INTRODUCTION

This manual is issued specifically for the data processing racks of the TA3840 or EMx40 system. It

contains instructions detailed for the installation of this system.

To use it in an optimal way, we advise you TO READ CAREFULLY THESE

INSTRUCTIONS and to respect them throughout the life of the equipment.

Keep this manual to hand so that you can refer to it at any time. Ensure that it is

complete and kept close to the equipment.

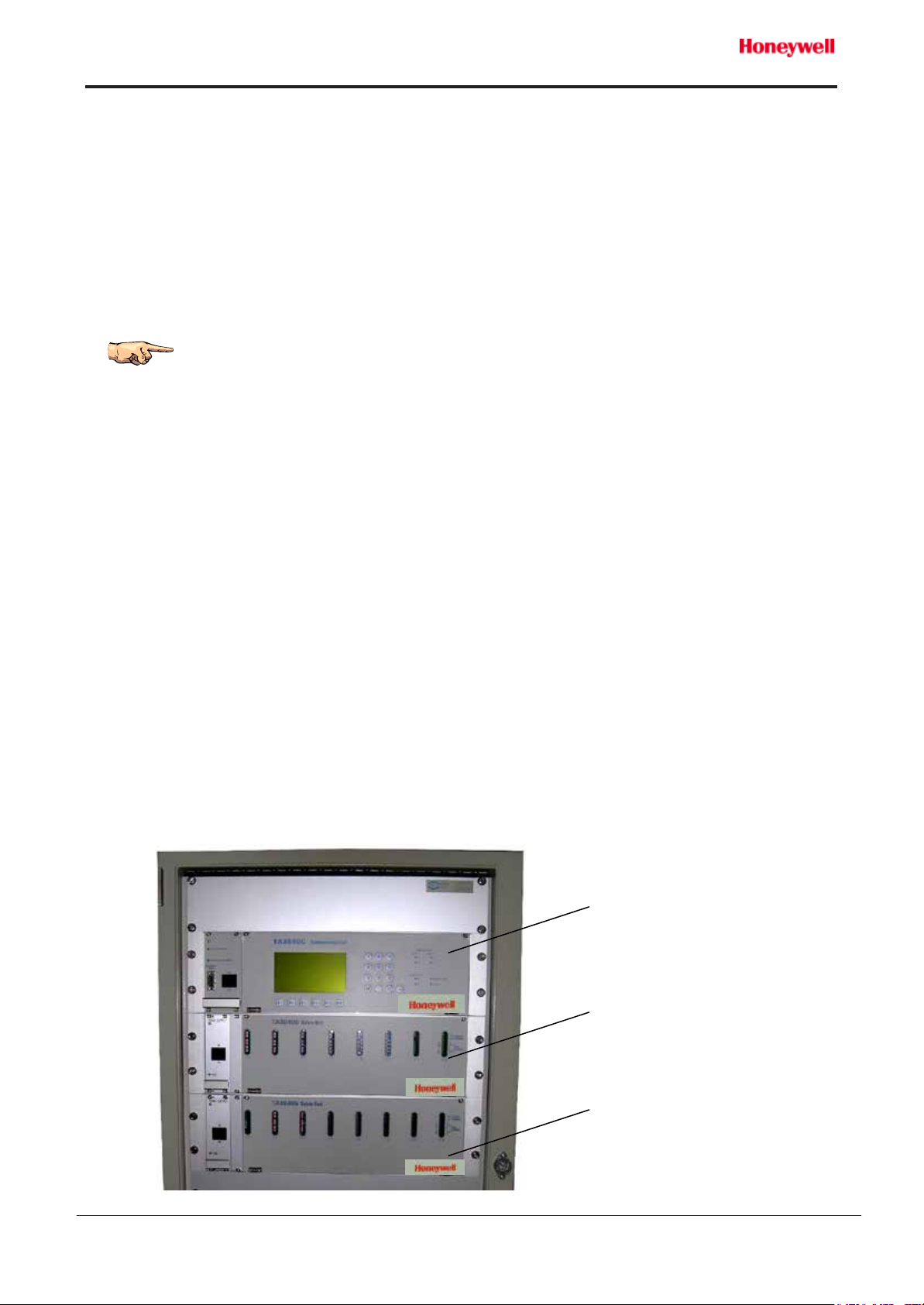

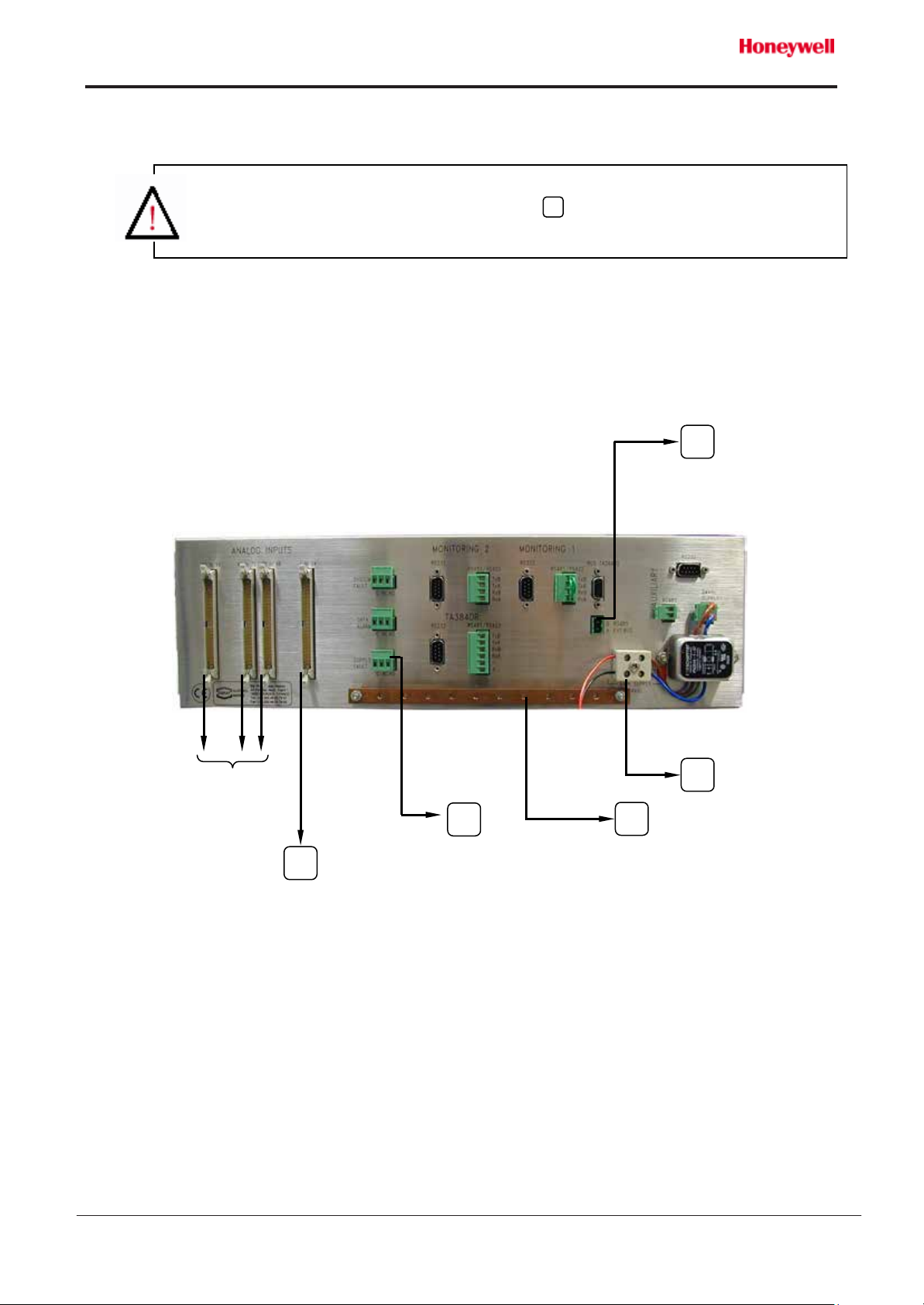

The racks TA3840C and TA3840S, as well as the TA3840R repeater module are integrated in the

system for processing the tankers liquid cargo. This system is intended for professional use, it

must be used by operators who are qualified and well-versed in the operating rules and safety

instructions set out in this manual.

We also draw your attention to the fact that the connection of equipments or the use of products

other than those recommended by Honeywell Marine may present risks for which we will not be

liable.

This manual must not be reproduced in any form whatsoever without the prior written approval of

Honeywell Marine who cannot be held responsible for any use of the information contained in this

manual.

As we want you to take advantage of the most of the latest technology and new equipment, as well

as to benefit from our experience, our equipments may undergo technical or design changes. As a

result, some of the features and information in this manual may change without prior notice and

without any obligation to up-date it.

Should you encounter any problems or have any questions about your TA3840 or EMx40 system,

please do not hesitate to contact your nearest Honeywell Marine customer service.

Other documents

The description and the operation of the racks TA3840C/R and TA3840S are described in the

MT5008E technical manual.

The maintenance of the racks TA3840C/R and TA3840S is described in the MM5008E

maintenance manual.

In order to avoid the electric shock or fire hazards, do not expose the equipments to

water projections. Take care to switch the power off before proceeding to any

disconnection or removal of the racks.

Never introduce parts, in particular metal ones, in the air vents of the racks.

Ensure that the racks are well ventilated and that the air vents are not covered.

Take care to maintain the racks distant from all heat sources (heating appliances…).