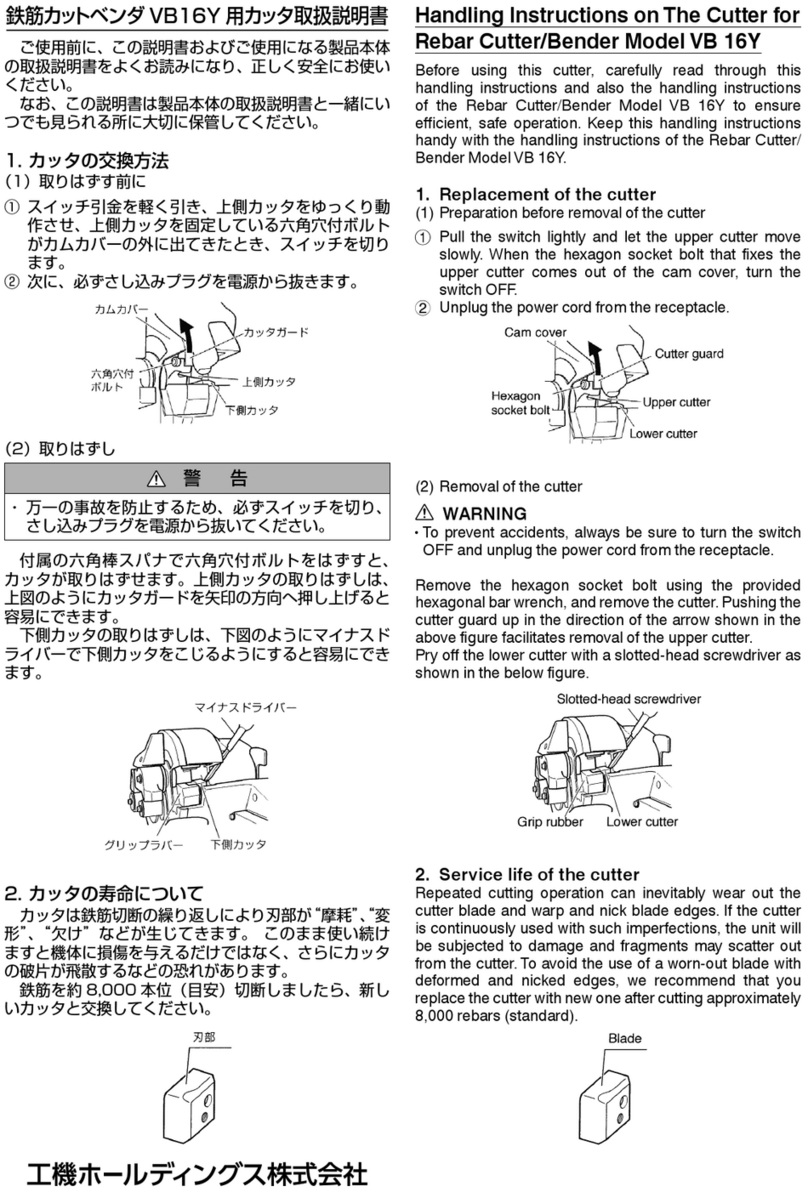

HIKOKI CM 4SB2 User manual

Other HIKOKI Cutter manuals

HIKOKI

HIKOKI CL 14DSL User manual

HIKOKI

HIKOKI CM 75EAP User manual

HIKOKI

HIKOKI CF 18DSL User manual

HIKOKI

HIKOKI CL 14DSL User manual

HIKOKI

HIKOKI CL 14DSL User manual

HIKOKI

HIKOKI CL 14DSL User manual

HIKOKI

HIKOKI CM 5SB User manual

HIKOKI

HIKOKI CL 14DSL User manual

HIKOKI

HIKOKI BENDOF DC-16MV User manual

HIKOKI

HIKOKI CD 1805DB User manual

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual