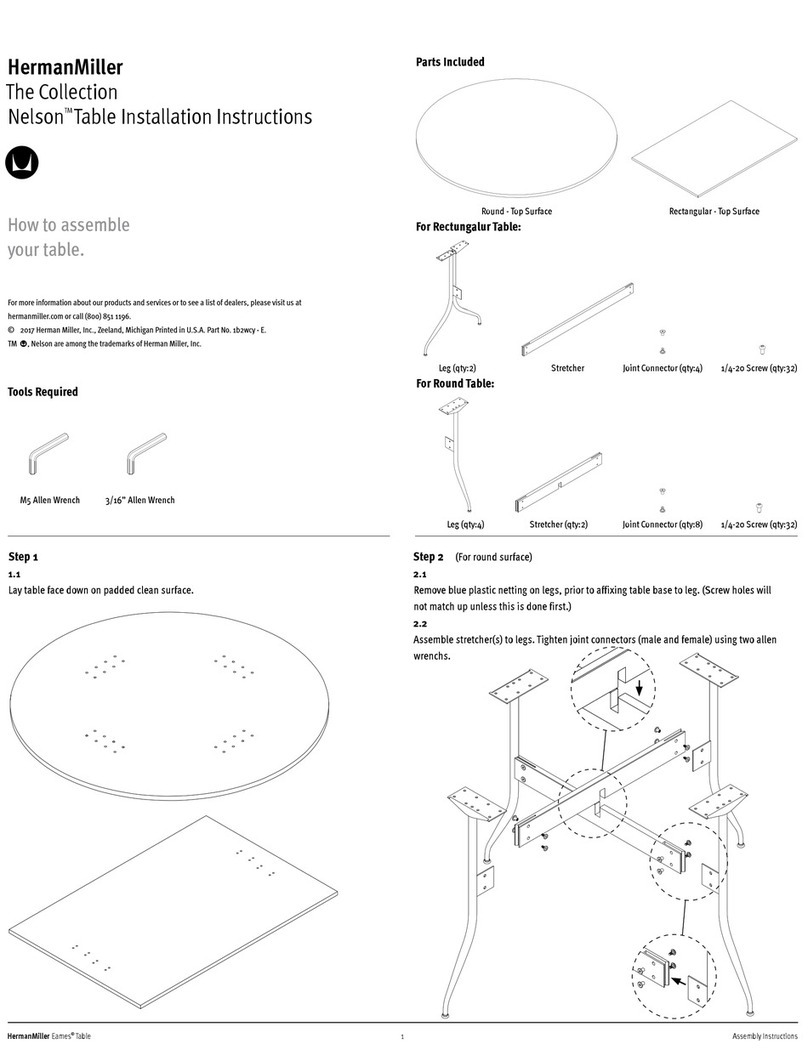

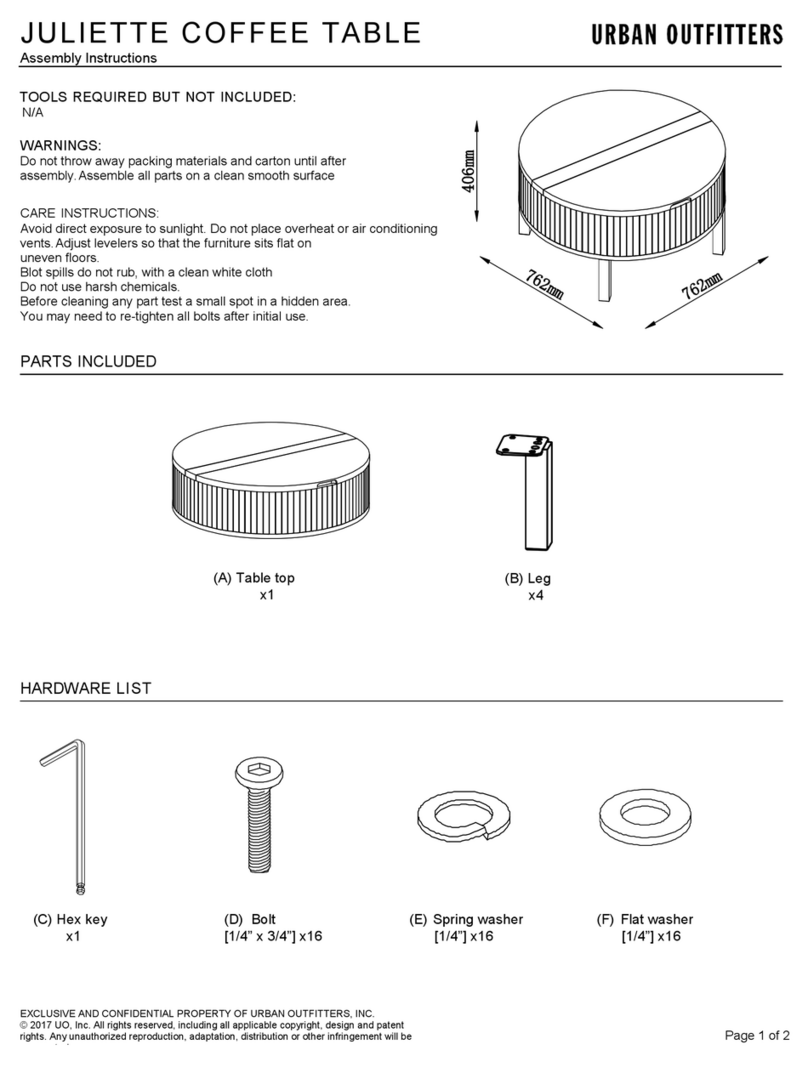

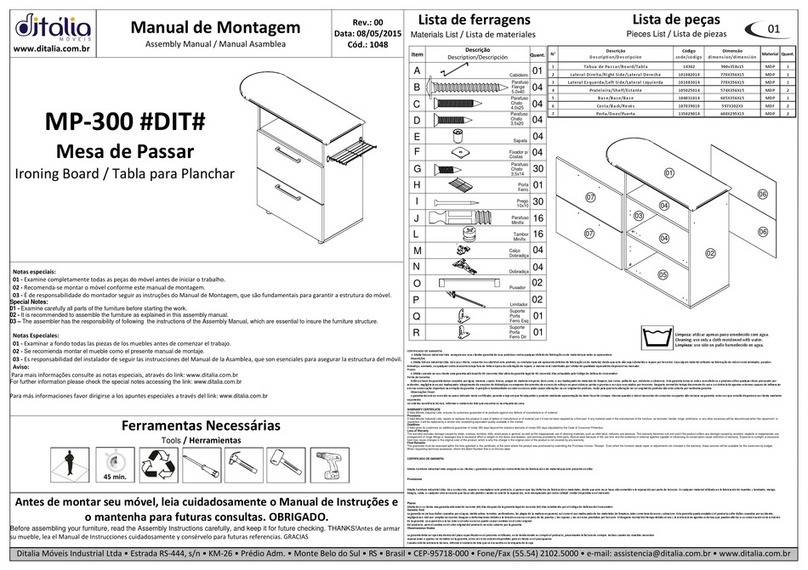

Tools Required

HermanMiller

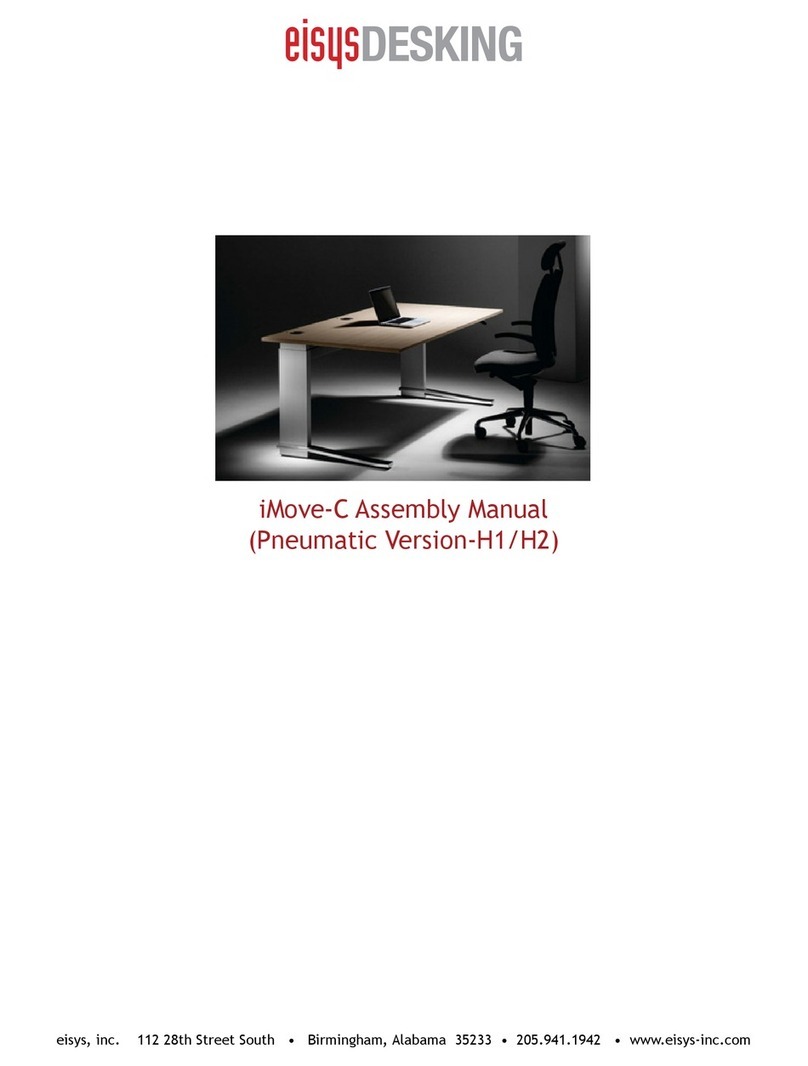

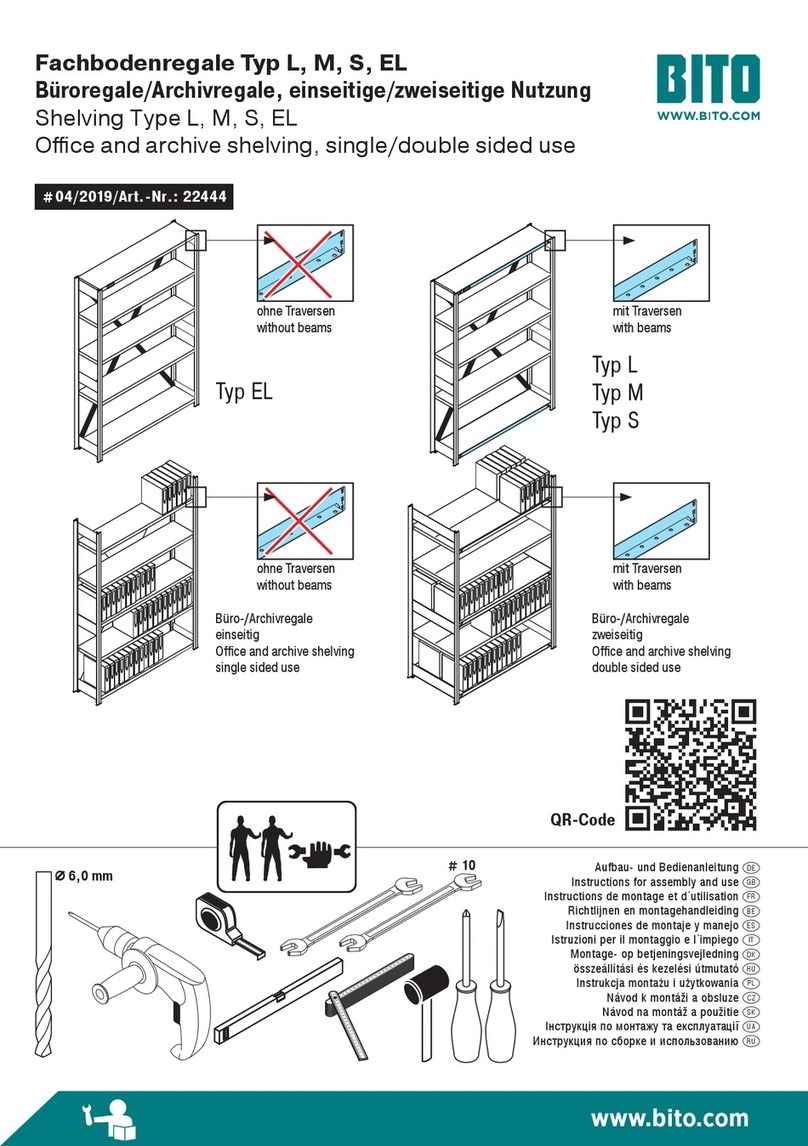

Rectangular table assembly Instructions

How to assemble Rectangular table

5mm Allen KeyPower Driver Phillips Bit

Parts Included

# Flat Head

Tapping Screw

# Pan Head

Tapping Screw

Stiffener (for 1500 wide table only) Stiener End Cap

M8 Flat Head Screw

Leg

Plate

Work surface

Rectangular table

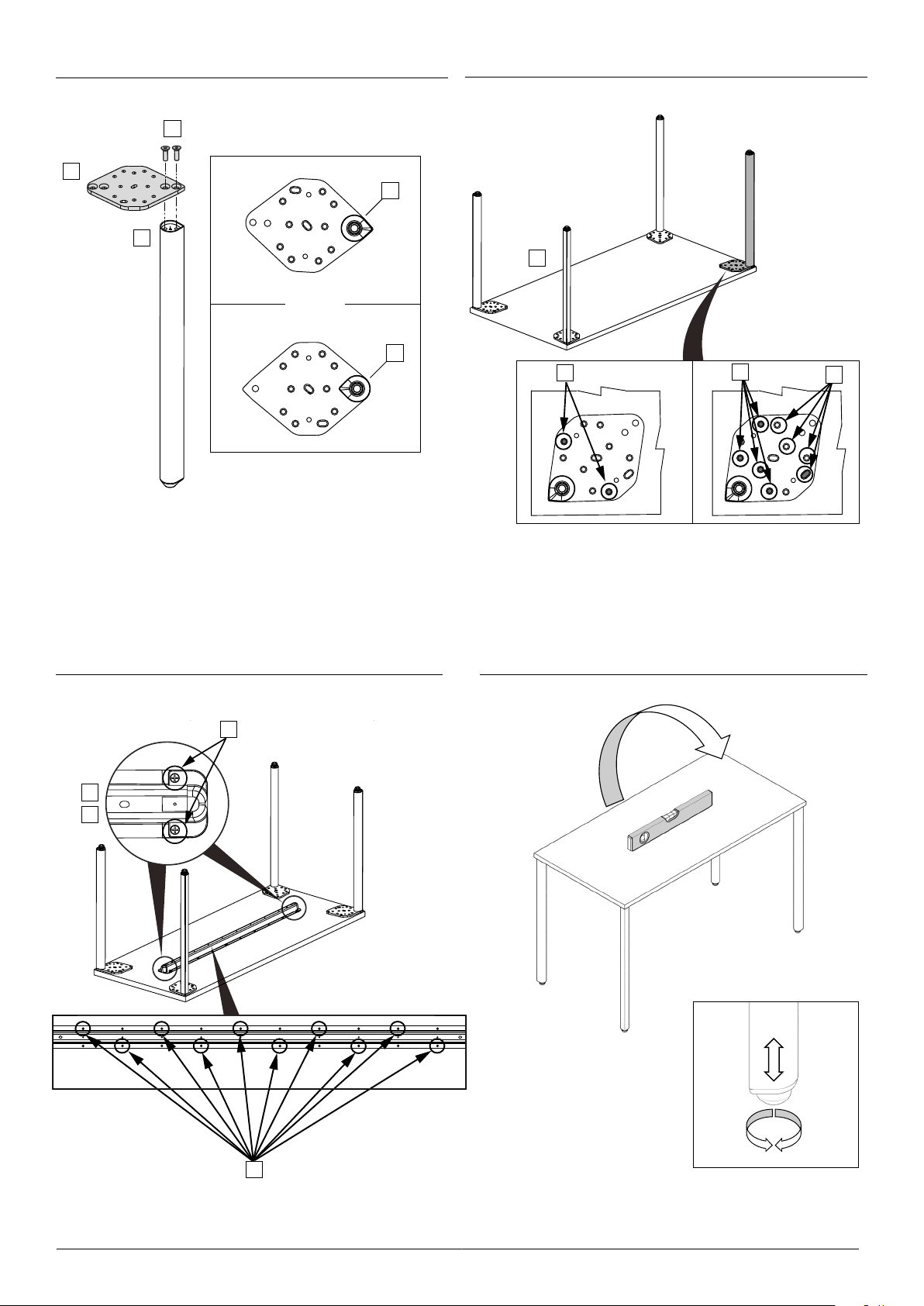

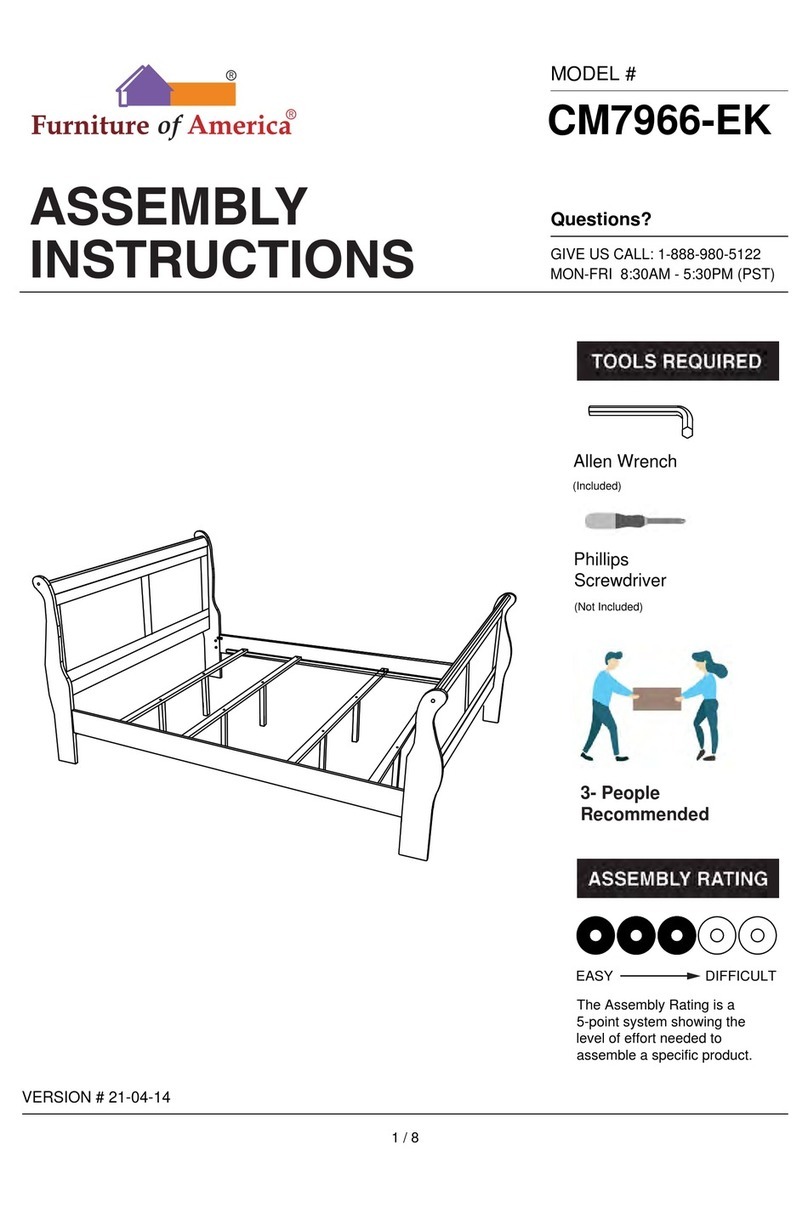

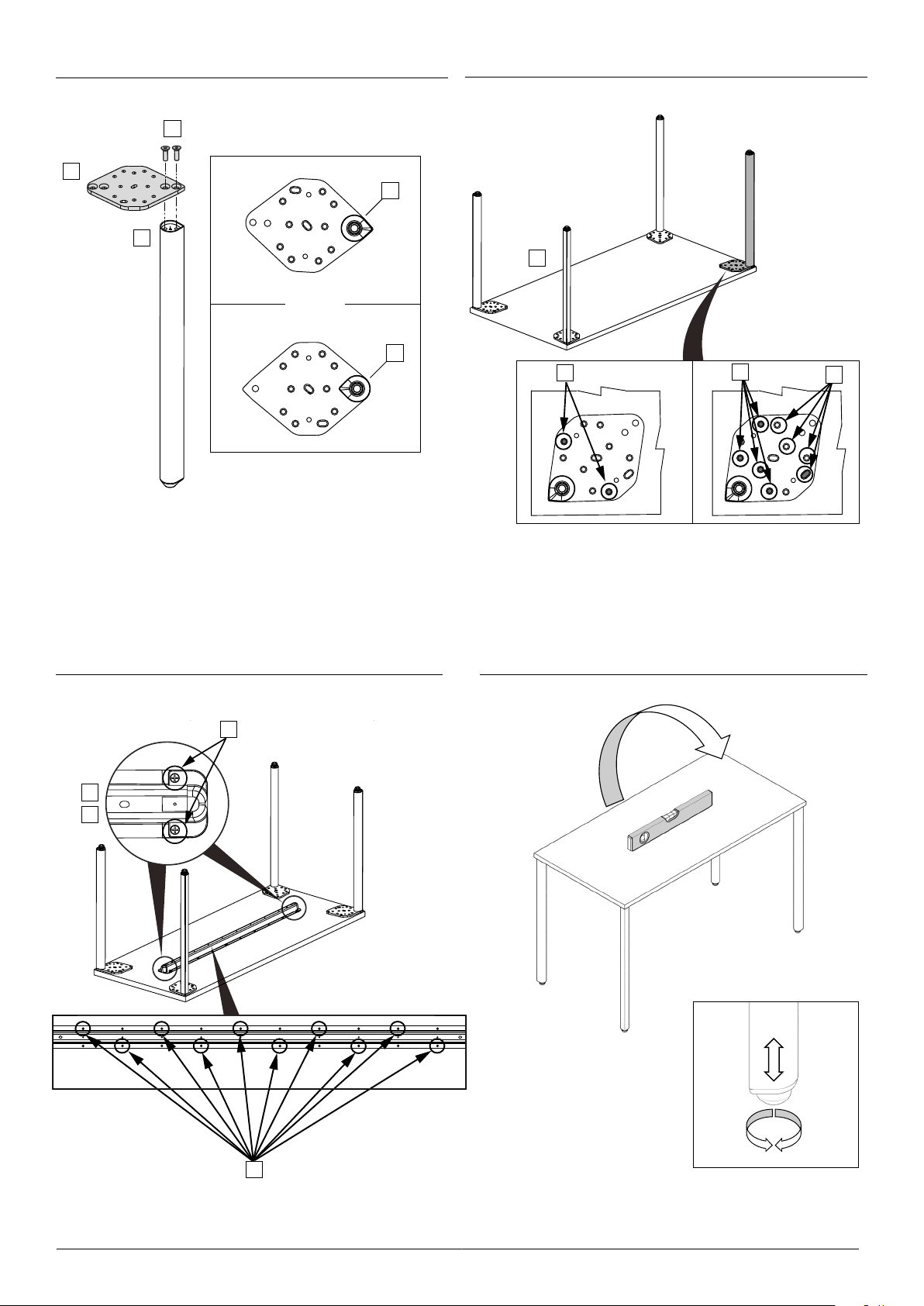

Step 1

. Attach top plate to the leg, with two M flat head machine screws.

Tighten screws until snug plus / turn.

. There are ways to mount the plate to the leg :

A. Creased edge facing outward.

B. Round edge facing outward.

A.

B.

OR

HermanMiller Assembly Instructions1

1BSSGX rev A

Tools Required

HermanMiller

Rectangular table assembly Instructions

How to assemble Rectangular table

5mm Allen KeyPower Driver Phillips Bit

Parts Included

# Flat Head

Tapping Screw

# Pan Head

Tapping Screw

Stiffener (for 1500 wide table only) Stiener End Cap

M8 Flat Head Screw

Leg

Plate

Work surface

Rectangular table

Step 1

. Attach top plate to the leg, with two M flat head machine screws.

Tighten screws until snug plus / turn.

. There are ways to mount the plate to the leg :

A. Creased edge facing outward.

B. Round edge facing outward.

A.

B.

OR

HermanMiller Assembly Instructions1

1BSSGX rev A

Tools Required

HermanMiller

Rectangular table assembly Instructions

How to assemble Rectangular table

5mm Allen KeyPower Driver Phillips Bit

Parts Included

# Flat Head

Tapping Screw

# Pan Head

Tapping Screw

Stiffener (for 1500 wide table only) Stiener End Cap

M8 Flat Head Screw

Leg

Plate

Work surface

Rectangular table

Step 1

. Attach top plate to the leg, with two M flat head machine screws.

Tighten screws until snug plus / turn.

. There are ways to mount the plate to the leg :

A. Creased edge facing outward.

B. Round edge facing outward.

A.

B.

OR

HermanMiller Assembly Instructions1

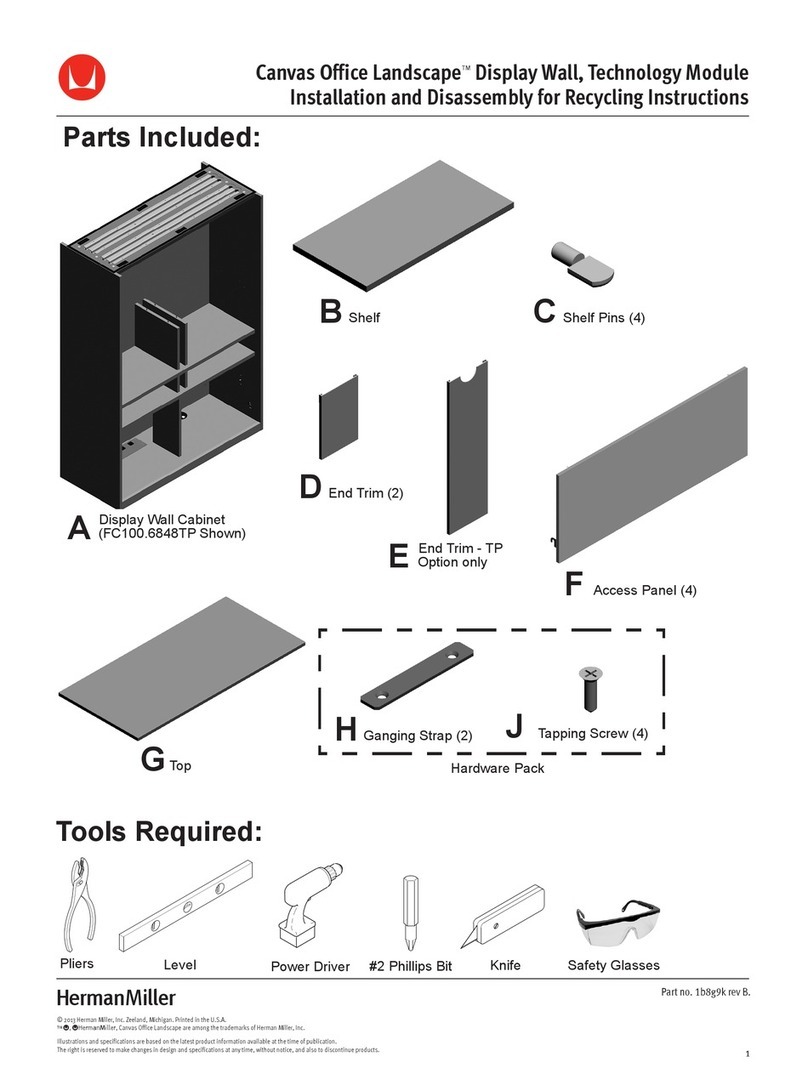

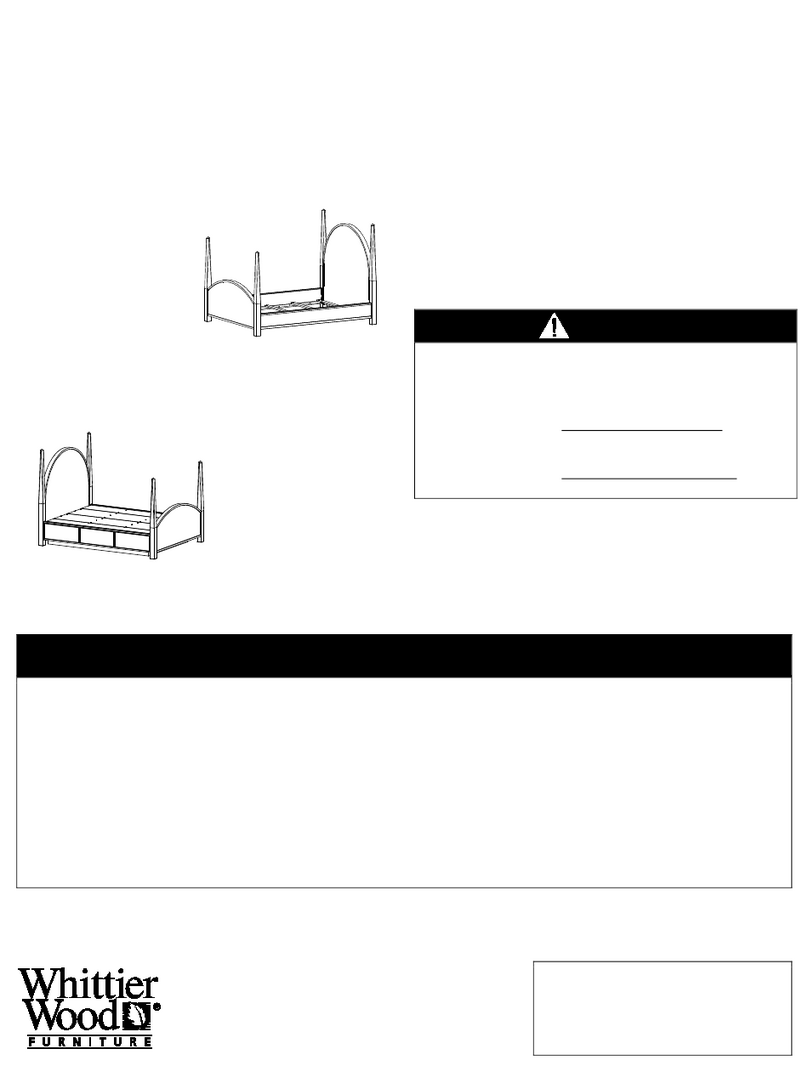

1.

3*. 4.

2.

x4

A

F

G

H

D

D

E

B

B

B

CCC

Assembly Instructions2HermanMiller 1BSSGX rev A

Step 3 (for 1500 wide table only)

To attach the stiffener to worksurface follow the below procedure.

A. Locate stiffener with pilot holes on the ends. Place end cap over

the end holes and install together with pan head screws.

B. Install remaining pan head screws in an alternating pattern.

A

B

Disassembly for Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling codes. Use these codes to identify

material type for recycling. Non marked components should be treated as mixed plastic. Ferrous

metals can be identied using a small magnet for recycling. Non-ferrous metals should be separated

andrecycled separately. To disassemble product, reverse the above installation steps

© 2009 Herman Miller, Inc., Zeeland, Michigan Printed in U.S.A.

® YHermanMiller, Abak, Action Oce, Avive, Co/Struc, Ethospace, Intersect, Meridian, Passage,

Prospects, Quadrant, Resolve, Scooter, Vivo interiors, Lifework, Teneo, and V-Wall are among the

registered trademarks of Herman Miller Inc.

TM Burdick Group, CLT, Flex-Edge, My Studio Environments, and Q system, are among the trademarks of

Herman Miller Inc.

Illustrations and specications are based on the latest product information available at the time of

publication. The right is reserved to make changes in design and specications at any time, without

notice, and also to discontinue products.

ABB

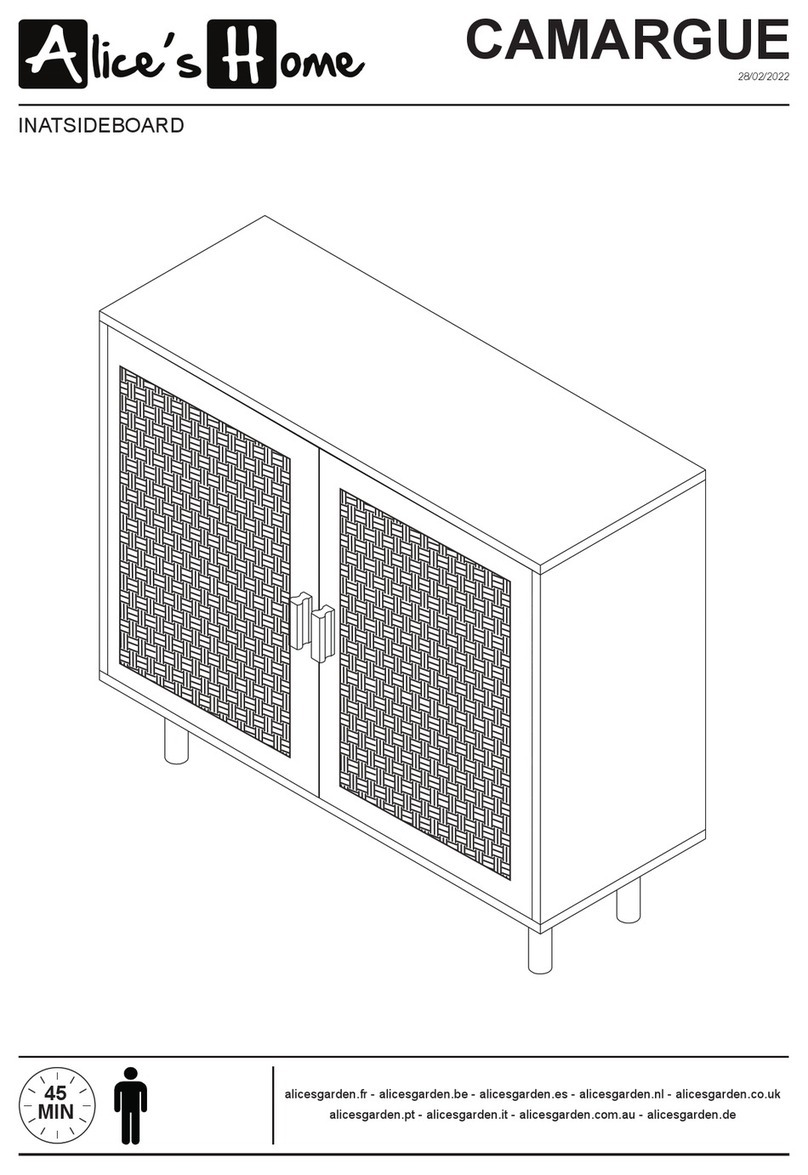

Step 2

To attach legs to the worksurface follow the below procedure.

A. Screw two flat head screws into marked two piloted holes first to locate

the leg.

B. Finish by installing additional flat head screws in marked locations that

are NOT piloted. These screws are field drilled.

Note: Attach legs with worksurface upside down

Assembly Instructions

1BSSGX rev A

Step 3 (for 1500 wide table only)

To attach the stiffener to worksurface follow the below procedure.

A. Locate stiffener with pilot holes on the ends. Place end cap over

the end holes and install together with pan head screws.

B. Install remaining pan head screws in an alternating pattern.

A

B

Disassembly for Recycling:

Materials Identication and Segregation:

Where possible, plastic components are marked with ASTM recycling codes. Use these codes to identify

material type for recycling. Non marked components should be treated as mixed plastic. Ferrous

metals can be identied using a small magnet for recycling. Non-ferrous metals should be separated

andrecycled separately. To disassemble product, reverse the above installation steps

© 2009 Herman Miller, Inc., Zeeland, Michigan Printed in U.S.A.

® YHermanMiller, Abak, Action Oce, Avive, Co/Struc, Ethospace, Intersect, Meridian, Passage,

Prospects, Quadrant, Resolve, Scooter, Vivo interiors, Lifework, Teneo, and V-Wall are among the

registered trademarks of Herman Miller Inc.

TM Burdick Group, CLT, Flex-Edge, My Studio Environments, and Q system, are among the trademarks of

Herman Miller Inc.

Illustrations and specications are based on the latest product information available at the time of

publication. The right is reserved to make changes in design and specications at any time, without

notice, and also to discontinue products.

ABB

Step 2

To attach legs to the worksurface follow the below procedure.

A. Screw two flat head screws into marked two piloted holes first to locate

the leg.

B. Finish by installing additional flat head screws in marked locations that

are NOT piloted. These screws are field drilled.

Note: Attach legs with worksurface upside down

BTFR Rev A

OR

* wide table only