HEROSE 01312 User manual

Other manuals for 01312

2

This manual suits for next models

9

Table of contents

Other HEROSE Control Unit manuals

HEROSE

HEROSE 0651 Series User manual

HEROSE

HEROSE 0681 Series User manual

HEROSE

HEROSE 03021 User manual

HEROSE

HEROSE 15C02 User manual

HEROSE

HEROSE 01312 User manual

HEROSE

HEROSE T118 User manual

HEROSE

HEROSE 08411 User manual

HEROSE

HEROSE 093 Series User manual

HEROSE

HEROSE 093 Series User manual

HEROSE

HEROSE 06001 User manual

HEROSE

HEROSE 06810 User manual

HEROSE

HEROSE 06001 User manual

HEROSE

HEROSE 0681 Series User manual

HEROSE

HEROSE 0131 Series User manual

HEROSE

HEROSE 0653X User manual

HEROSE

HEROSE 06001 User manual

HEROSE

HEROSE 15C01 User manual

HEROSE

HEROSE 06401 User manual

HEROSE

HEROSE 01420 User manual

HEROSE

HEROSE 0651 Series User manual

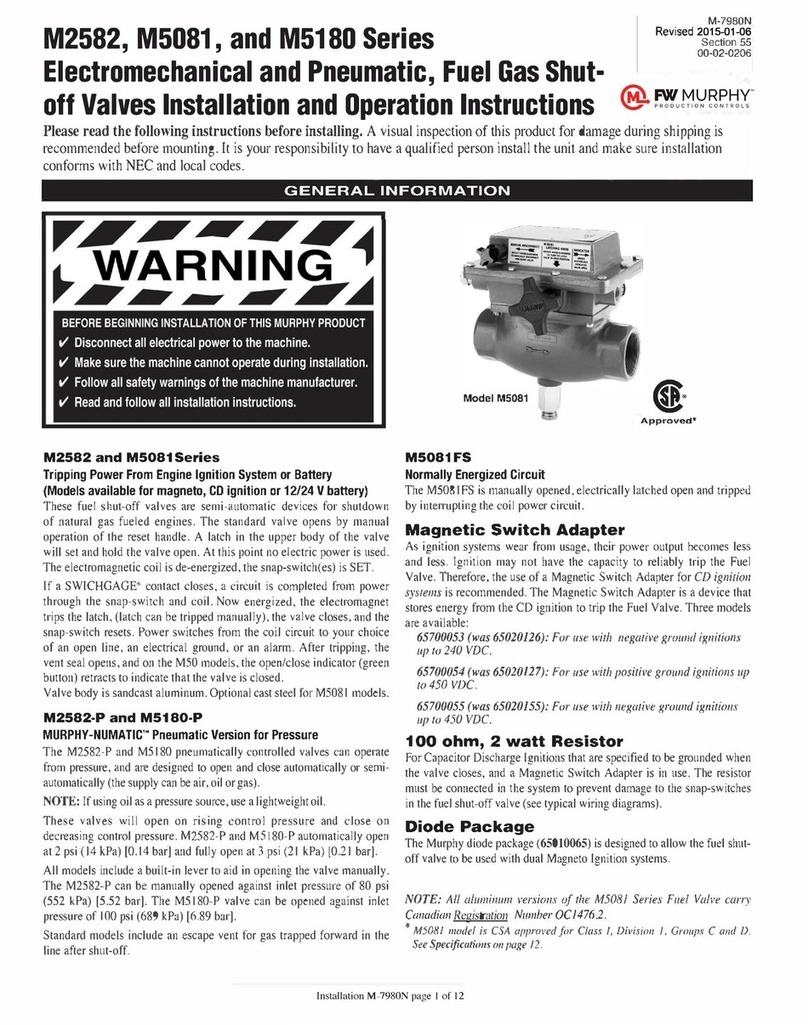

Popular Control Unit manuals by other brands

Honeywell

Honeywell 7800 SERIES manual

MFB

MFB CB/RS/MA-522 owner's manual

elobau

elobau eloFlex 471EFR Series Translation of the original operating instructions

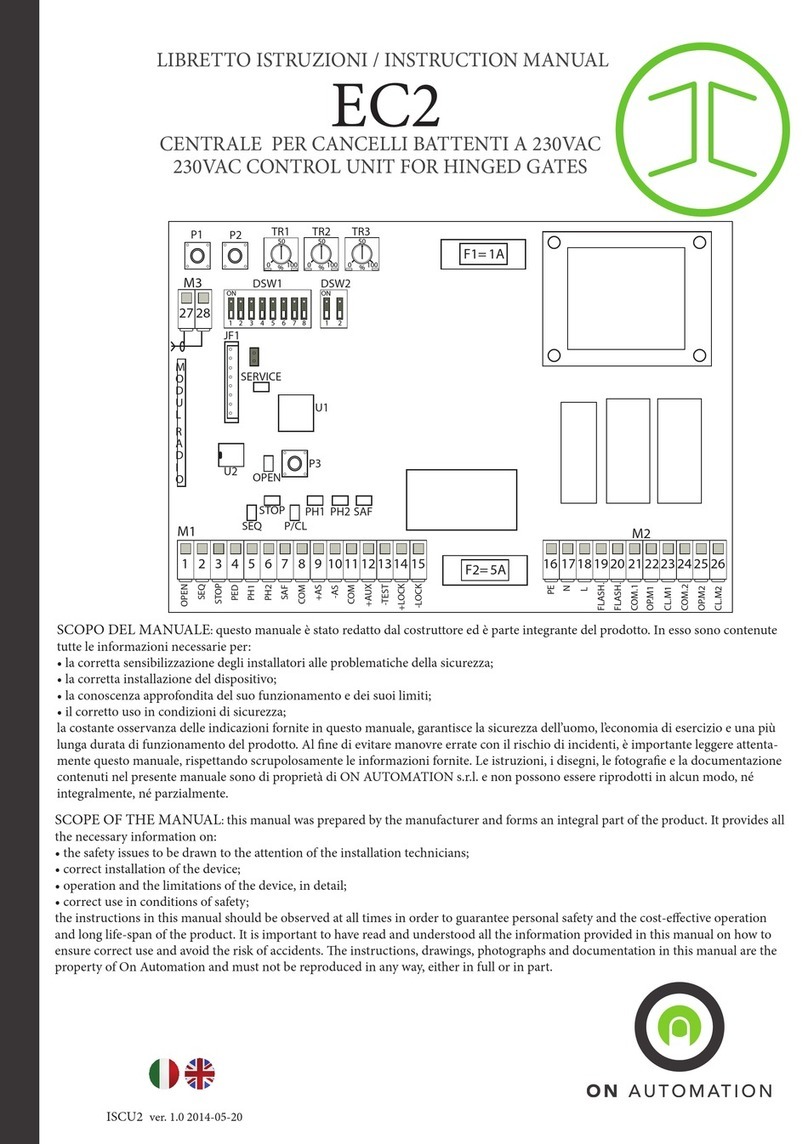

Bandini Industrie

Bandini Industrie GiBiDi GROUND 610 Instructions for installations

Santec

Santec ECL-200 quick start guide

Gemu

Gemu 9650100Z 26T1-C Installation, Operating and Maintenance Instruction