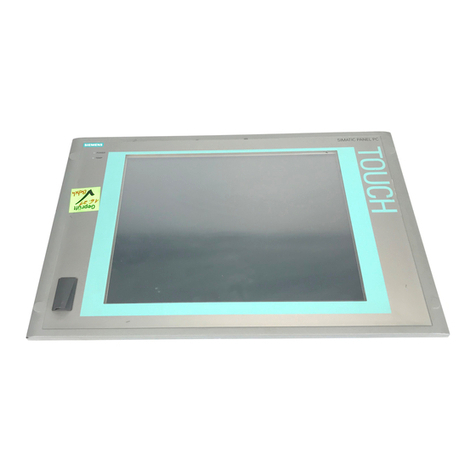

Siemens ST 80 · 2006 2/119

Operator Control and Monitoring Devices

Panels — 270 series

SIMATIC OP 270

2

■

Function

• Displaying and modifying process parameters

• Function keys

for direct triggering of functions and actions. Up to 16 functions

can be configured simultaneously on function keys.

The function keys can be used directly as PROFIBUS DP input

peripherals.

• Process display:

-OP 270 6“:

QVGA resolution (320 x 240 pixels),

OP 270 10“:

VGA resolution (640 x 480 pixels)

with 256 colors for display elements

- Vector graphics (various line-drawn and solid objects)

- Dynamic positioning and dynamic showing/hiding of objects

- Pixel graphics displays, curves and bar displays

- Presentation of up to 8 curves in a curve field;

Curve display with scroll and zoom functions for access to the

history and for flexible selection of the period for presentation;

read-off line for determining the actual values and display in

a table

- Comprehensive image libraries (SIMATIC HMI

Symbol Library)

- Graphics objects: Slider, gauge, clock

- Cyclic function processing using timers

• Multiplex function for variables

• Message system

- administration of status, fault and system messages

- Status and fault messages with message history

- Preconfigured message display, message window and

message line

• Archiving of messages and process values

(on CF Card, optionally over Ethernet)

- Different archive types: short-term archive and sequence

archive

- Storage of archive data in standard Windows format (CSV)

- Online evaluation of process value archives through curves

- External evaluation using standard tools (MS Excel and MS

Access) is possible

• Message log and shift log

• Print functions (see "recommended printers")

• Language selection

5 online languages, 32 configuration languages incl. Asiatic

and Cyrillic character sets

• Password protection with 10 levels

• Recipe management

- With additional data storage (on CF Card)

- Online/offline processing at the panel

- Storage of recipe data in standard Windows format (CSV)

- External processing using standard tools MS Excel and MS

Access is possible

• PG functions STATUS/CONTROL VAR in combination with

SIMATIC S5 and SIMATIC S7

• Display selection from the PLC

supports operator prompting from the PLC

• Visual Basic Script, flexibility through the implementation of

new functions including linking to ProTool variables (compari-

son operations, loops, etc.)

• Help texts

for process diagrams, messages and variables

• Mathematical functions

• Limit value monitoring

for reliable process control of inputs and outputs

• Permanent window

permanent display area for the output of information that is not

specific to the particular display (e.g. important process vari-

ables, date and time)

• Simple maintenance and configuration through

- Backup and restoring the configuration, operating system,

data records and firmware on the optional CF Card (Compact

Flash Card) or optionally over Ethernet

- Backup and restoring the configuration, operating system,

data records and firmware on a PC using ProSave

- Configuration download/upload over

USB/MPI/PROFIBUS DP/RS 232/Ethernet (optional)/modem

and CF Card (optional)

- Automatic transfer identification

- Individual contrast settings

- Configuration simulation directly on the configuration com-

puter

• Import/export of all texts including messages in CSV format for

translation using standard word processing programs

Additional functions when configuring with WinCC flexible

• Project-specific picture blocks that can be modified centrally

• Message system

- Bit messages and analog messages (limit value messages)

as well as the Alarm S message frame procedure for SIMATIC

S7 and SIMOTION

- Freely-definable message classes (e.g. status/fault

messages) for definition of acknowledgment response and

display of message events

• Language selection:

- Language-dependent texts and graphics

• Permanent window expanded by template concept;

- generation of screen templates

• User administration (security)

- User-oriented access protection according to requirements

of specific sectors

- Authentication by means of user ID and password

- Privileges specific to user groups

• Visual Basic Runtime object model

• Service functions

(optionally with "WinCC flexible/Sm@rtService")

- E-mail generation

- Remote operation of the SIMATIC HMI system based on

Internet explorer

- Web server with status HTML pages and control functions

• Client/server functions

(optionally with "WinCC flexible /Sm@rtAccess")

- Remote operation and monitoring of other SIMATIC HMI

systems

- Plant-wide scanning of information and archiving of process

data