TLM PRIME 400 Manual

Traslation of Original Instruction - Edition 01 of 27/01/2017

Via Venezia, 34/N-O-P - 10088 - Volpiano (Torino)

Tel. 011.9881307 –Fax. 011.9881084

www.tlmpack.com

USE AND MAINTENANCE

HANDBOOK

PRIME 400 PACKAGING MACHINE

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 2 of 71

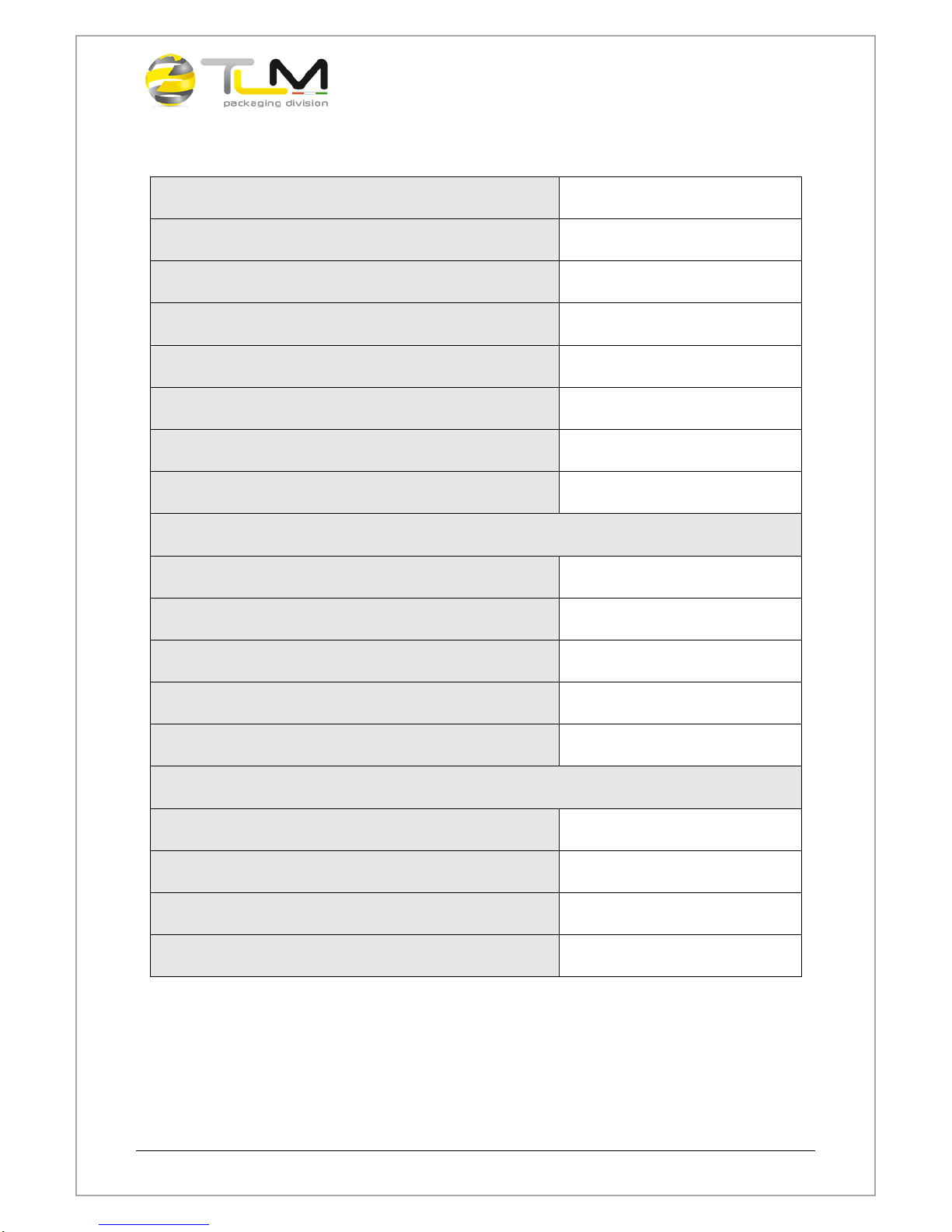

TABLE OF CONTENTS

1. PREFACE........................................................................................................... 4

2. WARNINGS AND GUARANTEES...................................................................... 5

3. SPARE SERVICES ............................................................................................ 6

4. INTENDED USE................................................................................................. 6

5. NON PERMITTED CONDITIONS OF USE ........................................................ 7

6. IDENTIFICATION PLATE................................................................................... 7

7. DESCRIPTION AND TECHNICAL SPECIFICATIONS ...................................... 8

7.1 Loading floor........................................................................................................10

7.2 Adjustable conveyor ............................................................................................10

7.3 Unwinding group..................................................................................................11

7.4 Perforator ............................................................................................................11

7.5 Welding group.....................................................................................................12

7.6 Discharge chute...................................................................................................13

7.7 Pneumatic system ...............................................................................................14

7.8 Electrical System.................................................................................................15

7.9 Technical specifications.......................................................................................16

8. TRANSPORT AND HANDLING ....................................................................... 17

9. INSTALLATION................................................................................................ 19

10. SAFETY............................................................................................................ 20

10.1 Particular recommendations................................................................................21

10.2 Intended, unintended and improper uses.............................................................23

10.2.1 Contraindication and danger of the unexpected uses..........................................25

10.3 Safety..................................................................................................................26

10.3.1 Introduction..........................................................................................................26

10.3.2 Danger of cutting and crushing............................................................................26

10.3.3 Stability loss.........................................................................................................26

10.3.4 Electrical hazards ................................................................................................27

10.3.5 Fire hazard ..........................................................................................................27

10.3.6 Danger of cutting.................................................................................................27

10.3.7 Thermic danger ...................................................................................................28

10.3.9 Danger due to the machine handling...................................................................29

10.4 Main protections..................................................................................................30

10.4.1 Mobile guards, access door to the internal components......................................31

10.4.2 Permanent guards...............................................................................................31

10.4.3 Pneumatics guards..............................................................................................32

10.4.4 Electrical protections............................................................................................33

10.4.5 Plate and indications............................................................................................35

10.5 Reference standards ...........................................................................................36

10.6 Risk analysis and the safety measures adopted..................................................37

10.6.1 Functioning in production.....................................................................................38

10.6.2 Functioning during fine tuning / Maintenance ......................................................43

10.7 Noise...................................................................................................................44

10.8 Electromagnetic compatibility ..............................................................................45

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 3 of 71

11. INSTRUCTIONS FOR USE.............................................................................. 46

11.1 Operator..............................................................................................................46

11.2 Safety regulations for a proper functioning ..........................................................47

11.3 Control panel.......................................................................................................48

11.4 Operator panel description ..................................................................................49

11.4.1 Main menu page..................................................................................................49

11.4.2 Jog and homing page..........................................................................................50

11.4.3 Piece counter page..............................................................................................51

11.4.4 Mark setup page..................................................................................................52

11.4.5 Bags length setup page.......................................................................................53

11.4.6 Recipe page ........................................................................................................54

11.4.7 Machine settings page.........................................................................................56

11.4.8 Jaws page...........................................................................................................56

11.4.9 Temperature page...............................................................................................57

11.5 Working phases...................................................................................................58

11.5.1 Functioning cycle.................................................................................................58

11.5.2 Machine switch-off...............................................................................................59

11.5.3 Reset after emergency stop.................................................................................59

11.5.4 Mounting the bobbin, film drawing-in and centring...............................................60

11.5.5 Regulating mark reading .....................................................................................60

11.5.6 Regulating the length of the bag..........................................................................60

11.5.7 Regulating Loading conveyor ..............................................................................61

11.5.8 Regulating the cut................................................................................................61

12. MAINTENANCE................................................................................................ 62

12.1 Program maintenance .........................................................................................64

12.1.1 Daily maintenance...............................................................................................64

12.1.2 Semi-annual maintenance...................................................................................64

12.1.3 Annual maintenance............................................................................................64

12.2 Extraordinary maintenance..................................................................................65

12.2.1 Jaws resistance replacement...............................................................................65

12.2.2 Jaws proximity sensor replacement.....................................................................65

12.2.3 Jaws sonda probe replacement...........................................................................66

12.2.4 Roller resistance replacement and adjustment....................................................66

12.3 Maintenance on the Pneumatic System...............................................................67

12.3.1 Filter and pressure regulator................................................................................67

12.3.2 Command valves with a pneumatical actuation direction.....................................68

12.3.3 Flow regulator......................................................................................................68

12.3.4 Actuators.............................................................................................................69

12.3.5 Calibration procedure of the flow regulators ........................................................69

13. DECOMMISSIONING AND DEMOLITION....................................................... 70

14. APPENDICES................................................................................................... 71

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 4 of 71

1. PREFACE

The purpose of the information in this “Use and Maintenance Manual” is:

To show the use of the machine envisaged by the design assumptions.

Provide the instructions for transport, installation, assembly, fine tuning and

use to the operators and the maintenance personnel...

Facilitating the ordering of any spares or materials subject to wear and tear.

Provide indications of the risks involved in carrying out the tasks assigned.

Enable the personnel who use the machine, to operate in safety and

guarantee perfect efficiency throughout its life.

This is to be considered an integral part of the machine and must be “kept” until

it’s finally dismantled.

Furthermore, the content of this manual does not contemplate any risks that may

derive from coupling with other machines.

As a rule it must always be made available for consultation and duly preserved in

a dry, protected place away from the rays of the sun and be known to all the

users (machine operators and maintenance personnel).

TLM PACKAGING reserves the right to make modifications or updates to this

manual at any time and without warning.

The machine to which this manual refers complies with the following Directives:

“Machine Directives” 2006/42/ EC

“Electromagnetic Compatibility 2014/30/UE

and it also takes into account indications deriving from consulting the harmonised

UNI and CEI standards, and Guide to application of the Machinery Directive

2006/42/EC 2nd Edition –June 2010. As defined by the directive, this document

has been drawn up in Italian and has, if necessary been translated into a

community language that has to be the language of the user.

This document will be accompanied by drawings and schematics necessary for

commissioning, maintenance, checking and inspection and, if necessary, repair.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 5 of 71

2. WARNINGS AND GUARANTEES

TLM PACKAGING, produces and designs its machines in the most complete respect

of the current safety regulations, with the purpose of ensuring the user the maximum

guarantee in carrying out all the operations envisaged and permitted, together with

the minimum possibility of incidents due to any residual risks. Even after

commissioning TLM PACKAGING shall be able to make modifications to the

machine, modifications that in its unimpeachable judgement represent improvements

for the functioning. TLM PACKAGING ensures that the machine contains no defects

in the materials or the workmanship for a period of 24 months from the date of the

purchaser’s final test, always without prejudice to different contractual conditions.

During this period, TLM PACKAGING undertakes to repair or to substitute, in the time

necessary, those parts that are damaged and/or contain defects at the origin

providing the purchaser notifies TLM PACKAGING of the fact by means of registered

letter with a notice of receipt slip, within seven days of the discovery. The above

conditions are without prejudice to different contractual conditions. In any event all

further obligation and/or indemnity on the part of TLM PACKAGING is excluded. The

warranty referred to above (or the contractual warranty) is only applied if the

purchaser has complied with the regulations in the contract and only if the installation

and the subsequent use of the system has been carried out by the purchaser in

compliance with the instructions contained in this instruction manual. The warranty

excludes all or any liability for direct or indirect injury to persons or damage to

property deriving from the inadequate or improper use or maintenance of the above

mentioned machine. This warranty does not extend to repaired or replaced parts.

Also excluded from the warranty are all the parts that because of their specific use

are subject to wear. In conclusion transport costs, inspections, dismantling and

reassembly due to the intervention of a TLM PACKAGING technician are excluded

from the warranty and will be charged to the purchaser if the flaws and/or defects

found are not covered by this warranty, the above being without prejudice to different

contractual conditions. The warranty automatically becomes null and void in the case

of repairs, modifications or removals or replacement of components aren’t previously

communicated to or agreed and approved by TLM PACKAGING.

The machine must not be used or any work must not carried out, thereon this

collection of documents as not been carefully read and fully understood.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 6 of 71

TLM PACKAGING cannot be held responsible for failures, problems or accident

due to non-compliance with this prohibition. Tampering with or altering the

machines and the installed devices, even partially, is prohibited.

The machine is designed in order to package products from various sectors,

including food sector, into specifics bags.

Before proceeding to the product changeover due to the change belongings field,

contact the TLM to get indications.

3. SPARE SERVICES

It may be possible over time that the above mentioned machine may need the

replacement of components, for this purpose the purchaser may order the

components to be replaced. Said customer (purchaser) is obliged to always

purchase O.E.M. spares. For any request of spare parts, it is always necessary to

specify the serial number of the machine that the spare part is referring to, as

indicated on the identification plates. As regards components, please refer to the

attached layout (APPENDIX 4).

4. INTENDED USE

CAUTION

THE MACHINE IS SUPPLIED WITH PERIMETRIC PROTECTIONS AND SAFETY DEVICES,

IN ORDER TO PACKAGE PRODUCTS FROM VARIOUS SECTORS, INCLUDING FOOD

SECTOR, INTO SPECIFICS BAGS.

THE MACHINE, AS PREVISTED BY ITS INTENDED USE, IS REALIZED TO RUN WITH

THE PROTECTIONS AND THE SAFETY DEVICES ACTIVED AND INSTALLED.

TO THE USER: IT’S ABSOLUTELY PROHIBITED ALTERING OR TAMPERING THE

MACHINE, EVEN PARTIALLY, IF NOT AGREED UPON BY THE CONSTRUCTOR; IN

CASE OF NON-COMPLIANCE WITH THIS RULE, THE CONSTRUCTOR CANNOT BE HELD

RESPONSIBLE

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 7 of 71

5. NON PERMITTED CONDITIONS OF USE

The Constructor declines all responsibility in the following cases:

Use of the machine different than the one provided for.

Improper use of the machine or personnel who are not properly trained.

Incorrect installation.

Defective power supply.

Serious shortcomings with regard to the required maintenance.

Unauthorised work on the machine.

Use of non OEM spares or spares that are not specific to the model.

Total or partial non-compliance with instructions.

Dimensional or geometric inaccuracies of parts to be worked.

Work material is not loaded properly.

Work material other than the one permitted.

Exceptional events.

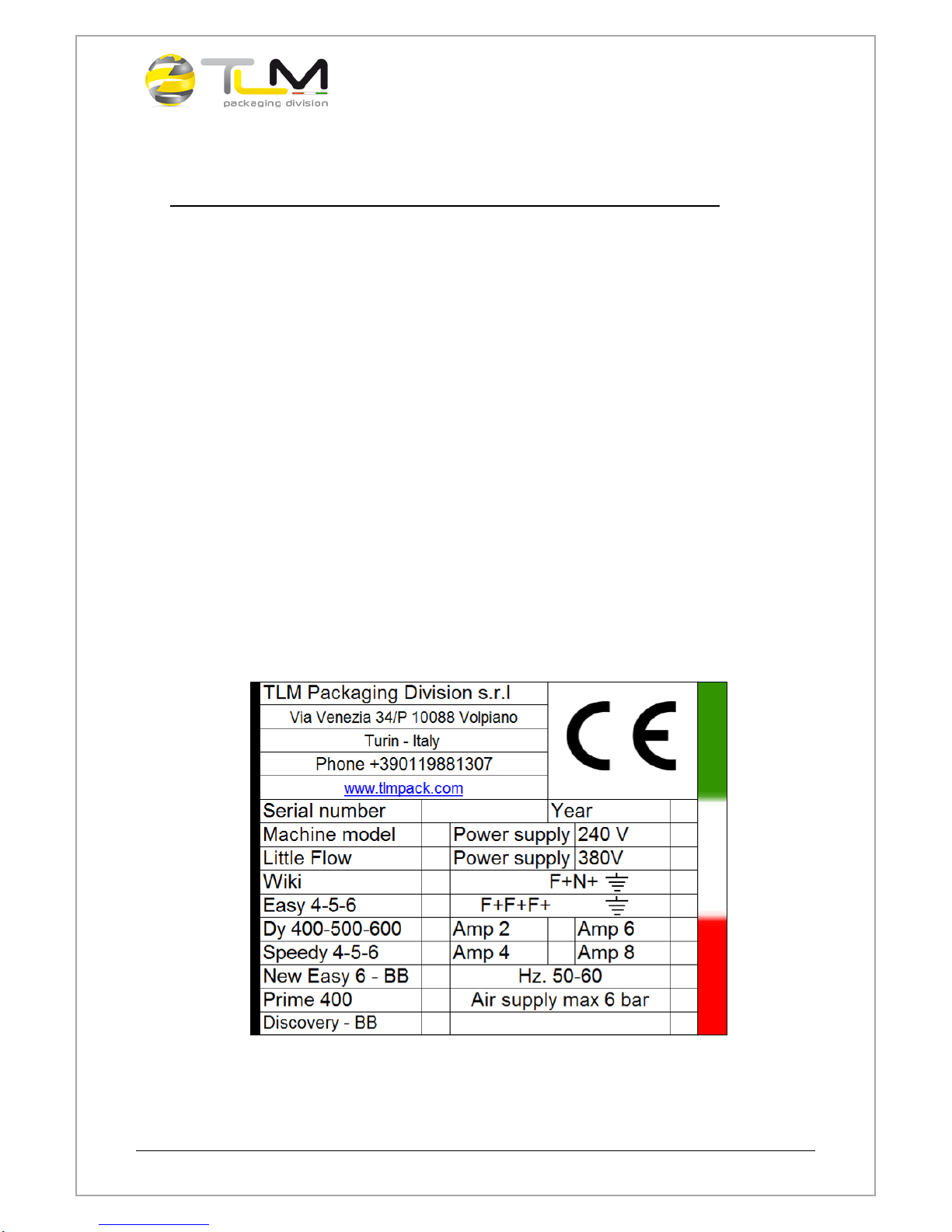

6. IDENTIFICATION PLATE

The following identification plate is attached to the machine:

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 8 of 71

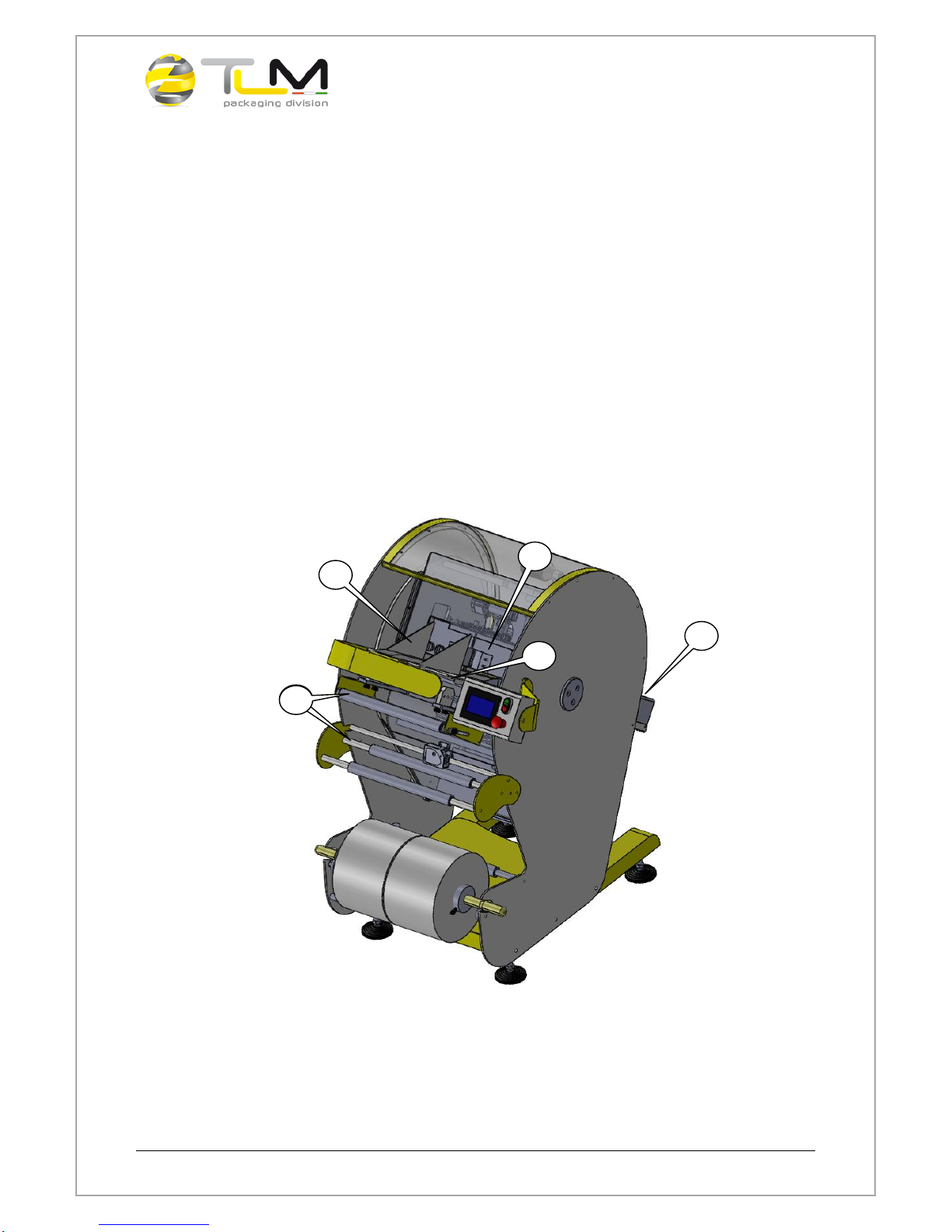

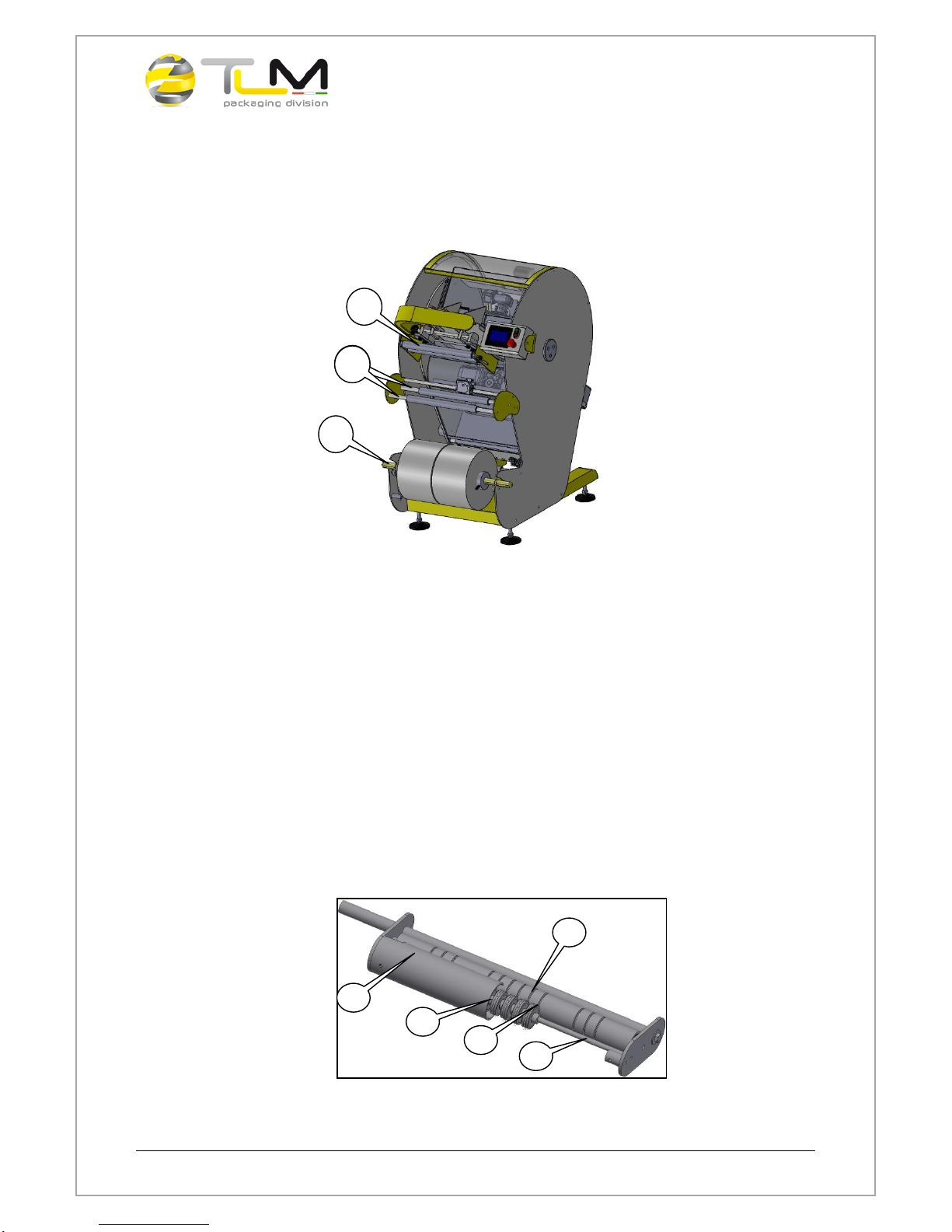

7. DESCRIPTION AND TECHNICAL SPECIFICATIONS

The machine is designed to package products into specifics bags. Loading

operation of the products to be packaged is performed manually by the operator.

The discharge chute conveys packaged products in an appropriate container.

The packaging machine is composed of :

A. Loading floor;

B. Adjustable conveyor;

C. Unwinding group;

D. Welding group;

E. Discharge chute;

D

C

E

A

B

C

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 9 of 71

CAUTION

The machine has as final use purpose the productive aim described

above and so can only be used to reach such objective, following the

procedure and the indications brought back in this manual, remaining

moreover very closely to the brought back functional limits.

A different use of the machine and/or also the overcoming of an only one

limit, held the user responsible of eventual damages, failures, and

accident on things or persons, caused of its acts.

Its recommended to the user to adhere scrupulously on whats indicate in

this manual, in particular regarding the safety and the preventions of

accidents, and, in case of doubt, always consult the constructor before

acting.

Under no circumstances may the system and/or this manual be modified

or tampered with by people not delegated to do so by the manufacturer,

the manufacturer cannot be held responsible of any derived

responsabilities due to non compliance with this provision.

This machine must never be used in environment where there is

explosion risk.

Note: the machine, as previsted by its destination of use, is realized

to work with protections and safety devices activated and installed.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 10 of 71

7.1 Loading floor

The loading floor (A) can be equipped with an optional tunnel wich allows to

maintain the alignment of the product while it reaches the packaging area. The

loading operation is performed manually by the operator.

7.2 Adjustable conveyor

The adjustable conveyor (C) is regulated according to the dimensions of the

product to be packed. Thanks to the adjustable conveyor, the packaging adheres

to the product while limiting the flexibility. The manufacturer’s technicians regulate

the conveyor during test run, the customer may change it a little.

A

C

B

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 11 of 71

7.3 Unwinding group

The unwinding group puts strain on the film and positions it into place. It is made

up of a shaft for the bobbin (A), some idler rollers (B) and a tensioning system(C).

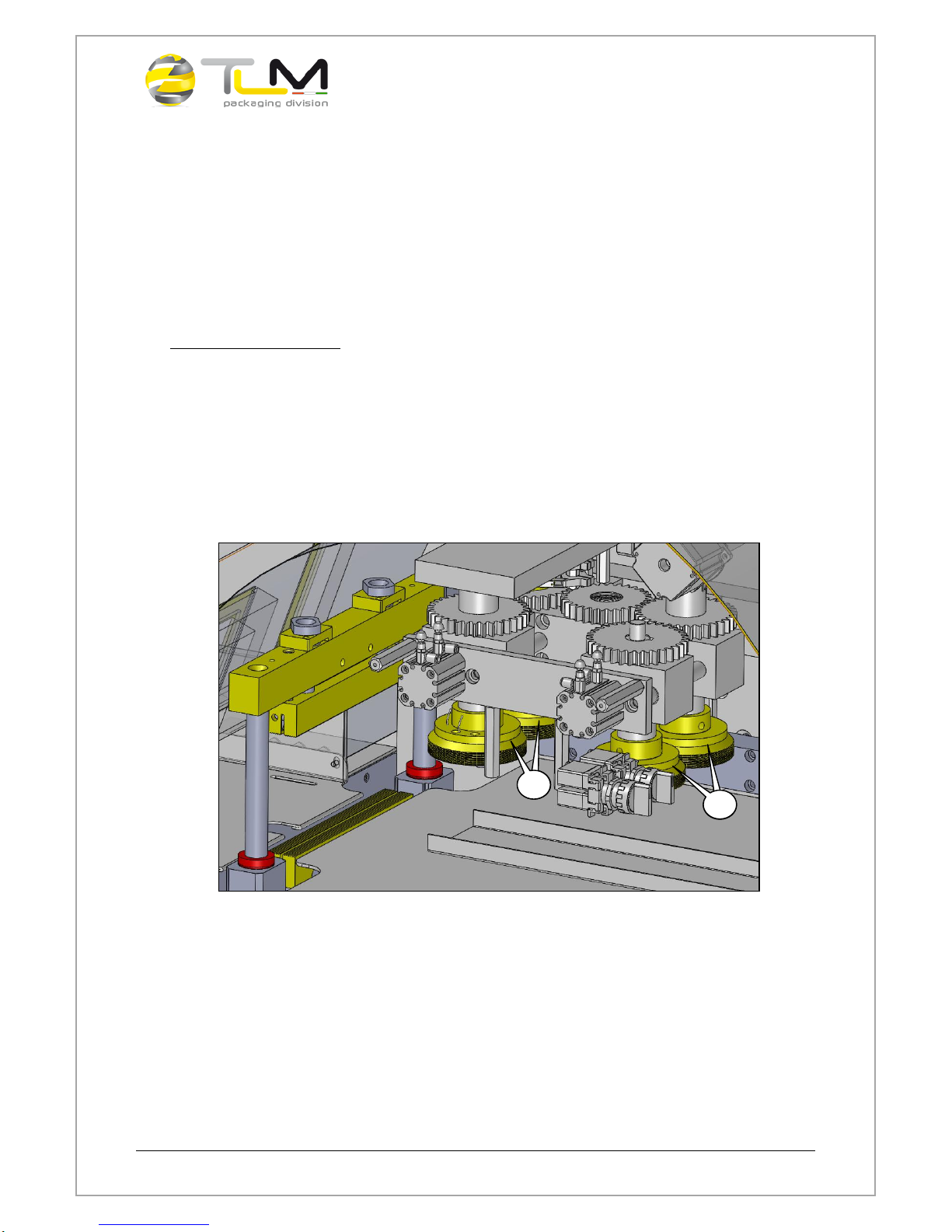

7.4 Perforator

The perforator is an optional accessory. The machine can be equipped with a

single or multiple type perforator to realise microperforations on the film, so that

the packages have not air inside. The multiple perforator is purpose-built based

on the final customer’s need. The series of idler rollers equipped with needles to

perforate the film (A) are placed on a regulating shaft (B), and then blocked by a

threaded dowel (C). The series of idler rollers can be moved into specific

positions by the grooves on the contrast roller placed in opposition to the needles

(D). The grooves are realised in a position suitable with the type of packaging to

be realised on the machine. A protective casing is placed in the front part, to

avoid contact with the needles in rotation (E).

Example of multiple perforator

A

B

C

B

A

E

D

B

C

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 12 of 71

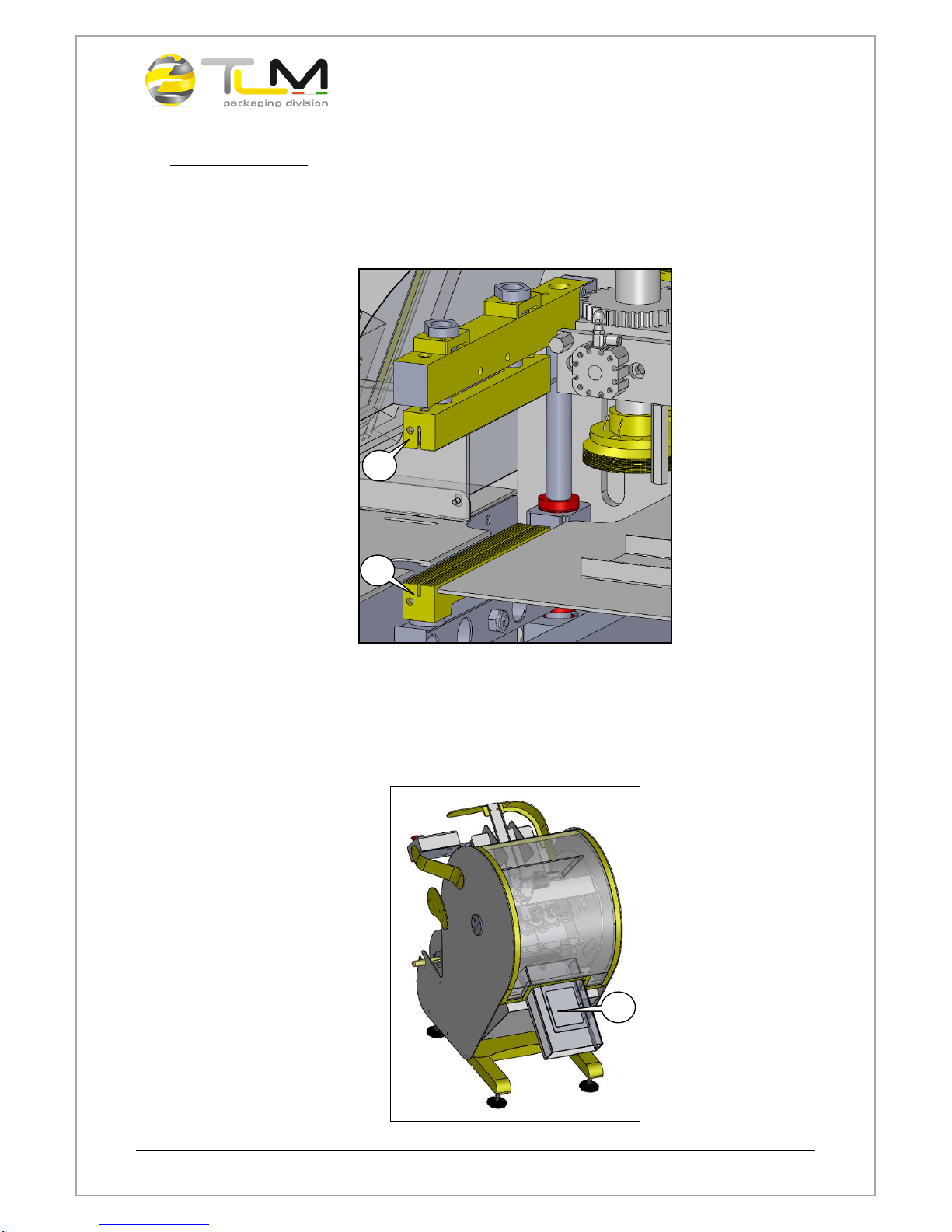

7.5 Welding group

The welding group is composed of four rollers that weld the film along the

longitudinal axis and two jaws that weld the film on the transversal axis and cut

the packaging. These four rollers are placed over the running surface of the

product.

WELDING ROLLERS

Before the two welding rollers (A) there are two cold dragging rollers (B) that drag

the product in the welding area. Inside the welding group there are the

resistances (both for the rollers and the jaws) equipped with probes that take the

welding temperature. The rollers for welding are equipped with a machined

welding surface that enables the hermetic welding during the transportation of the

film.

A

B

A

B

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 13 of 71

WELDING JAWS

Inside the two jaws –the upper one (C) and the lower one (D) –there is a slot.

The cutting blade is placed on the upper jaw. During the film cutting operation,

the blade can move inside the slot present on the lower jaw.

7.6 Discharge chute

The discharge chute (E) allows the exit of the packages coming from the

packaging machine. The packaged products are collected in an appropriate

container.

D

C

E

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 14 of 71

7.7 Pneumatic system

The customer is responsible for connetting the compressed air supply next to the

system. At the assembly, all the pneumatic control needed are done and any

further adjustment are not required.

For the pneumatic supply a max. 6 Bar pressure is required (3 Bar is adequate).

In order to change the pressure, an action on the top of the knob of the installed

regulator is needed. Rotating clockwise, the increase of the pressure in the

system increase, while rotating in counter-clokckwise sense, a decrease of the

pressure is reached.

CAUTION

THE CONVEYORS, THE DRAINING FILTERS AND OTHERS ACCESSORIES MUST

NEVER BE REMOVED WHILE THE SYSTEM IS UNDER PRESSURE.

CAUTION

BEFORE CARRYING OUT ANY KIND OF INTERVENTION, TURN OFF THE

COMPRESSED AIR SUPPLY LINES AND RELEASE THE PRESSURE FROM THE

SYSTEM.

For specific information on the pneumatic system refer to the technical

documentation provided with this manual.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 15 of 71

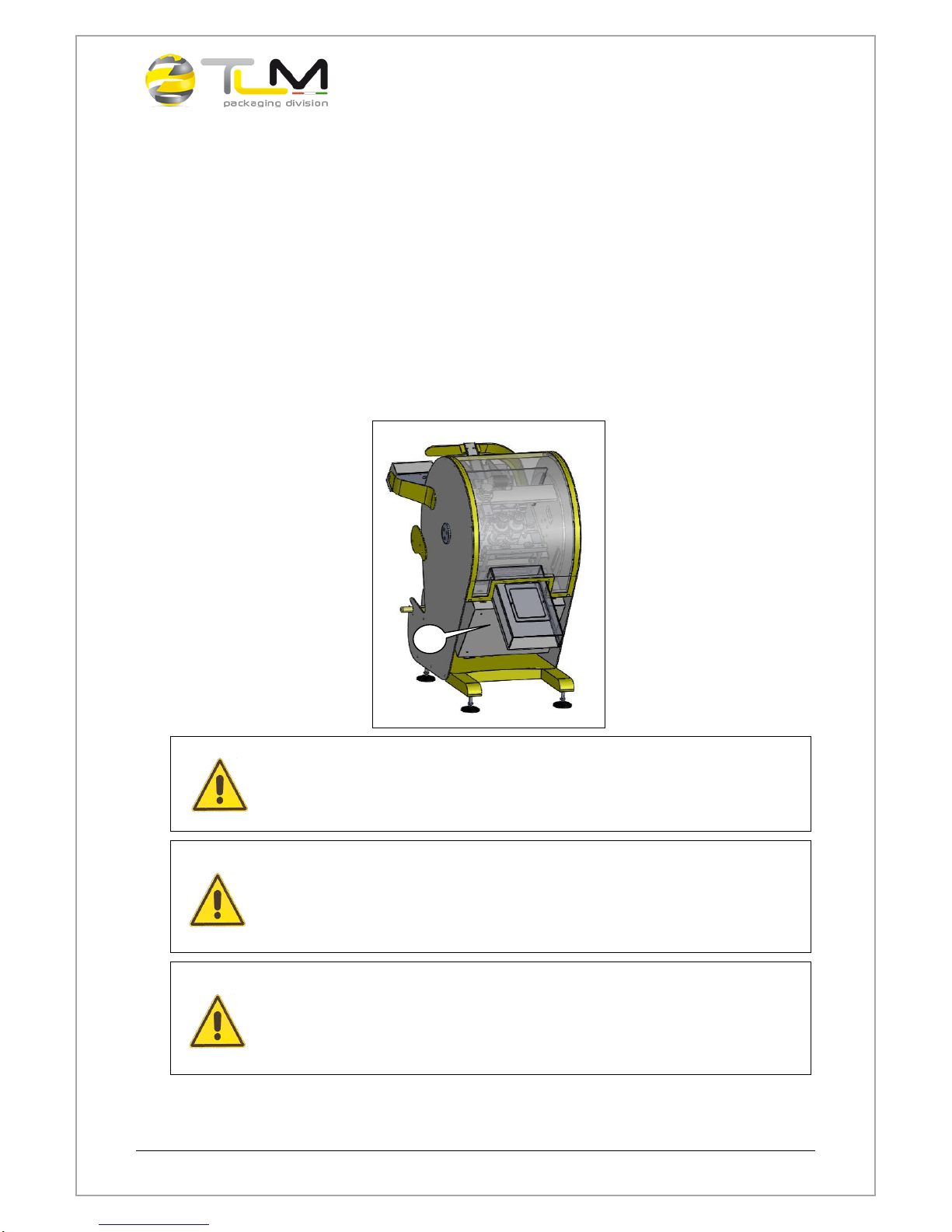

7.8 Electrical System

The packaging machine is supplied with a complete electrical system with wiring

on the machine. The electrical cabinet (A) is located in the rear of the machine,

below the discharge chute. The customer is responsible for connecting the

factory’s electrical cabinet and the main electrical panel, as well as connecting

the main electric panel to others apparatus where there are enabling interchange

signals to synchronised operations. The characteristics of the connections are

shown on the plate on the electrical panel and in the technical documentation

attached to this manual.

CAUTION

BEFORE CARRYING OUT ANY INTERVENTION ON THE ELECTRIC SYSTEM MAKE

SURE THAT IT IS NOT LIVE AND THAT ANY ACCUMULATIONS DEVICES ARE

DISCHARGED OR DISCONNECTED FROM THE SYSTEM.

CAUTION

BEFORE CARRYING OUT THE ELECTRICAL CONNECTION MAKE SURE THAT THE

ELECTRICAL CHARACTERISTICS CORRESPOND WITH THOSE SHOWN ON THE

IDENTIFICATION RATING PLATE OF THE SYSTEM AND THAT THE MACHINE HAS

BEEN FITTED WITH EARTHING.

CAUTION

WHEN CARRYING OUT THE CONNECTIONS CAREFULLY CHECK THE NUMBERING

OF THE CABLES AND THE JAWS REFERRING TO THE WIRING DIAGRAM, THE

POLARITY OF THE POWER SUPPLIES AND THE DIRECTION THE MOTORS

ROTATE.

For specific information on the Electric/Software system refer to the

technical documentation provided with this manual.

A

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 16 of 71

7.9 Technical specifications

LENGHT

860 mm

WIDTH

1300 mm

HEIGHT

1400 mm

POWER SUPPLY

220 Volt –50/60 Hz

INSTALLED POWER

3 kW

OPERATING AIR PRESSURE

3 Bar

MAXIMUM AIR PRESSURE

6 Bar

PIECES PRODUCTS

20 for minute

ENVIRONMENTAL CONDITIONS FOR USE

LOCAL

CLOSED

MIN TEMPERATURE

- 10 °C

MAX TEMPERATURE

40 °C for a period of 24h average

max. temperature 35 °C

RELATIVE HUMIDITY

max 50% - R.U. at 40 °C

MAX ALTITUDE

2000 m

ENVIRONMENTAL CONDITIONS FOR STORAGE

LOCAL

CLOSED

MIN TEMPERATURE

-10 °C

MAX TEMPERATURE

40 °C

RELATIVE HUMIDITY

max 50% - R.U. at 40 °C

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 17 of 71

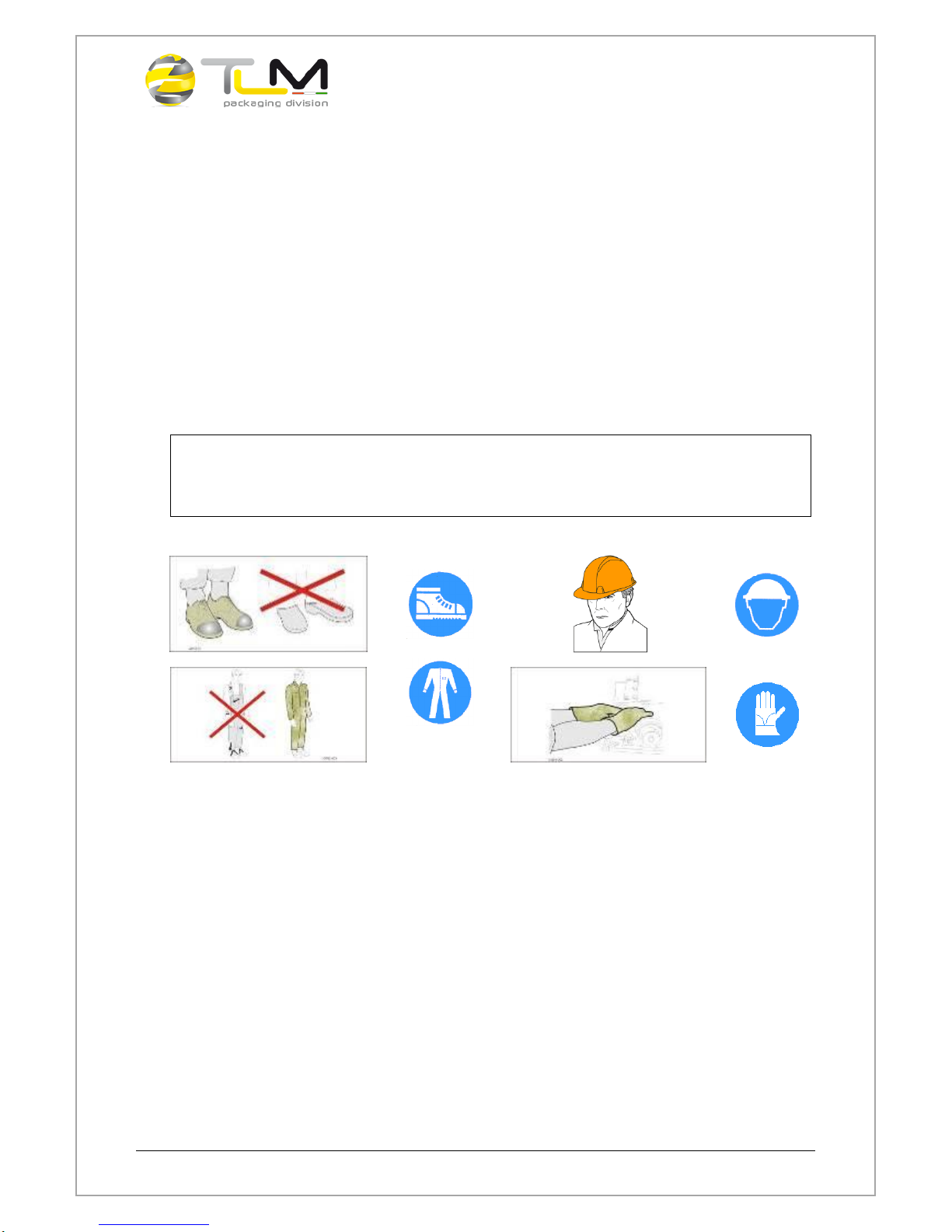

8. TRANSPORT AND HANDLING

For the handling and raising of the machine it is necessary to use the lower cross

beams of the frame with a forklift truck suitable for the weights indicated in the

relevant table of technical specifications.

While handling the entire surrounding area must be considered a danger area.

Make sure that nobody is in the danger area.

Do not stop or move under the suspended weights.

Keep the load at minimum distance from the ground.

!

CAUTION

DURING THE MOVEMENT OPERATION, THE USE OF THE RECOMMENDED PPE IS

COMPULSORY

WITHOUT LOOSE

OR HANDLING

PARTS

Handling operations must only be carried out specialised personnel taking into

account the following regulations:

Operations to be carried out with the maximum care being careful to make

sure that the instruments are efficient.

Delineate with barriers the area where the operation is carrying-out

Avoid knocks and back kicks during all the phases: during the raising and

during the movement and setting down.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 18 of 71

Handling with a forklift truck

In order to lift the machine with a forklift truck with driver on board o with the

driver on the ground, check the capacity for the mass to be lifted.

!

CAUTION

THE CAPACITY OF THE LIFTING EQUIPMENT MUST BE SUFFICIENT FOR THE

MASS TO BE HANDLED. ADHERE CLOSELY TO THE SAFETY REGULATIONS

DANGER

WHEN LIFTING AND MOVING THE MACHINES DO NOT STAND NEARBY. KEEP AT

A DISTANCE OF MORE THAN 2 METERS FROM THE LOAD.

!

CAUTION

THE MANUFACTURER DECLINES ALL LIABILITY FOR ANY INJURY TO PERSONS

OR DAMAGE TO PROPERTY CAUSED BY IMPROPER HANDLING OF THE LOADS

CARRIED OUT BY UNSUITABLE PERSONS AND:OR WITH LIFTING EQUIPMENT

THAT IS NOT ADEQUATE.

The operations to be carried out for moving are:

Cut off the power supply;

Properly lock all the mobile parts in order to avoid damaging or that they

suddenly get open during the transport phases;

Protect the equipment in order to prevent it from getting damaged during the

transport;

Use the appropriate lifting pockets suitable for the handling.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 19 of 71

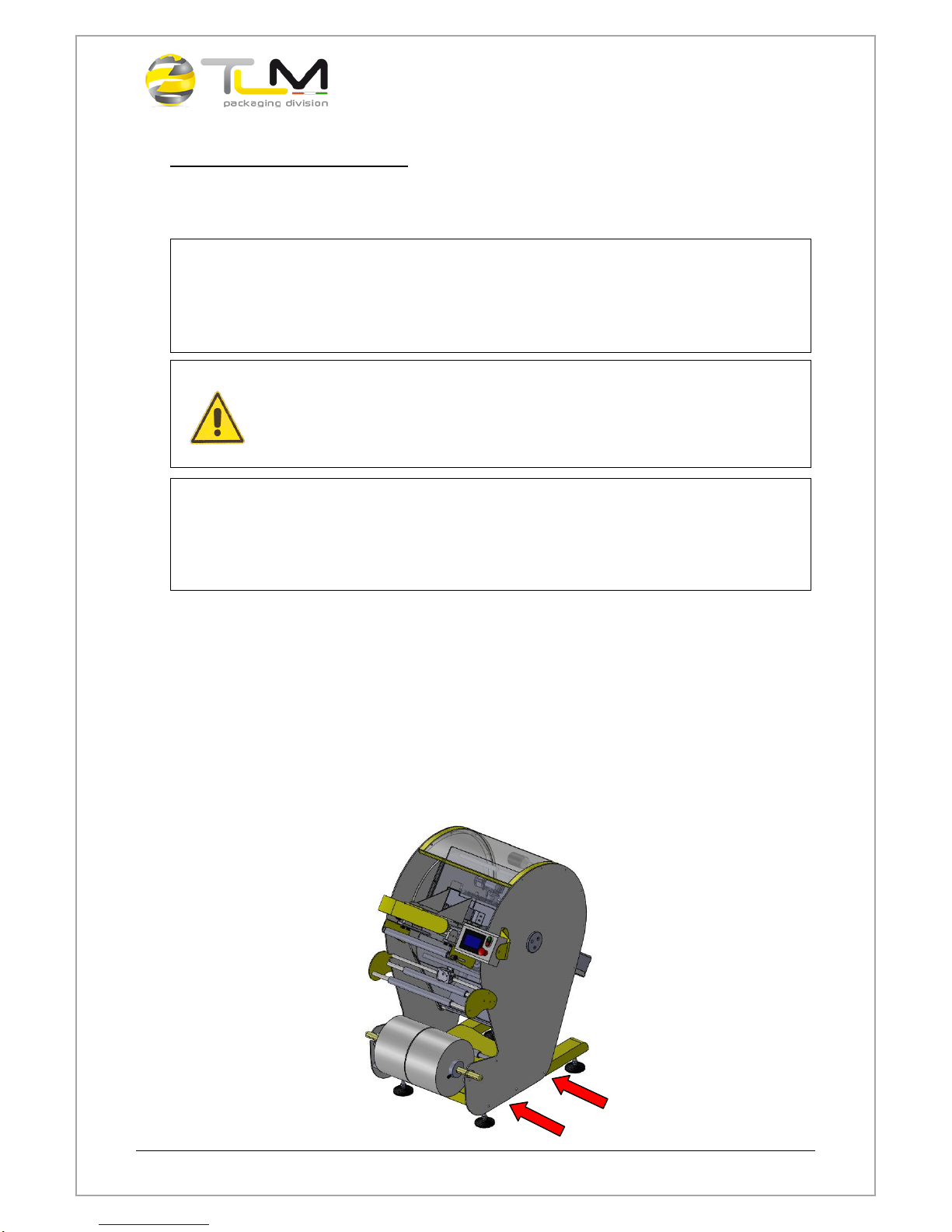

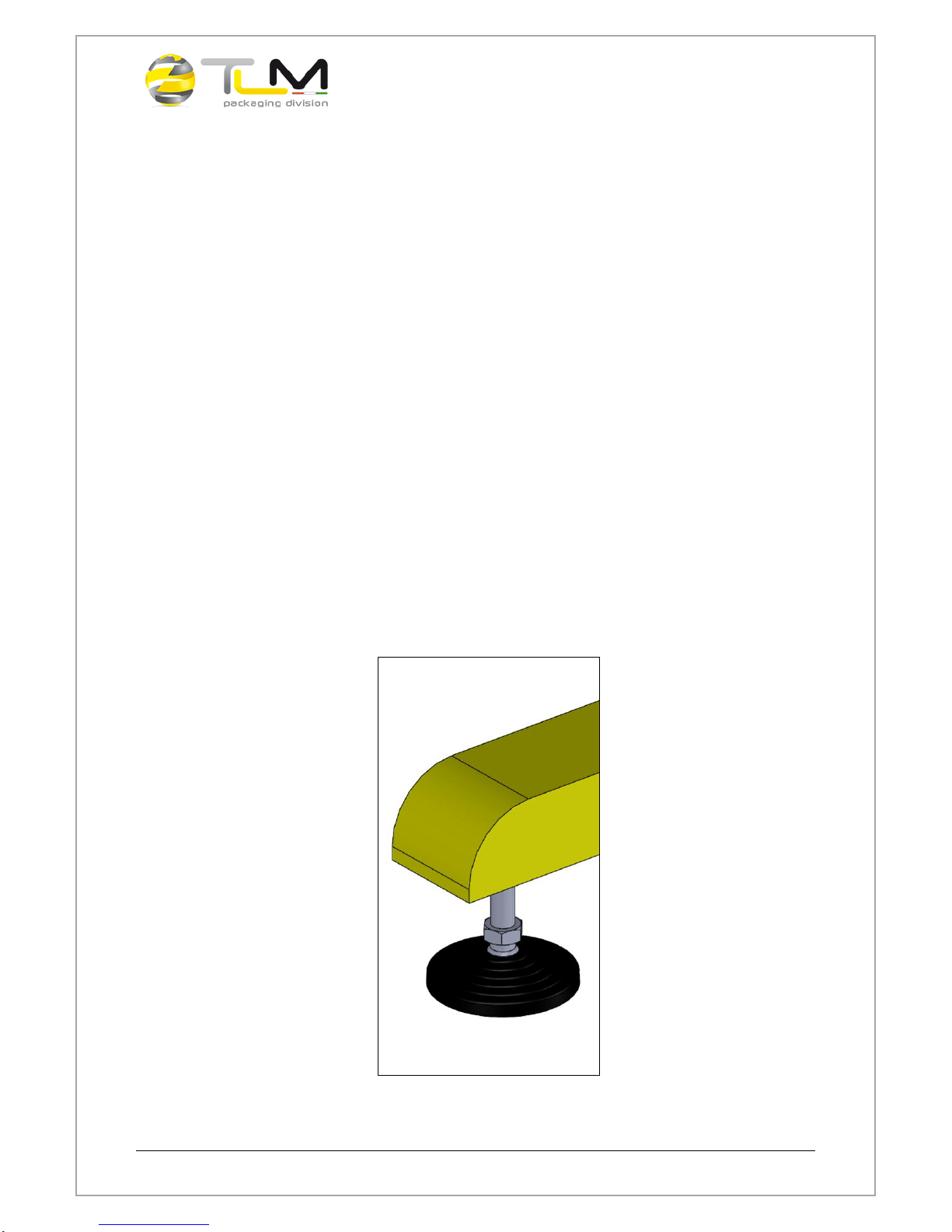

9. INSTALLATION

The machine that this manual refers to is installed in a workshop environment.

For the purpose of making installation possible, the floor on which the equipment

is to be placed must be checked to make sure it is flat and solid. To get the best

results in the production cycle, the floor must not be subject to vibrations. It is

advisable to make preliminary study in such a way as to optimise the accessibility

to the machine so as to be able to:

Carry out the installation,

Obtaining the spaces for manoeuvre,

Carrying out Use and Maintenance interventions

To check the exact levelling of the machine proceed as indicated below:

Place the bubble level on the machine plan.

Check the levelling eventually insert specifics thickness

Complete the operation by pulling the fastening nuts in order that the machine

stand uniformly on the floor.

Use and Maintenance Handbook –Prime 400 Packaging Machine

Page 20 of 71

10. SAFETY

The machine responds to the essential safety requisites conforming with what

has been described in Appendix 1 of the Machine Directive 2006/42/EC. In this

chapter all the possible risks that the machine in question might present including

in environmental and air and water pollution terms are considered.

CAUTION

THE MACHINE IS SUPPLIED WITH PERIMETRIC PROTECTIONS AND SAFETY

DEVICES, IN ORDER TO PACKAGE PRODUCTS FROM VARIOUS SECTORS,

INCLUDING FOOD SECTOR, INTO SPECIFICS BAGS.

THE MACHINE, AS PLANNED BY ITS INTENDED USE, IS REALIZED TO RUN WITH

THE PROTECTIONS AND THE SAFETY DEVICES ACTIVED AND INSTALLED.

TO THE USER: IT’S ABSOLUTELY PROHIBITED ALTERING OR TAMPERING THE

MACHINE, EVEN PARTIALLY, IF NOT AGREED UPON BY THE CONSTRUCTOR; IN

CASE OF NON-COMPLIANCE WITH THIS RULE, THE CONSTRUCTOR CANNOT BE

HELD RESPONSIBLE

CAUTION

DO NOT USE OR CARRY OUT INTERVENTIONS ON THE UNIT BEFORE READING THIS

INSTRUCTION MANUAL.

!

CAUTION

ADHERE TO THE SAFETY INSTRUCTIONS IN THIS MANUAL.

!

CAUTION

IT’S PROHIBITED TO USE THE MACHINE FOR ANY OTHER THINGS THAN THE ONE

INDICATED IN THIS MANUAL.

!

CAUTION

THE MANUFACTURER DOES NOT ASSUME ANY LIABILITY IN THE CASE OF

FAILURES, PROBLEMS OR INJURIES DUE TO THE NON-COMPLIANCE WITH WHAT IS

SET FORTH IN THIS MANUAL

!

CAUTION

THE DANGERS FOR THE PERSONNEL WORKING ON THE MACHINE CAN ONLY BE

ELIMINATED IF IT IS PROPERLY USED AS INDICATED IN THIS DOCUMENT, BY

SKILLED PERSONNEL WITH PROPER TECHNICAL TRAINING.

Table of contents

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual