Model CL10 with Dual Pendant Control

Installation, Operation, and Maintenance

Page

16

Rev. 4/22/11

LIFTING A VEHICLE

1) Insure that the lifting arms are parked, out to

full drive thru position.

2) Position the vehicle in the service bay so that

the vehicle’s center of gravity is on a line

between the two columns, and so the vehicle

is centered between the two columns.

DO NOT EXCEED 2500 POUNDS PER ARM.

DO NOT ATTEMPT TO LIFT THE VEHICLE WITH

ONLY TWO ARMS,AS THIS WILL VOID THE

WARRANTY

INSURE THAT THE HIGHEST POINT ON THE

VEHICLE WILL CONTACT THE OVERHEAD LIMIT

SWITCH BAR.

DO NOT PLACE THE VEHICLE IN THE SERVICE BAY

BACKWARDS.

REFER TO THE VEHICLE MANUFACTURERS SERVICE

MANUAL,TECHNICAL BULLETINS,“VEHICLE LIFTING

POINTS GUIDE”(ALI/LP-GUIDE)OR OTHER

PUBLICATIONS TO LOCATE THE RECOMMENDED

LIFTING POINTS.

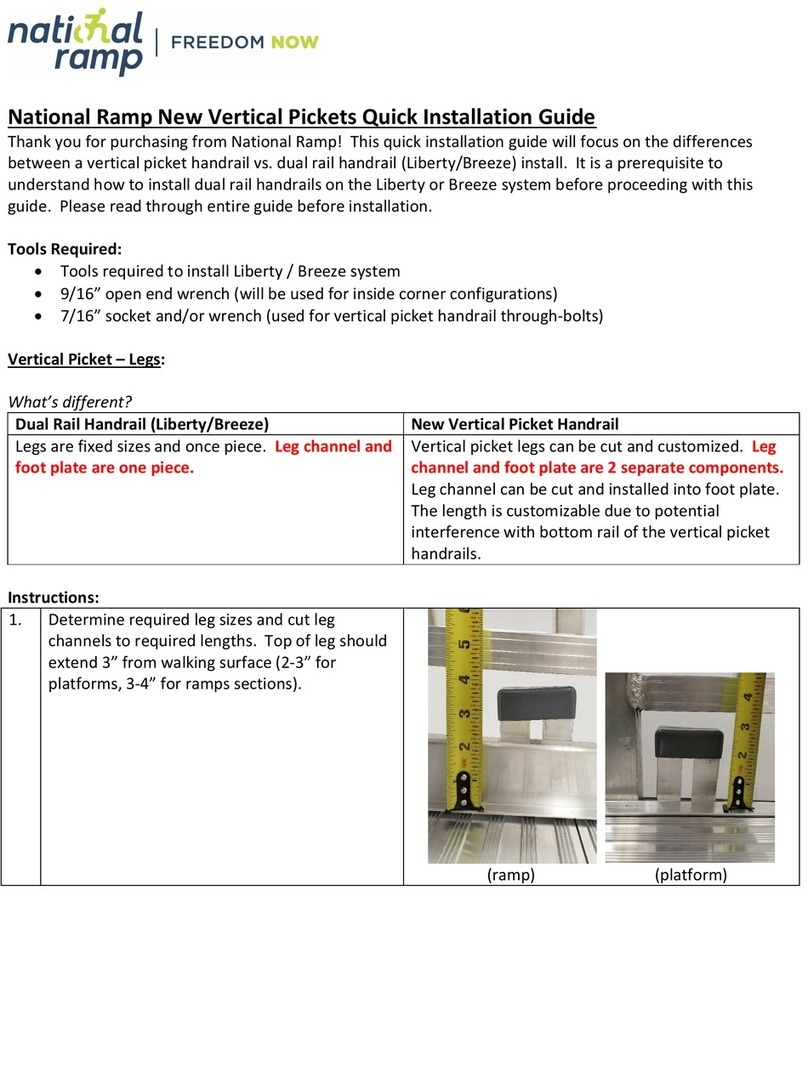

3) Position the arms and adapters so all four

pads contact the vehicle simultaneously.

The vehicle should remain level during lifting.

4) Raise the lift until all four wheels are off the

ground. Test the stability of the vehicle by

attempting to rock the vehicle. Check adapters

for secure contact with vehicle lift points. If the

vehicle seems unstable, lower the lift and

readjust the arms. If the vehicle is stable,

raise the vehicle to a height a few inches

above the desired working height.

5) Lower the vehicle until the safety latches on

both columns engage. The vehicle should

remain level when both latches are engaged.

If one side engages and the other continues to

descend, stop lowering the vehicle, raise it

several inches, and try again to engage both

latches.

Always lower lift into locks before entering

the area beneath the vehicle.

Always use safety stands when removing or

installing heavy components.

LOWERING A VEHICLE

1) Insure that the area under the vehicle is clear

of personnel and tools.

2) Raise the vehicle until both latches are free.

3) Disengage the latches by pulling down and

holding the lock release lever.

4) Lower the vehicle.

5) Continue to lower the vehicle until the

carriages stop against the base plate. Retract

the extension arms, and park them.

MAINTENANCE

To avoid personal injury, permit only qualified

personnel to perform maintenance on this

equipment. Maintenance personnel should follow

lockout/tagout instructions per ANSI Z244.1.

The following maintenance points are suggested

as the basis of a routine maintenance program.

The actual maintenance program should be

tailored to the installation. See ANSI/ALI ALOIM

booklet for periodic inspection checklist and

maintenance log sheet.

If lift stops short of full rise or chatters, check

fluid level and bleed both cylinders per

Installation Instructions.

Replace all Safety, Warning or Caution Labels

if missing or damaged (See Installation

instructions page 3.)

Daily

Keep lift components clean.

Check for loose or broken parts.

Check hydraulic system for fluid leaks.

Check adapters for damage or excessive wear.

Replace as required with genuine Challenger

Lifts parts.

Check lock release activation. When properly

adjusted, the idler column lock should rest

firmly against the back of the column when

engaged and against the spring mount tab

when disengaged.

Weekly

Check synchronizer cables and sheaves for

wear. Replace as required with genuine

Challenger Lifts parts.

Check lock release cable adjustment per

Installation Instructions step 42.

IMPORTANT: IF IDLER SIDE LOCK PAWL DOES

NOT FULLY DISENGAGE,DAMAGE MAY RESULT

TO IDLER SIDE CARRIAGE AND OR CABLE

SYNCHRONIZING SYSTEM.

Check synchronizer cable tension per

Installation Instructions. Adjust if necessary.

Monthly

Torque concrete anchor bolts to 80 ft-lbs.

Check overhead shutoff switch. While raising

lift, operate overhead shutoff bar. Power Unit

motor should stop when bar is raised.

Lubricate carriage slide tracks with heavy

viscous grease. (Grease all (4) corners of both

columns.)

Visually inspect concrete floor for cracks and/or

spalls within 12” of base plate

If any problems are encountered, contact

your local service representative.

CL10DPC-IOM-A.doc