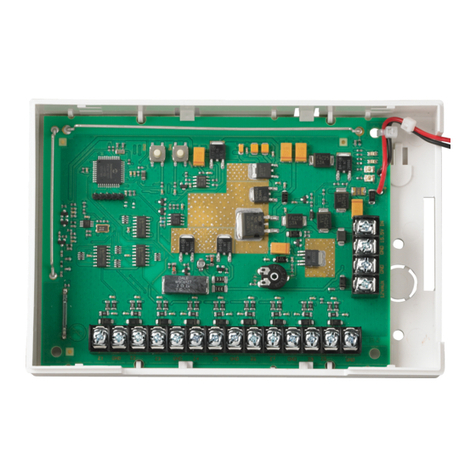

AQUATROL ZONE SYNCHRONIZING INJECTION/MIXING BOILER RESET CONTROLS

69-1990—03 4

Programming Instructions

Program the AQ252 by using the keypad and LCD display

to select parameters from the User Menu. Refer to

Fig. 1 on page 2 for an illustration of the LCD screen and

keypad.

NOTE: The figures in “User Menu Structure” on page 8

provide a graphical layout of the AQ252’s User

and Installer menus.

When a new AQ2000 component is connected on the

AQUATROL network, it will be seamlessly integrated in the

system after a few seconds. If one or more components are

disconnected or stop providing data to the network, a

message will appear on the System Status display until

the fault is corrected.

User Menu Overview

The User Menu is intended for use by the building owner

to choose the LCD display preferences, Zone Settings

(including setpoint temperatures and setback times for

each zone), and temperatures for the WAKE, LEAVE,

RETRN (return), and SLEEP programs.

The Home Page and User Menu allow the building owner

to:

• View the status of the system.

• Set up preferences for how the system information is

displayed.

• Set target temperatures for each zone (requires

AQ1000 thermostats).

• Program times of the day when the system will set back

the temperatures for all zones (requires AQ1000

thermostats).

NOTE: If there are any problems with the system’s opera-

tion, the AQ252 displays error codes on the Sys-

tem Status display of the LCD panel. For details

on these, refer to “Troubleshooting” on page 6.

TO ACCESS THE USER MENU:

Press the Menu button on the keypad at any time to

access the User Menu.

User Menu Settings

The User menu has five sub-menus.

• “System Status”

• “Preferences/Time”

• “Zone Settings (requires AQ1000 thermostats)”

• “Program Settings”

• “Statistics” on page 5

To make changes to the parameter settings in the User

Menu, refer to “LCD Display Navigation” on page 3.

SYSTEM STATUS

This is a detailed list of activities going on in the heating

system (e.g., call for heat, DHW disabled), and provide the

building owner with a quick snapshot of the heating

system’s operation, primarily for purposes of

troubleshooting and system diagnostics.

PREFERENCES/TIME

The preferences that the building owner can change in

this sub-menu are:

— The temperature scale for the display (Fahrenheit

or Celsius) for both the AQ252 control’s LCD and

the zone thermostats.

— The time display in 12 hour (e.g., 7:00 PM) or 24

hour format (e.g., 19:00).

— Date and time of day – allows building owner to

reset day and time of day in the event of a power

outage of more than 4 hours (refer to Trouble-

shooting section).

— The Home Page display view, Simple or Detail. The

factory default is Detail.

— The LCD Backlight – illuminated permanently (ON)

or set to automatically turn off backlight after 1

hour (AUTO).

POWER FAILURE

If a power disruption lasts for more than 4 hours, the

message PLS SET DAY/TIME displays and optionally, the

AQ252's backlight flashes repeatedly. This displayed

message continues until the DATE and TIME OF DAY are

updated. See “Power Disruption Greater Than 4 Hours” on

page 6.

ZONE SETTINGS (REQUIRES AQ1000 THERMOSTATS)

Settings in this sub-menu define:

— The temperature setpoints (target temperatures)

for each zone in the heating system.

— The temperature setback for each zone in the heat-

ing system. This is the desired temperature drop

when the heating system enters the setback pro-

gram SLEEP or LEAVE.

— The maximum and minimum setpoints that can be

entered by a user at a thermostat screen for each

zone.

— Whether each zone can be set independently by the

AQ252 (i.e., some zones can be locked while others

are unlocked) depending on whether or not the

keyboard on a thermostat is locked. When locked,

no changes can be made to a zone’s setpoint tem-

perature through the thermostat. Changes can still

be made through the Zone Settings menu on the

AQ252 control panel.

PROGRAM SETTINGS

Using the Program Settings sub-menu, the building owner

can define the time of day when the entire heating system

will change programs (e.g., from SLEEP to WAKE).

The AQ252 has provision for four different schedule

periods per day. They are defined as WAKE, LEAVE, RETRN

(return), and SLEEP:

WAKE: Period when you awaken and want your home at

a comfortable temperature.

LEAVE: Period when you are away from home and want

an energy-saving temperature.

RETRN: Period when you return home and want your

home back to a comfortable temperature.

SLEEP: Period when you are asleep and want an

energy-saving temperature.

There are three modes of operation – Automatic, Occupied

and Unoccupied:

AUTO: In AUTO mode, the AQ252 follows the WAKE,

LEAVE, RETRN, and SLEEP programs.