UVL-COIL ULTRAVIOLET LAMP KITS FOR AHU COILS

31-00402—02 6

Fig. 8. Installing UV Lamp.

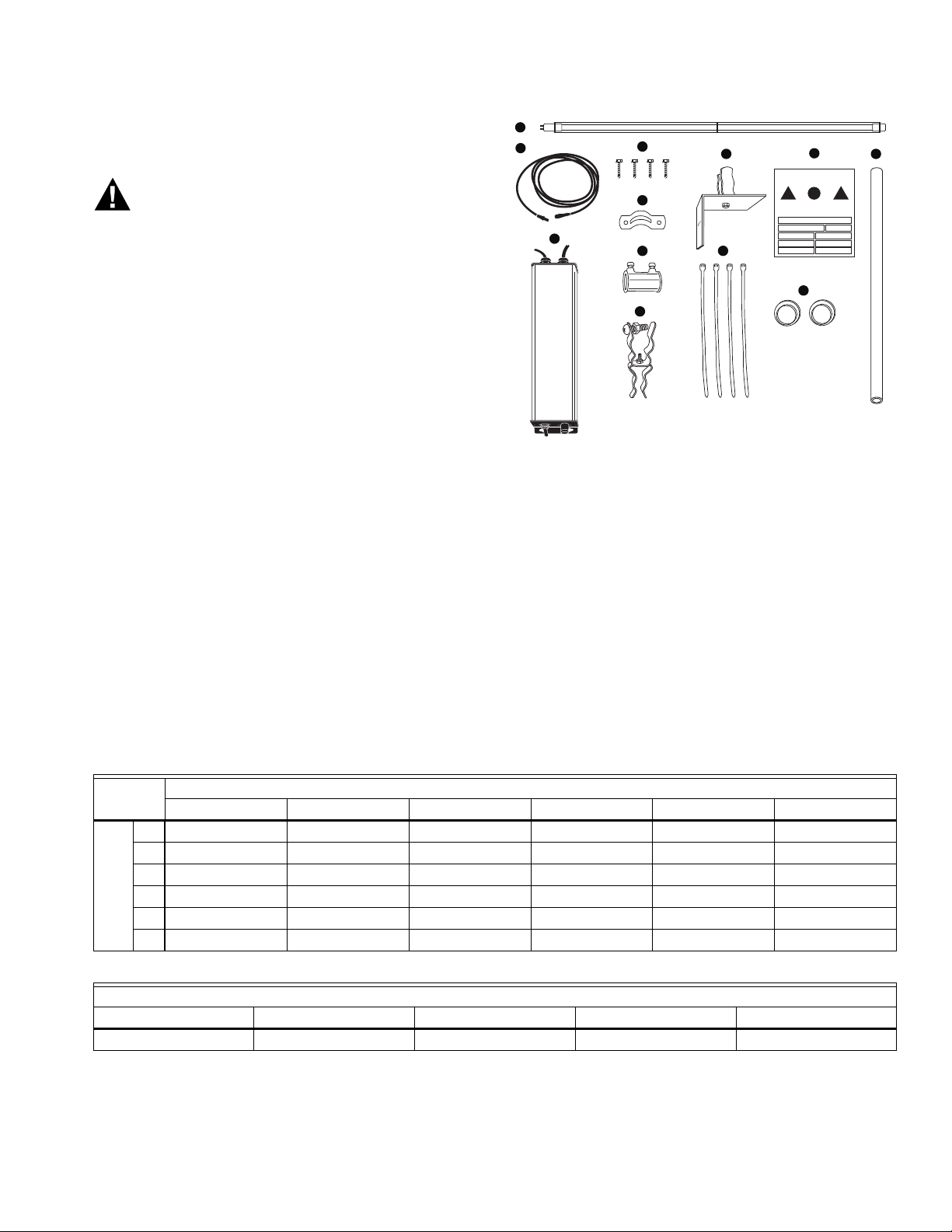

Mount Power Supply(s)

Mount the power supply in a location (inside or outside of

the HVAC system) that is convenient for access to the main

power supply and for connection to the UV lamps. The

power supply is weather resistant and is suitable for

mounting inside or outside of the air handler.

Use the supplied self-taping sheet metal screws to mount

the power supply in place through the mounting holes on

the sides of the base. It is recommended to use wire boxes,

cable strain relief fittings, or other sealing methods in order

to pass the power cord and lamp cables into the interior of

the air handler for connections.

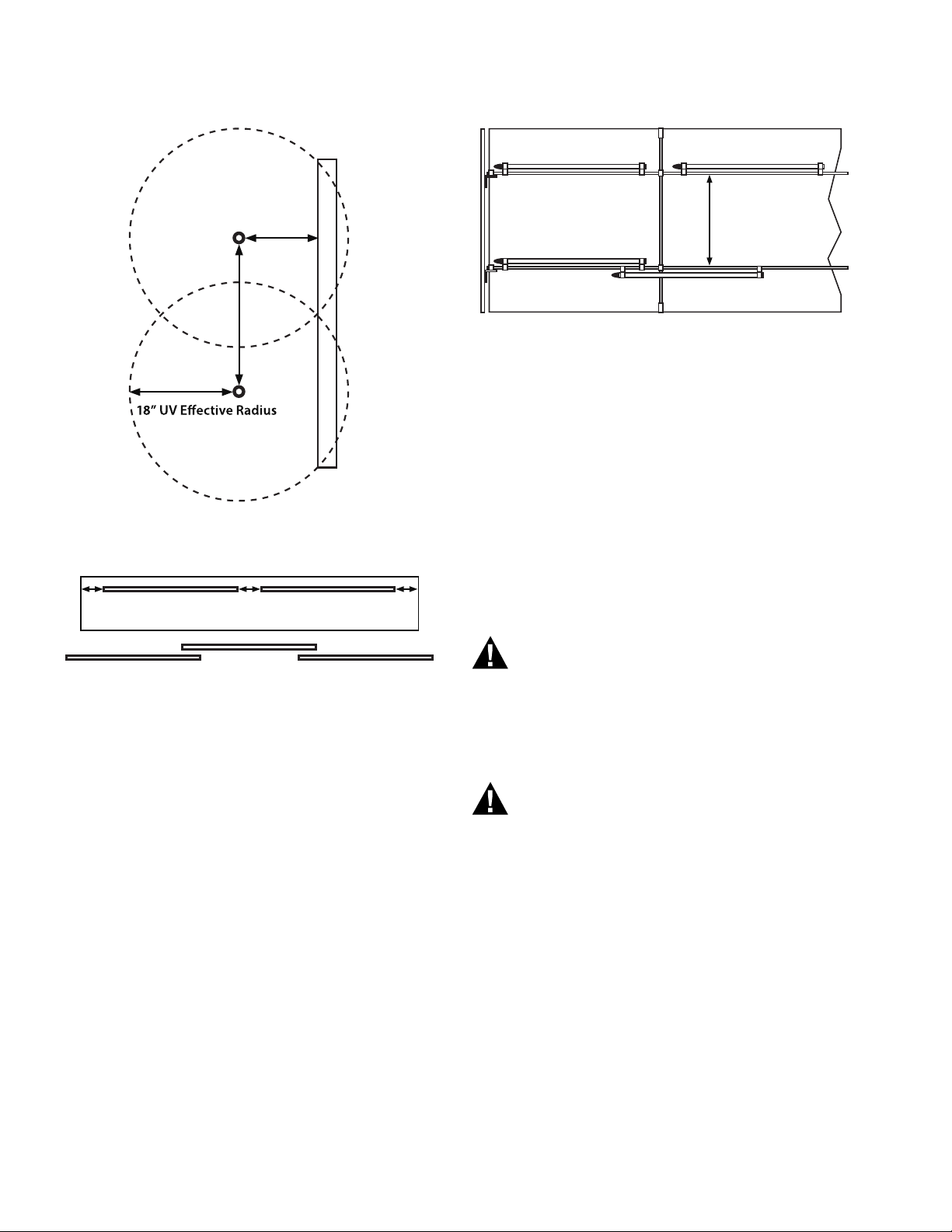

Sight Glass Installation

The sight glass allows safe viewing of the UV light system

when in operation. Find a suitable location such as a door

to the HVAC system for the sight glass. Drill a 1” hole and

press the base of the sight glass through it.

Fig. 9. Sight Glass Installation.

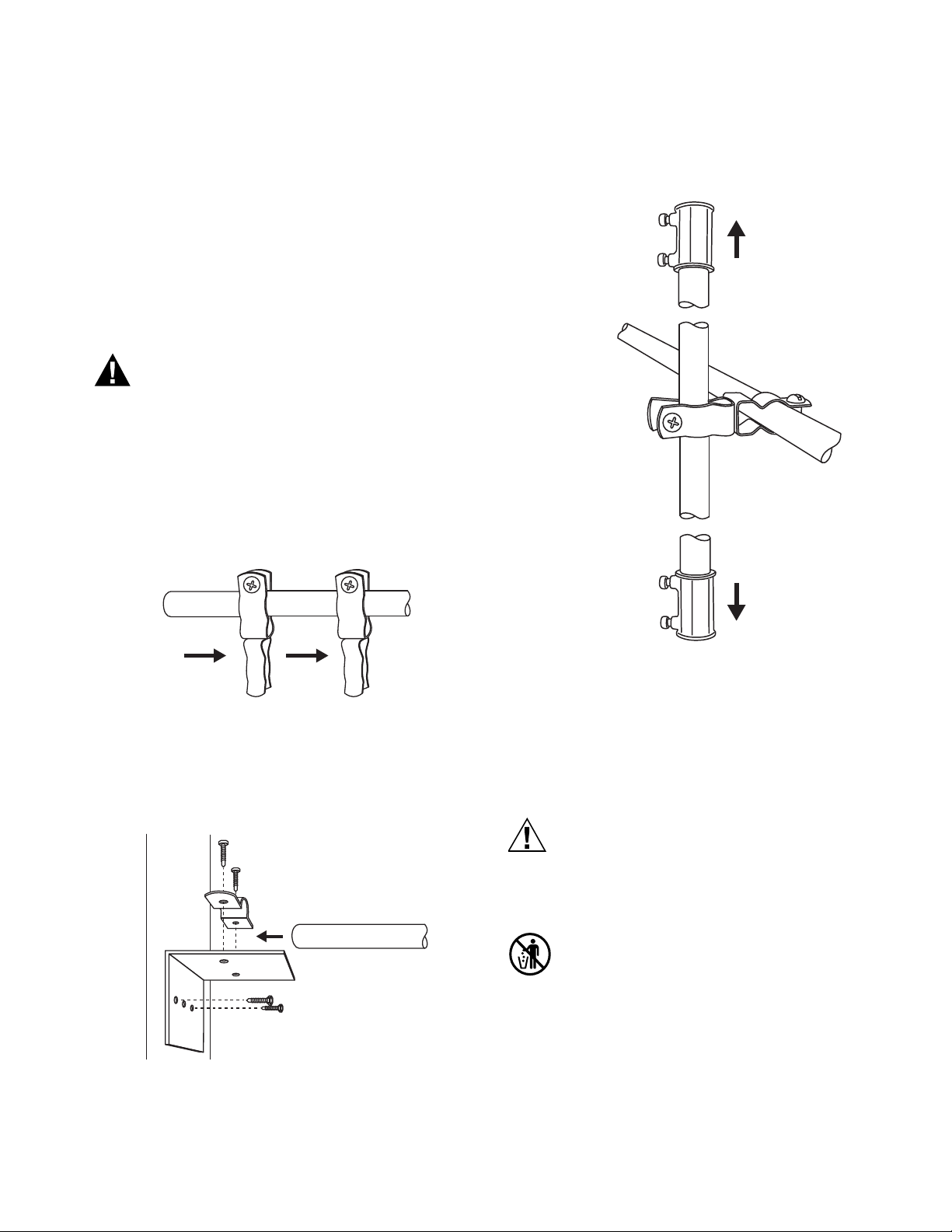

WIRING

Electric Shock Hazard.

Can cause personal injury.

Turn off main power before making electrical

connections.

Refer to electrical diagram (Fig. 10.) for proper connections

of the power supply to the main power.

Fig. 10. Electrical Connections.

Connect Lamps and Cables

Arrange cables as needed for installation. If necessary, use

cable strain relief fittings or other means to pass cables

through the cabinets or air system walls. When UV lamps,

power supplies, and cables are in place join the lamp and

power supply cables by aligning the electrical pins and

flanges on the rubber connectors and pushing them firmly

together.

Fig. 11. Align Pins and Lamp Key.

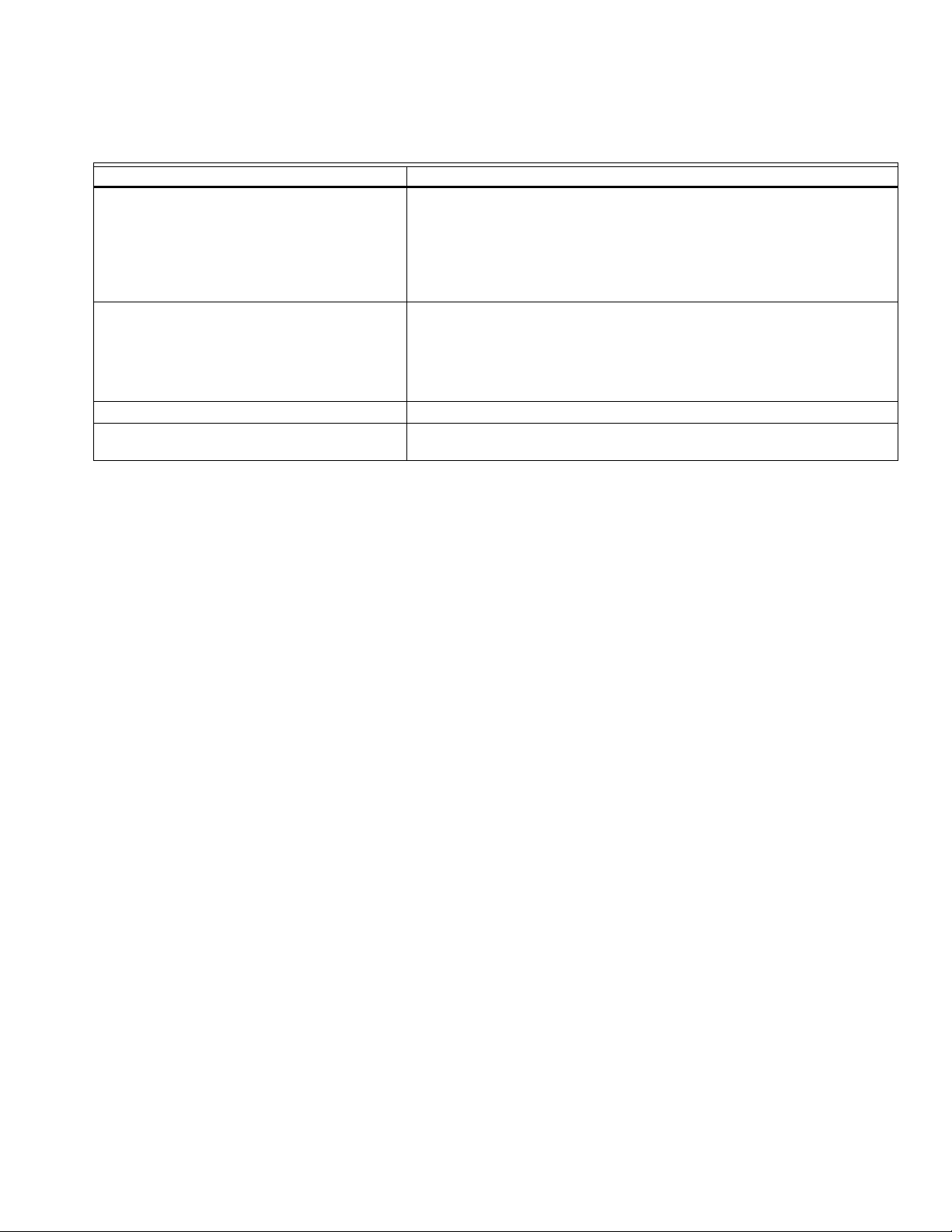

MAINTENANCE

Honeywell UVC lights are made of Hard Quartz. Unlike Soft

Quartz, these lamps do NOT need to be wiped of grease or

other contaminants, and are NOT affected by humidity.

They are warranted for 2 years of UVC output, to 60% of

their original output. Sizing guidelines are based on the

end of lamp life output levels.

Honeywell UV lamps are rated for two years germicidal

effectiveness. The visible blue light will continue to

illuminate, but does NOT have any germicidal

effectiveness. Bulbs must be replaced on schedule for the

system to function properly.

IMPORTANT

Use only Honeywell replacement lamps. Use of

replacement lamps from other manufacturers

voids the warranty. See Table 1 for replacement

lamp part numbers.

UV LAMP

UV LAMP

120-277 VAC

POWER SUPPLY

L1 BLACK

CONNECTORS

L2 or N WHITE

GND GREEN

Align Pins & Lamp Key

Push Firmly Together

UV Lamp

Power Supply

Cable

Lamp Key