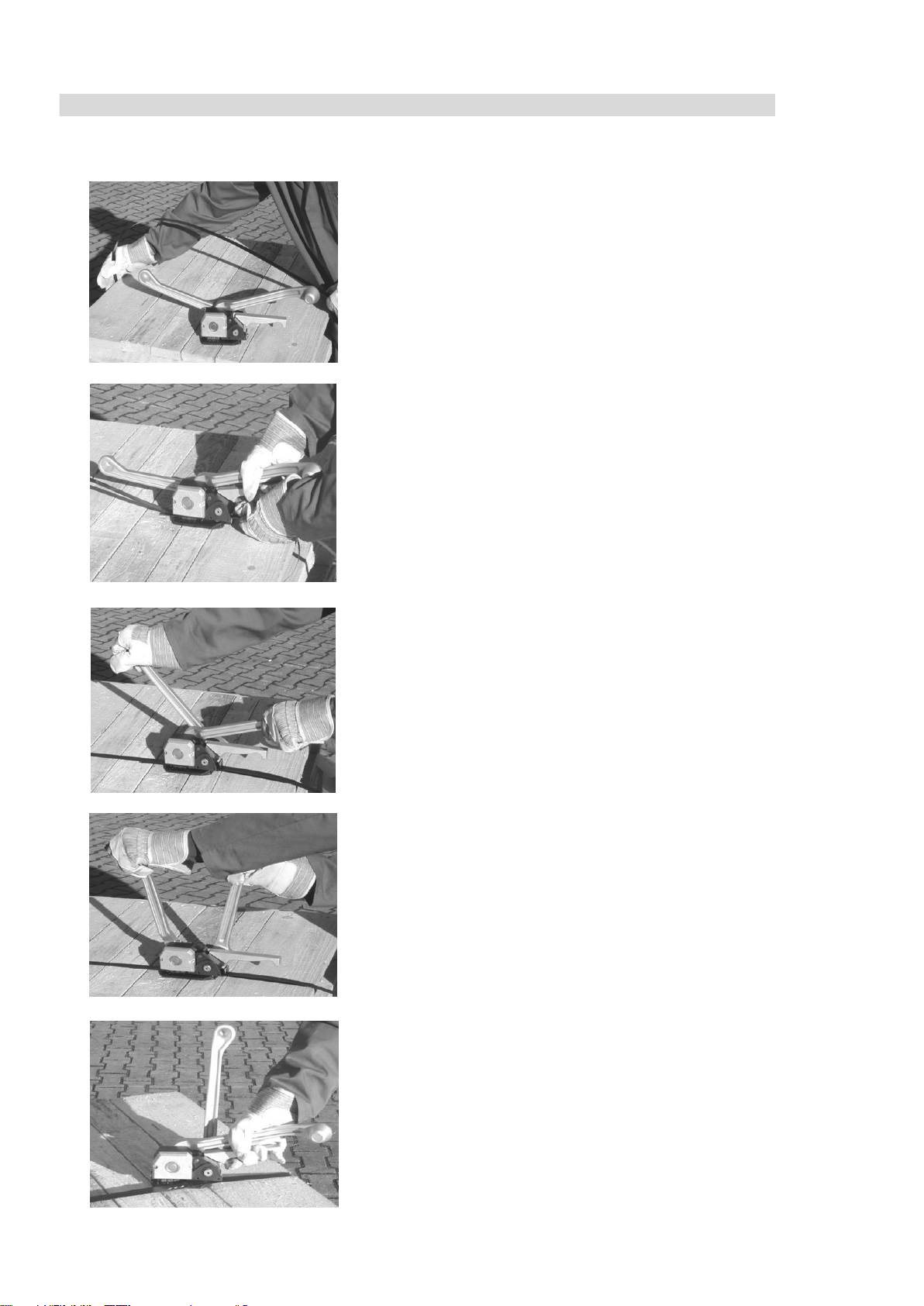

Dirt and chaff hamper the proper functioning of the tool.

For this reason the following areas should be cleaned once a week (blow off using compressed

air if possible):

-insertion slot,

-cavities between the upper and lower jaws,

-tensioning wheel,

-gripper plate.

Lubricate with fine conventional spray oil afterwards.

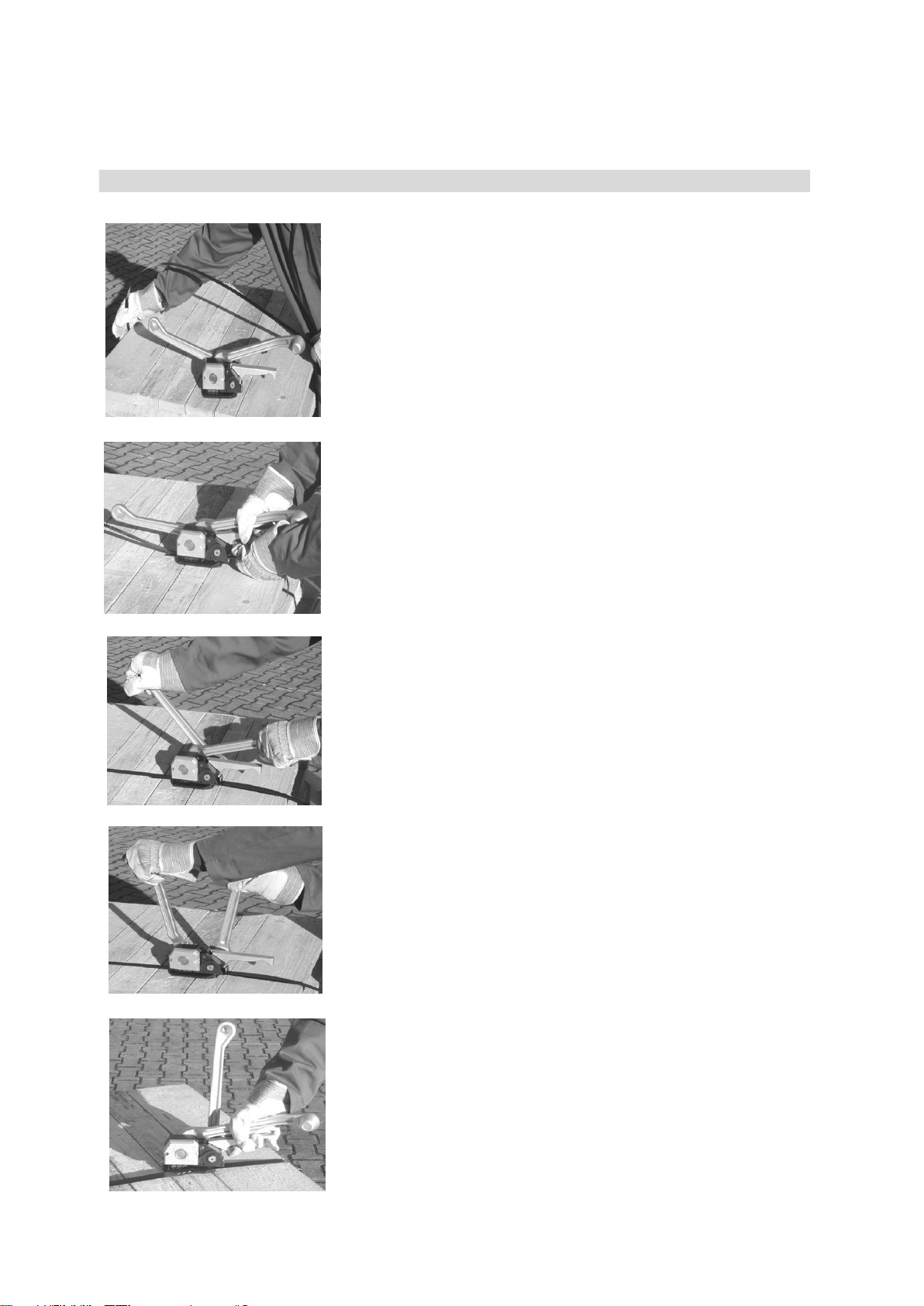

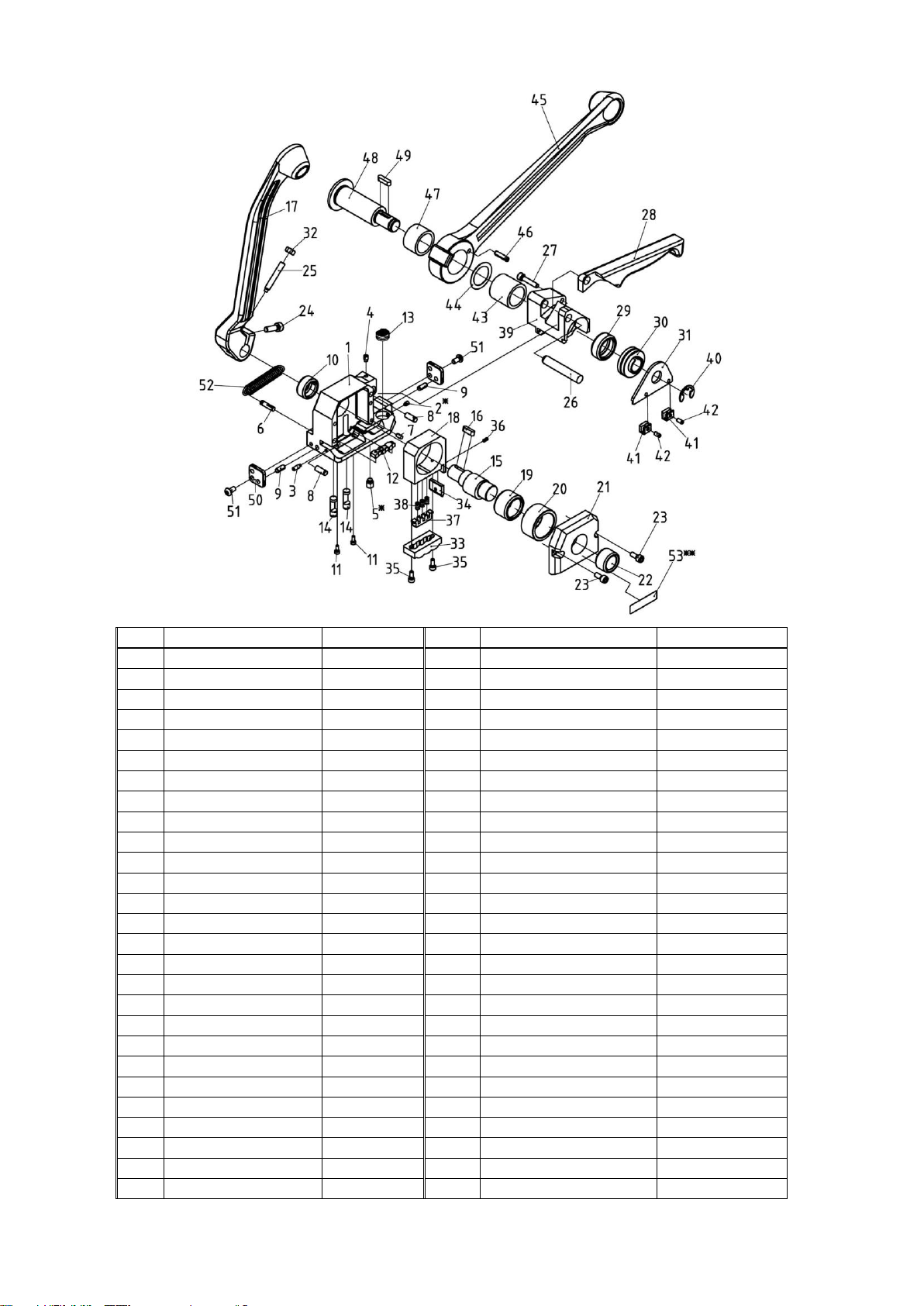

The correct strap width is set at item 31. For this purpose the safety

disc item 40 is to be removed with a screw driver, thereafter the feed

shaft item 48 is to be pushed back to make the strap guide accessible.

Compress lever item 28 and cutting lever item 17 and pull off the strap

guide. Provide the strap guide with the relevant 2 strap width spacers

item 41 such as shown on the sketch. For 13 mm strap the 3mm spacers,

for 16 mm the 2mm side point inside the tool, and for 19 mm strap no

spacer item 41 at all is required. After fitting the spacers the strap

guide is to be mounted again. Slip on safety disc item 40.As the strap

is being guided at three points in the tool, additionally the front and rear

strap guides item 50 are to be set to the correct strap widths. For this

purpose unscrew oval head screws of front and rear strap guides items 50,

remove strap guides, set the relevant widths (on the front sides the strap widths 13, 16,19

have been engraved.). Remount the strap guides in such a way that the engraved

widths point to the strapping.

Distance between the feed wheel and the

gripper plate

The cutter has to be adjusted for the respective

thickness in the case of varying strap

thicknesses.

Release lock nut item 32. Turn stop screw item

25 (set screw with flat point) by means of a

socket spanner in clockwise direction = less

cutting depth; counter-clockwise = greater

cutting depth. Fasten locknut item 32 after

adjustment has been completed.

Note: After adjustment there should not be any,

or very few, signs of cutting on the lower strap.

The distance between tension wheel item 30

and gripper plate item 13 is set in our factory to

0,2 mm. The thread pin item 5 is secured with

Loctite 242. After replacing the tension wheel or

the gripper plate, the distance has to be

checked and possibly to be readjusted by

means of the thread pin. Then, the thread pin

has to be secured again with Loctite 242.

Note: The feed wheel and the gripper plate

must not come into contact with each other,

otherwise both parts will be subject to

premature wear