SOLID CORE AND SPLIT CORE 4-20 MA OUTPUT CURRENT SENSORS

31-00142—01 2

PLEASE READ INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION!

• This product is not intended to be used for Life

or Safety applications.

• This product is not intended for use in any

hazardous or classified locations.

• The CTS-A and CTP-A Series Current Sensors

must be used on Insulated Conductors Only!

HIGH VOLTAGE

Disconnect and lock out all power sources before

installation as severe injury or death may result

from electrical shock due to contact with high

voltage wires.

INSTALLATION

Make sure that all installations are in compliance with all

national and local electrical codes. Only qualified

individuals that are familiar with codes, standards, and

proper safety procedures for high-voltage installations

should attempt installation. The current sensor is a 2-wire,

4 to 20 mA Loop Powered device that requires a regulated

+13.5 to 30VDC external power source.

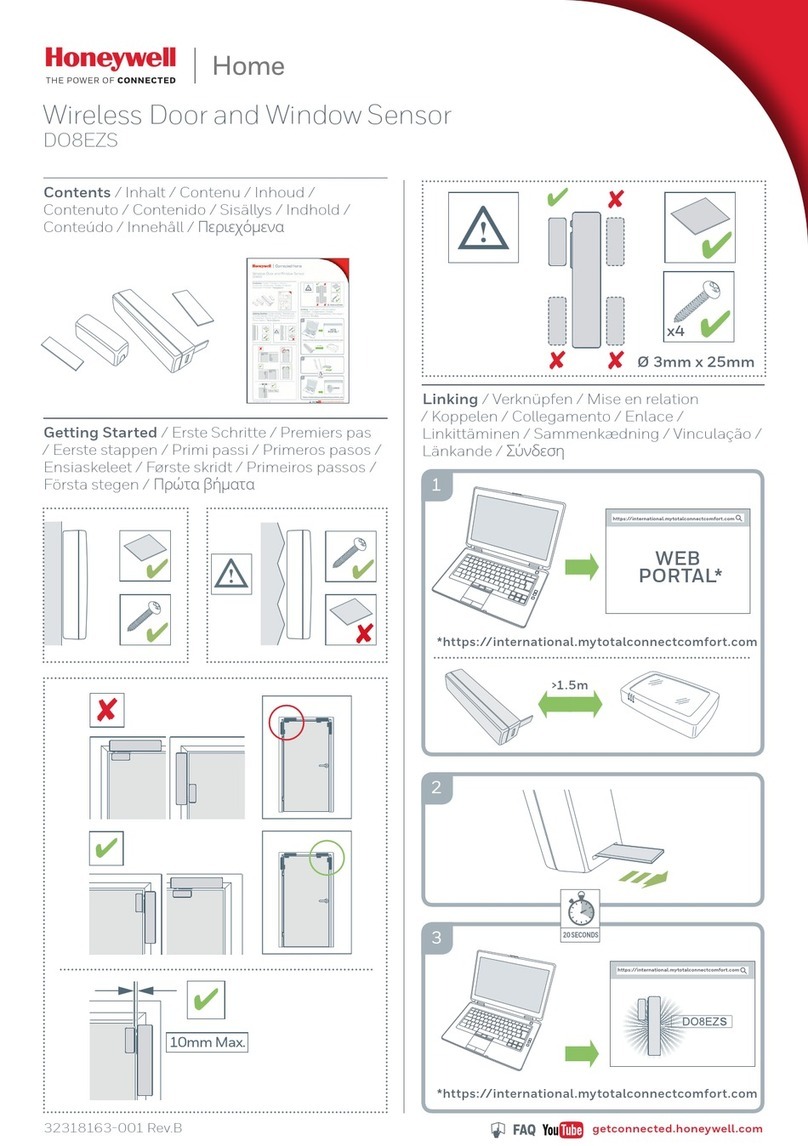

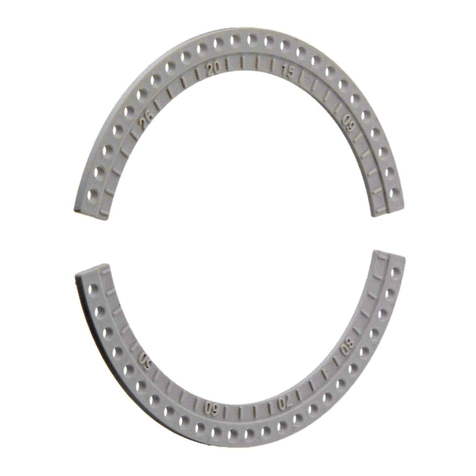

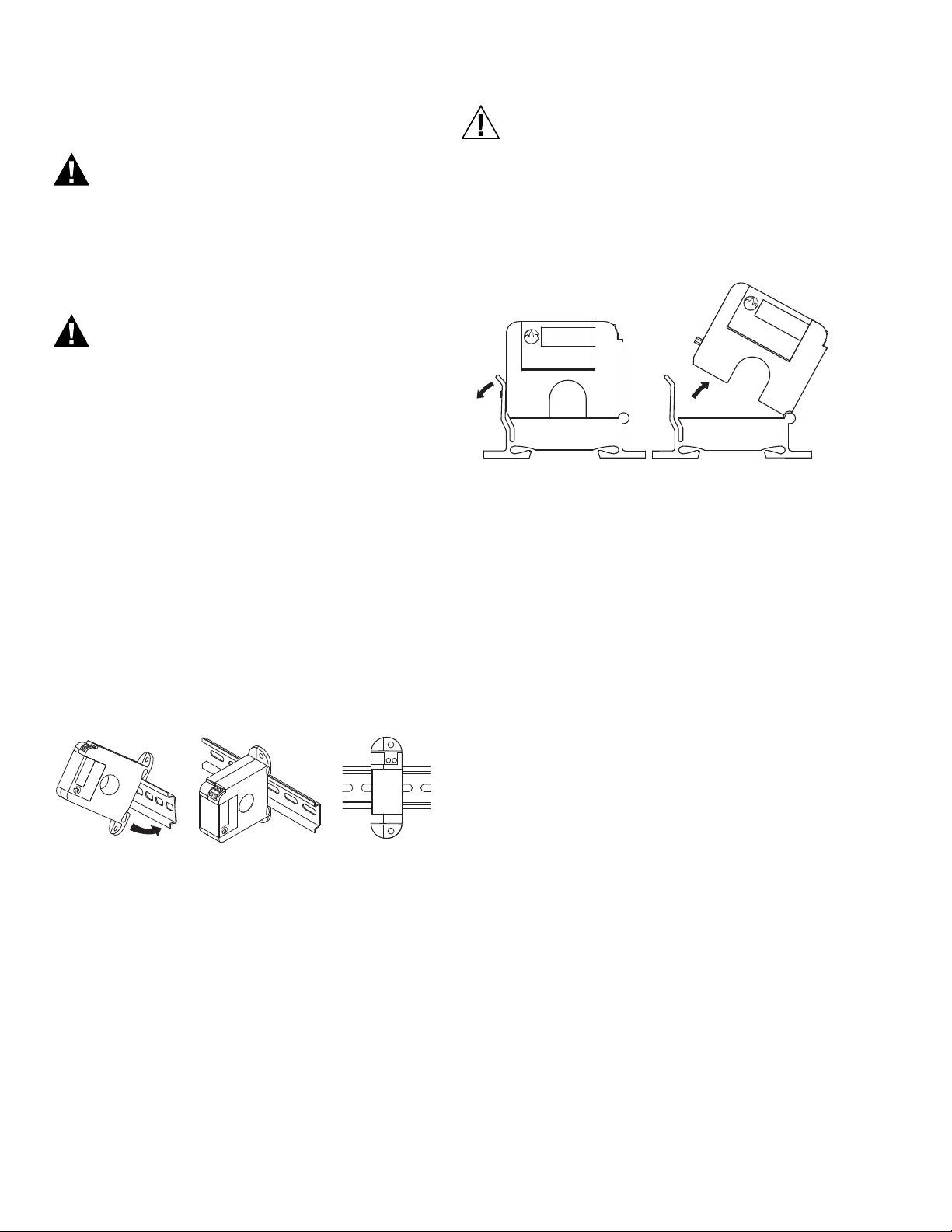

The current sensor may be mounted in any position using

the two #8 x ¾” Tek screws and the mounting holes in the

base, or snapped directly on to the 35mm DIN rail (See Fig.

1. Leave a minimum distance of 1” (3 cm) between the

current sensor and any other magnetic devices such as

contactors and transformers.

Fig. 1. Sensor Placed On Rail.

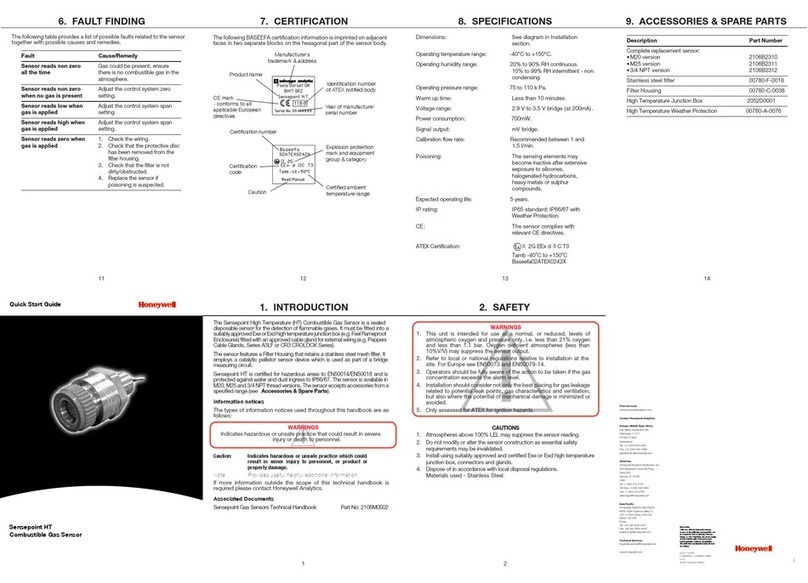

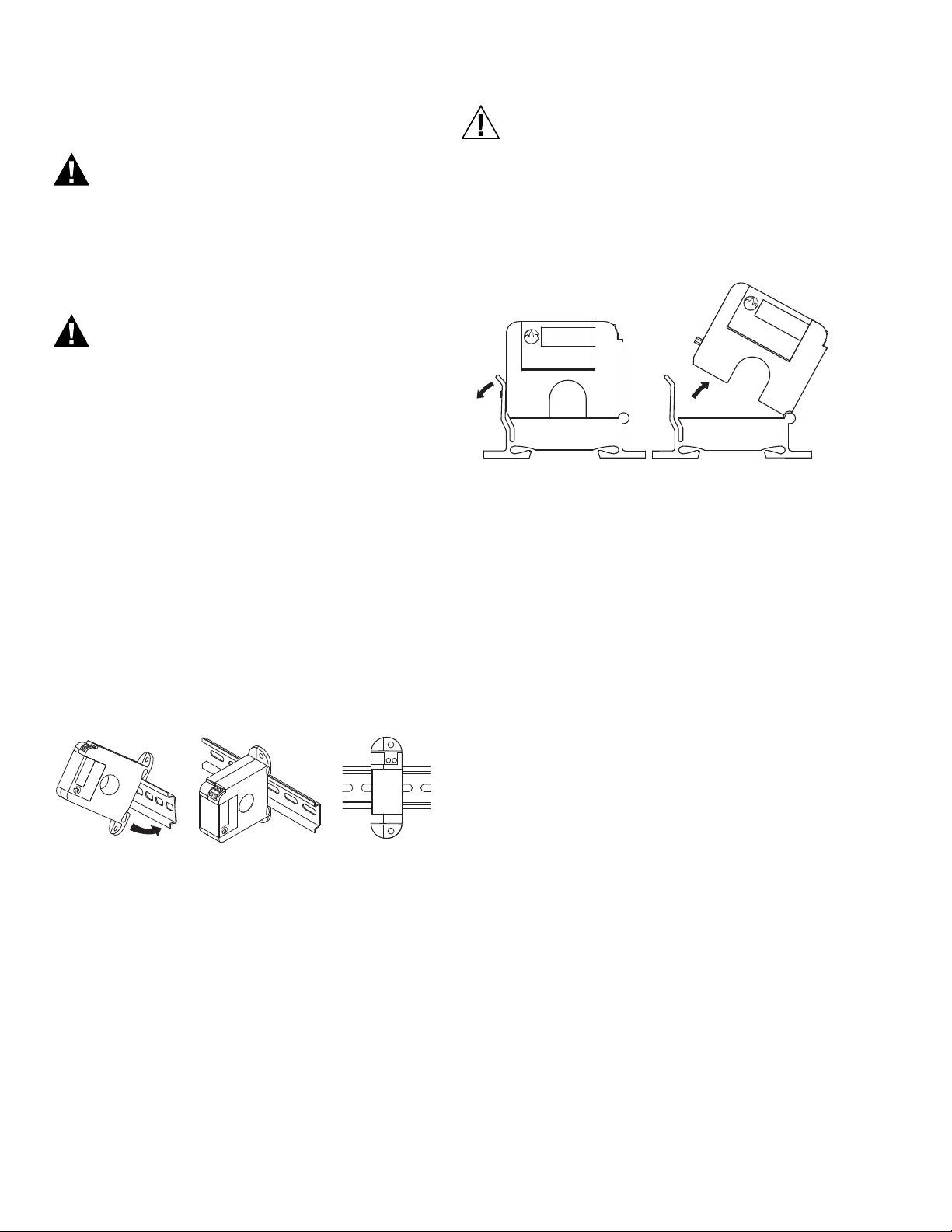

Latch Operation for CTP-A Series

Press down on the side tab and swing the top of the unit

up to open the split core current sensor as shown in Fig. 2.

Press down firmly on the cover to close the current sensor.

An audible “click” will be heard as the tab slides over the

tongue on the base.

Mating surfaces of the magnetic core are

exposed when the sensor is open. Electrical

contact grease, present on the cores to prevent

corrosion, can capture grit and dirt if care is not

exercised. Operation can be impaired if anything

prevents good contact between pole pieces.

Visually check the mating parts of the core

before closing the current sensor.

Fig. 2. Opening Split Core Models.

CURRENT SENSOR SETUP

The amperage range selected represents the maximum

current that can be applied to the conductor being

monitored. DO NOT EXCEED! All current sensors with

selectable ranges will have the range selection jumper

factory set on the high range. For models with field

selectable amperage ranges, select the correct amperage

range using the range selection jumper. Note that all RMS

models have True RMS outputs and should be used with

Variable Frequency Drives.

WIRING

We recommend the use of a two conductor 16 to 22 AWG

shielded cable, COPPER WIRE ONLY, for all 4 to 20mA

current sensor installations. A maximum wire length of

less than 30 meters (98.4 feet) should be used between

the current sensors and the Building Management

System or controller.

NOTE: When using a shielded cable, be sure to connect

only (1) end of the shield to ground at the control-

ler. Connecting both ends of the shield to ground

may cause a ground loop.

When removing the shield from the sensor end, make sure

to properly trim the shield to prevent any chance of

shorting. The current sensor terminals are polarity

sensitive and represent a linear and proportional 4 to

20mA output signal. The current sensors are available in

either an Average or True RMS output version. Tighten the

screws at the terminal block connections to the

recommended torque of 0.5 to 0.6 Nm (4.43 to 5.31 in-

lbs.). The aperture (hole) size of the current sensor is 0.75”

(1.90 cm).

M37378