Highlight PREDATOR XS User manual

OPERATION MANUAL

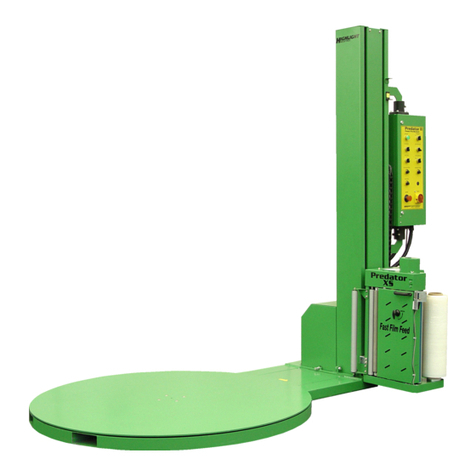

PREDATOR XS

TURNTABLE STRETCH WRAPPER

SERIAL NUMBER:

Please refer to the serial number in all correspondence with Highlight or any Highlight

Distributor. This identifies your machine and will help in our ability to quickly and

efficiently respond to your needs.

OPERATION MANUAL NUMBER: PREDXS-F/ FEB 2008

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

ii

SAFETY MESSAGES

SAFETY MESSAGESSAFETY MESSAGES

SAFETY MESSAGES

For the best result with the Predator Turntable Stretch Wrapper, carefully read this manual and all

of the warning labels attached to the equipment before installing and operating it, and follow

instructions exactly. Keep this manual handy for quick reference.

Definitions and Symbols

High Voltage

!

This symbol indicates high voltage. It calls your attention to items or

operations that could be dangerous to you or other persons

operating the equipment. Read the message and follow the

instructions carefully.

Warning

This symbol indicates a potentially hazardous situation which, if not

avoided, can result to bodily injury, or serious damage to the

product.

Notes

This symbol indicates an area or subject of special merit,

emphasizing the equipment’s capabilities, common errors in

operation or maintenance, or other special instructions that can

provide benefits to users.

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

iii

General Precautions – Read These First!

HIGH VOLTAGE!

Motor control equipment and electronic controllers are connected to

hazardous line volta

ges. When servicing drives and controllers, there

may be exposed components with housings or protrusions at or

above line potential. Extreme care should be taken to protect against

shock.

HIGH VOLTAGE!

The user is responsible for conforming to all applicable code

requirements with respect to grounding all requirements. Do NOT use

extension cords to operate the equipment.

HIGH VOLTAGE!

Disconnect AC input power before checking components, performing

maintenance, cleaning up, and when the machine is not i

n use. Do

NOT connect or disconnect wires and connectors while power is

applied to circuit.

HIGH VOLTAGE!

Wiring work should be carried out only by qualified personnel.

Otherwise, there is a danger of electric shock or fire.

WARNING

Loose clothing must

NOT be worn while the machine is in operation.

Stay clear of moving parts while the machine is running.

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

iv

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

Welcome

Congratulations on your purchase of Predator Turntable Stretch Wrapper! Designed for the high

volume industrial user the Predator will stretch wrap any load to the maximum stretch level of any

film with full independent control of the film force. This allows even light unstable loads to be

wrapped at the lowest possible cost and the maximum load holding force.

Limited Warranty

Highlight Industries, Inc. warrants its Predator manufactured by it, and sold pursuant to this order,

will be of merchantable quality, free from defects in material and workmanship as determined at

the date of shipment, by generally recognized, applicable and accepted practices and procedures

in the industry, for a period of three (3) years from the Highlight invoice date, under normal use

and service.

When the Purchaser gives Highlight written notice of any alleged defect within the applicable

warranty period, Highlight will, at its option repair or replace the same free of charge F.O.B. its

manufacturing plant, installation not included. Equipment replaced under the warranty shall have

the same warranty as new equipment but does not extend the warranty of the original equipment.

Satisfaction of this warranty, consistent with other provisions herein, will be limited to the

replacement or repair or modification of, or issuance of a credit for, the equipment involved, at

Highlight’s option.

Highlight neither assumes nor authorizes any person to assume for it any other obligation in

connection with the sale of Highlight’s equipment.

This warranty shall not apply to any equipment which has been repaired or altered by un-

authorized personnel in any way so as to, in the judgment of Highlight, affect serviceability, or

which has been subjected to misuse, negligence, accident, or to equipment made by Highlight

which has been operated in a manner contrary to Highlight’s instructions.

In no event regardless of the cause, shall Highlight be liable for penalties or penalty clauses of any

description or any damages resulting from loss of profits, use of products or for any incidental

indirect or consequential damages, even if advised of the possibility of such damages. This

limitation of Highlight’s liability will apply regardless of the form of action, whether in contract or

tort, including negligence. Any action against Highlight must be brought within twelve (12) months

after cause of action accrues.

“This warranty in lieu of all other warranties whether expressed, implied or statutory including

implied warranties of merchantability of fitness or extends only to the buyer or customer

purchasing from Highlight Industries, Inc or an authorized distributor.”

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

v

About This Document

The purpose of this manual is to provide you with information necessary to install, operate,

troubleshoot and maintain the Predator Turntable Stretch Wrapper. The audience for this manual

should have knowledge of basic mechanical and electronic components, standard electrical wiring

practices and schematics symbols.

To guarantee safe operation of the equipment, carefully observe the safety messages at the

beginning of and throughout this manual. Keep this operating manual handy and distribute to all

users for reference.

Application Assistance

If any assistance is desired, contact the distributor from whom you have purchased the unit, or call

the number listed on the bottom page of this manual. To receive quick and proper technical

support for the equipment you have purchased, please be prepared to provide the following

information:

1. Machine serial number

2. Date of purchase

3. Symptoms of any problem

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

vi

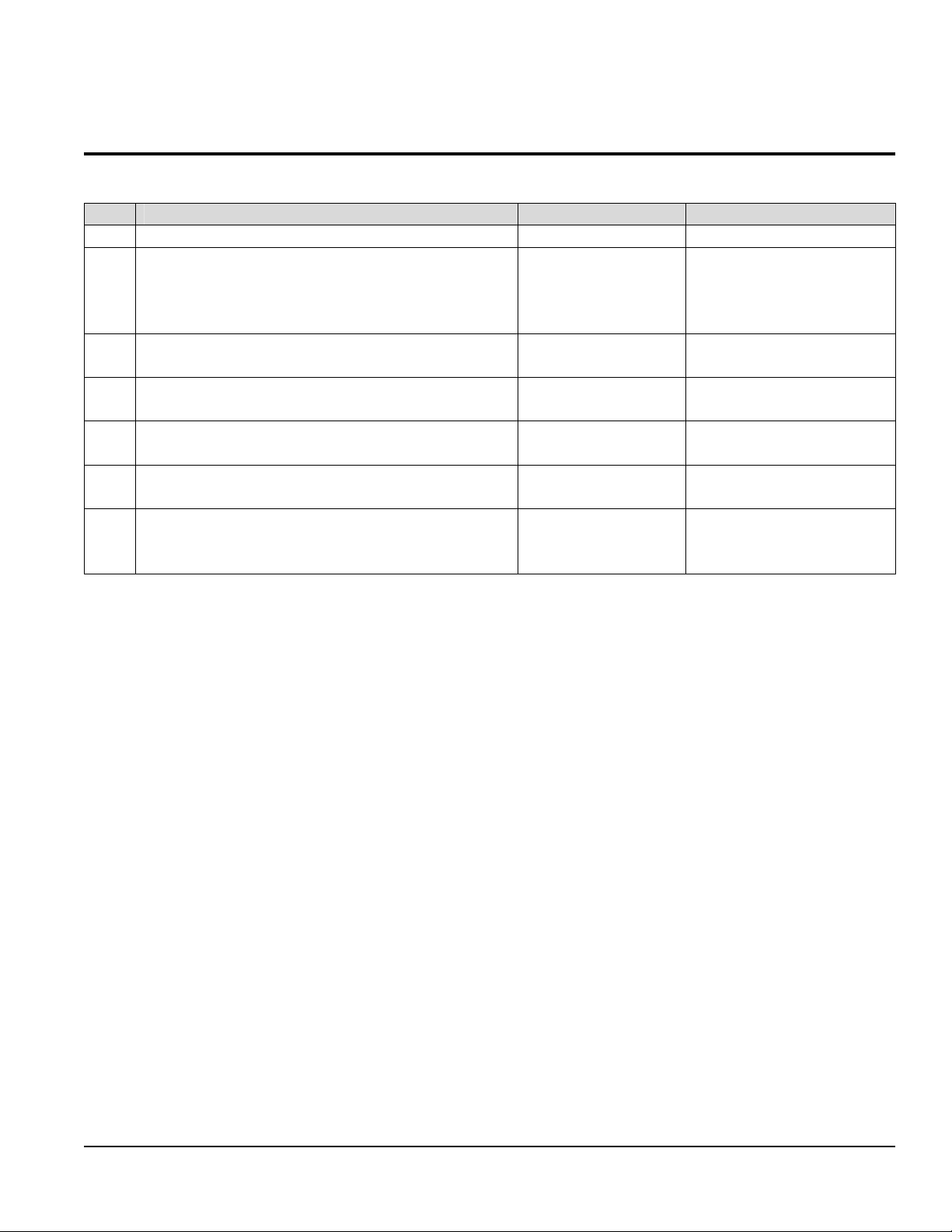

REVISION HISTORY TABLE

REVISION HISTORY TABLEREVISION HISTORY TABLE

REVISION HISTORY TABLE

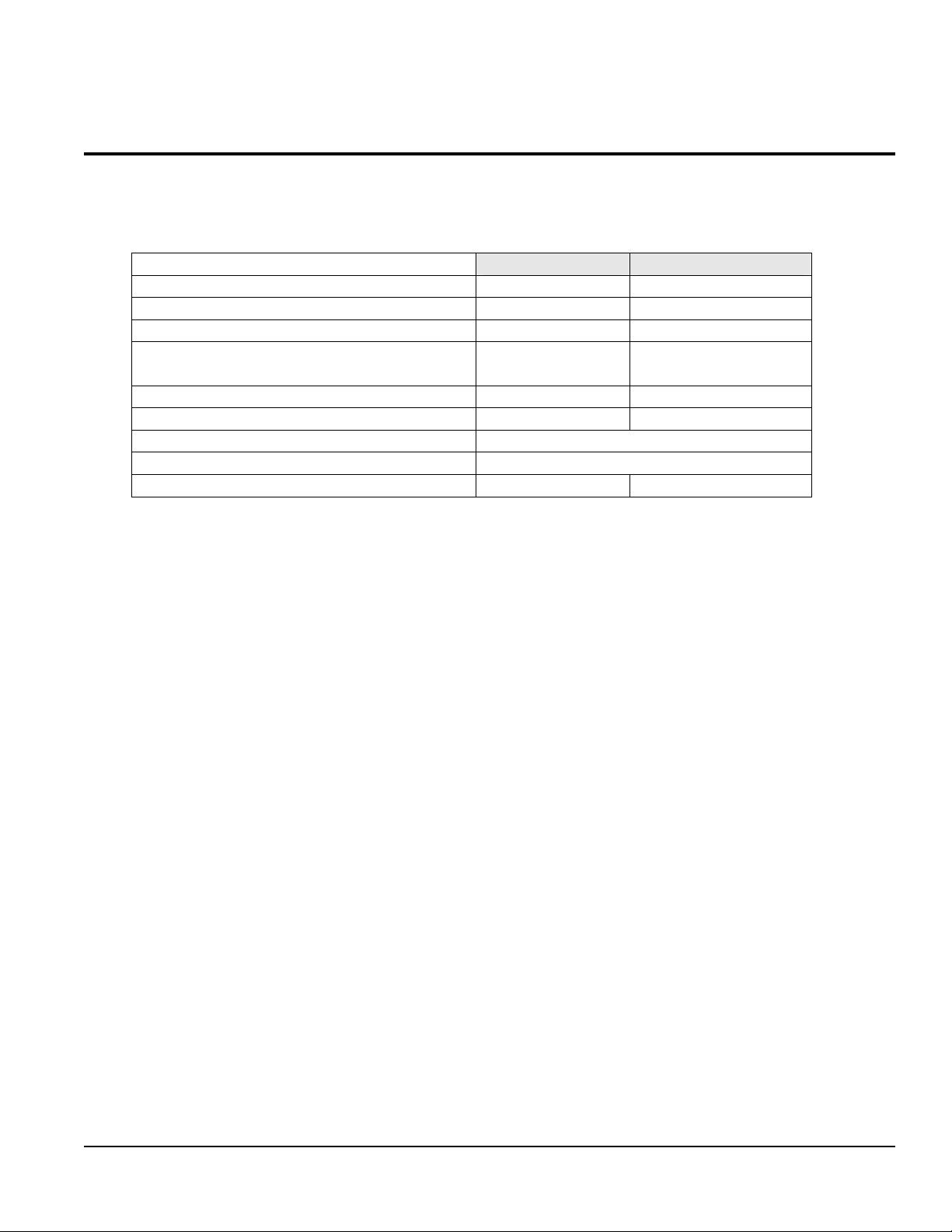

No. Revision Comment Date of Issue Operation Manual No.

Initial Release November 2005 PREDXS

1. Revision A

Added Drive Adjustment section

Modified drive board potentiometer settings.

Other minor corrections throughout

February 2006 PREDXS-A

2. Revision B

Changed format, added page numbers. September 2006 PREDXS-B

3. Revision C

New carriage and turntable design January 2007 PREDXS-C

4. Revision D

New optional height detection method April 2007 PREDXS-D

5. Revision E

Added optional scale package June 2007 PREDXS-E

6. Revision F

Removed Q60 information

Added Ultrasonic information

February 2008 PREDXS-F

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

vii

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY MESSAGES.........................................................................................................ii

INTRODUCTION................................................................................................................ iv

REVISION HISTORY TABLE............................................................................................. vi

TABLE OF CONTENTS......................................................................................................vii

LIST OF EXHIBITS.............................................................................................................ix

CHAPTER 1: GENERAL SYSTEM INFORMATION

System Specifications..............................................................................................I-1

System Overview Prints …….…………………………………………………….……. I-3

System Description……….......................................................................................I-5

CHAPTER 2: INSTALLATION AND ADJUSTMENTS

Machine Placement................................................................................................. II-1

Machine Set-Up....................................................................................................... II-2

Pre-Stretch Adjustment............................................................................................II-5

Frequency Drive…………………………...................................................................II-8

Film Feed Controller Card........................................................................................II-16

Optional Height Detection Sensor…........................................................................II-19

Optional Scale Package...........................................................................................II-20

CHAPTER 3: OPERATIONS INSTRUCTIONS

Operator Controls.................................................................................................... III-1

Film Loading……………………………………………………………………………… III-3

Machine Operation...................................................................................................III-4

CHAPTER 4: MAINTENANCE

Preventive Maintenance.......................................................................................... IV-1

Maintenance Schedule Table.................................................................................. IV-4

CHAPTER 5: TROUBLESHOOTING

Troubleshooting Guide

Power Problem..............................................................................................V-2

Turntable Problem.........................................................................................V-3

Film Carriage Problem.................................................................................. V-5

Film Delivery Problem...................................................................................V-9

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

viii

CHAPTER 6: TECHNICAL REFERENCE

Turntable Frame Assembly......................................................................................VI-1

Turntable Frame Part List........................................................................................ VI-2

Optional High Profile Turntable Frame Assembly....................................................VI-4

Optional High Profile Turntable Frame Part List......................................................VI-5

Tower Assembly...................................................................................................... VI-6

Tower Part List.........................................................................................................VI-7

Film Carriage/Elevator Assembly.............................................................................VI-9

Film Carriage/Elevator Part List...............................................................................VI-10

Control Box Assembly..............................................................................................VI-13

Control Box Part List................................................................................................VI-14

Electrical Schematics...............................................................................................VI-15

AC Frequency Drive Setting.................................................................................... VI-22

Electrical Sub-Panel Layout.....................................................................................VI-24

Electrical Sensors Layout........................................................................................ VI-26

CHAPTER 7: SPARE PARTS LIST

Recommended Spare Parts.....................................................................................VII-1

CHAPTER 8: NOTES

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

ix

LIST OF EXHIBITS

LIST OF EXHIBITSLIST OF EXHIBITS

LIST OF EXHIBITS

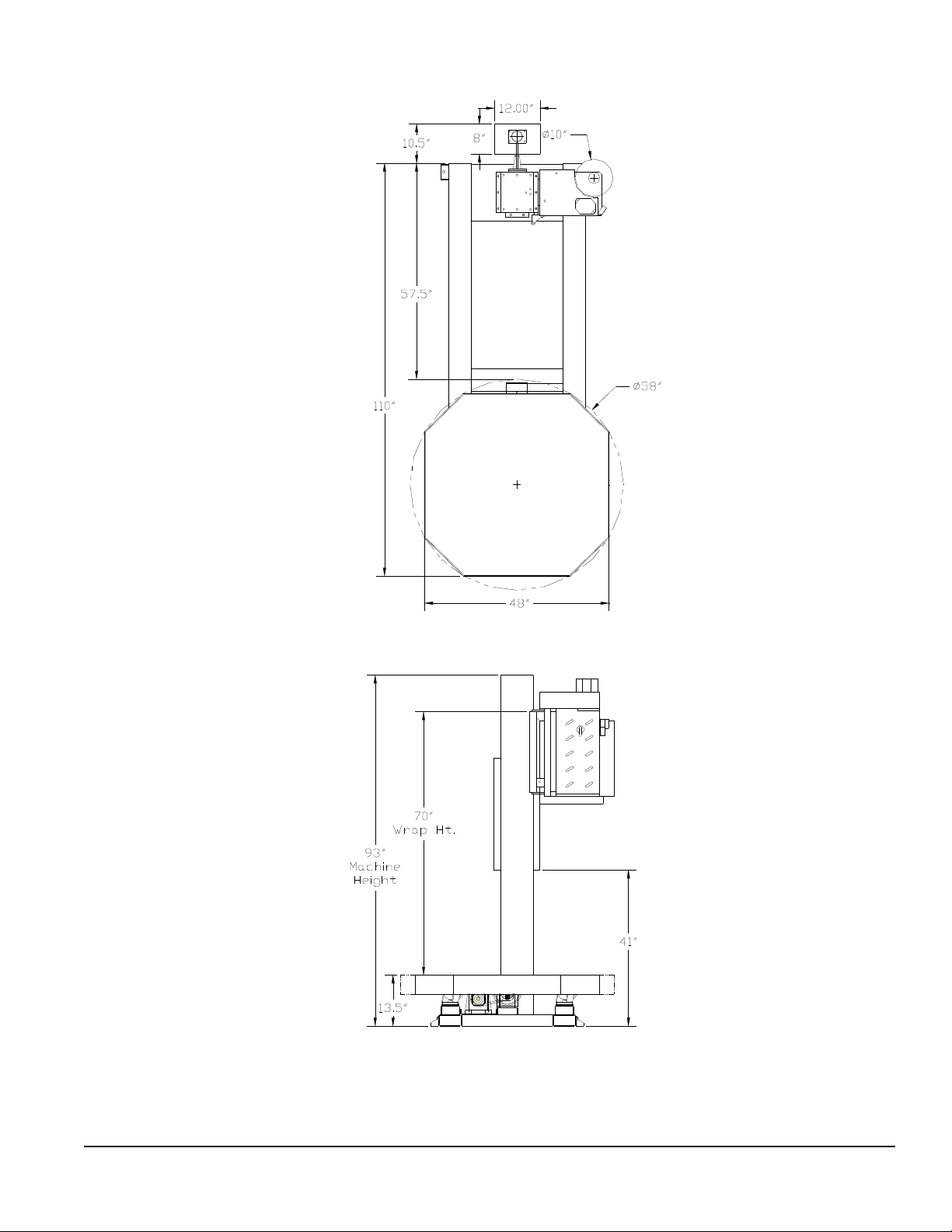

Exhibit 1-1: Predator XS Low Profile Overview Layout……………............………….......…I-3

Exhibit 1-2: Predator XS High Profile Overview Layout ………………………….............… I-4

Exhibit 1-3: Predator XS Low Profile Machine Description …..……............…………….… I-5

Exhibit 2-1: Ramp Positioning for Predator XS Low Profile….…………..…..........…...……II-2

Exhibit 2-2: Pre-Stretch Percentage Gear Set Swap……...……...……………..…..........…II-7

Exhibit 2-3: Description of Hitachi AC Drive Digital Keypad…………………...........………II-8

Exhibit 2-4: Navigation of Hitachi AC Drive Digital Keypad ……...…………...……............ II-9

Exhibit 2-5: Fault Detection of Hitachi AC Drive …………...........…...…………......……….II-10

Exhibit 2-6: Description of Cutler Hammer AC Drive Digital Keypad …..........……………. II-11

Exhibit 2-7: Explanation of the LED Indicator on Cutler Hammer AC Drive……............….II-11

Exhibit 2-8: Schematic of the Film Feed Controller Card....................................................II-16

Exhibit 2-9: Description of the Film Feed Controller Card………………...………………….II-17

Exhibit 2-10: Recommended Settings for the Film Feed Controller Card Trim Pots ……..II-18

Exhibit 3-1: Film Threading Diagram ………..……………...........…..………………………. III-3

Exhibit 4-1: Turntable Belt Adjustment …...……..…………....……………………...........….IV-1

Exhibit 4-2: Film Carriage Lift Chain Adjustment …...……..………………...…………....….IV-3

I. Chapter 1

HIGHLIGHT INDUSTRIES, INC.

Predator XS Turntable Stretch Wrapper Operation Manual

General System

Information

Chapter

1

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

I 1

SYSTEM SPECIFICATIONS

SYSTEM SPECIFICATIONSSYSTEM SPECIFICATIONS

SYSTEM SPECIFICATIONS

Machine Dimensions

Low Profile High Profile

Length (inch) 116 121

Width (inch) 65 88

Height (inch) 92 93

Turntable Diameter (inch) 65 48 Octagon

(58 Diagonal)

Turntable Height from Floor (inch) 3 ¼ 13 ½

Wrapping Height (inch) 80 70

Operation Space (inch) 125 x 70 x 100

Maximum Load Size (inch) 56 x 56 x 80

Approximate Shipping Weight (lbs) 1220 1500

Electrical Specifications

•120 VAC, 60 Hz, Single-phase, 15 AMP

•NEMA-12 rated electrical panel

•Operating temperature: +32°F to +110°F

•Lockable disconnect switch

•JIC wiring standard

•Programmable Logic Controller (PLC) with input/output diagnostic lights

Turntable System

•Low Profile: ½ HP 3-phase AC motor, ½ HP AC frequency drive

•High Profile: ¾ or 1 HP 3-phase AC motor, 1 HP AC frequency drive

•20-30 loads per hour (spiral)

•12 RPM turntable maximum speed

•4,000 lbs turntable maximum load capacity

Film Carriage/Elevator System

•½ HP 3-phase AC motor, ½ HP AC frequency drive

•Adjustable raise and lower speeds

•Automatic height detection photoelectric sensor

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

I 2

Film Delivery System

•¼ HP 3-phase AC motor, ½ HP AC frequency drive

•Adjustable film force

•200% / 250% average pre-stretch level

•10” diameter roll capacity

•20” height roll capacity

•OPTIONAL pre-stretch ratio of 230% / 300%

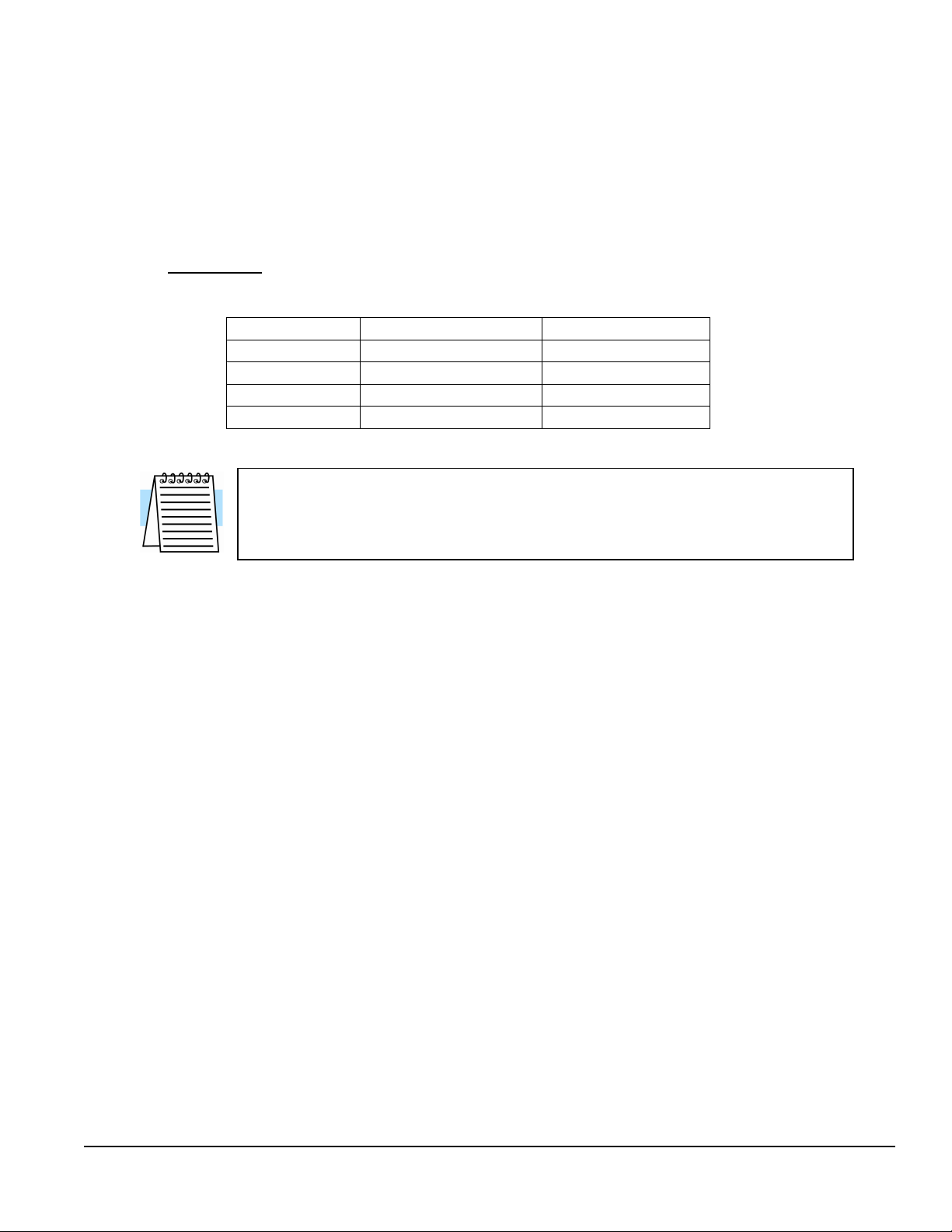

Requirements:

Part Number Description Number of Teeth

301339 Drive Gear 17

301340 Lower Fixed Gear 46

301341 Upper Fixed Gear 42

301342 Slip Gear 46/42

NOTE

Actual measured pre-stretch level may vary depending on film type

(thickness) and film force applied to the load.

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

I 3

SYSTEM

SYSTEMSYSTEM

SYSTEM OVERVIEW PRINT

OVERVIEW PRINT OVERVIEW PRINT

OVERVIEW PRINTS

SS

S

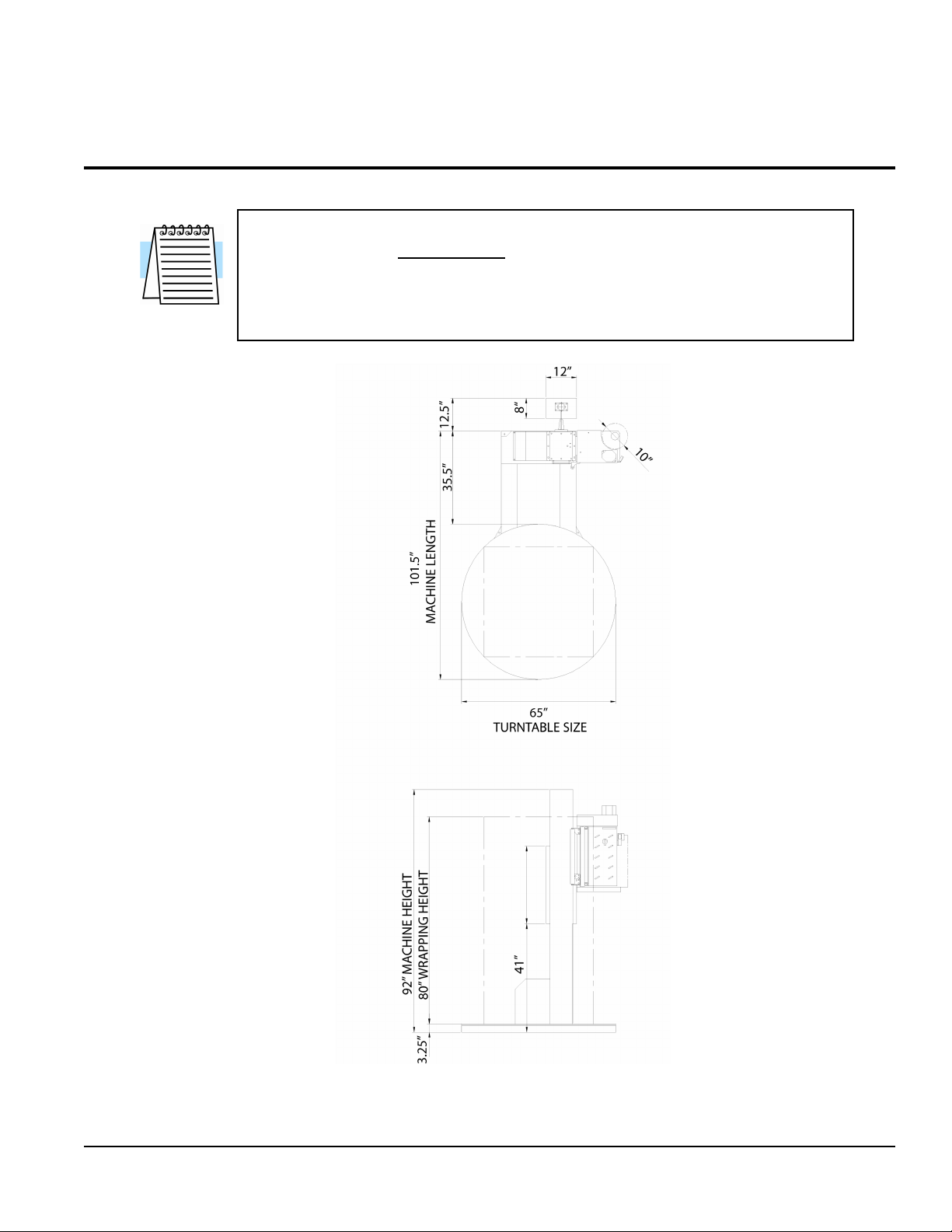

Exhibit 1-1: Predator XS Low Profile Overview Layout

NOTE

Shown below are STANDARD assembly drawings. It may not reflect

your purchased system, especially when optional items are added.

Refer to assembly drawings shipped inside the electrical enclosure for

more detail information.

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

I 4

Exhibit 1-2: Predator XS High Profile Overview Layout

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

I 5

SYSTEM DESC

SYSTEM DESCSYSTEM DESC

SYSTEM DESCRIPTION

RIPTIONRIPTION

RIPTION

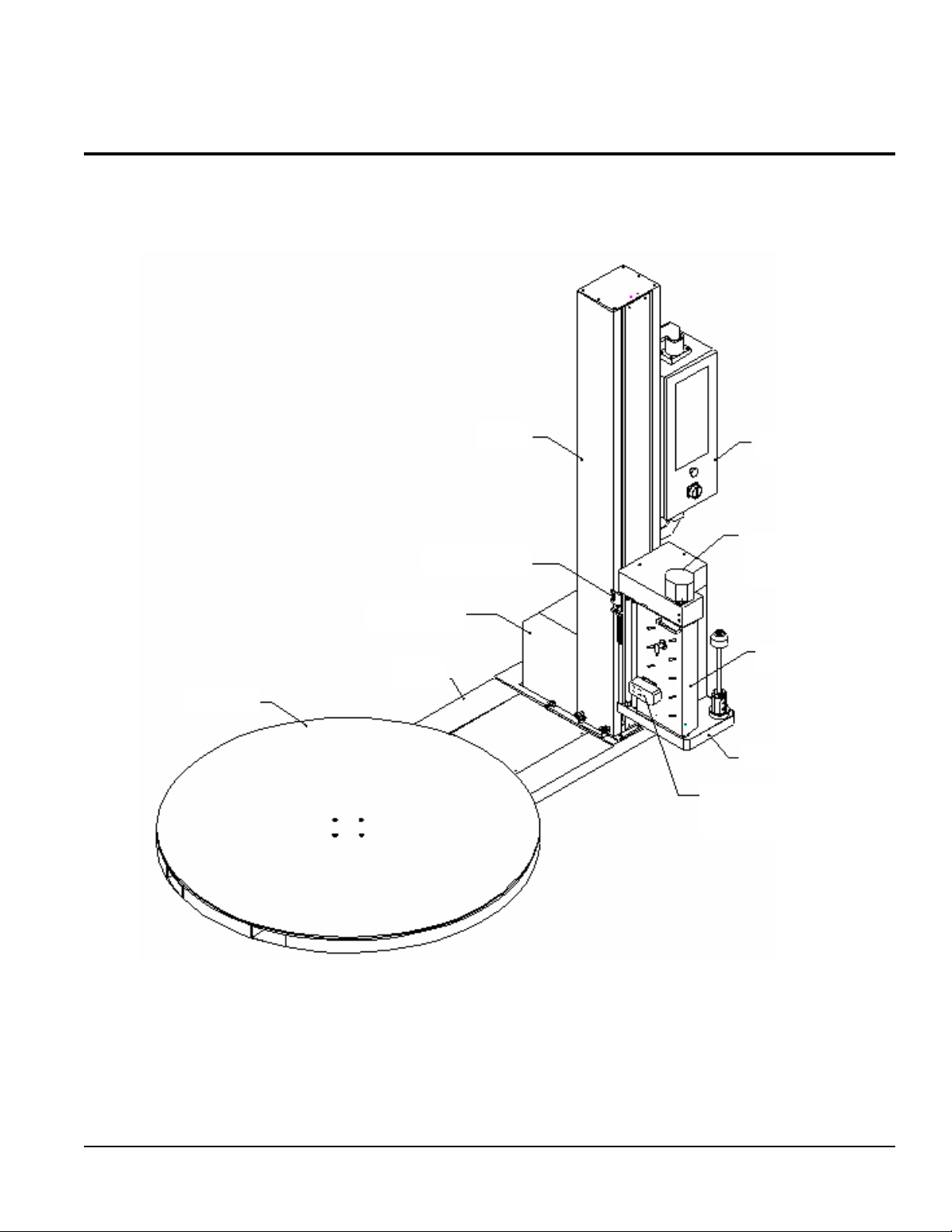

Shown below is the machine description.

Exhibit 1-3: Predator XS Low Profile Machine Description

Tower

Control Box

Stretch Selector

Cover

Photo Sensor

Film Carriage

Foot Security Pan

Auto Film Cut

Solenoid

Motor Cover

Frame

Turntable

II. Chapter 2

HIGHLIGHT INDUSTRIES, INC.

Predator XS Turntable Stretch Wrapper Operation Manual

Installation &

Adjustments

Chapter

2

PREDATOR XS TURNTABLE STRETCH WRAPPER OPERATION MANUAL

HIGHLIGHT INDUSTRIES, INC. ● 2694 PRAIRIE SW; WYOMING; MI 49519 ● 1 800 531 2465

II 1

MACHINE PLACEMENT

MACHINE PLACEMENTMACHINE PLACEMENT

MACHINE PLACEMENT

Receiving and Inspections

The Predator Turntable Stretch Wrapper has gone through quality control tests at the factory

before shipment. Upon receiving, please do the following:

1. Inspect the entire machine for visual damage during shipment. If found, immediately report

this damage to the truck line. Highlight Industries, Inc. has taken every precaution during

the packaging and loading of this equipment. However, it is YOUR RESPONSIBILITY to

inspect for damage before installation.

2. Make sure the part or serial number indicated on the machine corresponds with the part

number of your order.

Positioning of the Machine

Place the Predator Turntable Stretch Wrapper close to an area where you will be wrapping your

pallet loads. Make sure that there is sufficient room to load/unload the machine and that you do

not stretch the wiring cable. Remember, you will need to provide electrical service to a 120 VAC,

15-Amp outlet.

Floor Weight Bearing/Stress Tolerance

The floor must be able to bear the weight of the machine, the weight of the maximum load, plus a

safety factor. The floor must also be able to tolerate the stress of the machine’s operation. If the

fork trucks will operate on the same weight bearing area, add the weight of the trucks to the

weight bearing stress tolerance requirements.

The Predator can be installed on any type of floor constructions that meets the weight bearing and

stress tolerance requirements.

WARNING

The Predator must be anchored securely to the floor, using the type

of anchor recommended for your floor.

Table of contents

Other Highlight Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

Berran Industrial Group

Berran Industrial Group S600 Operation manual

XtraVac

XtraVac CM430 Operations & parts manual

Barry-Wehmiller

Barry-Wehmiller Accraply 204RH Operation and maintenance manual

ITW Mima

ITW Mima GIROTEC TWIN operating instructions

HSM

HSM StoreEx HDS 230 operating instructions

TLM

TLM PRIME 400 Use and maintenance handbook

Siebeck

Siebeck JET 2000 RBM operating manual

Titan

Titan L 221-0001 instruction manual

Minipack-Torre

Minipack-Torre Tunnel 50 Digit Installation, operation and maintenance

vc999

vc999 PACKAGING plus CM610FB Operations & parts manual

Hendi

Hendi Profi Series instructions

Pregis

Pregis EASYPACK QUANTUM Series user manual