Condition of LEDs

with No Motion

PIR

A

LARM MW

(Green) (Red) (Yellow)

Reaction of LEDs

to Walk-Test

PIR ALARM MW

(Green) (Red) (Yellow)

Type of Possible

Problem Causes

(Pattern disappears)

MWenvironmentalproblem

IMBALANCE MW rangetoo long

PIRwasblocked

RATIO

IMBALANCE

PIRrangetooshort

PIRaimedwrong

PIRnotreporting

(Patterndisappears)

RATIO

IMBALANCE

PIR environmental problem

PIR unstable

MW range too short

RATIO MW range too short

IMBALANCE MW not reporting

OperatingMode

Alert

Local Test

Standby

Remote Test

Walk Test LED's

Disabled Enabled Disabled Disabled

MicrowaveOscillator On On

Off

On

Alarm Outputs Enabled Enabled

Frozen

Enabled

Alarm Memory Activated

Yes

No No

Yes

Alarm Memory Reset

OnlywhenEntering No No No

Alarm Memory Displayed

(Red LED flashing)

Disabled Enabled Enabled Disabled

Trouble Disabled Enabled Enabled Disabled

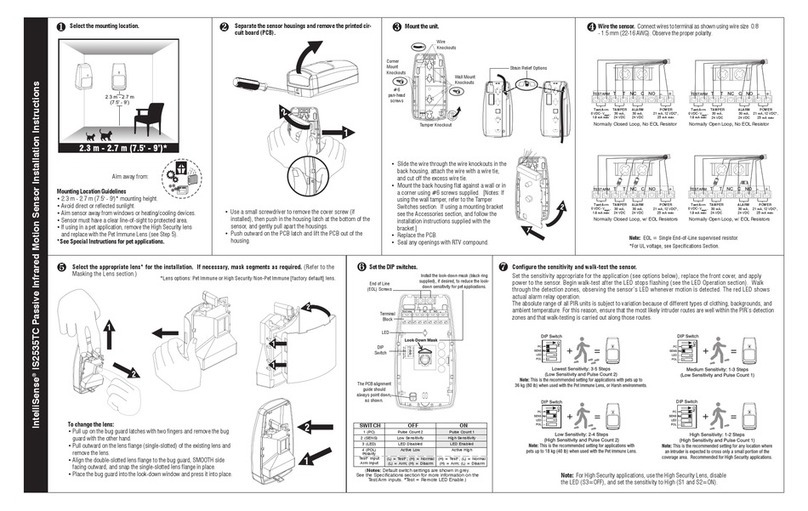

DT·900 Series DUAL TEC® Motion Sensor Supplemental Information

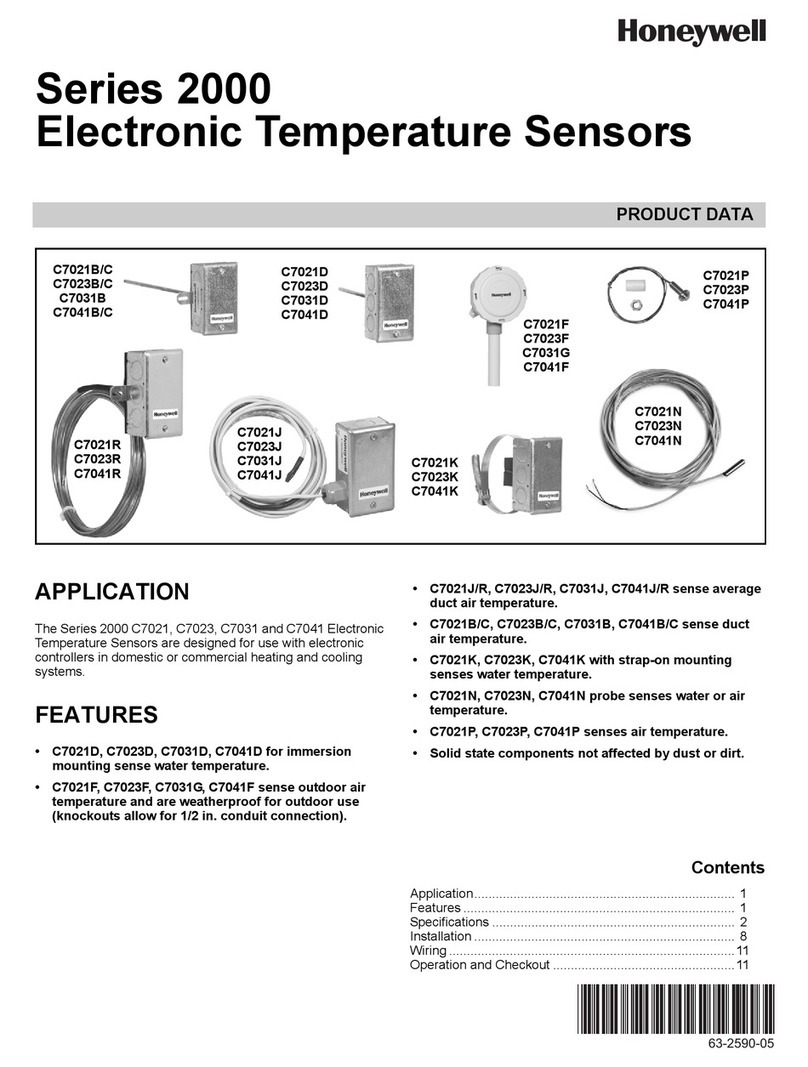

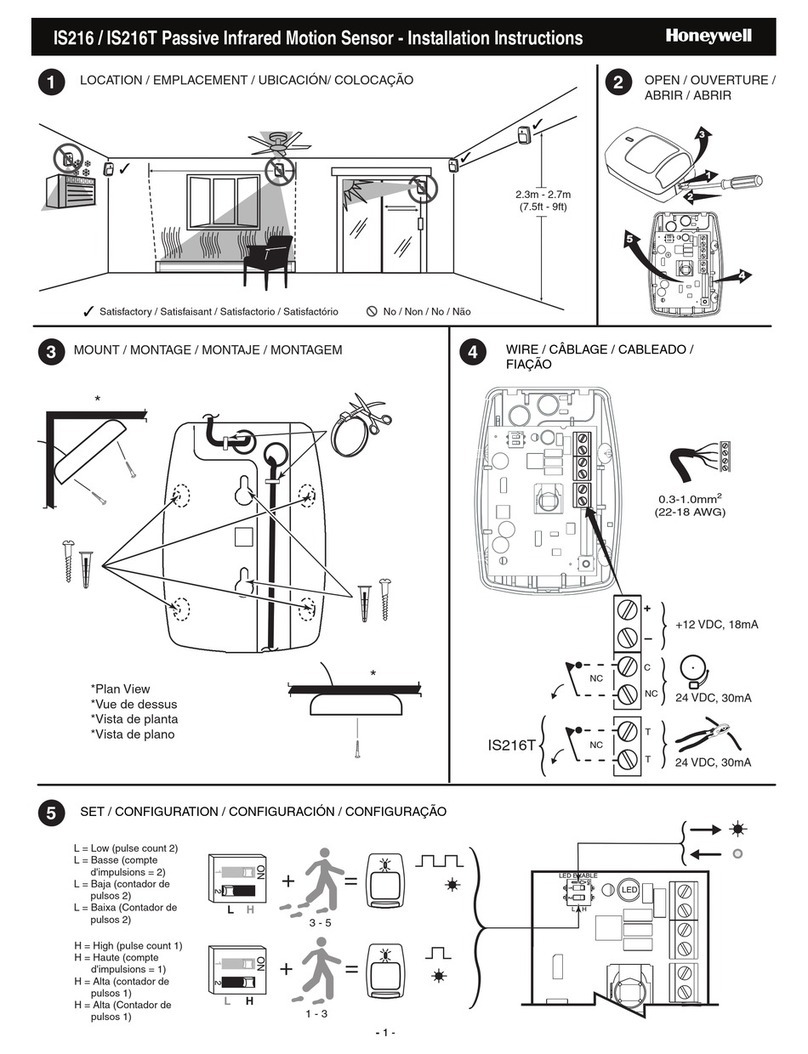

MOUNTING LOCATION DT-906 DT-900

Aimthesensortowardtheinterioroftheroom,awayfromwindows,movingmachinery,andheating/

cooling sources.

Makesurethesensorhasaclearline-of-sighttoallareasyouwishtoprotect.IfthePIRisblocked,the

unit will not alarm.

TAMPER

The sensor covers and wall mounting are tamper protected. A screw mustbe installed in the wall

to utilize the tamper feature.

WIRING

Reverse polarity will not damage the sensor

.

Knockouts are provided to allow wire entry via 1/2" EMT or surface wiring conduit.

NOTE: For proper wiring methods, refer to the National Electrical Code NFPA 70.

INFORMER MODE

The INFORMER circuit counts the number of events registered by both the microwave and PIR

technologies, and uses the resulting ratio to determine if either technology is working properly or is

misapplied. Establish the INFORMER mode using switch S2. (See Step 7.)

Mode 1: Set S2 to position 1. In Mode 1, 32 PIR events without a microwave event will cause the

unittogointoPIRINFORMER. 128microwaveeventswithoutaPIReventwillcausetheunit togo

intomicrowaveINFORMER. OneLEDindicationdoesnotrelatetoonePIRevent.

Mode 2: Set S2 to position 2. In Mode 2, 16 PIR events without a microwave event will cause the

unittogointoPIRINFORMER. 16microwaveevents withoutaPIReventwillcausetheunit togo

into microwave INFORMER. One LED indication does not relate to one microwave event.

NOTE: TheMode2settingisnot recommended. UseonlyiffastINFORMER activation

is required.

Trouble Memory

Disabled: To disable INFORMER function, set S2 to the open position. IftheLEDpatterndisappearsbeforeyouseeit,youcanretrievethepattern.The troublememoryfeaturestoresthelastLEDpatternfrom

a self-test detected problem or an INFORMER condition.

WhenanINFORMERconditionoccurs,thetroublerelayopens,andtheLEDsdisplayanINFORMERtroublecode.Thesensorperforms

a self-test within the hour to determine if the problem is internal. TorecovertheLEDpattern,firstopentheTopCover(seeStep2). Usingasmallscrewdriver,momentarilyshort circuitthetwoSelf-Test

pads located on the printed circuit board (see Supplemental Information, Figure 1). The trouble LED pattern will be re-displayed.

If a self-test error is detected, the self-test LED pattern, all three LEDs flashing, replaces the INFORMER LED pattern. Short the pads with the screwdriver again to clearthe LED patternand initiate a self-test.

If no self-test error occurs, the unit continues to display the INFORMER LED pattern and relay remains open. The problem is

misapplication. Walk-test the sensor to pinpoint the cause. (Referto Troubleshooting Table 3.) Anti-Mask

The DT-900Series anti-mask feature detects attempts to block or cover the sensor by sending an active infrared beam out into the

INPUT MODES sensor's field-of-view,at regular 8 second intervals. If the DT-900/DT-906 is blocked orcovered (i.e. with a box or fabric) the beam

The DT-900 Series accommodates several international operating requirements using two operating modes-Standardmode with is reflected back to the sensor. After two consecutive reflected beams, the sensor signals a trouble condition-green and red

remote LED enable and Command Input capability or European 2-Wire CENELEC mode (INPUT 1 and INPUT 2). For Standard LEDsflash rapidly and the mask relay opens.

Mode, remove jumperJ4 and installjumper J6. For CENELEC mode, remove jumper J6 (See Figure 1).

INFORMER Conditions

Table 1 Standard Mode-J6 Installed Table 2 CENELEC Mode-J6 Removed

Table3describestwotroublealertswhicharereportedbytheINFORMERcircuit. Tousethistroubleshootingmatrix:

1)

Find the trouble alert that describes the condition of the walk-test LEDs (with no motion in the area).

2)

Walk-test the sensor, carefully watching the reaction of the diagnostic LEDs.

3)

Refer to the Possible Causes column of the matrix for an explanation of the way in which the diagnostic LEDs

reacted to the walk-test.

Table 3 INFORMER

Troubleshooting Matrix

Table 4 Cenelec Functions

RATIO

TROUBLESHOOTING

VerticalAdjustment

Variousmountinglocationsmayrequirefineverticaladjustment(e.g.unevenwallsor floors,etc.). Duringthewalk-test,ifthePIRisshort-

ranged, turn the Vertical Adjust Screw counterclockwise. If the PIR is over-ranged, turn the Vertical Adjust Screw clockwise.

(See Step 5.)

Self-Test

The sensor microcontroller automatically performs aseries of self-tests inthe following instances:When theunit ispowered up, when

tests areinstaller initiated, uponCommand Input,or everyhour duringnormaloperation. A self-test errorcauses theTrouble relay

to openandall3LEDs flashuntilthe problemiscorrected. IftheproblempersistsandtheLEDs continuetoflash, theunitisdefective LED Legend: = LED is Flashing Slow =LED is OFF

and must be returned fo

air.

DETECTIONPATTERNS

Patternsfor: DT-900

Patterns for: DT-900

Pattern for: DT-906 TOP VIEW 27 m (90') Range 15 m (50') Range

61 m (200') Range Barrier Lens-All Zones TOP VIEW

TOP VIEW

Wide Angle Lens WideAngle Lens

SIDE VIEW

BarrierLens-All Zones

Pattern for: DT-906

TOP VIEW

37 m (120') Range Barrier Lens-All Zones

IndicatesDetectionArea

SIDE VIEW

Barrier Lens-All Zones SIDE VIEW SIDE VIEW

Wide Angle Lens WideAngle Lens

PRODUCT SPECIFICATIONS IMPORTANT: DT-900 Series sensors should be tested at least once each year to ensure proper operation.

Range:

DT-906

37 m x 3 m / 61 m x 5 m

120' x 10' / 200' x 15'

DT-900

15 m x 12 m / 27 m x 21 m

50' x 40' / 90' x 70'

Alarm relay:

Energized Form C; 25 VDC, 125 mA

22 ohm series protection resistor

Power requirements:

10 - 15 VDC; 50 mA (max) at 12 VDC

AC Ripple: 3V peak-to-peak at nominal

12 VDC

PIR white light immunity:

6500 Lux

RFI immunity:

30 V/m, 10 MHz – 1000 MHz

Trouble relay:

De-energized Form B;

(Normally closed); 30 VDC, 25 mA

Mask relay:

De-energized Form B

(Normally closed)

30 VDC, 25 mA

Input 1 & 2:

Self-test initiate

Active low 0 to 1.5V

Inactive high 5 to V+

Sensitivity:

2 – 4 steps within field of view

Tampers:

Wall, top & bottom covers

30 VDC, 25 mA (NC)

PIR fields of view:

61 m (200’) Range

2 long

6 intermediate long

4 intermediate

4 intermediate lower

8 lower

2 down

37 m (120’) Range

6 long

4 intermediate long

4 intermediate

8 lower

2 down

27 m (90’) Range

18 long

18 intermediate long

16 intermediate

12 intermediate lower

8 lower

2 down

15 m (50’) Range

18 long

16 intermediate long

12 intermediate

8 lower

2 down

Microwave frequencies:

X band

Operating temperature:

0° to 49° C / 32° to 120° F

Relative Humidity:

5% to 95% relative humidity

(non-condensing)

Dimensions:

20 cm x 16.5 cm x 15.2 cm

8” x 6 1/2” x 6”

Weight:

1.36 kg / 3 pounds

Packaged product:

1.6 kg / 3.5 pounds

Approvals/listings:

FCC certified

Industry Canada

UL listed

ULC listed

FEDERAL COMMUNICATIONS COMMISSION STATEMENTS

The user shall not make any changes or modifications to the equipment unless authorized by the Installation Instructions or User's Manual. Unauthorized changes or

modifications could void the user's authority to operate the equipment.

CLASS B DIGITAL DEVICE STATEMENT: This equipment has been tested to FCC requirements and has been found acceptable for use. The FCC requires the

following statement for your information:

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, instrict accordance with the manufacturer's instructions,

may cause interference to radio and television reception. Ithas been typetested and found to comply with the limits for a Class B computing device in accordance

with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference in a residential installation. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can

be determined by turning the equipment off andon, the useris encouraged to try to correct the interference by one or more of the following measures:

• Reorient the receivingantenna untilinterference is reduced or eliminated.

• Move the radio or televisionreceiver awayfrom the receiver/control.

• Move the antenna leads away from any wire runs to the receiver/control.

• Plug the receiver/controlinto a different outlet so that it andthe radio ortelevision receiver are on different branch circuits.

• Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA CLASS B STATEMENT

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme àla norme NMB-003 du Canada.

FCC / IC STATEMENT: This device complies with Part 15 of the FCC Rules, and RSS210 ofIndustry Canada. Operation is subject tothe following two conditions:

(1) This device may not cause harmful interference, and(2) This device must accept any interference received, including interference that may cause undesired

operation.

Cet appareil est conforme à la partie15 des règlesde la FCC &de RSS 210 desIndustries Canada. Sonfonctionnement est soumis aux conditions suivantes: (1) Cet

appareil ne doit pas causer d’interférences nuisibles. (2) Cet appareil doit accepter toute interférence reçue y compris les interférences causant une réception indésirable.

DUAL TEC and INFORMER are registered trademarks of Honeywell International Inc.

Copyright 2012 Honeywell International Inc. All rights reserved.

P/N 5-051-344-00 Rev H

Feet 6 8 10 12 14 50 90 120 200

Meters 1.8 2.4 3 3.7 4.3 15 27 37 61

Input Condition Operating Mode

HIGH/Not connected LOW Alert Local Test Standb