TFP1485

Page 7 of 20

the Diaphragm open, permitting water

to ow into the system piping, as well

as through the Alarm Port to actuate

the system alarms.

In the event of a fault detection in the

re detection system, the system con-

verts to operate as an ordinary dry pipe

system, which means the energized-to-

close Solenoid Valve in the actuation

loop becomes de-energized and open

to communicate any system air pres-

sure loss to the DP-1 Dry Pilot Actu-

ator. As soon as a sprinkler operates/

activates, the subsequent drop in air

pressure opens the Dry Pilot Actuator.

Water from the diaphragm pressure

piping will exit the Dry Pilot Actuator

through this drain, resulting in the acti-

vation of the DV-5aDeluge Valve.

Upon opening of the DV-5aValve,

whether by Solenoid Valve or Dry Pilot

Actuator, the Model MRA-1 Manual

Reset Actuator opens to constantly

vent the DV-5aDiaphragm Chamber

to hydraulically latch the DV-5ain the

tripped position until manually reset.

For more information on the TYCO

Model MRA-1 Manual Reset Actuator,

refer to Technical Data Sheet TFP1387.

Due to the functionality of the Model

MRA-1 Manual Reset Actuator, the

release circuit of the releasing panel

need only provide the typical ten

minutes of alarm condition intended

to energize the Solenoid Valve to

open. After the ten minute duration, at

which point should the Solenoid Valve

become de-energized and close (espe-

cially while operating under battery

back-up), the MRA-1 will have already

automatically opened, thereby prevent-

ing the DV-5a Diaphragm Chamber

from becoming re-pressurized, and

preventing an inadvertent closing of

the DV-5a during a re event.

Installation

The TYCO DV-5aValve with Preaction

Type A Trim is to be installed in accor-

dance with this section.

NOTICE

DV-5AAutomatic Water Control Valves

are designed to be used in freshwa-

ter systems. When the supply is from

an alternative source such as brackish

water, saltwater, or contains additives

such as foam, the limited warranty is

reduced to one year from the time of

installation. An increase in frequency of

inspections is required when the valve

is exposed to such supplies and other

corrosive conditions or chemicals that

could impact valve materials or the

operation of the assembly. The system

and all components must be designed

accordingly for the increased demand.

It is required to thoroughly flush the

valve and trim assembly with freshwa-

ter and reset to the set condition after

each operation.

Proper operation of the DV-5aValve

depends upon its trim being installed in

accordance with the instructions given

in this technical data sheet. Failure to

follow the appropriate trim diagram

may prevent the DV-5aValve from func-

tioning properly, as well as void approv-

als and the manufacturer’s warranties.

The DV-5aValve must be installed in a

readily visible and accessible location.

The DV-5aValve and associated trim

must be maintained at a minimum tem-

perature of 40°F (4°C).

Heat tracing of the DV-5aValve or its

associated trim is not permitted. Heat

tracing can result in the formation of

hardened mineral deposits that are

capable of preventing proper operation.

Always open the system control valves

slowly to avoid a sudden rush of water

entering the system.

The DV-5aValve is to be installed in

accordance with the following criteria:

Step 1. All nipples, ttings, and devices

must be clean and free of scale and

burrs before installation. Use pipe

thread sealant sparingly on male pipe

threads only.

Step 2. The DV-5aValve must be

trimmed in accordance with Figure 5.

Note:If the addition of an Alarm Control

Valve is desired or required by the local

AHJ, the Alarm Control Valve noted as

Item H in Figure 8 is to be a separately

ordered electronically supervised nor-

mally open valve.

Step 3. Care must be taken to ensure

that check valves, strainers, globe

valves, etc. are installed with the ow

arrows in the proper direction.

Step 4. Drain tubing to the Drip Funnel

must be installed with smooth bends

that will not restrict ow.

Step 5. The Main Drain and Drip Funnel

Drain may be interconnected provided

a check valve is located at least 12 in.

(300 mm) below the Drip Funnel.

Step 6. Suitable provision must be

made for disposal of drain water. Drain-

age water must be directed such that

it will not cause accidental damage to

property or danger to persons.

Step 7. Connect the Diaphragm Supply

Valve to the inlet side of the System

Main Control Valve in order to facilitate

setting of the DV-5AValve as shown in

Figure 8.

Step 8. Provisions must be made for

installation of an Inspector's Test Con-

nection (ITC) at the most hydraulically

demanding location of the sprinkler

system. The maximum orice size of

the ITC is to be no greater than the

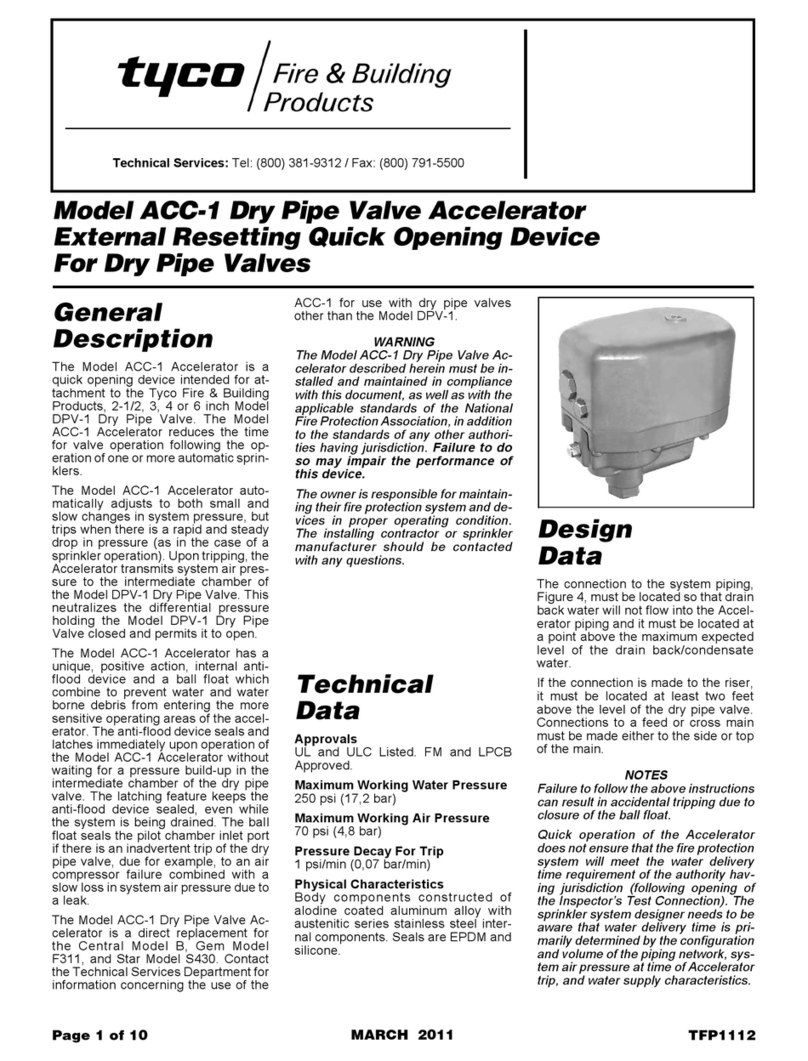

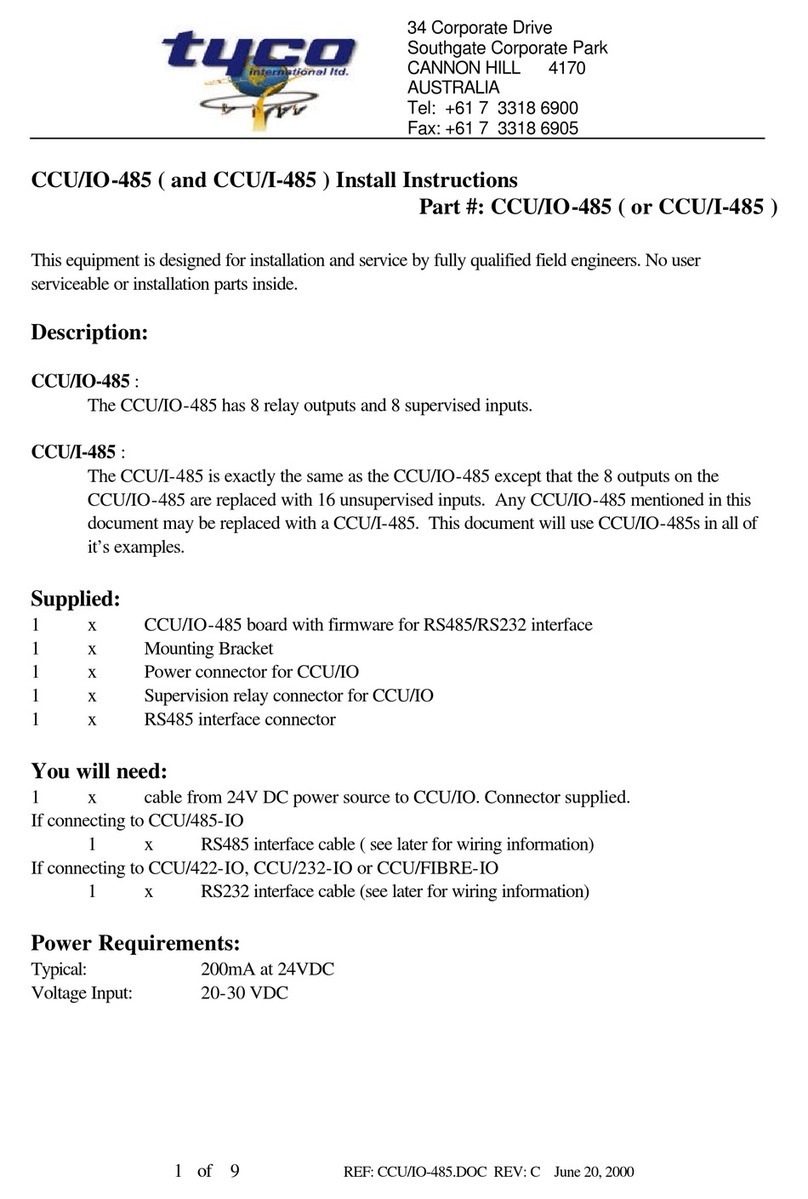

NOTES:

The dew point of the pilot line air pressure must be maintained

below the lowest ambient temperature to which the dry pilot

actuation system will be exposed. Accumulation of water in the

pilot line connection to the Actuator will lower the air pressure

at which the actuator will open and possibly prevent proper

operation. Also, introduction of moisture into the pilot lines

exposed to freezing temperatures can create an ice buildup

that could prevent proper operation of the Actuator.

An air dryer must be installed where the moisture content

of the air supply is not properly controlled at less than the

required value.

It is recommended that an AMD-3 Nitrogen Maintenance

Device be utilized in dry pilot actuation system applications

where the dew point must be maintained below -29°C. Refer

to Technical Data Sheet TFP1241.

WATER SUPPLY PRESSURE IN BAR

AIR PRESSURE IN BAR

1,0

0

2,0

4,0 6,0 10,0

8,0 12,0 14,03,0

SYSTEM AIR PRESSURE

RANGE OF ACTUATOR OPENING PRESSURE

GRAPH B

DV-5AVALVE - PREACTION TYPE A SYSTEM

AIR PRESSURE REQUIREMENTS