Hobie Twixxy User manual

Other Hobie Boat manuals

Hobie

Hobie PEARL User manual

Hobie

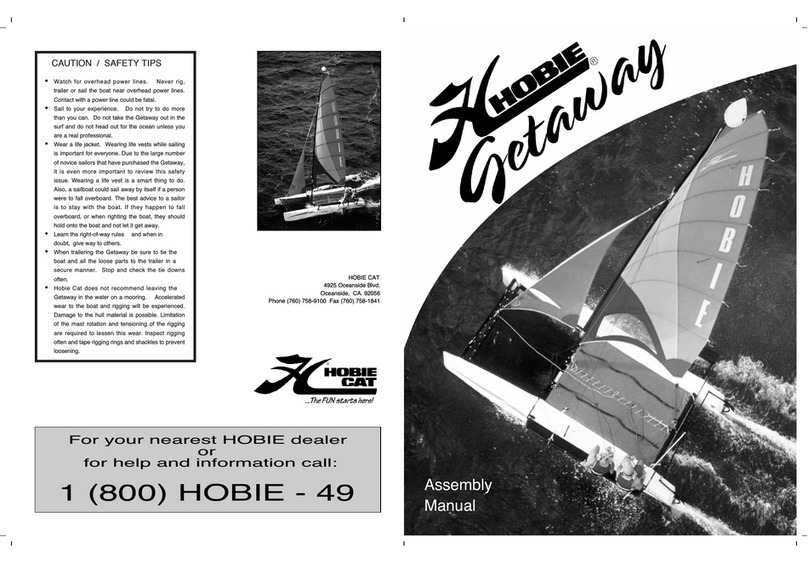

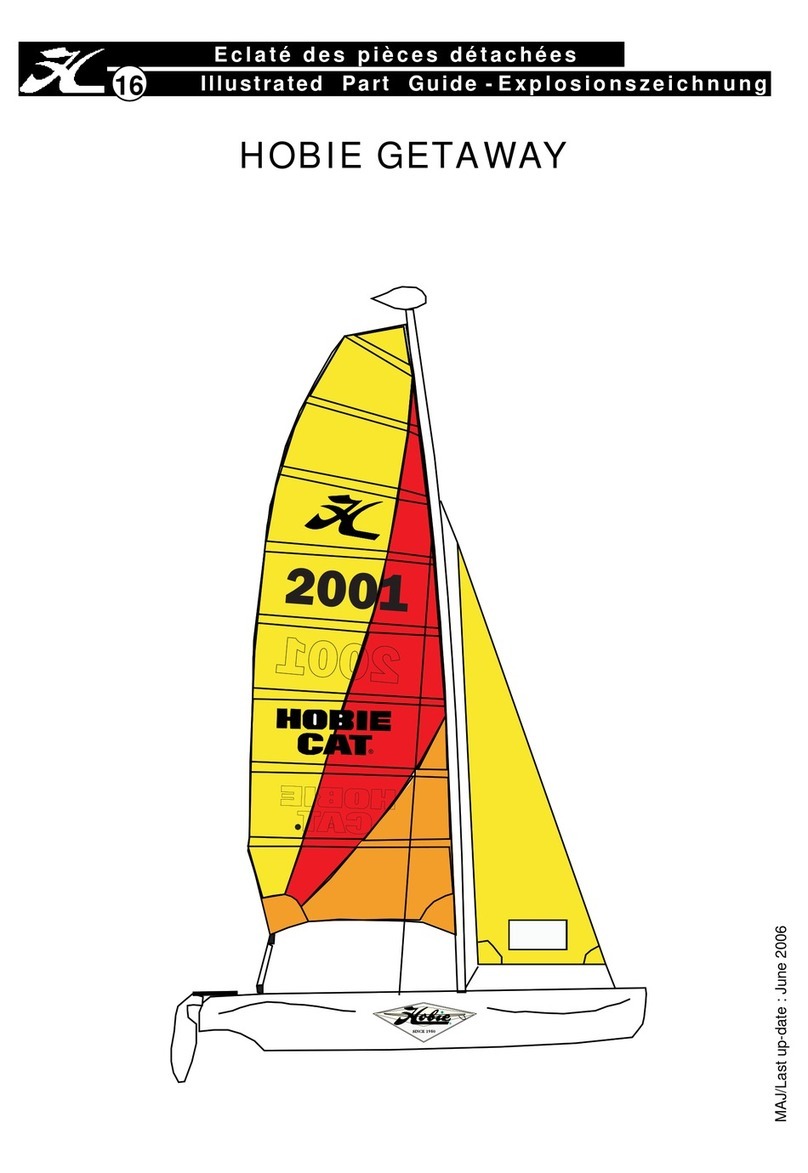

Hobie Getaway User manual

Hobie

Hobie 16 User manual

Hobie

Hobie Mirage Tandem Island User manual

Hobie

Hobie 15 Club User manual

Hobie

Hobie 17 User manual

Hobie

Hobie 15 User manual

Hobie

Hobie Mirage Vantage CT User manual

Hobie

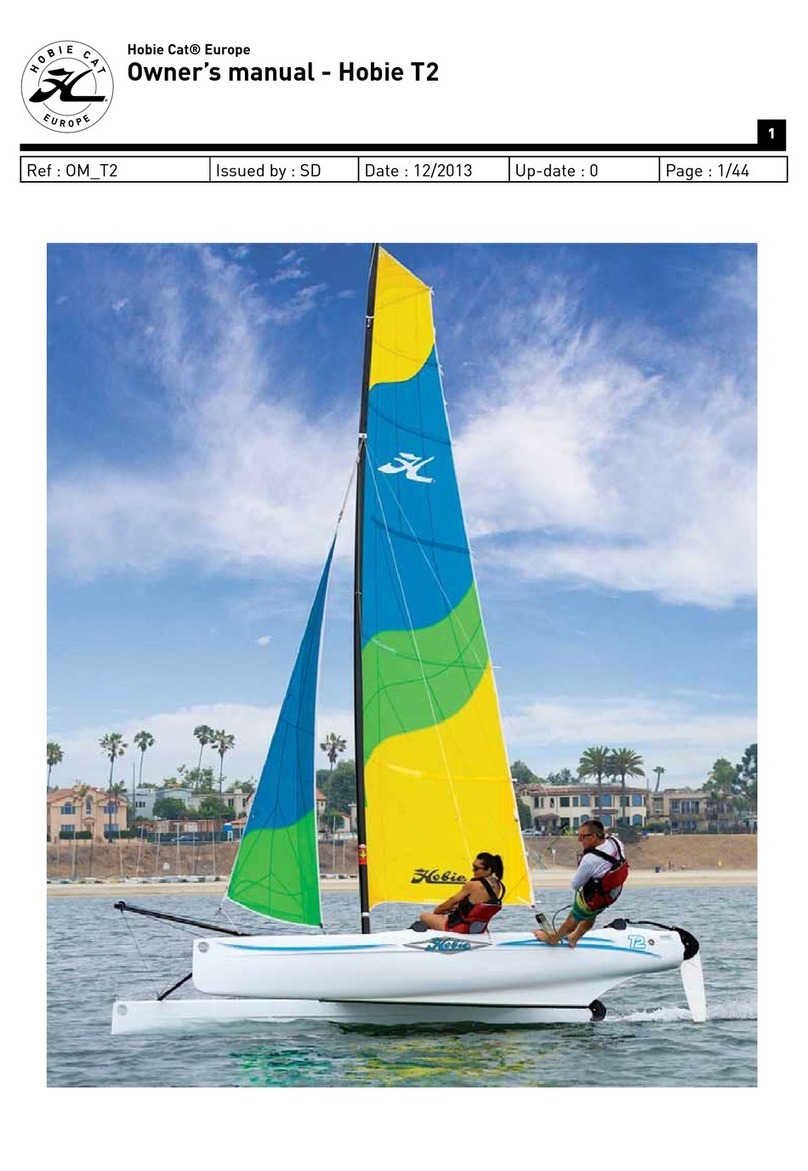

Hobie Hobie T2 User manual

Hobie

Hobie kayak User manual

Hobie

Hobie Getaway Setup guide

Hobie

Hobie Mirage Pro Angler User manual

Hobie

Hobie Fx One Setup guide

Hobie

Hobie SPORT CRUISER 21 User manual

Hobie

Hobie Mirage Compass User manual

Hobie

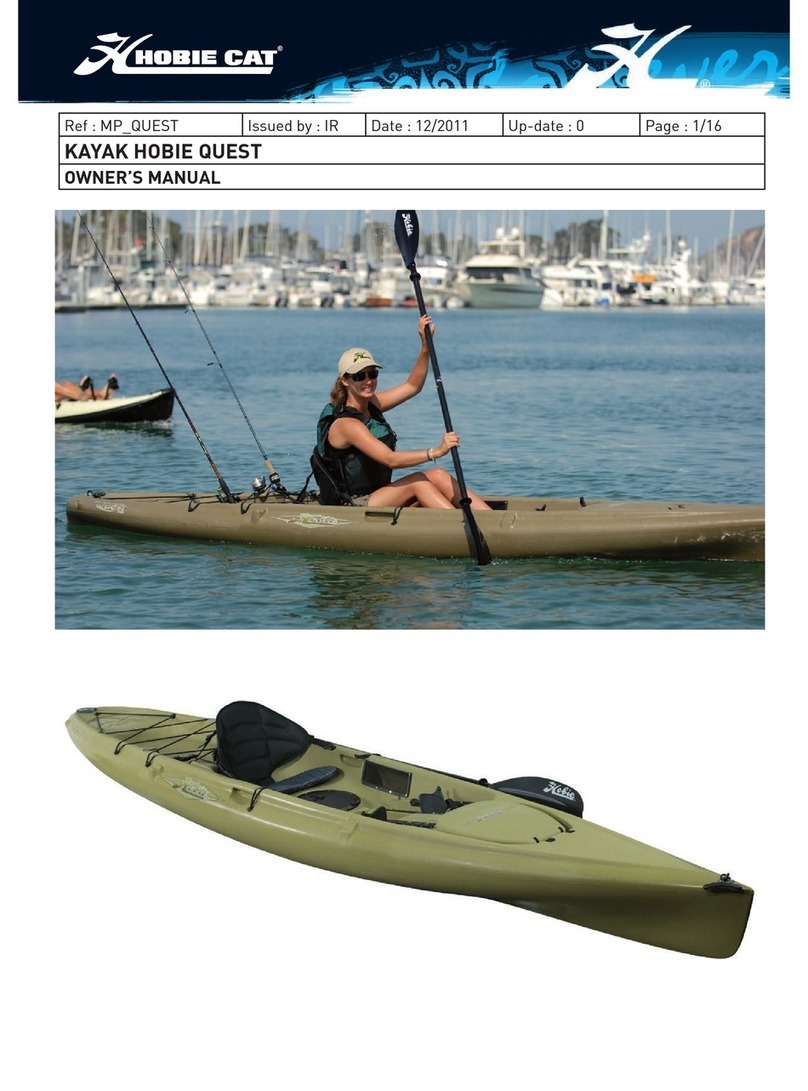

Hobie QUEST User manual

Hobie

Hobie Mirage Kayak User manual

Hobie

Hobie 16 User manual

Hobie

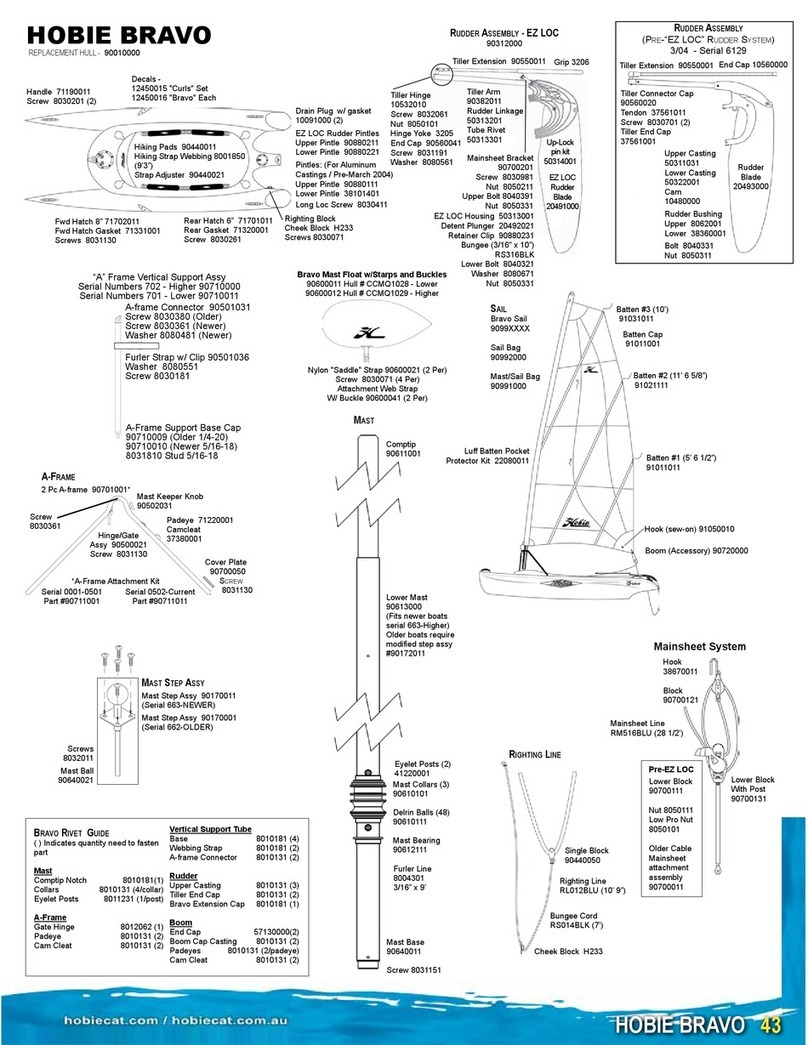

Hobie Bravo User manual

Hobie

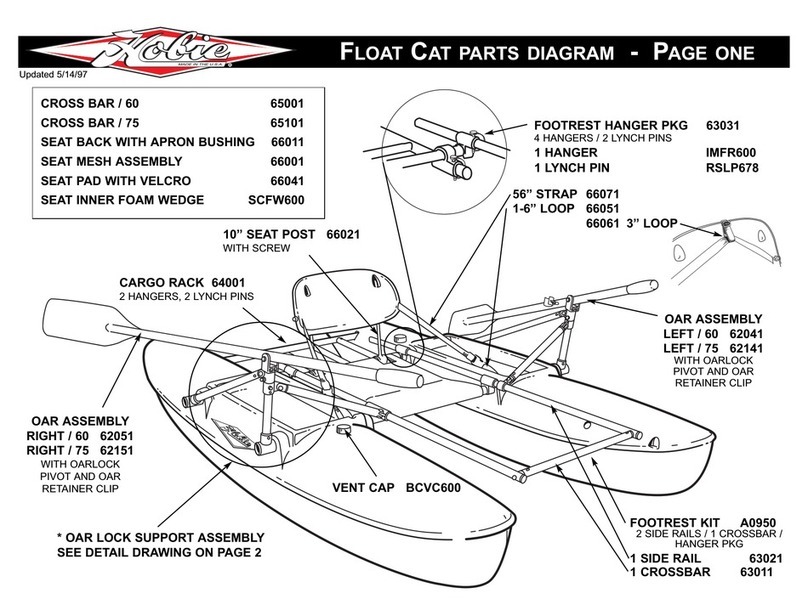

Hobie Float Cat Manual

Popular Boat manuals by other brands

Jeanneau

Jeanneau SUN ODYSSEY 41 DS owner's manual

Meridian

Meridian 490 Pilothouse owner's manual

Advanced Elements

Advanced Elements AdvancedFrame Expedition AE1009 owner's manual

Robo Marine Indonesia

Robo Marine Indonesia GEOMAR user manual

Swallow Boats

Swallow Boats BayRaider owner's manual

X SHORE

X SHORE EELEX 8000 owner's manual