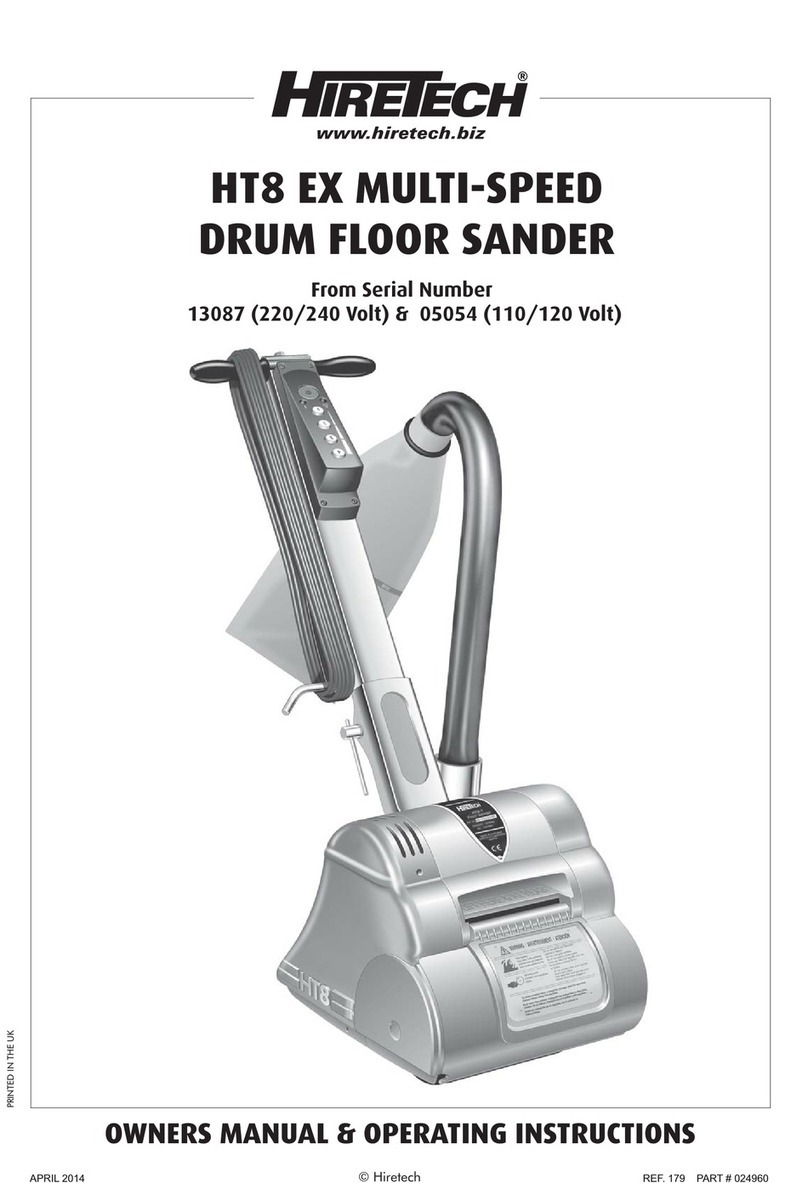

HireTech HT7-2 System manual

DISC FLOOR SANDER MODEL HT7-2

OWNERS MANUAL OPERATING INSTRUCTIONS&

0703/1811 REF PART. 69 # 011680

PRINTED IN THE UK

© Hiretech

ABC

From Serial Number

00607 (220/240 Volt) & 00466 (110/120 Volt)

NORTH AMERICAN SAFETY INSTRUCTIONS

WARNING: This floor sanding machine must be grounded.

This floor-sanding machine shall be grounded while in use to protect the operator from electric

shock. The machine is provided with a three-conductor cord and a moulded three-contact

grounding type attachment plug to fit the proper grounding type receptacle. The Green (or

Green and Yellow) conductor in the cord is the grounding wire. Never connect this wire to other

than the grounding pin of the attachment plug.

This floor-sanding machine is provided with an attachment plug as shown in sketch A. It is

intended for use on a nominal 120 volt circuit. If a properly grounded receptacle as shown in

sketch A is not available, an adaptor as shown in sketch 'C' should be installed as shown in sketch

B if the outlet box that houses the receptacle is grounded. Be sure to fasten the grounding tab with

a metal faceplate screw.

WARNING: Risk of explosion.

Floor sanding can result in an explosive mixture of fine dust and air. Use floor-sanding machine

only in a well-ventilated area free from any flame or match.

WARNING: Of potential injury.

Moving Parts - to reduce the risk of injury, unplug the machine before replacing abrasive sheets

or carrying out any form of adjustment or servicing.

USE AND APPLICATION

This machine is intended for commercial use connected with the laying and maintaining of wooden floors and

decks.

These types of surfaces may be found both in commercial and household environments.

ATTACHMENT PLUG SKETCH ‘C’

METAL

SCREW

COVER OF GROUNDED

‘B’OUTLET BOX SKETCH

ADAPTER

GROUNDING

MEANS

COVER OF GROUNDED

‘A’OUTLET BOX SKETCH

GROUNDING PIN

CONTENTS

WARNING i

MAINS CABLE WIRING PLUG- i

SPARE PARTS I

SPECIFICATION 1

SAFETY 1

SET UP

Assembly and Transport 2

Installing Abrasive Disc 2

PREPARATION 2

OPERATION 2,3

FLOOR SANDING TECHNIQUE

Drum Floor Sander 4

Disc Floor Sander 4

Orbital Floor Sander 4

Hand Sanding 4

FLOOR TYPES

Sanding Plank & Strip Floors 4

Veneered, Laminated & Thinner Floors 4

Parquet & Block Floors 5

Between Coats of Finish (Varnish) 5

ABRASIVE PAPER GUIDE 6

SERVICE AND ROUTINE MAINTENANCE

General 7

Visual Inspection 7

Dust Control System 7

Drive 7

Lubrication 7

Care of Motor 7,8

Sanding Pad Removal & Replacement 8

Sanding Pad Trimming 9

Adjsuting the Castors 10

Electrical Testing 10

FAULT FINDING 11

HT PARTS DRAWING7-2 12

HT PARTS LIST7-2 13

HT CIRCUIT DIAGRAM7-2 14

DECLARATION OF CONFORMITY 15

SERVICE REPAIR& 16

WARNING

For safe operation of this machine, read and understand all instructions. Look for the ‘warning/caution’ symbol.

This symbol means that if you do not follow the instructions injury can occur to the operator and

damage to the machine and floor may result.

MAINS CABLE WIRING PLUG-

Hiretech reserves the right to make changes or improvements to it's products without prior notice.

®

i

NORTH AMERICA

BLACK

WHITE

GREEN

BRASS

TERMINAL

SILVER

TERMINAL

EU

BLUE BROWN

GREEN/

YELLOW

UNITED KINGDOM

BLUE

(N - )NEUTRAL BROWN

(L - )LINE

GREEN YELLOW/

(E - )EARTH

SPARE PARTS

Use Hiretech genuine spare parts only for service and repair. Use of non-approved parts will void the product

warranty. See the back cover of this manual for the terms and conditions of the Hiretech Limited Warranty.

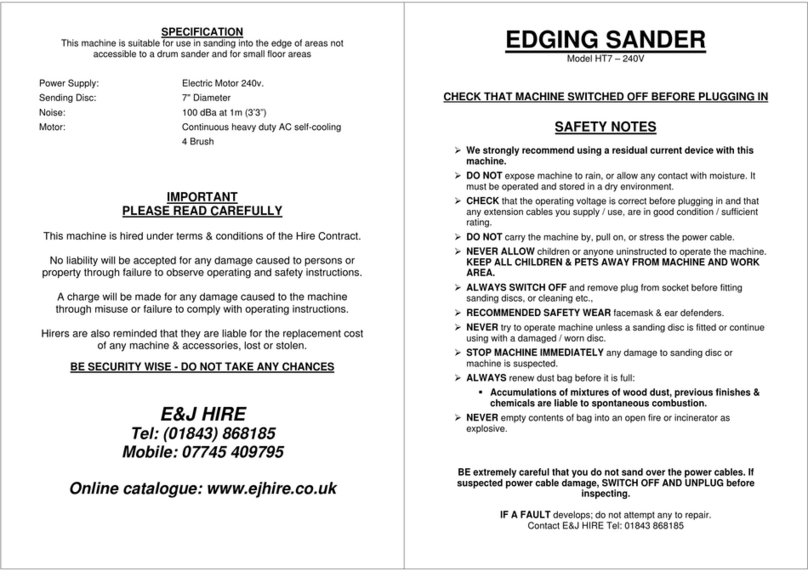

SPECIFICATION

The 7-2 Hiretech Edger (Disc Floor Sander) willHT

sand hard and soft wood floors, cork and

composition floors and any solid wood surface that

requires rapid sanding and leveling to a fine finish.

Ideal for confined areas such as closets and stair

treads the 7-2 will sand right up to the edge of aHT

floor without damage to the base (skirting) board.

Completely self contained with a high efficiency dust

pick-up the 7-2 is a high performance sanderHT

suitable for professional and home owner use.

SAFETY

1. For safety it is recommended that a residual

current circuit breaker (ground fault interrupter)

is used with this machine.

2. Check the operating voltage is correct and that

the machine is switched (O) beforeOFF

connecting to the power supply.

3. Never attempt to lock the switch in the (I)ON

position with tape or by any other means.

4. Always disconnect from the power supply when

changing the abrasive disc, servicing the floor

sander, replacing the dust bag or leaving the

machine unattended.

5. Always replace the dust bag (paper type) or

empty the dust bag (cloth type) when the dust in

the bag reaches the ‘ ’ line or when theMAX

machine is left unattended.

6. Never dispose of or empty the contents of the

dust bag into a fire or incinerator.

7. Never reuse the paper dust bag or use a non

standard bag. Cloth type bags must be in good

condition with no holes.

8. Always wear a dust mask when using the floor

sander, handling the dust bag or cleaning the

machine after use.

9. Wear ear protection when using the floor sander.

10. Ensure adequate ventilation of the work area to

avoid the formation of a combustible mixture of

flying dust and air.

11. Never smoke when using or servicing the floor

sander or when handling the dust bag.

12. Never expose the machine to rain or damp.

Always store in a dry place.

13. Stop the floor sander immediately if damage to

the machine or abrasive disc is suspected.

14. Never allow the power cable to come into contact

with the sanding disc when the floor sander is in

operation. If the power cable becomes damaged

and the inner conductors are exposed switch the

power and remove the plug beforeOFF

attempting to move the machine. The cable must

be replaced by an authorised agent or qualified

electrician using genuine Hiretech spare parts

only.

15. Keep hands, feet and loose clothing away from

all moving parts of the machine.

16. Punch down or remove all nails, screws, tacks

and other fixings from the floor before sanding to

prevent contact with the sanding disc.

17. Never use the machine above waist height as

control will be lost.

18. Keep children and pets clear at all times.

19. If the machine should fail to operate refer to the

fault finding guide on page 8.

1

CAUTION - read the following Safety

and Operational notes before using your

HT7-2 Disc Floor Sander.

Noise: 100 dBa at 1metre (3’ 3")

Switch: Bias Off, double pole.

Motor RPM: 13,000

Disc RPM: 3,000

Moving Parts: Sealed for life ball bearings.

Weight: 16.4kg (36.2lbs)

0.04 M² H Aeq8

(8 Hr. RMS )

7" (178") dia. x 7/8“ (22mm) dia.

centre hole. 24 to 120 grit fibre or

paper back.

Abrasive:

Continuous heavy duty AC/DC self

cooling 4 brush.

7" (178mm) dia. Metal backed and

rubber bonded.

High impact ABS with bronze bush.

Hardened steel alloy pinion and

large diameter aluminium bronze

drive gear.

Seated oversize vacuum fan,

disposable paper dust or cloth

bag.bags

Disc Guard:

Drive:

110/120 V 50/60 Hz

220/240 V 50/60 Hz

110/120 V 8A

220/250 V 5A

Average

Load Current:

110/120 V 15A

220/250 V 8A

Dust Pickup:

Vibration:

Power Supply:

Off Load

Current:

Motor:

Sanding Pad:

SET UP

Assembly and Transport

1. Always carry the floor sander by the two handles

with the bag frame in the up position and the

power cable stowed around the bag frame.

Protect the sanding disc with an abrasive disc

and ensure that the clamp bolt is secure. Ensure

that the floor sander is secure and cannot move

when being transported in a vehicle. The floor

sander is heavy. Take care when lifting and

carrying the machine.

2. To prepare the floor sander for use place the

machine on the floor and remove the cable from

the bag frame. Check that the cable is in good

condition and that all fittings are secure.

3. Lower the dust bag support frame and fit a paper

dust bag following the instructions printed on the

bag. Do not reuse or use a non standard bag. If a

cloth type bag is used ensure that it is tied securely

around the dust outlet and that the bag is in good

condition with no holes.

4. To dismantle the floor sander reverse procedure

2 to 3 above.

Installing Abrasive Disc

1. Ensure the power cable is disconnected from the

power supply.

2. Tip the floor sander upside down and rest the

machine on it's top and handles.

3. Remove the Wrench Ref.61 from the clips inside

the skirt of the floor sander situated in between

the castors and remove the Bolt Clamp Ref.59

and Washer Clamp Ref.58 from the centre of the

sanding disc.

4. Select a suitable grade of abrasive disc (see

Abrasive Paper Guide on page 5).

5. Place the bolt clamp through the centre of the

washer clamp and abrasive disc and carefully

thread the bolt into the sanding disc.

CAUTION - never fit more than one

abrasive disc . If more than one abrasive

disc is fitted the setup of the sander will

be affected and the clamp bolt and

washer and sanding pad will be

damaged.

6. Using the wrench, tighten the bolt clamp

ensuring that the abrasive disc is centred and the

washer clamp is properly located. The bolt

should be secure but do not try to over tighten.

Heavy grit abrasive discs will seat down as you

tighten the bolt so take care to ensure the washer

clamp is properly located. Heavy grit abrasive

discs may not lie flat on the sanding disc, this is

quite normal and the abrasive disc will flatten

immediately upon operation.

7. Do not use damaged or incorrectly sized

abrasive discs under any circumstance, damage

will result to the machine and floor.

PREPARATION

1. Where possible remove all furniture from the

area or room. The 7-2 Disc Floor SanderHT

features an efficient dust pickup, however, some

dust will escape. Protect all vulnerable

furnishings with dust sheets.

2. Remove all tacks, staples and other unwanted

fixings from the floor. Failure to do so will result

in damage to the abrasive disc and sanding disc.

3. Punch all nails below the surface of the floor

using a suitable nail punch and hammer. Any

screws used to fix boards should be counter sunk

below the surface. During sanding, any nails or

screws that become exposed must be punched or

counter sunk further.

4. Firmly fix all loose boards or blocks.

5. Remove heavy wax, grease and dirt deposits by

hand.

6. Sweep and vacuum the floor thoroughly to

remove dirt and discarded fixings.

7. Ensure good ventilation by opening windows.

8. If sanding a work bench or similar work piece

follow the instructions above to prepare it ready

for sanding. Make sure that the work piece is

secure. Never use the floor sander above waist

height.

Note: Use Hiretechgenuine floor sander abrasives for

the best sanding performance and finish.

OPERATION

1. Move the floor sander to the location of your

work.

2. Make sure the switch is in the (O) positionOFF

then connect the power cable to a suitable power

supply ideally located behind or to one side of

the machine and work area.

3. Wear a dust mask and ear defenders.

4. Kneel behind the machine on one knee (use knee

pads to protect knees) and hold both handles

with the power cable held in the right hand in a

small loop and then pass the cable over the right

shoulder. Tilt the floor sander back so that the

2

sanding disc does not touch the floor or work

piece.

5. Switch by pushing the / switch to (I)ON ON OFF

position and hold in place with your thumb. To

switch (O), release the pressure on theOFF

switch and it will automatically return to the OFF

position.

CAUTION HT- the 7-2 Disc Floor Sander

is a powerful machine. Always ensure

you have a firm grip before switching on.

6. Now lower the floor sander slowly forward so

that the abrasive disc comes into contact with the

floor or work piece. At the same time move the

machine in a sideways motion so when the

abrasive disc comes into contact with the work

surface it is moving to one side. This will ensure

that the sander does not dwell in one position

and damage the floor or work piece.

CAUTION - to prevent damage to the

floor surface, work piece or machine

follow these rules.

i. Always ensure that the floor sander is

moving when in operation and the

sanding disc is in contact with the floor.

ii. Never lift the back of the machine when

sanding.

iii. Never apply pressure to try to increase the

rate of sanding. Damage to the floor or

work piece will occur.

iv. Never bounce or drop the floor sander on

to the floor or work piece, always lower the

machine gently.

v. Never dwell in one place, move steadily at

all times.

vi. Never allow the power cable to come into

contact with the sanding disc.

7. When the dust in the dust bag reaches the ‘ ’MAX

line stop sanding. Switch (O) andOFF

disconnect the power cable from the power

supply and remove the paper dust bag. Turn the

top of the paper dust bag over to stop the escape

of dust and dispose of into a suitable container.

Never reuse the paper dust bag or empty it.

Never dispose of it into a fire. If the cloth bag is

used empty into a suitable container being

careful to contain the dust. Do not dispose of the

contents into a fire.

8. Fit a new paper dust bag, or refit the cloth bag.

Reconnect the floor sander to the power supply

and continue sanding.

3

9. When taking a break from work switch ‘O’OFF

and disconnect the power cable from the supply,

remove and dispose of the paper dust bag, or

empty the cloth bag as detailed in 7. above.

Never leave the floor sander unattended with a

dust bag in place containing dust.

10. On completion disconnect the power cable from

the supply. Remove and dispose of the paper

dust bag, or empty the cloth bag as detailed in 7.

above. Replace the bag frame in its up position

and stow the power cable. Leave the old abrasive

disc inplace to protect the sanding disc. Carry out

maintenance as recommended in Maintenance

and Servicing.

- never leave the floor sanderDANGER

unattended with dust in the dust bag.

Always remove the dust bag and dispose

of into a suitable container.

FLOOR SANDING TECHNIQUE

HT8-1.2 Floor Sander (Drum) - a powerful floor

sander designed for the rapid leveling and sanding of

all types of wood flooring excluding thin laminated or

veneered floors. Load the sander with abrasive

making sure that it is skin tight around the drum.

Loose sheets will tear. Place the sander on the right

hand wall (unless you are making an angled cut on

uneven floors) with about two thirds of the floor in

front of you. Start the sander with the drum off the

floor then walk forward at an even pace and ease the

drum on to the floor. As you near the end of the pass,

gradually raise the drum off the floor. Practice this

technique before turning on the sander.

Cover the same path you made on the forward cut by

pulling the machine backwards and easing the drum

to the floor as you begin the backward pass until you

reach the original starting point, then ease the drum

off the floor.

When two thirds of the floor is sanded, turn the floor

sander around and sand the remaining third in the

same way. Overlap the one third area by 0.6 to 0.9

meters (2 to 3 feet ) with the two thirds area to blend

the two areas together.

WARNING - never bounce the sanding

drum or dwell in one place as this will

sand dips and hollows in the floor.

HT7-2 Disc Floor Sander (Edger) - a powerful disc

floor sander designed for sanding along the edges of

a floor without damaging the baseboards or

moldings. Also suitable for smaller areas where the

HT8-1.2 Floor Sander will not reach like stair treads

and closets load the abrasive disc making sure the

retaining bolt is tight. Start the edger with the disc off

the floor then lower the disc to the floor as you move

the sander. Work progressively moving the sander in

a sweeping motion from side to side.

HTF-2 Floor Sander (Orbital) - a orbital action floor

sander designed for re-finishing, sanding between

coats of varnish and re-surfacing floors in good

condition. load the abrasive sheet, pad or strip. Start

the sander, move immediately and sand in the

direction of the grain using the same technique as the

drum floor sander. For difficult to reach areas use the

disc floor sander with a fine grit abrasive, or sand by

hand.

Hand Sanding - to sand difficult to reach areas

scrape and sand the floor by hand. Use a scraper to

remove old finishes, always scraping in the direction

of the grain, and then sand by hand using the same

grit abrasive as you finished with when machine

sanding. See Floor Sanding Technique diagrams on

page 5.

FLOOR TYPES

PLANK STRIP FLOORS&

Old floors in good condition - when the floor is in

good condition - no uneven edges, cupping or

crowning of planks and strips - and you want to re-

surface the floor, sanding back to new wood, start

sanding in the direction of the planks or strips - with

the wood grain. Start with a medium grit abrasive.

Complete the first cut with the 8-1.2 Floor SanderHT

then sand up to the baseboards and door thresholds

with the 7-2 Disc Floor Sander, using a mediumHT

grit abrasive, blending the edges in with the main

floor area. Sweep the floor. Using a medium/fine grit

abrasive, sand the main floor area with the drum

sander and then complete the floor with the edger

using a fine grit abrasive. Sweep the floor. Finish

sanding the main floor area with the drum floor

sander using a fine grit abrasive. If the floor is in

particularly good condition (level with no deep

scratches or blemishes) you may re-surface the floor

using the -2 Floor Sander, however, as theHTF

sanding action of this machine is less aggressive than

the 81.2 Floor Sander the job will take more time.HT

Uneven floors - when the floor is uneven sand

diagonally at 45 across the room in both directions

o

using the 8-1.2 Floor Sander with a coarse gritHT

abrasive. Only make one cut on both diagonals, this

will achieve a basic level. Now complete the floor as

for a level strip or plank floor. Use the same grit

abrasive as was used on the 45 cut for the first cut

o

parallel to the planks or strips.

Floors with an existing finish - when re-finishing a

floor remove as little of the existing surface as

possible. If the old finish is worn and the floor is

generally in good condition use the -2 FloorHTF

Sander with abrasive pads and strips whichHiretech

have been especially designed for re-finishing floors.

These will maintain the integrity of any stain used to

colour the wood and prepare the surface for a new

coat of finish. If the floor is badly marked and

scratched and has to be sanded back to new wood

use the 8-1.2 Floor Sander and 7-2 Disc FloorHT HT

Sander. Always try a medium grit paper first,

particularly on a diagonal cut. If 90% of the old finish

is removed and the floor is generally leveled, you do

not need to use a coarse grit abrasive.

VENEERED LAMINATED THINNER FLOORS,&

Use the -2 Floor Sander for veneered andHTF

laminated floors or thinner floors that may have been

subjected to repeated sanding. The -2 willHTF

remove old surface finishes and prepare the floor for

re-finishing. Sand the floor using the same method

as a strip, plank, or parquet floor. If the floor has

deeper scratches or marks these should be sanded

4

out by hand and blended in with the main floor. To

check the wood depth in the floor remove a

baseboard or molding from around the edge of the

floor. This should provide access to the edge of the

floor for inspection.

PARQUET BLOCK FLOORS&

The grain of the wood will run in a number of

directions so sand the floor in the direction of the

main source of natural light in the room. If there is no

source of natural light sand in the direction of the

longest side of the room or, if the room is square, in

the direction the furniture is laid out and how people

normally use and view the room.

This technique will help mask any imperfections in the

floor. Complete the sanding operation as detailed

for plank or strip floors.

BETWEEN COATS OF FINISH VARNISH()

Use the -2 Floor Sander to sand between coats ofHTF

floor finish, particularly when using water based

varnishes. These types of finishes tend to raise the

wood grain when first applied to raw wood. Allow

each coat of varnish to dry completely following the

manufactures directions. Use Hiretech abrasive pads

to sand between each coat of varnish. The fine

abrasive pads will remove light brush/applicator

marks and raised grain while maintaining the

integrity of the coat of varnish applied.

unsanded boards sanded boards

level very uneven

floors by sanding

diagonally in both

directions

unsanded boards

unsanded boards

Level uneven floors.

Sand main floor area.

Sand and blend edges in with main floor area.

FLOOR SANDING TECHNIQUE

Plank and Strip Floors - sand in the

direction the boards are laid, with the

wood grain.

-Parquet and Wood Block Floors

sand in the direction of the main

source of natural light. If there is no

natural source of light, sand in the

direction of the longest side of the

room. If the room is square, sand in

the direction the furniture is laid out

and how people normally use the

room.

5

FLOOR SANDER ABRASIVE GUIDE

6

DO NOT OVER SAND USE ONLY AS HEAVY GRADE ABRASIVE AS IT TAKES TO DO THE-

JOB PROGRESS FROM FIRST GRADE USED THROUGH FOLLOWING GRADES TO.

REMOVE ALL VISIBLE SANDING MARKS DO NOT MISS GRADE.A.

FLOOR SANDER ABRASIVES

Abrasive Grade Floor Type and Condition

Grit P24 Open Coat

(Very Coarse non-glogging)

For removing surface coatings from old floors such as varnish, stains and wax

polishes. For the rapid sanding and removal of scratches and marks. Sanding

level the joints of sub-flooring like particle board and masonite.

Grit P24

(Very Coarse)

For the rapid sanding and removal of scratches and marks. Sanding level the

joints of sub-flooring like particle board and masonite.

Grit P36 to P50

(Coarse/Medium)

For removing surface coatings from old floors such as varnish, stains and wax

polishes. For the rapid sanding and removal of scratches and light marks.

Sanding level the joints of sub-flooring like particle board and masonite.

Grit P60 to P80

(Medium)

For the rapid sanding and removal of scratches and light marks. Sanding level

the joints of sub-flooring like particle board and masonite.

Grit P100 to P120

(Medium/Fine)

Intermediate sanding of all types of wood floor. For final sanding of all types of

wood floor.

Grit P150 - P180

(Fine/Very Fine)

For final sanding of all types of wood floor. First sanding of cork or composition

floors. For sanding between coats of solvent based and 2 pack varnishes.

Hiretech Abrasives

Hiretech recommend the

following abrasive range

which are suitable for all floor

types and applications.

P16 - - 01025 - - -

P24 Grit Open Coat 01001 - - 01044 - -

P24 Grit 01002 01010 01026 - - -

P36 Grit - 01011 ----

P40 Grit 01003 01012 - 01045 01750 -

P50 Grit - 01013 01027 - - -

P60 Grit - 01014 - - 01751 -

P80 Grit 01004 01015 01028 01046 01752 -

P100 Grit - 01016 ----

P120 Grit 01005 01017 01030 01048 01754 -

P150 Grit - 01018 ----

P180Grit ----01756 -

P280Grit/BackingPad -----01769

HTF FLOOR

SANDER SHEET

ADHESIVE

BACKED

25 & 50/CASE

HTF ABASRIVE

PAD

20/CASE

HT8/DU8

FLOOR SANDER

SHEET

20 & 50/CASE

HT8 EX

FLOOR SANDER

BELTS

5/CASE

HT7/SUPER 7

EDGER DISC

FIBRE BACKED

25/CASE

HT7/SUPER 7

EDGER DISC

PAPER BACKED

25 & 50/CASE

SERVICE ROUTINE MAINTENANCE&

CAUTION - maintenance and repairs

must be carried out by authorised

personnel only. To prevent injury, always

remove the power cable from the power

supply before undertaking any work on

the machine. Do not operate this

machine unless it is fully assembled and

all guards are in place. Use Hiretech

genuine spare parts only.

General

1. Always make a list when first examining the

machine, to remind you of parts or action

needed on completion of repair/service.

2. The 7-2 is subject to high speeds. All screwsHT

should be fitted using a suitable thread lock

compound.

3. On completion of any work or service on an

electrical tool or appliance statutory safety tests

must be carried out by a competent person and

recorded (see Testing for Electrical Safety page 7

and 8).

4. The 7-2 needs no lubrication during routineHT

servicing.

5. Always ensure that the electrical supply is

disconnected before starting any routine

servicing or repair.

Visual Inspection

1. To clean the machine and remove dust, use a

vacuum cleaner to avoid damage and prevent

inhalation of dust.

2. Examine all guards and mechanical parts for

condition including the Disc Guard Ref.54 which

should be undamaged and moving freely.

3. Examine the sanding pad, a worn or damaged

pad must be replaced to maintain performance

and to avoid injury. There must be a minimum of

4mm ( / “) ‘tread depth’.

5

32

4. Examine the power cable for damage. If the

outer insulation shows the slightest of abrasions

or the inner conductors are exposed then the

cable must be replaced. The cable must not be

repaired with tape or insulation sleeve.

5. Ensure all labels are sound, readable and

secure.

6. Check that the castors are sound and moving

freely. If a castor is found to be loose or damaged

then the ‘cutting’ angle must be checked and

reset as necessary (see Setting Castors page 9).

Replace damaged castors.

7. Check the condition of the Bolt-Clamp Ref.59

and clean the threads.

8. Check that the Wrench Ref.61 is in place and in

good condition.

9. If a cloth type bag is in service check the

condition, clogged dust bags or bags with holes

make for inefficient dust pickup.

Dust Control

1. Turn the sander upside down and rest the

machine on the handles. Check the dust skirt for

pieces of abrasive disc and build up of dust.

Clean as needed.

Drive

1. The dive gear does not require maintenance

under normal operating conditions.

Lubrication

1. The 7-2 features sealed for life bearings whichHT

do not require any lubrication. In the unlikely

event that a bearing has to be replaced use a

Hiretech genuine spare part only as the grease

contained in the bearings is special. A standard

bearing is not suitable and may result in further

damage.

2. Should the gearbox require service the gear

housing and gears must be cleaned thoroughly

and the gearbox refilled with grease Part No.

011270. This is a special grease designed for

the high speed and temperatures generated

within the gear box. Under no circumastnce

must a standard automotive grease be used.

Using such a grease will result in gear failure and

damage to the motor and other components.

The grease may also melt and leak from the gear

box staining the floor or work piece being

sanded.

Care of Motor

1. The motor must be kept clean and free from

grease and dust.

2. The motor brushes must be checked regularly.

As it is necessary to remove the Cover Motor

Ref.4 during routine electrical testing, it is then a

simple matter to check the condition of the motor

brushes and avoid costly breakdowns.

3. Replace motor brushes when any oneALL FOUR

brush has worn to 12mm ( / ”) or less in length.

15

32

Brushes slide freely in the brush holders.MUST

There is no need to remove or disconnect any

internal leads when changing the brushes, only

the small braided shunt (pigtail) is disconnected

to release the brush.

7

4. To replace the motor Brushes Ref.12.

i. Remove the four Screws Ref.1 from the

Cover Motor and lift the cover off.

ii. Remove the four Spring Brush Ref.17 and

set to one side. The springs are removed by

pushing the spring tag in towards the

brush and lifting out.

iii. Using a cross recess screwdriver remove

the four brush shunt (pigtail) retaining

screws and lock washers Ref.16.

iv. Remove the four brushes.

v. Thoroughly clean the brush assembly and

housing using a soft brush and a suitable

vacuum cleaner.

vi. Inspect the four brushes for damage or

wear and if any one brush is found to be

damaged or worn to a length of

/ “(16mm) or less then replace all four

5

8

brushes. Always replace all four brushes

together.

vii. When replacing brushes ensure that each

brush moves freely in each holder and fit

the brush with the shunt (pigtail) in such a

position as to allow free movement

throughout the brush life. Ensure that

each brush shunt is connected securely

with the Screw and Washer Ref.16. (two

spare screws and washers are provided

with each pack of brushes). The brush

should be fitted so that the brush shunt

(pigtail) is at the bottom of the brush.

viii. Refit the brush springs by inserting into the

holder with the coil spring over the brush

then push in until the tag comes into

contact with the holder, slide the tag away

from the brush and release. The brush

spring will clip into position. Check the

springs and brushes for correct alignment

and free movement.

ix. Carry out electrical safety test and record

results (see Testing for Electrical Safety

page 7 and 8).

x. Finally check that all leads and cables are

clear of moving parts and will not be

trapped when refitting the cover motor.

xi. Refit the cover motor and secure with the

four Screws Ref.1.

Sanding Pad

It is very important to maintain the 7-2 EdgerHT

sanding pad in perfect condition for score free

sanding and to maximise the life of the abrasive disc.

In normal operation the sanding pad needs little

maintenance apart from periodic trimming, however,

if the pad is worn below its minimum thickness or it is

damaged it must be replaced.

Reasons for Removing/Replacing the Sanding Pad

1. The sanding pad is worn below its minimum

tread thickness of 4mm ( / ”)

5

32

2. Physical damage that cannot be removed by

trimming.

3. To gain access to maintain/repair the fan, gears,

motor and bearings.

4. To remove an obstruction from the dust pickup.

Removal and Replacement of the Sanding Pad

1. Disconnect the edger from the power supply.

2. Turn the edger upside down and rest it on its

handles.

3. Remove the Bolt Clamp (Ref.59) and Clamp

Washer (Ref.58).

4. Using a 18mm (11/16“) hardwood dowel

approximately 150mm (6") long, lock the Fan

Intake (Ref.31) in position to stop it turning by

inserting the dowel through the underside of the

edger to the rear of the sanding pad.

5. Using service tool Part No.011730 Sanding Pad

Wrench, remove the sanding pad in a counter

clockwise direction (right hand thread). Take care

to support the edger.

Note: The sanding pad can be tight, if needed use a

soft mallet to tap the wrench to help removal.

CAUTION - when the sanding pad

becomes loose carefully remove it by

hand. Take care not to lose the Shims

(Ref.56) which may come away with the

sanding pad. These shims, which may

vary in quantity with a minimum of two,

are used on the Shaft Drive (Ref.47) to

pack out the sanding pad.

6. Thoroughly clean the Guard Disc (Ref.54) and

refit all the Shims (Ref. 56) if removed.

7. Fit a new sanding pad and tighten using the

service tool.

8

9

3. To trim the sanding pad fix a piece of fine grit

floor sander abrasive (120 grit) face up to a solid

flat board that is large enough to stand on and

operate the edger. Place the board on a flat even

floor and the edger on top of the board with the

pad over the abrasive. Do not fit an abrasive

disc.

CAUTION - make sure that the Clamp

Bolt (Ref.59) is secure and properly

tightened

4. Connect the edger to the power supply, stand on

the board and tip the edger back and switch

' '. Carefully lower the edger so that theON

sanding pad comes into contact with the

abrasive. Move the edger from side to side across

the abrasive under its own weight for a few

seconds. Tip the edger back and switch ' ’OFF

5. Disconnect from the power supply and check the

condition of the sanding pad. You should witness

an even surface with no high or low spots around

the whole surface of the sanding pad in the

contact area as shown in the diagram below.

Note: Do not hold the edger in place, always keep it

moving across the abrasive sheet. Do not over trim

the sanding pad or you will reduce it's life. Do not lift

or force the edger while trimming the pad, allow the

edger to move under it's own weight. The sanding pad

minimum tread depth is 4mm ( 5/32“) .

Reasons for Trimming the Sanding Pad

1. As part of routine maintenance.

2. The sanding pad has been damaged.

3. The sanding pad has been replaced.

4. The sanding pad has been removed to gain

access to other components or to remove an

obstruction from the dust pick-up.

5. The castors have been replaced and/or

adjusted.

Trimming the Sanding Pad

1. Disconnect the edger from the electrical supply

and place the edger on a flat, smooth surface

such as a work bench. Visually check to see that

only the front of the sanding pad is in contact

with the surface it is standing on. That is, the

castors are adjusted so that the edger is ‘tipped’

forward.

2. Use a piece of paper or 0.005" feeler gauge to

check under and around the sanding pad to

confirm that only the front part of the sanding

pad is in contact with the surface it is standing

on.

The correct contact area is illustrated in the

diagram below.

If the contact area is wrong or can not be

identified accurately check and adjust the

castors as detailed below in - Adjusting the

Castor

CONTACT AREA

Sanding Pad Static Contact Area

Sanding Pad Trimmed Contact Area

Adjusting the Castors

The castors are set to achieve the correct contact

area across the sanding pad as illustrated in the

diagrams above.

1. To check the castor setting place a clean sheet of

glass across the two castors and the sanding

pad. Inserting a 0.005" feeler gauge (or a sheet

of paper) between the glass and the sanding

pad. Check the correct contact area is achieved

(see diagram above - Sanding Pad Static Contact

Area)

An alternative method is to lightly dampen the

rubber sanding pad and then place the glass

sheet across the two castors and sanding pad.

Apply light pressure to the glass sheet, which will

witness the dampened area of the sanding pad

in contact with the glass.

WARNING - use toughened glass only

with a minium thickness of 6mm (¼”)

with rounded/polished edges. Take care

when handling glass. Always use suitable

gloves, eye protection and protective

clothing.

2 To adjust the castors loosen the two castor lock

nuts using the special tool Part No. 011720 and

5mm ball allen key. Adjust the castors and check

the contact area on the sanding pad. When the

contact area is correct tighten the two castor lock

nuts securely. Use a suitable thread lock

compound. Finally check the contact area is still

correct after tightening the castor lock nuts.

4. Trim the sanding pad as detailed above.

Electrical Testing.

CAUTION - testing for electrical safety

should only be undertaken by a

competent person and all results

recorded. Do not exceed 1250 volt

insulation test duration of 3 seconds.

1. Examine the power cable for damage. If the

outer insulation shows the slightest of abrasions

or the inner conductors are exposed then the

cable must be replaced. The cable must not be

repaired with tape or insulation sleeve.

2. Open and check the mains plug for condition,

loose connections, damaged wires, etc.

3. Remove the four Screws Ref.1 and lift off the

Cover Motor Ref.4 to check the switch,

connections, leads etc. Pay special attention to

any gaskets, ‘O’ rings and seals intended to

exclude dust from the switch and switch housing

area. These must be maintained in good

condition.

Carefully brush and vacuum clean the switch

and brush block assembly and inside the cover

motor.

4. Refit the cover motor taking care not to trap any

leads.

5. Using a piece of insulation tape or a small soft

wedge lock the bias off switch in the ‘ ’ON

position.

6. Use the standard procedure test for electrical

safety (Class I Earthed Appliances [U.K.]). Do

not exceed 1250 volt insulation test duration of 3

seconds.

7. Record the test results.

8. Complete a functional (run) test and record

results.

CAUTION - when undertaking a

functional (run) test make sure the

machine is secure. Remember the

sanding disc will rotate..

10

FAULT FINDING

FAULT CAUSE ACTION

The machine does not run. The power cable is not Connect the power cable to the

connected to the power supply. power supply.

The motor brushes are worn. Replace the motor brushes.

The voltage is too low. Check the main power

complies with the machine's

serial plate data.

The machine will not pickup The dust bag is full. Replace the paper dust bag or

dust. empty the cloth dust bag.

There is an obstruction in the Disconnect the machine from

dust pickup. the power supply, turn the

machine over and check for

obstruction.

The machine does not sand The sanding pad is damaged. Check and replace the sanding

evenly. pad.

The castors are out of Check and adjust the castors.

adjustment.

The sander scores or burns The machine is not being Read the instructions, do not

the wood. operated properly. apply pressure when sanding.

The machine runs slow. The voltage is low. Check the supply voltage.

If an extension lead is being

used it is undersize and/or

it is coiled.

A motor brush is not making Check and refit or replace

contact. the motor brushes.

11

12

DISC FLOOR SANDER MODEL HT7-2

42

5

37

40

9

8

6

30

56

57

52

69 70

250

1

4

2

10

11

65

16

12

17

7

13

14

65

15

22

23

24

25

18

19

20

21

26

27

28

29

31

32

33

34

35

25

36

60

62 100

59

58

55

41

54

53

20

45

51

48

50

47

46

27

49

48

39

44

61

43

HIRETECH

SERVICE TOOL

DISC FLOOR SANDER

7-2MODEL HT

DISC FLOOR SANDER

7-2MODEL HT

OWNERS MANUAL OPERATING INSTRUCTIONS&OWNERS MANUAL OPERATING INSTRUCTIONS&

From Serial Number

00446 - 110/120 Volt (Excl.North America)

00634 - 110/120 Volt (NorthAmerica)

00487 - 220/240 Volt

From Serial Number

00446 - 110/120 Volt (Excl.North America)

00634 - 110/120 Volt (NorthAmerica)

00487 - 220/240 Volt

NOVEMBER2000NOVEMBER2000 REF PART.69 # 011680REF PART.69 # 011680

PRINTEDIN THE UKPRINTEDIN THE UK

DISC FLOOR SANDER

7-2MODEL HT

DISC FLOOR SANDER

7-2MODEL HT

OWNERS WORKSHOP MANUALOWNERS WORKSHOP MANUAL

NOVEMBER2000 REF PART.70 # 011820REF PART.70 # 011820

PRINTEDIN THE UKPRINTEDIN THE UK

ABC ABC

13

DISC FLOOR SANDER MODEL HT7-2

1 010010 4 Screw

2 011600 1 Switch 220/240 Volt (Bias Off)

2 011610 1 Switch 110/120 Volt (Bias Off)

4 010050 1 Cover Motor

5 010070 1 Housing Motor

6 010080 1 Strain Relief

7 010090 1 Cable Main Assembly 220/240 Volt ( )UK

7 010100 1 Cable Main 110 Volt ( )NA

7 010110 1 Cable Main Assembly 220 Volt ( )EEC

7 010120 1 Cable Main Assembly 240 Volt ( )AUS

7 010130 1 Cable Main Assembly 110 Volt ( )UK

8 010140 2 Handles Pack of 2

9 010150 4 Screw Handle

10 010160 1 Cable Switch Assembly

11 010170 1 Brush Block Assembly

12 010180 4 Brush Motor

13 010190 4 Screw Pack of 4

14 010200 4 Washer

15 010210 4 Screw

16 010220 4 Screw and Washer Set

17 010230 4 Brush Spring

18 010240 1 Field 110/120 Volt 7HT

18 010250 1 Field 220/240 Volt 7HT

19 010260 2 Washer Clamp

20 010270 5 Washer Lock

21 010280 2 Screw

22 010290 1 Baffle

23 010300 3 Screw

24 010600 1 Spring Washer

25 010320 2 Bearing

26 010330 1 Armature 110/120 Volt

26 010340 1 Armature 220/240 Volt

27 010350 3 Key

28 010360 1 Fan Motor

29 010370 1 Gasket

30 010380 1 Plate Exhaust

31 010390 1 Fan Intake

32 010400 1 Ring Retainer

33 010410 1 Spacer Bearing

34 010420 1 Seal

35 010430 1 Ring Retainer

36 010440 1 Pinion

37 010450 1 Housing Gear

39 010470 4 Screw

40 010480 1 Frame Bag Support

41 010490 1 Bag Dust Cloth

42 07038 25 Disposable Paper Dust Bag 7/HT HTF

Pack 2 (box 25)

42 07040 50 Disposable Paper Dust Bag 7/HT HTF

(box 50)

43 010510 2 Clip Wrench

44 010520 2 Screw

45 010530 2 Castor & Nut

46 010540 1 Spring Load

47 010550 1 Shaft Drive

48 010560 2 Bearing

49 010570 1 Gear Drive

50 010580 1 Ring Retaining

51 010590 1 Cover Gear

52 010220 4 Screw & Washer Set

53 010610 3 Screw

54 010620 1 Guard Disc

55 010630 1 Retainer

56 010640 4 Shim

57 012310 1 Sanding Pad (Metal Backed)

58 010660 1 Washer Clamp

59 010670 1 Bolt Clamp

60 010680 1 Pin Cotter

61 010690 1 Wrench

62 010720 1 Washer, Clamp and Pin Cotter Kit

65 010750 2 Brush Shunt

69 011680 1 Owners Manual & Operating Instructions

70 011820 1 Owners Workshop Manual

The following items are not illustrated.

Special Tools

250 011720 1 Service Tool - Castor Adjuster

250 011731 1 Service Tool - Sanding Pad

Fitting/Removal

250 011740 1 Service Tool - Pinion Fitting/Removal

250 011850 1 Service Tool - Extractor Gear Cover

250 011860 2 Service Tool - Extractor Seal

Consumables

110 010760 1 Carton Transit

100 011270 1 Grease Gear Disc Floor Sander

Ref. Pack DescriptionPSTK Qty. Ref. Pack DescriptionPSTK Qty.

14

HT CIRCUIT DIAGRAM7-2

DECLARATION OF CONFORMITY

This declaration identifies the product, manufacturer's name and address, and applicable specifications

recognised in the European community.

15

DECLARATION OF CONFORMITY

Manufacturer's Name: Hire Technicians Group Ltd.

Manufacturer's Address: Chalk Hill House

8 Chalk Hill

Watford

Herts Wd19 4BH

declares that the product:

Product Name: Hiretech Disc Floor Sander

Model Name: HT7.2 230 Volt 50Hz Insulation Class 1

7.2 110 Volt 50Hz Insulation Class 1HT

conforms to the following:

Machinery Directive (Harmonised) 89/392- as amendedEU

Low Voltage Directive (Harmonised) 73/23/ as amendedEU

Electromagnetic Compatibility Directive 89/336/ as amendedEU

following the provisions of the directives:

89/392/ , 93/44 , 73/23/ , 93/68/ , 89/336/ , 91/368/ ,EU EU EU EU EU EU

92/31/EU

EN HD BS EN60 335-1-88 ( 251-1-3) 3456-201 292-1-91

292-2-91 60204-1-92EN EN

55014-93 ( 800) 50082-1-92EN BS EN

745-2-4 ( 400.2) ( 2769-2-2.4)IEC HD BS

electrical safety test procedures comply with:

IEC HD BS CSA335 pt. 1-2, 251 1-3 1982, 2769 & 3456, C22.2,

K78A1/W1 & W3, 503./89, 0700 1/04.88KEMA NEMKO DIN VDE

264.S2 15/07.86HD

Where the product is licensed to carry a National Approval Mark it is

certified that all such products comply with the terms of that license.

C.J. Hedger, Director of Engineering. 1 April 2012

16

SERVICE REPAIR&

Contact your reseller for the name of your local service agent. Service and repairs undertaken by non-approved

service agents will void the product warranty. If you should have difficulty in obtaining service please contact your

distributor nearest to you at the address given below.

For the latest list of Hiretech dealers check on the Hiretech web site at www.hiretech biz/contact/dealerlist.html.

Name Address

Hiretech Pty Ltd Unit 2

62 Owen Street

Glendenning

NSW 2761

AUSTRALIA

Tel:

Fax:

Email:

Web:

+61 29625 9337

+61 29625 4770

sales@hiretech.com.au

www.hiretech.com.au

Abmast Inc

(Canada East)

6935 Rue Picard

Saint-Hyacinthe

QC

J2S 1H3

CANADA

Tel:

Fax:

Email:

Web:

(800) 361-0854

(800) 341 0554

asimard@abmast.com

www.abmast.com

STCasPraha Konevova33

130 00 Praha 3

CZECH REPUBLIC

Tel:

Fax:

Email:

+ 4202 22585810

+42 02 22584421

ruzena.muzikantova@stcnet.cz

Tool Matic A/S Vedskollevej

Herfolge

4681

DENMARK

Tel:

Fax:

Email:

Web:

+45 56250708

+45 56250705

sales@tool-matic.dk

www.tool-matic.dk

VIF Diffusion rue du Chateau-BP70112

59052 Roubaix

Cedex 1

FRANCE

Tel:

Fax:

Email:

+33 320 207880

+33 320 207889

infos@vif-furniture.com

Tucks Limited Hume Avenue

Park West Industrial Estate

Dublin 12

REPUBLIC OF IRELAND

Tel:

Fax:

Email:

Web:

+353 (01) 621 5555

+353 (01) 621 5563

info@tucks.ie

www.tucks.ie

Turner Morris (Pty) Ltd 39 Robyn Road

Benrose

P.O. Box 27252

2011

SOUTH AFRICA

Tel:

Fax:

Email:

Web:

+27 11 618 4313

+27 11 618 2620

dbnsales@turnermorris.co.za

www.turnermorris.co.za

Hire Technicians Group Ltd Chalk Hill House

8 Chalk Hill

Watford

Herts

WD1 4BH

UNITED KINGDOM

Tel:

Fax:

Email:

Web:

+44 01923 332424

+44 01923 332525

sales@hiretech.biz

www.hiretech.biz

Hiretech North America Inc PO Box 1564

Cliffotn Park

NY 12065

USA

Tel:

Fax:

Email:

Web:

+1 518 348 1300

(800) 563 2472

+1 518 348 1400

(800) 465 5981

sales.usa@hiretech.biz

www.hiretech.biz

Telephone, Facsimile, Email & Web

MANUFACTURED BY

HIRE TECHNICIANS GROUP LIMITED

, 8 , ,CHALK HILL HOUSE CHALK HILL WATFORD

, 19 4 .HERTS WD BH UNITED KINGDOM

TEL FAX: +44 (0)1923 332424 : +44 (0)1923 332425

HIRETECH LIMITED WARRANTY

Hiretech warrants to the original purchaser that the Hiretech machine covered by this warranty is free from defects

in workmanship and materials. Should any part fail in the period of two years from the date of the original

purchase as a result of a defect, Hiretech will (at it’s option) either repair or replace the part without charge

provided that the machine has been operated in accordance with the Owners Manual and Operating Instructions.

Should any such defect arise, please contact your nearest authorised repair agent. Standard service over land

mainland freight costs will be refunded on warranty repairs at the sole discretion of Hiretech or the authorised

repair agent. If the repair is non-warranty, the customer will be advised before any work is undertaken.

This warranty is the sole warranty by Hiretech and is in lieu of all other warranties express or implied and releases

Hiretech from all other obligations and liabilities.

This warranty does not apply to normal wear and tear to the machine, and in particular does not cover normal

wear parts such as mains cable, wheels, switches, relays, brushes, rubber parts, hoses and bearings. This

warranty also does not cover, and Hiretech will not be liable for, excessive wear caused by abnormal use.

Hiretech will under no circumstances be liable for alterations to the machine or for damage caused by third

persons, or for misuse or abuse of the machine, or damage caused during transportation. Repairs of the machine

made or attempted by persons other than those specifically authorised by Hiretech shall render this warranty void

and Hiretech will not be liable for such repairs, the cost of such repairs, or the consequences of such repairs.

Where spare parts are used on the machine and they do not conform to Hiretech specifications, this warranty will

be rendered void and Hiretech will not be liable.

Hiretech will not be liable for any indirect or consequential loss, damage, cost or expense of any kind whatever

and however caused whether arising under contract, tort (including negligence) or otherwise including (without

limitation) loss of production, loss of profits or contracts or of operating time or goodwill or anticipated savings.

Every effort has been made to present all information in this publication accurately, however no liability is

accepted for any inclusions or advice given or for omissions from this publication. Hiretech reserves the right to

make changes or improvements to its products without prior notice. Hiretech is a registered trademark of Hire

®

Technicians Group Ltd., all other trademarks are the property of their respective owners.

© Hire Technicians Group Ltd.

Other manuals for HT7-2

1

Table of contents

Other HireTech Sander manuals

HireTech

HireTech HT8 EX User manual

HireTech

HireTech HT8 System manual

HireTech

HireTech HT7-2 User manual

HireTech

HireTech HT8-1.2 System manual

HireTech

HireTech HT8 System manual

HireTech

HireTech HT8-1.2 User manual

HireTech

HireTech HTF-2 System manual

HireTech

HireTech HT8 System manual

HireTech

HireTech HT7 User manual

HireTech

HireTech HTF System manual