Hillrom Liko Multirall 200 User manual

Product Descripon

In this document, the person being lied is referred to as the paent, and the person helping is referred to as the caregiver.

Mulrall™ 200

Overhead li

Instrucons for Use

LikoTM MulrallTM 200 overhead li Prod. No. 3130001

7EN125103 Rev. 13

ENGLISH 2020

g. 2g. 1

Mulrall™ 200 overhead li is a general-purpose li

with the intended use in; health care, intensive care and

rehabilitaon. Mulrall 200 overhead li is easy to move

between facilies and useful for room-to-room transions.

Mulrall™ 200 overhead li can be mounted to the

rail carriage in two dierent ways;

- mounted with the li strap under the li unit (g. 1), or

- mounted with the li strap above the li unit (g. 2).

Intended for use in all common li and transfer situaons,

for example, between bed/wheelchair, to/ from oor,

toilet visits, gait training, and for horizontal lis with

stretchers.

Accessories

The Liko™ product range includes several sling models

in many sizes and dierent designs. Also available as an

accessory is a praccal trolley for transfer and storage

of the li, as well as an Extension Arm, for use when

connecng the listrap to the rail carriage.

Mulrall™ 200 overhead li is adapted to LikoTM Quick

Release System for safe and easy changing of liing

accessories.

Multirall

Multirall

Multirall

Multirall

IMPORTANT!

Liing and transferring a paent always involves a certain level of risk. Read the instrucons for use for both the paent li and

liing accessories before use. It is important to completely understand the contents of the instrucons for use. The equipment

should only be used by trained personnel. Ensure that the liing accessories are suitable for the li used. Exercise care and cauon

during use. As a caregiver, you are always responsible for the paent’s safety. You must be aware of the paent’s ability to make it

through the liing situaon. If something is unclear, contact the manufacturer or supplier.

2

7EN125103 Rev. 13 • 2020 www.hillrom.com

Table of Contents

Symbol Descripon .......................................................................................................................... 3

Safety Instrucons ........................................................................................................................... 4

Denions ....................................................................................................................................... 5

Technical Data ................................................................................................................................... 5

Dimensions ......................................................................................................................................... 6

EMC Table ......................................................................................................................................... 6

Assembly .......................................................................................................................................... 10

Operaon ......................................................................................................................................... 15

Charging the Baeries ...................................................................................................................... 17

Room-to-Room transfer ..................................................................................................................... 18

Maximum Load ................................................................................................................................. 20

Recommended Liing Accessories ...................................................................................................... 20

Simple Troubleshoong ..................................................................................................................... 23

Recycling Instrucons ........................................................................................................................ 24

Cleaning and Disinfecon .................................................................................................................. 24

Inspecon and Maintenance ............................................................................................................. 28

3

7EN125103 Rev. 13 • 2020 www.hillrom.com

Symbol Descripon

These symbols can be found in this document and/or on the product.

Symbol Descripon

For indoor use only.

The product has extra protecon against electric shock (Insulaon Class II).

Protecon level against electric shock Type B.

Warning; this situaon requires extra care and aenon.

Read instrucons for use before use.

CE-mark.

IP N1 N 2 Protecon level against: ingress of solid objects (N1) and ingress of water (N2).

Legal Manufacturer.

Date of manufacture.

Cauon! consult instrucons for use.

Read instrucons for use before use.

Baery.

,

Pb

,

All baeries in this product must be recycled separately.

- Pb underneath the symbol indicate baeries containing lead

- Single Black line underneath the symbol indicate this product have been placed on the market aer 2005.

UL Recognized Component Mark for Canada and the United States.

EFUP, Environmental Friendly Usage Period (years).

Environmentally-friendly product which can be recycled and reused.

The Australian Safety/EMC.

PSE Mark (Japan).

Product Idener.

Serial Number.

Medical Device.

Recyclable.

The safety and essenal performance of medical electrical equipment.

Proof of Product compliance to North American safety standards.

Non-ionizing electromagnec radiaon.

X%

Y% ≤Tmin

Duty cycle for non-connuous operaon.

The maximum acve operaon me X% of any given me unit, followed by a deacvaon me, Y%.

The acve operaon me shall not exceed the specied me in minutes, T.

(01) 0100887761997127

(11) Y Y MM D D

(21) 012345678910

GS1 Data Matrix Barcode that may contain following informaon

(01) Global Trade Item Number

(11) Producon Date

(21) Serial Number

4

7EN125103 Rev. 13 • 2020 www.hillrom.com

Safety Instrucons

No modicaon of the product is allowed.

Portable RF communicaons equipment (including peripherals such as antenna cables and external antennas) should be

used no closer than 30 cm (12 inches) to any part of the li, including cables specied by the manufacturer. Otherwise,

degradaon of the performance of this equipment could result.

Use of the product adjecent to other equipment should be avoided because it could result in improper operaon, if

such use is neccessary, observe and verify that the other equipment is operang normally.

Electromagnec disturbance, may aect the liing performance of the product. Modicaon using other parts than original

spare parts (cables etc.) may aect the electromagnec compability of the product. Parcular care must be taken when

using powerful sources of electromagnec disturbance, such as diathermy, etc, so that, for example, diathermy cables are not

posioned on or near the li.

If you have any quesons, please consult the responsible assisve device technician or the supplier.

The li is not suitable for use in the presence of ammable mixtures, for example, in areas where ammable goods are

stored.

Before liing, always make sure that:

• the li strap is not twisted or worn and can move in and out of the li freely

• the liing accessories are not damaged

• the liing accessory is correctly and safely applied to the paent in order to prevent injuries

• the liing accessories are properly aached to the li

• the liing accessories hang vercally and can move freely

• the sling bar latches are intact; missing or damaged latches must always be replaced

• the sling’s strap loops are correctly connected to the sling bar hooks when the sling straps are extended, but before the

paent is lied from the underlying surface.

Incorrect aachment of sling to slingbar may cause severe injury to the paent.

Only use the MulrallTM overhead li with a carriage, adapter, sling bar and other accessories approved by LikoTM.

Never leave a paent unaended during a liing situaon!

Before use, make sure that:

• the li is assembled in accordance with the assembly instrucons

• the liing accessories are properly aached to the li

• the baeries have been charged for at least 8 hours

• you have read the instrucon for use for the li and liing accessories

• personnel using the li are informed of the correct use of the li and liing accessories

• the liing accessory is selected appropriately, in terms of type, size, material and design with regard to the paent’s needs.

Installaon of carriages for MulrallTM overhead li shall be made by personnel authorized by LikoTM in accordance with

the installaon instrucons and recommendaons for the current li system.

Intended use

This product is not intended to be used by the paent alone. Liing and transferring a paent shall always be performed

with the assistance of at least one caregiver. This product is used as a means to perform the li but is not in contact with the

paent; therefore we do not go into the various paent condions in this instrucon for use.

Contact your Hill-Rom representave for support and advice.

Mulrall™ 200 overhead li has been tested by an accredited tesng instute

5

7EN125103 Rev. 13 • 2020 www.hillrom.com

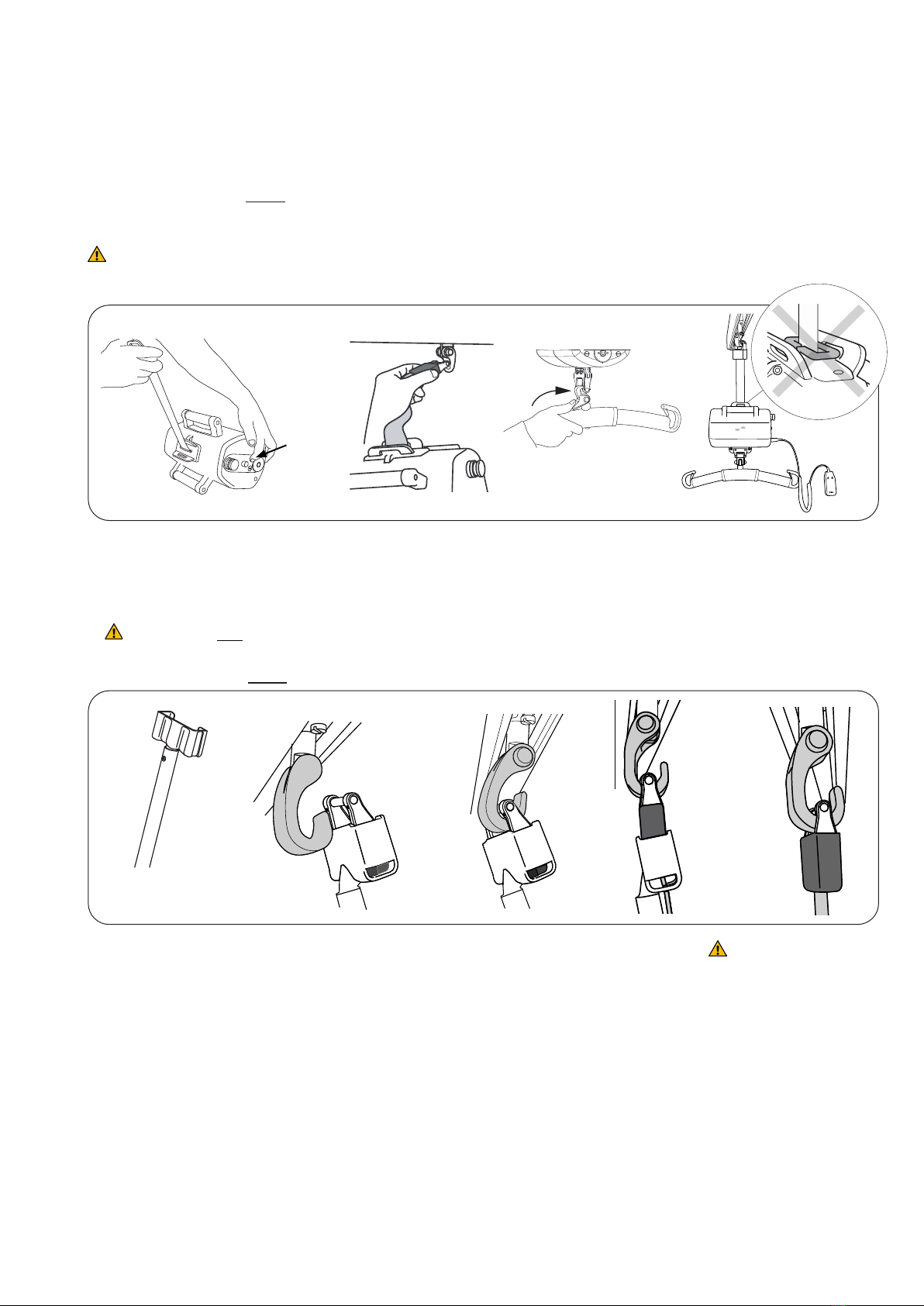

1. Carriage Hook (S65 Carriage with Single

Hook)

2. Q-Link II (quick fastener)

3. Q-Link (quick fastener)

4. Emergency stop

5. End cover

6. Mechanical Emergency Lowering

7. Electrical Emergency Lowering/Raising

8. Contact for hand control

9. Hand control

10. Hang-up HandControl Hanger

11. Sling bar

12. Latches

13. Quick-Release Hook

14. Carriage Adapter MR for S65

15. Li unit

16. Handle

17. SSP Limit Switch

18. Extension Belt connector

19. Li strap

Denions

3

6

1

8

5

7

9

4

10

Multirall

Multirall

11

13

14

16

17

18

19

15

2

12

Multirall

Multirall

Technical Data

Mulrall™ 200 overhead li is equipped with an SFS (Single Fault Safety) safety drum. This safety design provides protecon

against uncontrolled lowering. The li strap has a tenfold safety.

Component X1 (Murata CSTCC4M00G53) on PCBA contains a SVHC, Lead tanium zirconium oxide (Pb(Ti,Zr)O3), which

exceeds the limit according to REACH Regulaon.

Intermient

power:

Int. Op 10/90, acve operaon max 6 min.

Sound level: 62.2 dB(A)

Protecon class: IP 30 (li unit)

IP 43 (hand control)

Operang forces

of controls:

Buon on hand control: 4.5 N

Buon on end cover: 4 N

Surrounding

funconal

environment:

Temperature: +10°C to +40°C, (50° F to 122° F)

Humidity: 20% to 90% at 30°C non-condensing,

Atmospheric pressure: 700-1060hPa.

Intended for indoor use.

Type B, in accordance with the electrical shock protecon

class.

Class II equipment.

Maximum load: 200 kg (440 lbs)

Baeries: 2 X 12 V DC, (2.4 Ah - 2.6 Ah), Valve-regulated

lead-acid gel-type baeries. New baeries are

provided by Liko®.

Baery charger: SMP CC-10-43-24; 100-240 V AC,

40-60 Hz, max 600 m A

Liing speed: 60 mm/s (2.3 in/s)

Liing interval: 1600 mm (63 in)

Electrical data: 24 V DC, 8.5 A

Li motor weight:

8.7 kg (19 lbs)

Emergency

lowering device:

Mechanical and electrical

6

7EN125103 Rev. 13 • 2020 www.hillrom.com

Overhead

view

Lateral view

CSP (Central Suspension Point)

* Min. distance from ceiling to CSP at max. liing height.

** Installaon dimensions: the distance between the aachment point for the li unit on the carriage and the CSP at max. liing height.

*** Liing interval: the distance between max. liing height and min. liing height measured in CSP.

Measurements in mm.

C

A

B

H** D*

L***

A B CD* H** L***

264 295 210 443 308 1600

Ceiling

A B CD* H** L***

10.4 11.6 8.3 17.4 12.1 63.0

Measurements in inch.

Dimensions

Guidance and manufacturer’s declaraon – electromagnec emissions

The overhead li is intended for use in the electromagnec environment specied below. The customer or the user of the

overhead li should assure that it is used in such an environment.

”Essenal performance according to the manufacturer: The li shall not move unintenonally while being submied to

disturbances.”

Emissions test Compliance Electromagnec environment - guidance

RF emissions

CISPR 11

Group 1 The overhead li uses RF energy only for its internal funcon.

Therefore, its RF emissions are very low and are not likely to

cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class B

The overhead li is suitable for use in all establishments inclu-

ding domesc establishments and those directly connected

to the public low-voltage power supply network that supplies

buildings used for domesc purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage uctuaons/ icker emissions

IEC 61000-3-3

Complies

EMC Table

7

7EN125103 Rev. 13 • 2020 www.hillrom.com

Guidance and manufacturer’s declaraon – electromagnec immunity

The overhead li is intended for use in the electromagnec environment specied below. The custo-

mer or the user of the overhead li should assure that it is used in such an environment.

”Essenal performance according to the manufacturer: The hoist shall not move unintenonally while

being submied to disturbances.”

Immunity test IEC 60601 test level Compliance level Electromagnec

environment - guidance

Electrostac discharge

(ESD)

IEC 61000-4-2

+/- 6 kV contact

+/- 8 kV air

+/- 6 kV contact

+/- 8 kV air

Floors should be wood, concrete or

ceramic le.

If oors are covered with synthec

material,

the relave humidity should be at

least 30 %.

Electrical fast

transient / Burst

IEC 61000-4-4

+/- 2 kV for power supply

lines

+/- 1 kV for input/output

lines

+/- 2 kV for power supply

lines

+/- 1 kV for input/output

lines

Mains power quality should be that

of a typical commercial or hospital

environment.

Surge

IEC 61000-4-5

+/- 1 kV Line to Line

+/- 2 kV Line(s) to Earth

+/- 1 kV Line to Line

+/- 2 kV Line(s) to Earth

Mains power quality should be that

of a typical commercial or hospital

environment.

Voltage dips, short

interrupons and

voltage variaons on

power supply input lines

IEC 61000-4-11

<5 % UT

(>95 % dip in UT)

for 0,5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

<5 % UT

(>95 % dip in UT))

for 5 sec

<5 % UT

(>95 % dip in UT)

for 0,5 cycle

40 % UT

(60 % dip in UT)

for 5 cycles

70 % UT

(30 % dip in UT)

for 25 cycles

<5 % UT

(>95 % dip in UT))

for 5 sec

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of the

[Equipment or System] requires

connued operaon during power

mains interrupons, it is recom-

mended that the [Equipment or

System] be powered from an unin-

terrupble power supply or baery.

Power frequency (50/60

Hz) magnec eld

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnec elds

should be at levels characterisc

of a typical locaon in a typical

commercial or hospital environ-

ment

NOTE UT is the a.c. mains voltage prior to applicaon of the test level.

8

7EN125103 Rev. 13 • 2020 www.hillrom.com

Guidance and manufacturer’s declaraon – electromagnec immunity

The overhead li is intended for use in the electromagnec environment specied below. The custo-

mer or the user of the overhead li should assure that it is used in such an environment.

”Essenal performance according to the manufacturer: The hoist shall not move unintenonally while

being submied to disturbances.”

Immunity test IEC 60601 test level Compliance level Electromagnec environment - guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

10 V/m

80MHz to 2,5GHz

3 Vmrs

10 V/m

Portable and mobile RF communicaons

equipment should be used no closer to any

part of the overhead li, including cables,

than the recommended separaon distance

calculated from the equaon applicable to the

frequency of the transmier.

Recommended separaon distance

Pd 2,1=

P

d2,1=

d = 0,35 80 MHz to 800 MHz

Pd 7,0=

800 MHz to 2,5 GHz

where P is the maximum output power rang

of the transmier in was (W) according to

the transmier manufacturer and d is the

recommended separaon distance in meters

(m).

Field strengths from xed RF transmiers, as

determined by an electromagnec site survey,

a should be less than the compliance level in

each frequency range. b

Interference may occur in the vicinity of

equipment marked with the following symbol.

NOTE 1 At 80MHz and 800MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situaons. Electromagnec propagaon is aected by absorpon and reected

from structures, objects and people.

a Field strengths from xed transmiers, such as base staons for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theorecally with accuracy. To

assess the electromagnec environment due to xed RF transmiers, an electromagnec site survey should be considered.

If the measured eld strength in the locaon in which the overhead li is used exceeds the applicable RF compliance level

above, the overhead li should be observed to verify normal operaon. If abnormal performance is observed, addional

measures may be necessary, such as reorienng or relocang the overhead li.

b Over the frequency range 150 kHz to 80 MHz, eld strengths should be less than 10 V/m.

9

7EN125103 Rev. 13 • 2020 www.hillrom.com

Recommended separaon distances between portable and mobile RF communicaons

equipment and the overhead li

The overhead li is intended for use in an electromagnec environment in which radiated RF distur-

bances are controlled. The customer or the user of the overhead li can help prevent electromagnec

interference by maintaining a minimum distance between portable and mobile RF communicaons

equipment (transmiers) and the overhead li as recommended below, according to the maximum

output power of the communicaons equipment.

Rated maximum output

power of transmier

W

Separaon distance according to frequency of transmier

m

150 kHz to 80 MHz

Pd 2,1=

80 MHz to 800 MHz 800 MHz to 2.5 GHz

Pd 7,0=

0.01 0,12 0,035 0,07

0.1 0,38 0,11 0,22

1 1,2 0,35 0,7

10 3,8 1,11 2,21

100 12 3,5 7,0

For transmiers rated at a maximum output power not listed above, the recommended separaon distance d in meters

(m) can be esmated using the equaon applicable to the frequency of the transmier, where P is the maximum output

power rang of the transmier in was (W) according to the transmier manufacturer.

Note 1: At 80 MHz and 800 MHz, the separaon distance for the higher frequency range applies.

Note 2: These guidelines may not apply in all situaons. Electromagnec propagaon is aected by absorpon and

reecon from structures, objects and people.

P

d2,1=

d = 0,35

10

7EN125103 Rev. 13 • 2020 www.hillrom.com

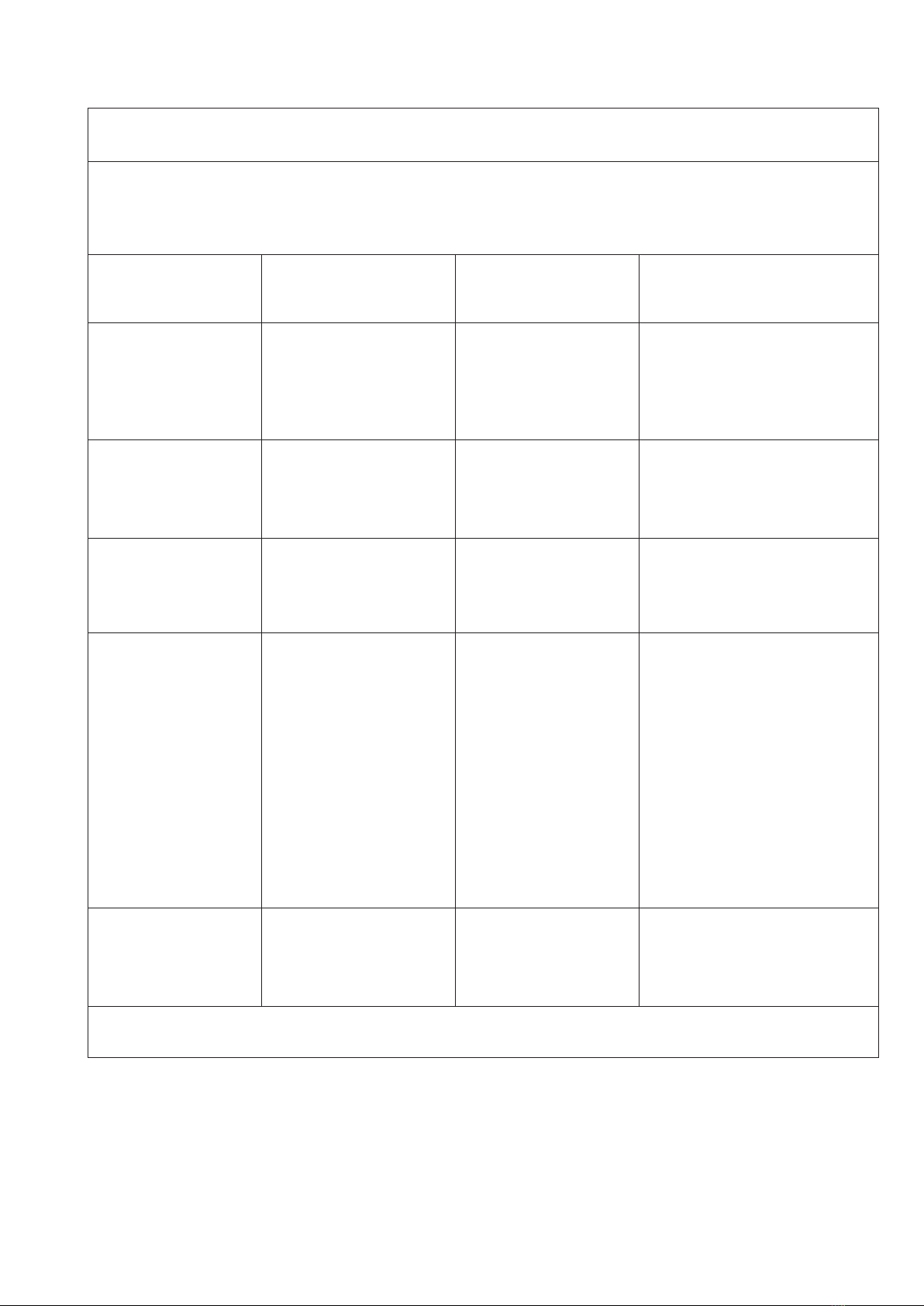

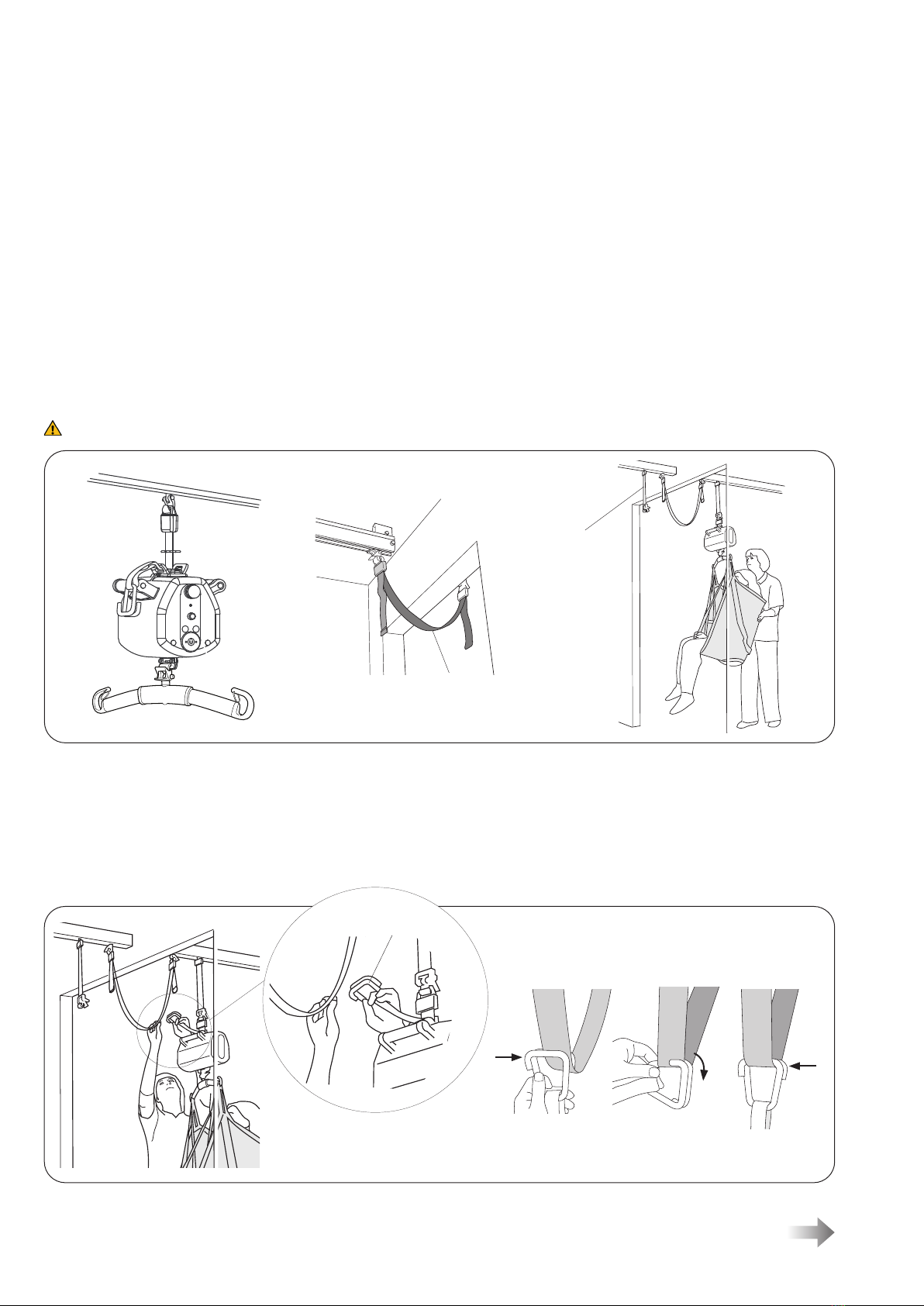

Approved combinaons

See individual combinaons 1, 2 and 3, below.

Note! no other combinaons are allowed, whether the parts are LikoTM products or products from

another company.

# 3136015

Carriage Hook for MR/LR:

Available as a service part only

#3136040

Extension Arm Adapter MR:

Available as a service part only

Combinaon 1: Q-Link or Q-Link II, # 3136015, # 3136016, # 3136040

# 3136016

Adapter MR/

LR: Available as a

service part only

Q-Link: Available

as a service part

only

Assembly: See chapter ”Assembly to Carriage Hook for MR/LR” in this document.

#3136011

Carriage S65

with single hook

Q-Link II

(Mulrall std)

Combinaon 2: Q-Link or Q-Link II, # 3136011, # 31390013 Incorrect use!

#31390013

Extension Arm Mulrall

Assembly: See ”Assembly to Carriage S65 with single hook” in this document.

Assembly

Q-Link

Available as a

service part only

#3136010

Carriage MR, S50

#31390012

Helping Hand Mulrall

Combinaon 3: Q-Link or Q-Link II, # 3136010, # 31390012

Incorrect use!

Prod. No. 3136010 Available as a service part only.

Prod. No. 31390012 Available as a service part only.

Assembly: See assembly instrucon for item 31390012.

Q-Link II

(Mulrall std)

Q-Link II

(Mulrall std)

Q-Link: Available

as a service part

only

11

7EN125103 Rev. 13 • 2020 www.hillrom.com

2. Insert the Adapter

MR/LR in to the

Q-Link or Q-Link II.

1. Feed out desired length of li strap by applying tension

to the li strap and simultaneously pressing the electrical

emergency lowering buon.

Operate the li only when tension is applied to the li strap!

5. Connect the desired liing accessory to the universal

connector at the li unit, see chapter “Operaon”.

Before the rst use,

• Charge the li’s baery for at least 8 hours, see chapter “Charging the Baeries”.

• Connect the Handcontrol MR-2 (Prod. No. 3136001) to the contact for handcontrol on the li unit.

4. Raise the li to an appropriate height.

NOTE! Remove the Hang-Up HandControl Hanger when

the li is installed with the li strap above the li unit.

Alt. A, with the li strap above the li unit

This alternave is recommended in cases where the li is to be moved frequently between dierent rail systems, or when the

li is to be used for room-to-room transfers.

A li assembled with the li strap above the li unit must not be used in wet areas.

Multirall

Multirall

3. Connect the Adapter MR/

LR to the Carriage Hook for

MR/LR.

Recommended accessory for (Alt. A, with the li strap above the li unit).

Extension Arm Adapter MR Prod. No 3136040: Available as a service part only.

connect or disconnect the Adapter MR/LR to or from the Carriage Hook for MR/LR.

1. Insert the Adapter MR/LR in to

the Q-Link or Q-Link II.

3. Connect disconnect the Adapter MR

to/from the Carriage hook MR/LR

with the Extension Arm Adapter MR.

2. Place the Adapter MR/LR in

the Extension Arm Adapter MR, in its

intended holder.

Mulrall™ 200 overhead li can be mounted to the Carriage hook for MR/LR in two dierent ways. See alternaves below.

Assembly to Carriage Hook for MR/LR:

12

7EN125103 Rev. 13 • 2020 www.hillrom.com

• the li’s funcons correspond to the markings of the hand

control

• emergency lowering works properly (mechanical and

electrical)

1. Insert the Adapter MR/LR in to the universal

connector or MulRall carriage adapter

3126020.

• the baery charger works properly and the indica-

tor lamps are illuminated during charging

• the baeries are charged.

Aer assembly, make sure that:

Alt. B, with the li strap under the li unit

This alternave is recommended in cases where the li is to be installed in the same rail system for a longer period of me

without being moved.

Mulrall™ 200 overhead li must not

be equipped with a Strap Gripper when

the li strap is mounted under the li

unit. This may result in the Strap Gripper

geng caught in the li strap.

3. Connect the desired liing accessory to the Q-Link or Q-Link II, see

chapter “Operaon”. The li strap and liing accessory are then

suspended under the li unit.

Multirall

Multirall

2. Connect the Adapter MR/LR in to the Carriage Hook for MR/LR.

13

7EN125103 Rev. 13 • 2020 www.hillrom.com

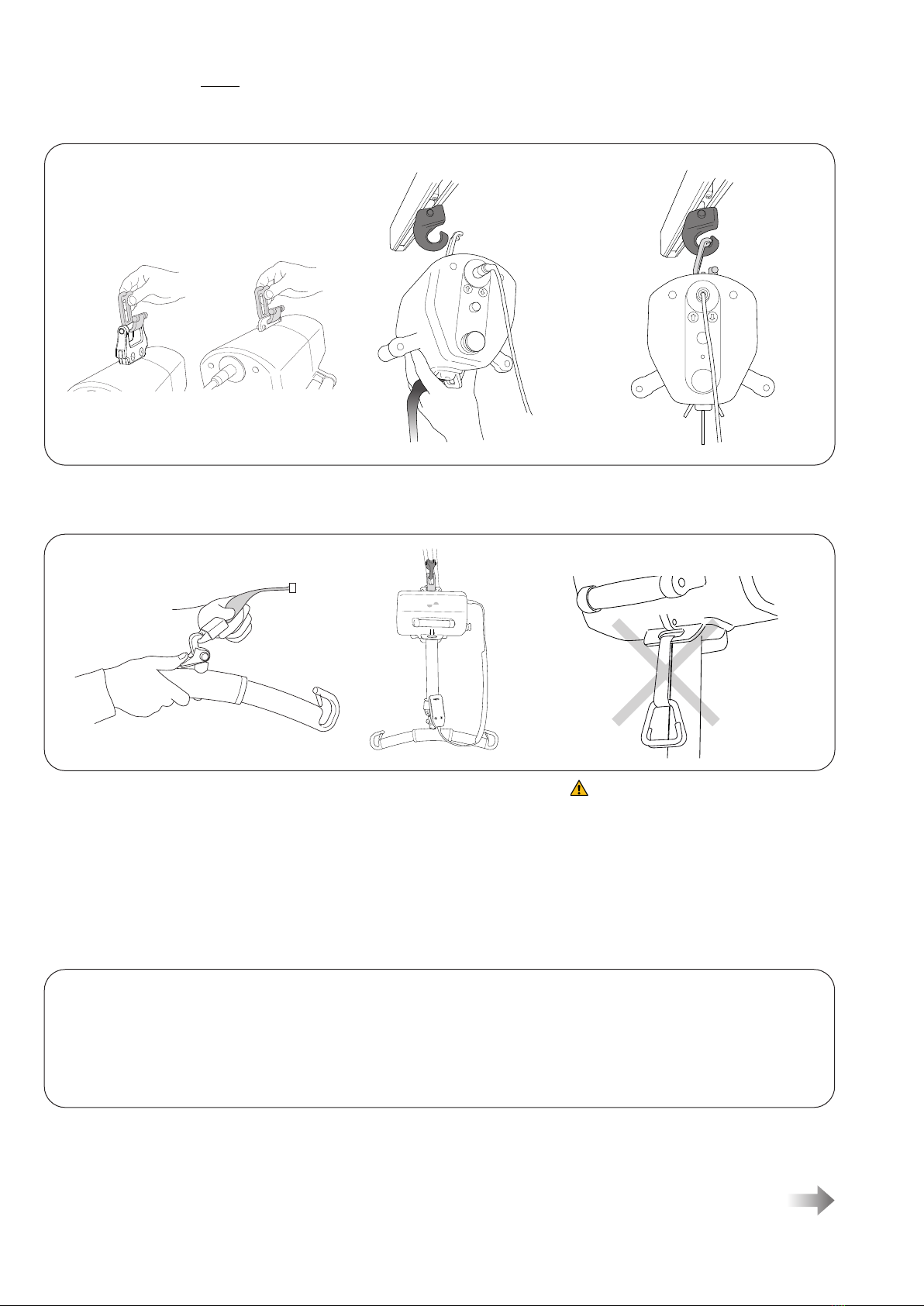

Alt. A, with the li strap above the li unit, using the: Extension Arm Mulrall Art. nr. 31390013

2. Connect the Q-Link

or Q-Link II to the rail

carriage and raise the

li to an appropriate

height.

1. Feed out desired length of li

strap by applying tension to the li

strap and simultaneously pressing

the electrical emergency lowering

buon.

Operate the li only when tension

is applied to the li strap!

Assembly to Carriage S65 with single hook

Before the rst use,

• Charge the li’s baery for at least 8 hours, see chapter “Charging the Baeries”.

• Connect the Handcontrol MR-2 (Prod. No. 3136001) to the contact for handcontrol on the li unit.

Mulrall™ 200 overhead li can be mounted to the Carriage S65 with single hook in two dierent ways, see alternaves below.

Alt. A, with the li strap above the li unit

This alternave is recommended in cases where the li is to be moved frequently between dierent rail systems,

or when the li is to be used for room-to-room transfers.

A li assembled with the li strap above the li unit must not be used in wet areas.

NOTE! Remove the

Hang-Up HandControl

Hanger when the li is

installed with the li strap

above the li unit.

Extension Arm Mulrall

3. Connect the desired

liing accessory

to the universal

connector of

the li unit, see

“Operaon”.

Multirall

Multirall

Multirall

Multirall

3. Aer mounng, make

sure that the Q-Link or

Q-Link II is properly posi-

oned into the carriage

hook and that the li strap

is safely aached to the

hook. The li strap must

hang vercally before li-

ing begins (see illustraon).

1. Place the li strap with the

Q-Link or Q-Link II in the

Extension Arm. Move the

Extension Arm with the

Q-Link or Q-Link II towards

the carriage hook accord-

ing to the illustraon

above.

2. Connect the Q-Link or Q-Link

II to the carriage hook.

14

7EN125103 Rev. 13 • 2020 www.hillrom.com

1. Install the MulrallTM overhead li by

placing the top connector directly into

the carriage hook. Check that the unit is

resng securely at the boom of the hook

before applying a load or liing a paent.

Alt. B, with the li strap under the li unit

This alternave is recommended in cases where the li is to be installed in the same rail system for a longer period of me

without being moved.

Mulrall™ 200 overhead li must not

be equipped with a Strap Gripper when

the li strap is mounted under the li

unit. This may result in the Strap Gripper

geng caught in the li strap.

2. Connect the desired liing accessory to

the Q-Link or Q-Link II, see “Operaon”.

The li strap and liing accessory are

then suspended under the li unit.

Multirall

Multirall

Multirall

Multirall

4. Mulrall™ overhead li is now properly mounted and

ready for use.

Before liing it is important to ensure that the Q-Link

or Q-Link II is securely fastened to the carriage hook. If this

is not the case, repeat steps 1-4 before starng a li.

3. Unhook the

Q-Link or Q-Link II

from the carriage

hook.

4. Remove the Q-Link

or Q-Link II and the

Extension Arm from

the carriage hook.

1. Lower the li motor to a

Mulrall™ overhead li Trolley

or other suitable locaon.

Unload the li strap by apply-

ing tension to the strap, while

pressing the buon, marked

in the desired direcon.

2. Place the Q-Link or

Q-Link II in the Exten-

sion Arm according

to the illustraon

above.

Remove the li strap from the carriage hook S65, using the: Extension Arm Mulrall Art. nr. 31390013

15

7EN125103 Rev. 13 • 2020 www.hillrom.com

Change of liing accessories

Mulrall™ 200 overhead li is adapted to LikoTM Quick Release

System for safe and easy changing of liing accessories.

Liing accessories that are not equipped with a Quick Release Hook

can easily be updated with a Quick Release Hook so that they can be

used with Mulrall. See “Quick Release Hook”, page. 21.

Before liing check that the Quick-release

Hook is correctly aached to the Q-Link or

Q-Link II, see illustraon above.

Quick

Release Hook

Q-Link or

Q-Link II

Li correctly!

Before each li, make sure that:

– the Sling loops at opposite sides of the Sling are at the same height

– all the Sling loops are fastened securely in to the Slingbar hooks

– the Slingbar is level during the li, see Figure 1.

If Slingbar is not level (see Figure 2) or if the sling loops is wrongly

aached to the slingbar (see Figure 3) lower the user to a rm surface

and adjust according to the Instrucon for use of Sling in use.

An improper li can be uncomfortable for the user and cause dam-

age to the li equipment! (see Figure 2 and gure 3).

Figure 1. Figure 2. Figure 3.

Operaon

Operang

Mulrall™ 200 overhead li is operated by lightly pressing the buons on the

hand control. The arrows indicate the direcon of movement. The movement

stops when the buons are released. Mulrall™ 200 overhead li can also be

operated with the corresponding buons on the end cover of the li unit.

The arrow corresponds to the direcon of travel when the li is mounted with

the li strap above the li unit.

Operate the li only when tension is applied to the li strap!

Operate the li only when the li is correctly mounted to the carriage hook.

Hang-up HandControl Hanger

When not in use, the hand control

can be hung on the Hang-up

HandControl Hanger.

Installaon of Latches

Aer installaon, check that the latch

locks and moves freely in the sling bar

hook.

16

7EN125103 Rev. 13 • 2020 www.hillrom.com

Adjustable Fricon Brake

The amount of drag on the li can be

adjusted with the fricon brake on the

carriage. Turn the brake clockwise for

increased resistance and counter clockwise

for reduced resistance.

fricon brake

Electrical Emergency Lowering

In the event that the hand control or electronics malfuncon, the li

can be lowered by pressing the buon on the end cover of the li unit.

The arrow corresponds to the direcon of travel when the li is

mounted with the li strap above the li unit.

Ensure the paent is lowered into a bed, wheelchair or other suitable place.

Mechanical Emergency Lowering

Press the buon marked “Emergency” on

the end cover of the li unit. Note that load

must be applied to the li in order for the

mechanical emergency lowering to work.

Ensure the paent is lowered into a bed,

wheelchair or other suitable place.

SSP Limit Switch

It is important that the liing moon of the li strap is performed as

vercally as possible to ensure safe operaon. The SSP Limit Switch

is intended to stop the liing moon if the li strap is subjected

to harmful strain, for example, if it is pulled sideways or folded

over during the liing moon. The SSP Limit Switch also provides

protecon against pinching. If the SSP Limit Switch has been

acvated and the liing moon stopped, the li strap must rst be

operated downwards before it can be operated upwards again.

Charge Indicator

Two indicators will warn when the baery has a

low charge:

• buzzer that sounds when liing

• LED that is lit during liing.

When either of these signals sounds or illuminates,

the unit should be charged as soon as possible. See

“Charging the Baeries” below.

Acvate Reset

Emergency Stop

Enable the emergency stop: press the red buon.

Reset the emergency stop: turn the buon in the direcon indicated

by the arrows on the buon.

The red buon on the li unit end cover is intended for use in an

emergency situaon. When the buon is pressed, contact between

the motor and power source is broken, which stops the liing moon.

17

7EN125103 Rev. 13 • 2020 www.hillrom.com

In order to ensure maximum baery life, it is important to charge the

baeries regularly. We recommend that you charge the baeries aer use

or every night.

The baeries are fully charged aer approximately 8 hours. When fully

charged, baeries in good condion are sucient for approximately 60 li

cycles. The connector cable of the baery charger cannot be repaired. If the

cable is damaged, it should be replaced by a new one!

Charging

1. Check to ensure that the emergency stops are not pressed in during

charging.

2. Place the hand control in its intended place on the charger.

3. Connect the charger to an electrical outlet (100-240 V AC).

The charging starts automacally. The green LED indicates that the

charger is connected to a power supply. The yellow LED indicates that

the baery is charging. When the baery is fully charged, the charger is

switched o automacally and the yellow LED turns o.

NOTE! If the li is not to be used for a longer period of me, the hand

control should be placed in the charger. If the charger is not connected to

a power supply, the emergency stop buon should be pressed in order to

prevent the baery from discharging.

Charging the Baeries

1.

3.

2.

Green

Yellow

White

(no funcon)

Prod. No. 3126101- 3126104

The AC connector of the charger unit

must be easy accessible to the operator.

Please read the instrucon for use before use.

Baery is charging when yellow led is lit.

AC is connected when green led is lit.

18

7EN125103 Rev. 13 • 2020 www.hillrom.com

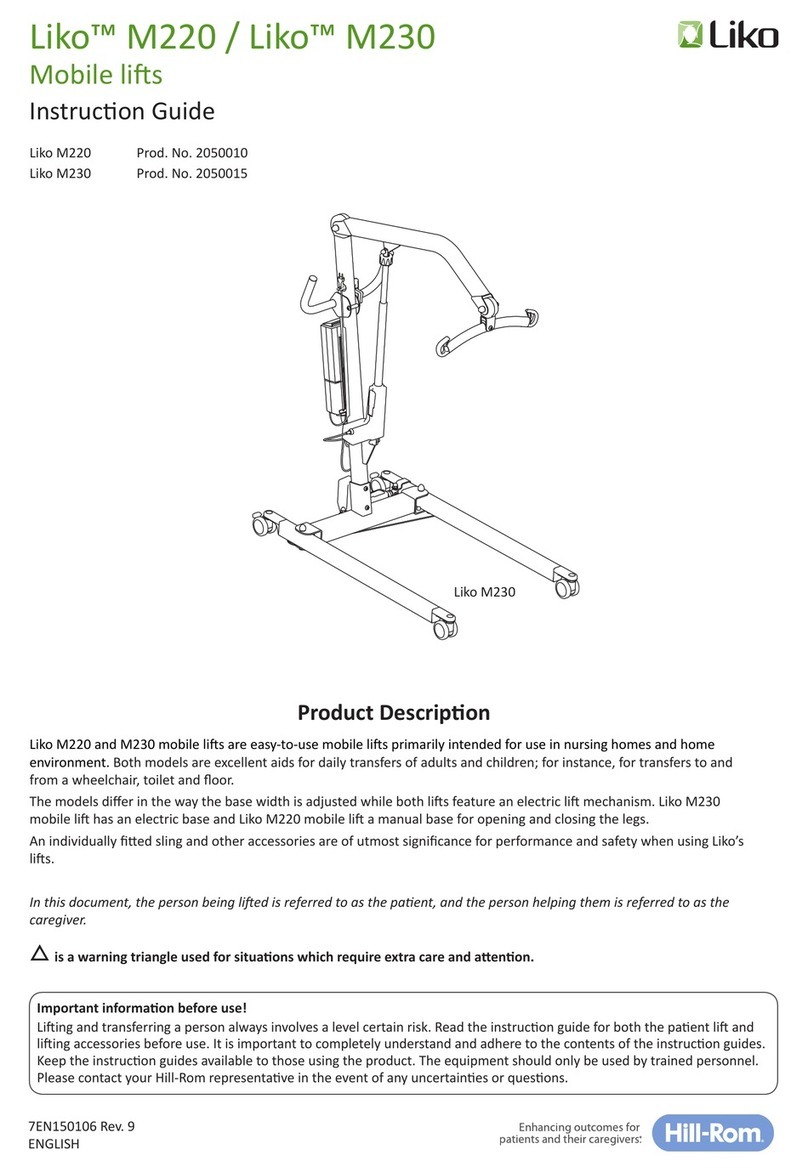

Room-to-Room transfer

Connect the Strap Gripper with both hooks to the

Room-to-Room Strap, see illustraon to the right.

R2R strap

Install the li according to assembly

alternave A. Install the Strap Gripper

in accordance with applicable assembly

instrucons.

Room 1

Room 2

The LikoTM R2R (Room-to-Room) system is an eecve soluon for safe and easy transfer of paents between two or more

rooms. The R2R system is mounted without making openings in walls over doors, and full isolaon is therefore retained

between the rooms supported by the system.

In order to perform room-to-room transfers with Mulrall™ 200 overhead li, the following condions are required:

• Both rooms have separate rail systems, each with a carriage mounted in the rail.

• Between the rooms, suspended under the doorframe, a Room-to-Room Strap is mounted, acng as a bridge between the

rooms.

• Mulrall™ 200 overhead li is equipped with a Strap Gripper, which is installed to either of the Extension Belt connectors

on the li.

• An adjustable extension belt is mounted to the carriage, in order to obtain an appropriate liing height. Alternavely, if the

liing height becomes too low when using the Extension Belt, the Extension Arm Mulrall/Mulrall Helping Hand can be

used for connecng Q-Link II or Q-Link directly to the carriage hook, providing a maximum liing height.

Room-to-Room Transfer

Below is a descripon of an R2R transfer with Mulrall, Strap Gripper, Room-to-Room Strap and adjustable Extension belt.

Check carefully at each stage that the Q-Link or Q-Link II is correctly applied to the carriage hook/extension belt!

Install the Room-to-Room

Strap between the two rooms.

For installaon and length

adjustment, see applicable

assembly instrucons.

Mulrall is pending in the carriage, alternavely

in an extension belt, in room 1. Move the li

with the paent forwards, as close as possible

to the doorway. Lower the paent as far down

as is comfortably possible, but not so far that

the caregiver cannot reach the Room-to-Room

Strap with the Strap Gripper.

Extension Belt

Strap Gripper

19

7EN125103 Rev. 13 • 2020 www.hillrom.com

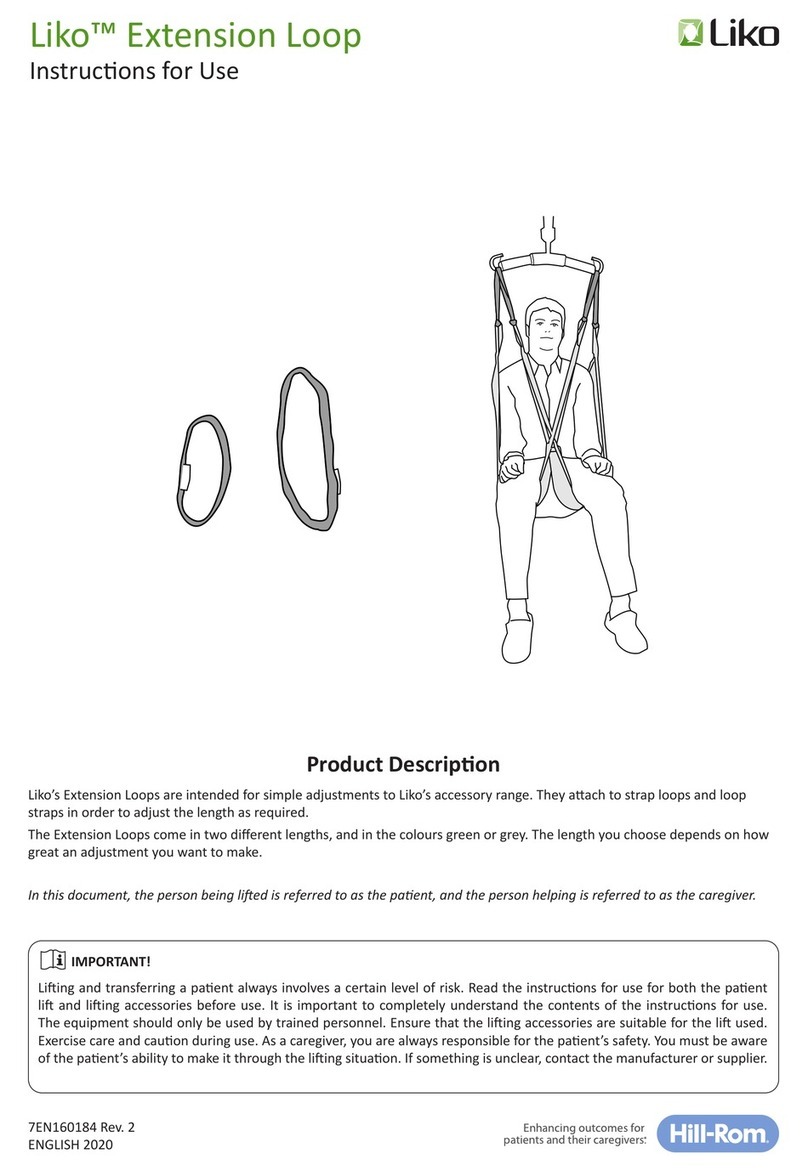

Only when the li strap runs straight into the li unit can the

transfer to room 2 proceed (see small illustraon). Raise the li

unl the weight of the paent has been fully transferred to the

carriage in room 2.

While the li is raised, it is very important to ensure that the

li strap is not twisted, in order for it not to fold when it enters

the li unit.

Then disconnect the Strap Gripper.

Move the paent further on in room 2.

Lower the Mulrall™ 200 overhead li

unl the Room-to-Room Strap carries

the full weight of the paent. Then run

out an extra 10 cm (4 in) of li strap to

provide enough slack for disconnecon.

Keep hand tension on the li strap

as you run it out of the li motor.

Disconnect the li strap from the carriage/extension belt in room 1

and connect it to the carriage/extension belt in room 2. To prevent the li strap

from twisng, which in turn may cause the SSP limit switch to acvate

(see p. 16), the li unit must be turned manually so that the li strap is straight

when it enters the li unit (see small illustraon).

Check carefully to ensure that the Q-Link or Q-Link II is correctly applied

to the carriage hook/extension belt!

20

7EN125103 Rev. 13 • 2020 www.hillrom.com

Universal SlingBar 350 with Quick-release Hook Prod. No. 3156084

Fixed connecon, prod. no. 3156074*

Max. load 300 kg (660 Ibs)

Universal SlingBar 450 with Quick-release Hook Prod. No. 3156085

Fixed connecon, prod. no. 3156075*

Max. load 300 kg (660 Ibs)

Universal SlingBar 600 with Quick-release Hook Prod. No. 3156086

Fixed connecon, prod. no. 3156076*

Max. load 300 kg (660 Ibs)

Universal SlingBar 670 Twin with Quick-release Hook Prod. No. 3156087

Fixed connecon, prod. no. 3156077*

Max. load 300 kg (660 Ibs)

Universal SideBars 450 Prod. No. 3156079

including bag

Max. load 300 kg (660 Ibs)

Sling Cross-bar 450 with Quick-release Hook Prod. No. 3156022

Fixed connecon, prod. no. 3156021*

Max. load 300 kg (660 Ibs)

Sling Cross-bar 670 with Quick-release Hook Prod. No. 3156019

Fixed connecon, prod. no. 3156018*

Max. load 300 kg (660 Ibs)

* Sling bars with xed connecon can be equipped with Quick-release Hook

Carriage Adapter MulRall for S65 Prod. No 3126020

Recommended Liing Accessories

Using liing accessories other than those approved can entail a risk.

Recommended sling bars and accessories for Mulrall™ 200 overhead li are described below.

For addional guidance in selecng a sling, study the instrucon for use for the respecve sling models. Here, you will also nd

guidance for combining Liko® sling bars with Liko® slings.

Contact your Hill-Rom representave for advice and informaon on the Liko® product range.

Maximum Load

Dierent maximum loads may apply to dierent products on the assembled li system: rail, li, sling bar, sling and any

other accessories used. For the assembled li system, the maximum load is always the lowest maximum load rang of any

of the components. For example: a Mulrall™ 200 overhead li that is approved for 200 kg (440 lbs) can be equipped with

a liing accessory that is approved for 300 kg (660 lbs). In this case, the maximum load of 200 kg (440 lbs.) applies to the

assembled li system. Check the markings on the li and liing accessory or contact your Hill-Rom representave if you have

any quesons.

Other manuals for Liko Multirall 200

1

Table of contents

Other Hillrom Lifting System manuals

Hillrom

Hillrom Likorall 242 User manual

Hillrom

Hillrom Liko Ultra Series User manual

Hillrom

Hillrom Liko SafetyVest 93 Manual

Hillrom

Hillrom Liko Golvo 7000 Series User manual

Hillrom

Hillrom Liko M220 Manual

Hillrom

Hillrom Likorall 200 User manual

Hillrom

Hillrom Liko HygieneVest 50 Manual

Hillrom

Hillrom Liko User manual

Popular Lifting System manuals by other brands

SmarterHome

SmarterHome Universal XL installation manual

Huchez

Huchez CT3 instruction manual

Savaria

Savaria DELTA owner's manual

HSS Hire

HSS Hire 70132/3 Operating & safety guide

WITTUR

WITTUR WSG09 Operating and maintenance manual

Challenger Lifts

Challenger Lifts CL10 Installation, operation & maintenance manual