Highlight Synergy 0.5 User manual

SYNERGY 0.5

LOW PROFILE

TURNTABLE STRETCH

WRAPPER

SERIAL NUMBER

Please refer to the serial number in all correspondence with Highlight or

any Highlight Distributor. This identifies your machine and will help in

our ability to quickly and efficiently respond to your needs.

OPERATION MANUAL NUMBER: SYN0.5LPSTD2013 / JULY-2015 / JAN-2019

Operation Manual

Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 1

Table of Contents............................................................................................................. 1

Table of Figures................................................................................................................ 2

General Information........................................................................................ 3

Safety Messages.............................................................................................................. 4

Introduction and Warranty ................................................................................................ 6

Revision History................................................................................................................ 8

Specifications.................................................................................................. 9

Specifications ................................................................................................................. 10

System Overview Prints.................................................................................................. 11

Installation & Adjustments............................................................................. 12

Machine Placement........................................................................................................ 13

Machine Set-Up.............................................................................................................. 14

Frequency Drive Adjustments......................................................................................... 15

Pre-Operation Adjustments ............................................................................................ 26

Load Compression Testing............................................................................................. 27

Optional Scale Package ................................................................................................. 28

Operation Instructions................................................................................... 31

Film Loading................................................................................................................... 32

Machine Operating Instructions...................................................................................... 33

Film Cutting .................................................................................................................... 34

Maintenance................................................................................................. 35

Preventative Maintenance.............................................................................................. 36

Maintenance Schedule................................................................................................... 38

Trouble-shooting........................................................................................... 39

Troubleshooting Guide ................................................................................................... 40

Power Problems............................................................................................................. 41

Turntable Problems........................................................................................................ 42

Technical References................................................................................... 43

Recommended Spare Parts ........................................................................................... 44

Mechanical Drawings...................................................................................................... 45

Electrical Drawings......................................................................................................... 51

Notes............................................................................................................ 54

Table of Contents

Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 2

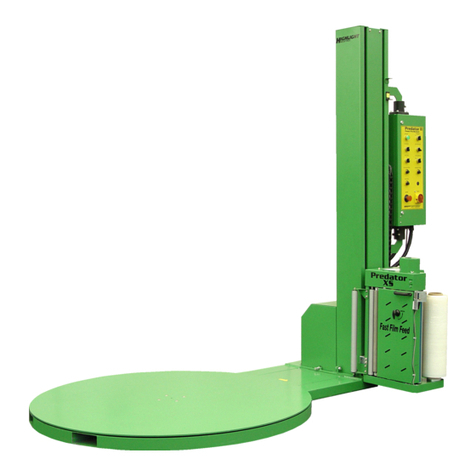

Figure 1: Synergy 0.5 Low Profile, Side View .................................................................... 11

Figure 2: Altivar 12 AC Drive Keypad................................................................................. 15

Figure 3: Film Loading/Threading Diagram........................................................................ 32

Figure 4: Top View of Package, Film Cut Location ............................................................ 34

Figure 5: Side View of Package, Film Tear Angle.............................................................. 34

Table of Figures

1

Highlight Industries, Inc.

Synergy 0.5 Turntable Stretch Wrapper Operation Manual

General

Information

General

Information Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 4

For the best result with the Synergy Turntable Stretch Wrapper, carefully read this manual

and all of the warning labels attached to the equipment before installing and operating it,

and follow instructions exactly. Keep this manual for machine reference.

Definitions and Symbols

High Voltage!

This symbol indicates high voltage. It calls your attention to items or

operations that could be dangerous to you or other persons operating

the equipment. Read the message and follow the instructions carefully.

Warning!

This symbol indicates a potentially hazardous situation which, if not

avoided, can result to bodily injury, or serious damage to the product.

Notes

This symbol indicates an area or subject of special merit, emphasizing

the equipment’s capabilities, common errors in operation or

maintenance, or other special instructions that can provide benefits to

users.

Safety Messages

General

Information Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 5

General Precautions –Read These First!

High Voltage!

Disconnect AC input power before checking components, performing

maintenance, cleaning up, and when the machine is not in use. Do NOT

connect or disconnect wires and connectors while power is applied to circuit.

High Voltage!

Wiring work should be carried out only by qualified personnel. Otherwise, there

is a danger of electric shock or fire.

High Voltage!

The user is responsible for conforming to all applicable code requirements with

respect to grounding all requirements. Do NOT use extension cords to operate

the equipment.

High Voltage!

Motor control equipment and electronic controllers are connected to hazardous

line voltages. When servicing drives and controllers, there may be exposed

components with housings or protrusions at or above line potential. Extreme

care should be taken to protect against shock.

Warning!

Loose clothing must NOT be worn while the machine is in operation. Stay clear

of moving parts while the machine is running.

General

Information Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 6

Introduction

Thank you for your purchase of a Synergy 0.5 Turntable Stretch Wrapper! Designed for the

high volume industrial user the Synergy 0.5 offers the flexibility to precisely adjust the level

of film stretch to match the load-holding requirements.

Limited Warranty

Highlight Industries, Inc. warrants its Synergy manufactured by it, and sold pursuant to this

order, will be of merchantable quality, free from defects in material and workmanship as

determined at the date of shipment, by generally recognized, applicable and accepted

practices and procedures in the industry, for a period of three (3) years from the Highlight

invoice date, under normal use and service.

When the Purchaser gives Highlight written notice of any alleged defect within the

applicable warranty period, Highlight will, at its option repair or replace the same free of

charge F.O.B. its manufacturing plant, installation not included. Equipment replaced under

the warranty shall have the same warranty as new equipment but does not extend the

warranty of the original equipment.

Satisfaction of this warranty, consistent with other provisions herein, will be limited to the

replacement or repair or modification of, or issuance of a credit for, the equipment involved,

at Highlight’s option.

Highlight neither assumes nor authorizes any person to assume for it any other obligation

in connection with the sale of Highlight’s equipment.

This warranty shall not apply to any equipment which has been repaired or altered by un-

authorized personnel in any way so as to, in the judgment of Highlight, affect serviceability,

or which has been subjected to misuse, negligence, accident, or to equipment made by

Highlight which has been operated in a manner contrary to Highlight’s instructions.

In no event regardless of the cause, shall Highlight be liable for penalties or penalty clauses

of any description or any damages resulting from loss of profits, use of products or for any

incidental indirect or consequential damages, even if advised of the possibility of such

damages. This limitation of Highlight’s liability will apply regardless of the form of action,

whether in contract or tort, including negligence. Any action against Highlight must be

brought within twelve (12) months after cause of action accrues.

“This warranty in lieu of all other warranties whether expressed, implied or statutory

including implied warranties of merchantability of fitness or extends only to the buyer or

customer purchasing from Highlight Industries, Inc or an authorized distributor.”

Introduction and Warranty

General

Information Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 7

About This Document

The purpose of this manual is to provide you with information necessary to install, operate,

troubleshoot, and maintain the Synergy Turntable Stretch Wrapper. The audience for this

manual should have basic knowledge of mechanical and electronic components, standard

electrical wiring practices, and schematics symbols.

To guarantee safe operation of the equipment, carefully observe the safety messages

throughout this manual. Keep this operating manual and distribute it to all users for

reference.

Application Assistance

If any assistance is desired, contact the distributor from whom you have purchased the unit,

or call the number listed on the bottom of each page of this manual. To receive quick and

proper technical support for the equipment you have purchased, please be prepared to

provide the following information:

1. Machine Serial Number

2. Date of Purchase

3. Symptoms of any problems

General

Information Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 8

Revision

Revision Comment

Date of Revision

Initial Release

April 2011

Updated turntable drawing –ref 2008

Oct 2013-RDU

Updated Film Diagram

July 2015-WBK

Tension Knob Assembly added

Jan 2019-JMR

Revision History

2

Highlight Industries, Inc.

Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Specifications

Specifications Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 10

Machine Dimensions

Low Profile

Length (inch)

95

Width (inch)

60

Turntable Height from Floor (inch)

3.25

Operation Space (inch)

105 L x 75 W

Maximum Pallet Size (inch)

52 x 52

Shipping Weight (lbs)

1000

Electrical Specifications

120VAC, 60Hz, Single Phase, 15Amp

NEMA 12 Rated Electrical Enclosure

Off the Shelf Components

Turntable

4,000 lbs Maximum Turntable Load Capacity

12 RPM Maximum Turntable Speed

1/2 HP 3-Phase AC Motor

1/2 HP AC Frequency Drive

Specifications

Specifications Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 11

Note

Shown below are STANDARD assembly drawings. It may not reflect your

purchased system, especially when optional items are added. Refer to the

Technical References section of the manual for more detailed information.

Figure 1: Synergy 0.5 Low Profile, Side View

System Overview Prints

3

Highlight Industries, Inc.

Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Installation &

Adjustments

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 13

Receiving and Inspections

The Synergy Turntable Stretch Wrapper has gone through quality control tests at the

factory before shipment. Upon receiving, please do the following:

1. Inspect the entire machine for visual damage during shipment. If found, immediately

report this damage to the trucking line. Highlight Industries, Inc. has taken every

precaution during the packaging and loading of this equipment, however, it is YOUR

RESPONSIBILITY to inspect for damage before installation.

2. Make sure the part or serial number indicated on the machine corresponds with the

part number of your order.

Positioning of the Machine

Place the Synergy Turntable Stretch Wrapper close to an area where you will be wrapping

your loads. Make sure that there is sufficient room to load/unload the machine and that you

do not stretch the power cable. Remember, you will need to plug the machine in to a

120VAC, 15-Amp outlet.

Floor Weight Bearing/Stress Tolerance

The floor must be able to bear the weight of the machine, the weight of the maximum load,

plus a safety factor. The floor must also be able to tolerate the stress of the machine’s

operation. If the fork trucks will operate on the same weight bearing area, add the weight of

the trucks to the weight bearing stress tolerance requirements.

The Synergy can be installed on any type of floor constructions that meets the weight

bearing and stress tolerance requirements.

Warning!

The Synergy must be anchored securely to the floor, using the type of anchor

recommended for your floor.

Machine Placement

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 14

Unpacking and Moving the Machine

It is very important to read all instructions before undertaking any of these steps. The

following steps should help achieving a safe and quick machine set-up.

1. Place the skidded machine close to the designated wrap area. Remove all shipping

fasteners holding the machine to the pallet.

2. Place the forks of the forklift through the tubes provided on the base of the machine,

remove the machine from the shipping skids, and place it in the designated wrap

area.

Warning!

It is very important that the machine be leveled. Uneven floors will cause

premature turntable support roller failure.

Power and Control Wiring Checks

1. Using a volt meter, check the AC voltage coming to the machine and insure the

proper voltage is present.

2. Plug the machine in and turn the Power Switch ON. Power should now be applied to

the AC frequency drives.

Machine Set-Up

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 15

An AC Frequency Drive is a device that controls the 3-phase AC motor’s speed by varying

the frequency and voltage sent to the motor. The Synergy Turntable Stretch Wrapper uses

Schneider Electric Altivar 12 Adjustable Frequency Drives. Refer to the Electrical

Schematic Drive Parameters Technical References section for detailed drive parameter

settings. Refer to the drive manufacturer’s manual provided on their CD provided with this

machine for more detailed drive information.

Altivar 12 Digital Keypad Description

The digital keypad includes the displays panel and the keypad. The display panel provides

the parameter display and shows the operation status of the AC drive. The keypad provides

programming and control interface.

Figure 2: Altivar 12 AC Drive Keypad

Keypad Description:

1. Value LED. When illuminated it indicates when a numeric value is being displayed.

2. Charge LED. When illuminated it indicates when drive capacitors are fully charged.

Frequency Drive Adjustments

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 16

3. Unit LED. When illuminated it indicates when a unit, such as AMPS, is being

displayed.

4. ESC button. Exits a menu or parameter, or aborts the displayed value and returns to

the previous value in the memory.

5. STOP button. Stops the motor. The run command will have to be cycled before the

motor will be allowed to run again.

6. RUN button. Starts running the motor if the drive is configured for control by the

drive keypad.

7. Jog Dial. Used for navigation of the menus. Turn clockwise or counterclockwise to

scroll through the menu list and is used for selection/validation when the dial is

pressed.

8. MODE button. Switches between the control/programming modes.

9. CONFIGURATION mode LED. When illuminated it indicates when a value can be

changed.

10.MONITORING mode LED. When illuminated it indicates when the display is

monitoring the current status of the drive.

11.REFERENCE mode LED. When illuminated it indicates when the display is showing

the speed reference value.

12.Four 7-Segment displays. The display of the drive for menus and settings.

Menu Structure

To access the monitoring parameters, press the wheel on the

face of the frequency drive. Using the wheel, scroll through the

menu until the display shows Non (Mon) for monitoring mode.

This gives the user access to all the monitoring parameters.

To access the complete set of drive parameters first press the wheel to access different

modes. Using the wheel, scroll to “COnF” and press the wheel again; this will access

different sets of parameters. Using the wheel, scroll to “FULL” and press the wheel; this will

give the user access to the complete parameter set.

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 17

Monitoring Parameters

Code

Name/Description

Unit

LFr

External reference value:

External keypad or local force mode configured. Forced local reference

FLOC page 61 set to LCC and Forced local assignment FLO page 61

different to nO.

Displays the speed reference coming from the remote keypad. This

value is not visible in factory setting.

Hz

rFr

Output Frequency:

This function provides the estimated motor speed. It corresponds to the

estimated motor frequency (on the motor shaft). In Standard law the

Output frequency rFr is equal to stator frequency. In Performance law

the Output frequency rFr motor speed is equal to the estimated motor

speed.

Range: -400 to 400 Hz

Hz

LCr

Motor Current:

Estimation of the effective motor current from phase current

measurements with an accuracy of 5%. During DC injection, the current

displayed is the maximum value of current injected in the motor.

A

ULn

Main Voltage:

Line voltage from the point of view of the DC bus, motor running or

stopped.

A

StAt

Product Status:

rdY –Drive Ready

rUn –Drive Running

ACC –Acceleration in progress

dEc –Deceleration in progress

dCb –DC injection braking in progress

CLi –Current limit

nSt –Freewheel stop control

Obr –Auto-Adapted deceleration

CtL –Controlled stop on mains phase loss

tUn –Auto-tuning in progress

FSt –Fast stop active

nLP –No line power

N/A

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 18

Programming Functions

All functions have been Highlight factory set and tested. The factory settings listed in this

manual are the drive manufacturer’s factory setting, not the Highlight Industries factory

settings. Refer to the Electrical Schematic Drive Parameters page of the Technical

References section for the Highlight factory settings. Some of the most commonly adjusted

programmable functions (parameters) are listed below.

Note

Refer to the drive manufacturers Operation Manual or website for complete lists

and explanations of the programming parameters.

I_O Menu

Code

Sub-

Code

Name/Description

Factory

Setting

tCC

Type of Control:

2C –2-wire control

3C –3-wire control

2C

AI1-

AI1t

Analog Input 1 Type:

5U –0-5VDC input voltage

10U –0-10VDC input voltage

0A –0-20mA current input

5U

r1

Relay Output 1 Assignment:

nO –Not assigned

FLt –No error detected

rUn –Drive run

FLt

AO1-

AO1

Analog Output 1 Assignment:

nO –Not Assigned

OCr –Motor current

OFr –Output Frequency

nO

AO1t

Analog Output 1 Type:

10U –0-10VDC

0A –0-20mA

4A –4-20mA

0A

Installation & Adjustments Synergy 0.5 Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW,Wyoming, Mi 49519 ● 1-800-531-2465 19

drC Menu

Code

Sub-

Code

Name/Description

Adjustment

Range

Factory

Setting

bFr

Standard Motor Frequency

50/60

50 Hz

nPr

Rated Motor Power (% of drive rated HP)

0.5-1.2

1

UnS

Rated Motor Voltage

100-480V

230V

nCr

Rated Motor Current

plate

Varies

FrS

Rated Motor Frequency

10-400Hz

50 Hz

nSP

Rated Motor Speed

0-24000rpM

Varies

tFr

Maximum Frequency

10-400Hz

72 Hz

Ctt

Motor Control Type:

PErF –Performance, Sensorless Vector

Std –Standard, Volts/Hertz

PUNP –Pump, low torque

Std

UFr

IR Compensation:

Optimizes torque at very low speeds

25-200%

100%

SLP

Slip Compensation

0-150%

100%

StA

Frequency Loop Stability:

Adjusts overshoots and oscillations at the end

of acceleration or deceleration. A higher

number decreases oscillations

0-100%

20%

FLG

Frequency Loop Gain:

Adjusts the slope of the speed increase. A

lower number decreases oscillations.

0-100%

20%

tUn

Motor Auto Tuning:

Automatically tunes the drive to the motor

profile

nO/YES/dOnE

nO

Table of contents

Other Highlight Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

EC-PACK

EC-PACK EC-JET 2000 manual

Fimap

Fimap FV9+ B Use and maintenance manual

SCHÜTZ

SCHÜTZ ECOBULK WITH IMPELLER operating manual

NEUBRONNER

NEUBRONNER ALPHA X1-400 operating manual

Minipack-Torre

Minipack-Torre SC55 Installation, operation and maintenance

Audion Elektro

Audion Elektro Sealmaster MAGNETA MG 300 Instructions for use

SealerSales

SealerSales FS-205 operating instructions

Promax

Promax DC-800-P-H Operation manual

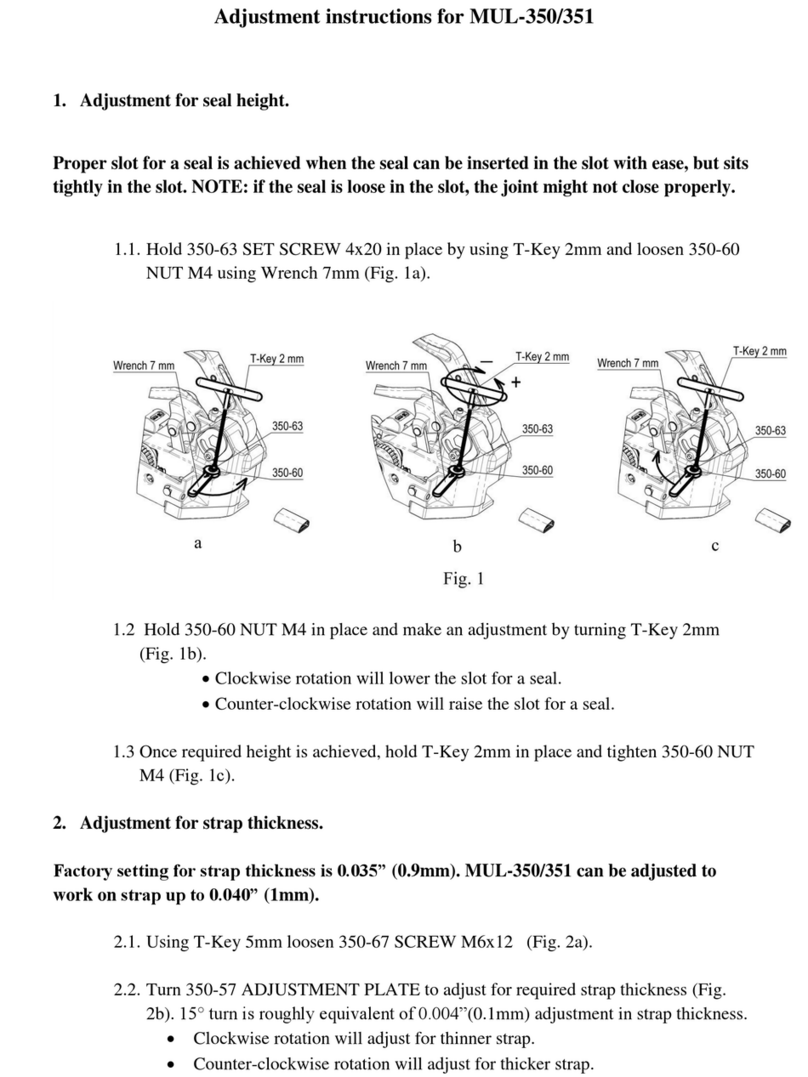

Teknika

Teknika MUL-350 Adjustment instructions

Advanced Poly-Packaging

Advanced Poly-Packaging Advanced Poly-Bagger T-1000 Operation guide

U-Line

U-Line Green Machine H-3518 instructions

Sealed Air

Sealed Air Fill-Air Rocket user guide