NOTE: Some panels support extended addressing. In order to set the module

above address 99 on compatible systems, carefully remove the stop on the

upper rotary switch (see Figure 7). If the panel does not support extended ad-

dressing, do not set the lowest address above 90.

FIgURE 7:

TENS

0

78

6

5

4

3

21

910

11

12

13

14

15

4. A shunt is provided to disable a maximum of two unused modules in

Class B operation and one unused module in Class A operation. Modules

are disabled from the highest address and work downward. If two mod-

ules are disabled, the lowest eight addresses will be functional, while the

highest two will be disabled. For example, in Class B operation, if the

shunt for Address Disable is placed on “two” and the base switch is set

to 28, the modules will be assigned to 28, 29, 30, 31, 32, 33, 34 and 35

while disabling the highest two positions.

5. A communications loss feature is available on some panels. When a

module detects an alarm condition on the Initiating Device Circuit and

there is no activity on the communication loop, the MMF-300-10 will

send a periodic signal of its own to alert other receiving devices in the

system. A single shunt is used to enable (shunt on) or disable (shunt off)

this feature for all modules on the board.

NOTE: Place unused shunts on single pin to store on board for future use.

NOTE: Power must not be applied to the unit when changing functionality of

the shunts.

wIRINg NOTES

Power-limited circuits must employ type FPL, FPLR, or FPLP cable as •

required by Article 760 of the NEC.

PROgRAMMINg

The MMF-300-10 module operates with the following Fire Alarm Control Panels:

MS-9200•

MS-9600•

The modules are programmed as devices in each system according to the pro-

gramming instructions in the appropriate FACP manual.

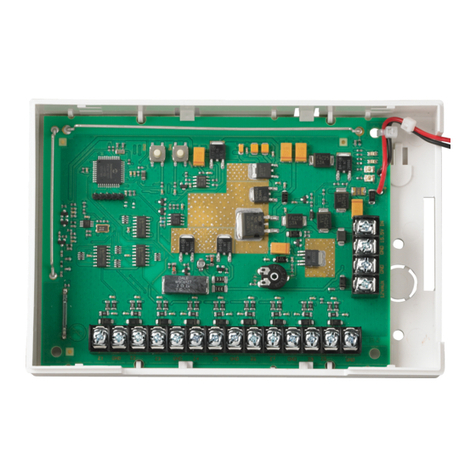

FIgURE 6B. INSTALLATION OF MMF-300-10 MODULE IN FRONT

CHASSIS POSITION:

Step 1: Insert the bottom edge of the MMF-300-10 module down into a

front slot of the chassis.

Step 2: Carefully swing the upper edge of the board towards the back of

the chassis until it touches the 11/4˝ (31.75mm) standoffs installed

on the rear module.

Step 3: Align two 4-40 screws with the two standoffs and tighten.

Step 4: Address and wire the modules according to the instructions in this

manual.

wIRINg

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations.

1. Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2. All wiring to the MMF-300-10 is done via terminal blocks. In order to

properly make electrical connections strip approximately 1/4˝ of insula-

tion from the end of wire, sliding the bare end of the wire under the

clamping plate screw.

3. Set the address on the modules per the job drawing. Use the rotary code

switches to set the address of the first module (between 01 and 150).

In Class B operation, the remaining modules are automati-

cally assigned to the next nine higher addresses. For exam-

ple, if the base address switch is set to 28, the next nine

modules will be addressed to 29, 30, 31, 32, 33, 34, 35, 36, and 37.

The module is shipped in Class B position, remove shunt for Class

A. When operating in Class A, alternate modules are paired to-

gether (+0/+1, +2/+3, +4/+5, +6/+7, +8/+9), result-

ing in a total of five modules. For example, if the base address

switch is set to 28, then 30, 32, 34 and 36 will be automatically as-

signed to the modules while 29, 31, 33, 35 and 37 are available to be

used for other modules on the SLC. For Class A and B operation, DO NOT

set the lowest address above 150, as the other modules will be assigned

to nonexistent addresses.

F300-20-00 3 I56-1873-005

This device complies with part 15 of the FCC Rules. Operation is subject to the fol-

lowing two conditions: (1) This device may not causeharmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to pro-

vide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

com-munications. However, there is no guarantee that interference will not occur in a

C0226-00

C0227-00

particular installation. If this equipment does cause harmful inter-ference to radio or

television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following

measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

FCC STATEMENT