HireTech HT8 System manual

2018/09 © Hiretech Part # 163829

OWNERS MANUAL & OPERATING INSTRUCTIONS

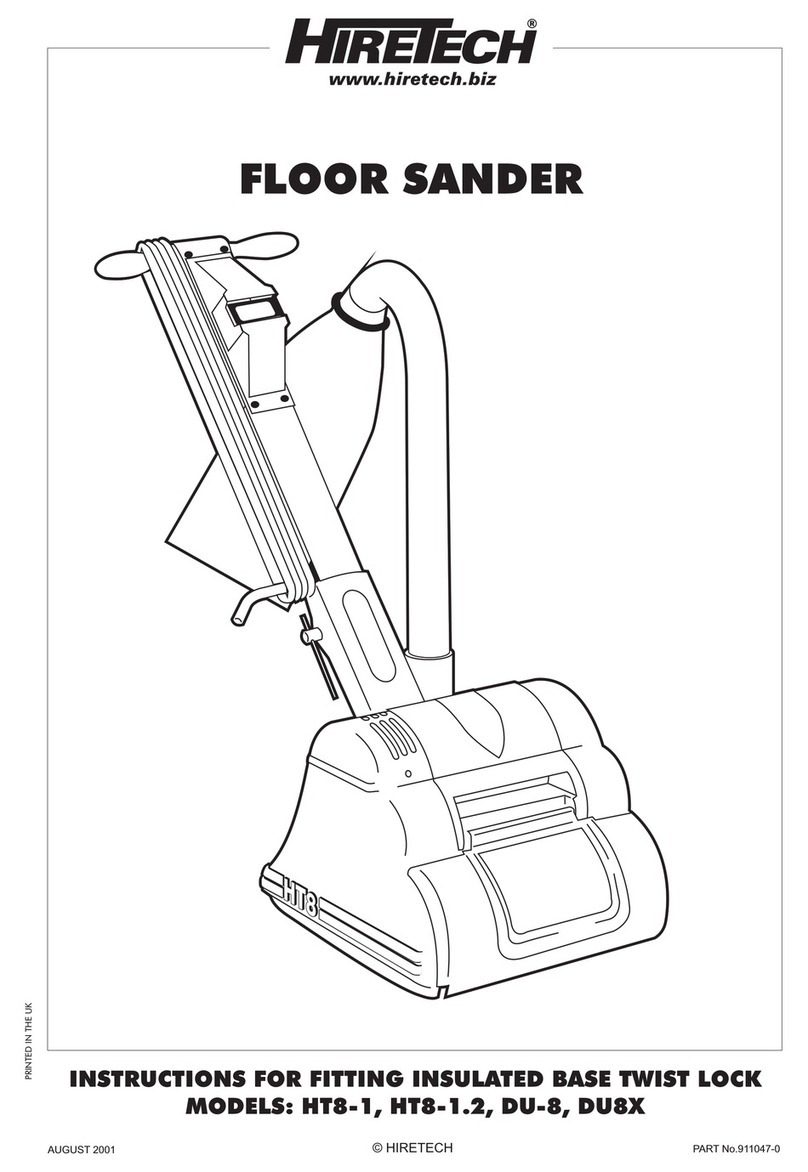

HT8 DRUM FLOOR SANDER

From Serial Number

07294 (240/240 Volt) & 03415 (110/120 Volt)

HSS2105 (L01A)

WARNING

For safe operation of this machine, read and understand all

instructions. Look for the ‘warning/caution’ symbol.

This symbol means that if you do not follow the instructions

injury can occur to the operator and damage to the

machine and floor may result.

WARNING: Risk of explosion.

Floor sanding can result in an explosive mixture of fine

dust and air. Use this floor-sanding machine only in a well-

ventilated area free from any flame, match or source of

ignition.

WARNING: Risk of fire.

Never leave the floor sander unattended with dust in the

dust bag.

WARNING: Risk of potential injury.

Moving Parts - to reduce the risk of injury, unplug the

machine before replacing abrasive sheets or carrying out

any form of adjustment or servicing.

NORTH AMERICAN SAFETY INSTRUCTIONS

WARNING: This floor sanding machine must be grounded.

This floor-sanding machine shall be grounded while in use to protect

the operator from electric shock. The machine is provided with a

three-conductor cord and a moulded three-contact grounding

type attachment plug to fit the proper grounding type receptacle.

The Green (or Green and Yellow) conductor in the cord is the

grounding wire. Never connect this wire to any pin other than the

grounding pin of the attachment plug.

This floor-sanding machine is provided with an attachment plug

as shown in sketch A. It is intended for use on a nominal 120 volt

circuit. If a properly grounded receptacle as shown in sketch A

is not available, an adaptor as shown in sketch ‘C’ should be

installed as shown in sketch B if the outlet box that houses the

receptacle is grounded. Be sure to fasten the grounding tab with a

metal faceplate screw.

MAINS CABLE WIRING - PLUG

USE & APPLICATION

This machine is intended for commercial use connected with the

laying and maintaining of wooden floors and decks.

These types of surfaces may be found both in commercial and

household environments.

SPARE PARTS

Use Hiretech genuine spare parts only for service and repair.

Use of non-approved parts will void the product warranty. See

the back cover of this manual for the terms and conditions of the

Hiretech Limited Warranty.

Hiretech reserves the right to make changes or improvements to it’s

products without prior notice.

For the latest product news and updates, spare parts, downloads

and service information visit www.hiretech.biz.

ATTACHMENT PLUG SKETCH ‘C’

METAL

SCREW

COVER OF GROUNDED

OUTLET BOX SKETCH ‘B’

ADAPTER

GROUNDING

MEANS

COVER OF GROUNDED

OUTLET BOX SKETCH ‘A’

GROUNDING PIN

CONTENTS

Warning 1

North American Safety Instructions 1

Use & Application 1

Spare Parts 1

Mains Cable Wiring - Plug 1

Specification 2

Safety 2

Set Up 2

Preparation 3

Operation 3

Floor Sanding Technique 4

Floor Types 4

Floor Sanding Tecnique 5

Floor Sander Abrasive Guide 6

Floor Sander Abrasives 6

Service & Routine Maintenance 7

Fault Finding 10

Parts Diagram 11

Parts Diagram 12

Parts List 13

Circuit Diagram 14

Fitting Replacement Switch 14

1 © Hiretech

SPECIFICATION

The HT8-1.2 Hiretech Floor Sander will sand hard and soft wood

floors, cork and composition floors that require rapid sanding and

levelling to a fine finish. A powerful motor drives a finely balanced

sanding drum which is covered in a unique drum rubber providing a

high quality finish to both hard and soft woods and other surfaces.

Completely self contained with a high efficiency dust pickup the

machine breaks down into three simple component parts for easy

transport. With low voltage trip and overload protection the HT8-

1.2 is a high performance sander suitable for professional and

home owner use.

Power Supply 110/120 V 50/60 Hz

220/240 V 50/60 Hz

Off Load Current 110/120 V 8A

220/250 V 5A

Average Load Current 110/120 V 15A

220/250 V 8A

Noise 95 dBa at 1metre (3’ 3”)

Vibration 1.60 m/s² r.m.s.

Switch Low voltage trip and overload

protection.

Motor Continuous heavy duty AC/

DC self cooling 4 brush.

Motor RPM 8,500

Drum RPM 3,300

Sanding Drum 8” (203mm) wide aluminium

extrusion with moulded rubber

drum cover.

Drive Non-slip toothed timing belts

and gear cut pulleys.

Dust Pickup Seated oversize vacuum fan

with adjustable dust pan,

disposable paper dust or cloth

bag.

Moving Parts Sealed for life ball bearings.

Guards High impact injection moulded

ABS.

Abrasive 495mm (19.5”) total length x

203mm (8”) wide sheet with

notched and angled ends 24

to 120 grit.

Power Cable 7m (23’) Non-marking outer

insulation.

Weight Net 41.5kg (91.5lbs)

Shipping Weight 50.0kg (110.3lbs)

Shipping Dimensions 78 x 40 x 44cm

(30.75” x 15.75” x 17.5”)

Warranty 2 years

Read the following Safety and Operational notes before

using your Hiretech Floor Sander.

SAFETY

1. For safety it is recommended that a residual current circuit

breaker (ground fault interrupter) is used with this machine.

2. Check the operating voltage is correct and that the machine is

switched OFF (‘O’) before connecting to the power supply.

3. Always disconnect from the power supply when changing the

abrasive paper, servicing the floor sander, replacing the dust

bag or leaving the machine unattended.

4. Always replace the dust bag (paper type) or empty the dust

bag (cloth type) when the dust in the bag reaches the ‘MAX’

line or when the machine is left unattended.

5. Never dispose of or empty the contents of the dust bag into a

fire or incinerator.

6. Never reuse the paper dust bag or use a non standard bag.

Cloth bags must be in good condition with no holes.

7. Always wear a dust mask when using the floor sander,

handling the dust bag or cleaning the machine after use.

8. Wear ear protection when using the floor sander.

9. Ensure adequate ventilation of the work area to avoid the

formation of a combustible mixture of flying dust and air.

10. Never smoke when using or servicing the floor sander or

when handling the dust bag.

11. Never expose the machine to rain or damp. Always store in a

dry place.

12. Stop the floor sander immediately if damage to the machine

or abrasive paper is suspected.

13. Never allow the power cable to come into contact with the

sanding drum when the floor sander is in operation. If the

power cable becomes damaged and the inner conductors

are exposed switch the power OFF and remove the plug

before attempting to move the machine. The cable must be

replaced by an authorised dealer or qualified electrician

using Hiretech® genuine spare parts only.

14. Keep hands, feet and loose clothing away from all moving

parts of the machine.

15. Punch down or remove all nails, screws, tacks and other

fixings from the floor before sanding to prevent contact with

the sanding drum.

16. Never operate the machine without all the guards in place.

17. Keep children and pets clear at all times.

18. If the machine should fail to operate refer to the Fault Finding

Guide on page 10.

19 The HT8 is heavy, take care when lifting and transporting the

machine. Always break down the machine into its component

parts when lifting and transporting.

SET UP

Assembly and Transport

1. The HT8-1.2 breaks down into three component parts, the

main body, handle assembly and dust tube for easy handling

and transport. To assemble loosen the Clamp Bracket Ref.21

and slide the handle assembly into the Handle Bracket Ref.51.

Adjust the height of the handle so that your arms are slightly

bent when standing upright behind the machine. This will

provide you with maximum control in operation. Tighten the

clamp bracket firmly. Always ensure that the clamp bracket is

tight, check periodically during use.

2. Connect the Cable Handle Ref.20 to the Body Twist Lock

Ref.24 at the rear right hand side of the floor sander body.

2© Hiretech

Align the plug with the pins, push in and twist clockwise to

lock.

3. Slide the Exhaust Tube Ref.59 into the Exhaust Bracket Ref.56

and push fully home.

4. Fit a paper dust bag following the instructions printed on the

bag. If a cloth bag is used ensure that it is tied securely around

the dust tube neck and that the bag is in good condition with

no holes.

5. To prepare the floor sander for use place the machine on the

floor and remove the main cable from it’s storage position

on the handle assembly. Check that the cable is in good

condition and that all fittings are secure.

6. To dismantle the floor sander reverse procedure 1 to 5 above.

7. Always ensure that the floor sander is secure and cannot

move when being transported in a vehicle. The floor sander

is heavy. Take care when lifting and carrying the machine.

Always break down the machine into its component parts

when lifting and transporting.

Installing Abrasive Paper

1. Ensure the power cable is disconnected from the power

supply.

2. Tip the floor sander back so that it rests on the handle.

3. Lift the Drum Guard Ref.35 and turn the Drum Ref.168 to

expose the Paper Clamp Bar Ref.175. Take care not to trap

your fingers when turning the drum.

4. Loosen the 2 Paper Clamp Screws Ref.174 with a coin or

suitable screw driver so that the clamp bar raises about 1/2“

(12mm) only. DO NOT remove the screws completely.

5. Select a suitable grade of abrasive paper (see Abrasive Paper

Guide on page 6). To help install course grit abrasive papers

draw the smooth side (back) of the paper over the edge of a

work bench to make it curl .

6. Kneeling in front of the machine place one end of the abrasive

paper under the clamp bar so that the notches align with the

clamp bar screws and clamp bar.

Carefully holding the abrasive paper in place rotate the drum

1 revolution. Tuck the other end of the abrasive paper under

the clamp bar and use both hands to squeeze the sheet tight

around the drum. Make sure it is square to the edges of the

drum with no overlap and both ends of the abrasive sheet are

equal distance under the paper clamp bar.

Firmly tighten the two clamp bar screws. Check the abrasive

sheet is skin tight around the drum. If in doubt repeat the

above procedure. Loose or damaged abrasive sheets will

tear during sanding and can be expensive to keep replacing.

Damage may also occur to the floor and floor sander.

7. Lower the drum guard and stand the machine up. The floor

sander is now ready for use.

Note: Use Hiretech genuine floor sander abrasives for the best

sanding performance and finish. They will also reduce the risk of

tearing due to poor fit which is a common problem with generic

and non standard abrasives.

PREPARATION

1. Where possible remove all furniture from the area or room.

The HT8-1.2 Floor Sander features an efficient dust pickup,

however, some dust will escape.

2. Remove all tacks, staples and other unwanted fixings from the

floor. Failure to do so will result in damage to the abrasive

paper and sanding drum.

3. Punch all nails below the surface of the floor using a suitable

nail punch and hammer. Any screws used to fix boards should

be counter sunk below the surface. During sanding any nails

or screws that become exposed must be punched or counter

sunk further.

4. Firmly fix all loose boards or blocks.

5. Remove heavy wax, grease and dirt deposits by hand.

6. Sweep and vacuum the floor thoroughly to remove

dirt and discarded fixings.

7. Ensure good ventilation by opening windows.

OPERATION

1. Move the floor sander to the location of your work.

2. Connect the power cable to a suitable power supply ideally

located behind or to one side of the machine and work area.

3. Wear a dust mask and ear protection.

4. Hold both handles with the main cable held in a small loop in

the left hand and then passed over the left shoulder.

5. Apply light downwards pressure on the handles to tip the floor

sander back to raise the sanding drum off the floor. Switch on

by pushing the ON/OFF switch to the ‘I’ position.

CAUTION: the HT8-1.2 Floor Sander is a powerful

machine. Always ensure that you have a firm grip before

switching on.

6. Now move the floor sander slowly forward and at the same

time release the pressure on the handles to gently lower it so

that the sanding drum comes into contact with the floor.

7. Guide the floor sander in a straight line at a slow walking

pace. Do not force or hold the floor sander back. Allow the

machine to do the work and always move at an even pace.

8. At the end of the pass while still moving forward tilt the floor

sander back so that the sanding drum comes clear of the

floor. Now moving backwards lower the floor sander again

and pull it backwards over the area just sanded moving at a

steadily even pace. Take care to ensure that the power cable

is kept clear of the sanding drum at all times. At the end of the

sanding pass and while still moving backwards tilt the floor

sander back so once again the sanding drum comes clear of

the floor.

Move the machine over so that it overlaps the area just sanded

by 3” (75mm) and start to sand the next pass repeating the

above technique.

CAUTION: to prevent damage to the floor surface, work

piece or machine follow these rules.

i. Always ensure that the floor sander is moving when in

operation and the sanding drum is in contact with the

floor.

ii. Never lift the back of the machine when sanding.

iii. Never apply pressure to try to increase the rate of

sanding. Damage to the floor and machine will occur.

iv. Never bounce or drop the floor sander on to the floor.

Always lower the machine gently.

v. Never dwell in one place, move steadily at all times.

vi. Never allow the power cable to come into contact with

the sanding drum.

3© Hiretech

9. When the dust in the dust bag reaches the ‘MAX’ line stop

sanding. Disconnect the power cable from the power supply

and remove the paper dust bag. Turn the top of the paper

dust bag over to stop the escape of dust and dispose of into a

suitable container. Never reuse the paper dust bag or empty

it or dispose of it into a fire. If a cloth bag is used empty into

a suitable container being careful to contain the dust. Do not

dispose of the contents into a fire.

10. Fit a new paper dust bag or refit the cloth bag. Reconnect the

floor sander to the power supply and continue sanding.

11. When taking a break from work disconnect the power cable

from the supply, remove and dispose of the paper dust bag, or

empty the cloth bag as detailed in 8. above. Never leave the

floor sander unattended with the dust bag in place containing

dust.

12. On completion disconnect the power cable from the supply.

Remove and dispose of the paper dust bag, or empty the

cloth bag as detailed in 8. above. Stow the cable on the

handle assembly and if required dismantle for transportation.

Carry out maintenance as recommended in Maintenance and

Servicing.

DANGER: never leave the floor sander unattended with

dust in the dust bag. Always remove the dust bag and

dispose of into a suitable container.

FLOOR SANDING TECHNIQUE

HT8 Drum Floor Sander - a powerful floor sander designed for the

rapid levelling and sanding of all types of wood flooring excluding

thin laminated or veneered floors. Load the sander with abrasive

making sure that it is skin tight around the drum. Loose sheets

will tear. Place the sander on the right hand wall (unless you are

making an angled cut on uneven floors) with about two thirds of

the floor in front of you. Start the sander with the drum off the floor

then walk forward at an even pace and ease the drum on to the

floor. As you near the end of the pass, gradually raise the drum

off the floor. Practice this technique before turning on the sander.

Cover the same path you made on the forward cut by pulling the

machine backwards and easing the drum to the floor as you begin

the backward pass until you reach the original starting point, then

ease the drum off the floor.

When two thirds of the floor is sanded, turn the floor sander around

and sand the remaining third in the same way. Overlap the one

third area by 0.6 to 0.9 meters (2 to 3 feet ) with the two thirds

area to blend the two areas together.

WARNING: never bounce the sanding drum or dwell in

one place as this will sand dips and hollows in the floor.

HT7 Disc Floor Sander (Edger) - a powerful disc floor sander

designed for sanding along the edges of a floor without damaging

the baseboards or mouldings. Also suitable for smaller areas

where the HT8-1.2 Floor Sander will not reach like stair treads and

closets load the abrasive disc making sure the retaining bolt is tight.

Start the edger with the disc off the floor then lower the disc to

the floor as you move the sander. Work progressively moving the

sander in a sweeping motion from side to side.

HTF Orbital Floor Sander - a orbital action floor sander designed

for re-finishing, sanding between coats of varnish and re-surfacing

floors in good condition. Load the abrasive sheet, pad or strip.

Start the sander, move immediately and sand in the direction of

the grain using the same technique as the drum floor sander. For

difficult to reach areas use the disc floor sander with a fine grit

abrasive, or sand by hand.

Hand Sanding - to sand difficult to reach areas scrape and sand

the floor by hand. Use a scraper to remove old finishes, always

scraping in the direction of the grain, and then sand by hand using

the same grit abrasive as you finished with when machine sanding.

See Floor Sanding Technique diagrams on page 5.

FLOOR TYPES

Plank & Strip Floors

Old floors in good condition - when the floor is in good condition

- no uneven edges, cupping or crowning of planks and strips - and

you want to re-surface the floor, sanding back to new wood, start

sanding in the direction of the planks or strips - with the wood grain.

Start with a medium grit abrasive. Complete the first cut with the

HT8-1.2 Floor Sander then sand up to the baseboards and door

thresholds with the HT7-2 Disc Floor Sander, using a medium grit

abrasive, blending the edges in with the main floor area. Sweep

the floor. Using a medium/fine grit abrasive, sand the main floor

area with the drum sander and then complete the floor with the

edger using a fine grit abrasive. Sweep the floor. Finish sanding

the main floor area with the drum floor sander using a fine grit

abrasive. If the floor is in particularly good condition (level with no

deep scratches or blemishes) you may re-surface the floor using the

HTF-2 Floor Sander, however, as the sanding action of this machine

is less aggressive than the HT81.2 Floor Sander the job will take

more time.

Uneven floors - when the floor is uneven sand diagonally at 45o

across the room in both directions using the HT8-1.2 Floor Sander

with a coarse grit abrasive. Only make one cut on both diagonals,

this will achieve a basic level. Now complete the floor as for a

level strip or plank floor. Use the same grit abrasive as was used

on the 45o cut for the first cut parallel to the planks or strips.

Floors with an existing finish - when re-finishing a floor remove as

little of the existing surface as possible. If the old finish is worn and

the floor is generally in good condition use the HTF-2 Floor Sander

with Hiretech abrasive pads and strips which have been especially

designed for re-finishing floors. These will maintain the integrity of

any stain used to colour the wood and prepare the surface for a

new coat of finish. If the floor is badly marked and scratched and

has to be sanded back to new wood use the HT8-1.2 Floor Sander

and HT7-2 Disc Floor Sander. Always try a medium grit paper first,

particularly on a diagonal cut. If 90% of the old finish is removed

and the floor is generally level, you do not need to use a coarse

grit abrasive.

Engineered and Thin Floors

Use the HTF-2 Floor Sander for engineered or thinner floors that

may have been subjected to repeated sanding. The HTF-2 will

remove old surface finishes and prepare the floor for re-finishing.

Sand the floor using the same method as a strip, plank, or parquet

floor. If the floor has deeper scratches or marks these should be

sanded out by hand and blended in with the main floor. To check

the wood depth in the floor remove a baseboard or moulding from

around the edge of the floor. This should provide access to the

edge of the floor for inspection.

Parquet & Block Floors

The grain of the wood will run in a number of directions so sand

4© Hiretech

the floor in the direction of the main source of natural light in the

room. If there is no source of natural light sand in the direction of

the longest side of the room or, if the room is square, in the direction

the furniture is laid out and how people normally use and view the

room.

This technique will help mask any imperfections in the floor.

Complete the sanding operation as detailed for plank or strip

floors.

Between Coats of Finish (varnish)

Use the HTF-2 Floor Sander to sand between coats of floor finish,

particularly when using water based varnishes. These types of

finishes tend to raise the wood grain when first applied to raw

wood. Allow each coat of varnish to dry completely following

FLOOR SANDING TECHNIQUE

5© Hiretech

the manufactures directions. Use Hiretech abrasive pads to sand

between each coat of varnish. The fine abrasive pads will remove

light brush/applicator marks and raised grain while maintaining

the integrity of the coat of varnish applied.

FLOOR SANDER ABRASIVE GUIDE

DO NOT OVER-SAND USE ONLY AS HEAVY GRADE ABRASIVE AS IT TAKES TO DO THE JOB. PROGRESS

FROM FIRST GRADE USED THROUGH FOLLOWING GRADES TO REMOVE ALL VISIBLE SANDING MARKS.

DO NOT MISS A GRADE.

FLOOR SANDER ABRASIVES

Hiretech Abrasives

HT8/DU8

FLOOR SANDER

SHEET

20 & 50/CASE

HT8 EX

FLOOR SANDER

BELTS

5/CASE

HT7/SUPER 7

EDGER DISC

FIBRE BACKED

25/CASE

HT7/SUPER 7

EDGER DISC

PAPER BACKED

25 & 50/CASE

HTF FLOOR

SANDER SHEET

ADHESIVE

BACKED

HTF ABASRIVE

PAD

20/CASE

Hiretech recommend

the following abrasive

range which are suitable

for all floor types and

P16 - - 01025 - - -

P24 Grit Open Coat 01001 - - 01044 - -

P24 Grit 01002 01010 01026 - - -

P36 Grit -01011 ----

P40 Grit 01003 01012 -0104501750-

P50 Grit -01013 01027---

P60 Grit -01014 --01751-

P80 Grit 01004 01015 01028 01046 01752 -

P100 Grit -01016 ----

P120 Grit 01005 01017 01030 01048 01754 -

P150 Grit -01018 ----

P180Grit ----01756-

P280 Grit/Backing Pad -----01769

Abrasive Grade Floor Type and Condition

Grit P24 Open Coat

(Very Coarse non-glogging)

For removing surface coatings from old floors such as varnish, stains and wax

polishes. For the rapid sanding and removal of scratches and marks. Sanding

level the joints of sub-flooring like particle board and masonite.

Grit P24

(Very Coarse)

For the rapid sanding and removal of scratches and marks. Sanding level the

joints of sub-flooring like particle board and masonite.

Grit P36 to P50

(Coarse/Medium)

For removing surface coatings from old floors such as varnish, stains and wax

polishes. For the rapid sanding and removal of scratches and light marks.

Sanding level the joints of sub-flooring like particle board and masonite.

Grit P60 to P80

(Medium)

For the rapid sanding and removal of scratches and light marks. Sanding level

the joints of sub-flooring like particle board and masonite.

Grit P100 to P120

(Medium/Fine)

Intermediate sanding of all types of wood floor. For final sanding of all types

of wood floor.

Grit P150 - P180

(Fine/Very Fine)

For final sanding of all types of wood floor. First sanding of cork or

composition floors. For sanding between coats of solvent based and 2 pack

varnishes.

6© Hiretech

FAULT FINDING

10 © Hiretech

Other manuals for HT8

3

This manual suits for next models

2

Table of contents

Other HireTech Sander manuals

HireTech

HireTech HTF System manual

HireTech

HireTech HTF-2 System manual

HireTech

HireTech HT8-1.2 User manual

HireTech

HireTech HT8 System manual

HireTech

HireTech HT7-2 User manual

HireTech

HireTech HT7-2 System manual

HireTech

HireTech HT7 User manual

HireTech

HireTech HT8 EX User manual

HireTech

HireTech HT8 EX User manual

HireTech

HireTech HT8-1.2 System manual