2

中文

作业上的一般注意事项

警告!

当使用电动工具时,为了减少造成火灾、电击和人身伤害,必须时刻遵守基本

注意事项,以及下述操作注意事项。

在操作本机之前,请通读本说明书,并予以妥善保管。

安全操作注意事项 :

1. 工作埸所应打扫干净,清理妥当,杂乱无章将导致事故。

2. 确保妥适的作业环境。电动工具不可任其风吹雨打。不得在潮湿的地方作业。

工作埸所需保持充分的亮度。请勿在有可能造成火灾或爆炸的地方使用电动

工具。

3. 谨防触电事故。应避免身体同大地或接地表面不可让访客触摸电动工具或延

伸线缆接触 (例如:管道、散热器、炉灶、冰箱等)

4. 不可让孩童靠近工作埸所。与作业无关的访客也必须保持安全距离。

5. 不使用的电动工具应存放到干燥而孩童伸手不及的高处,并加锁保管。

6. 不得使劲用力推压。电动工具需按设计条件才能有效而安全地工作,绝不可

勉强。

7. 妥选使用工具。不可用小型工具或附件去干重活。不可用于规定外的作业。

举例说,用圆锯进持伐木打枝或原木锯切作业。

8. 工作时衣服穿戴要合适。不要让松散的衣角和宝石类卷入转动部份。屋外作

业时,最好手戴橡胶手套,脚穿防滑胶鞋。同时要戴上能够罩笼长发的工作帽。

9. 绝大多数的电动工具作业时,均需戴安全眼镜。进行粉尘飞扬的切削作业时,

需戴防尘面罩。

10. 连接除尘设备

如果提供连击除尘和集尘的设备,请确认是否已经连接好并且使用正常。

11. 不要拿电线提起电动工具,也不得拉扯电线从电源插座拆除插头。电线需从

热源和油液隔开,并避免与锐利的边缘接触。

12. 作业以安全第一为原则。工件要用夹具或台钳卡紧。这样做,比用手按压更

为可靠,也能够让双手专心操作。

目次

作业上的一般注意事项...............................2

使用高速切割机前的注意事项................3

符号.......................................................................4

部件名称.............................................................4

规格.......................................................................4

标准附件.............................................................4

用途.......................................................................4

作业之前.............................................................5

切割顺序.............................................................5

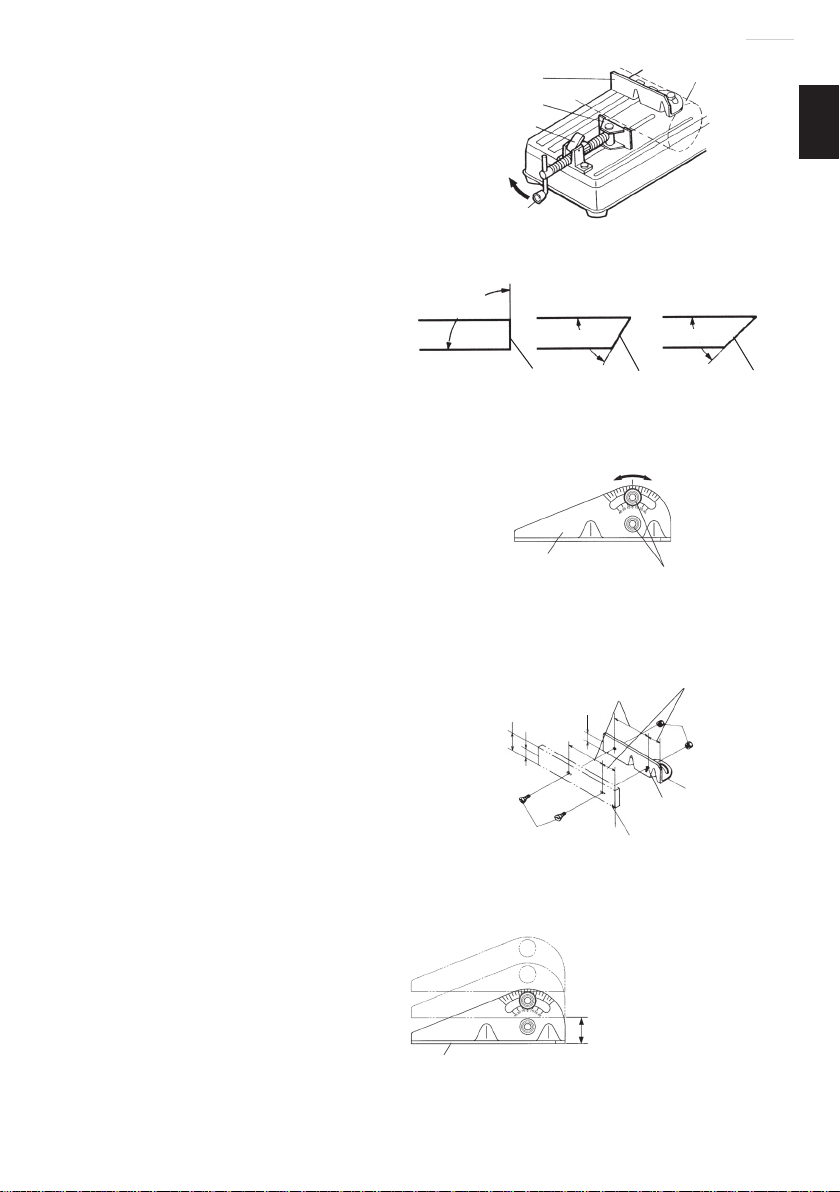

切割轮的装卸...................................................6

操作方法.............................................................6

维护和检查........................................................8

维修零部件一览表......................................10

000BookCC14SFChS.indb2000BookCC14SFChS.indb2 2016/07/2711:18:032016/07/2711:18:03