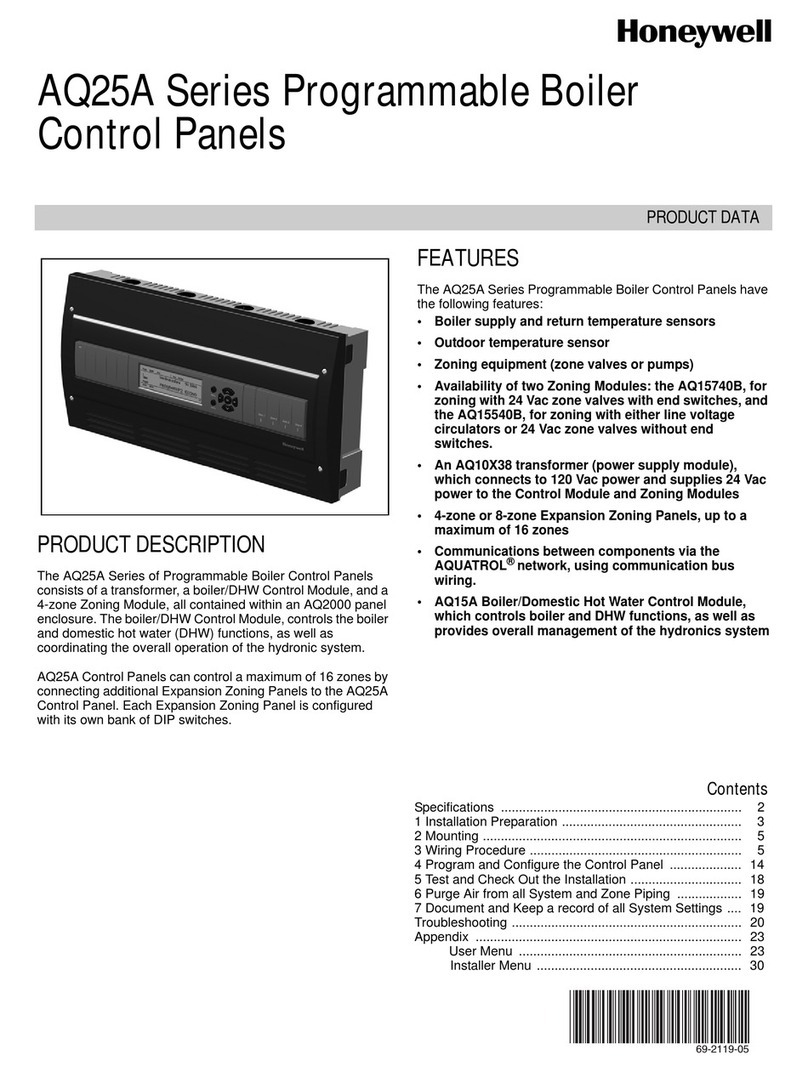

AQ252 Universal Injection/Mixing Boiler Reset Control Panels

369-1986—02

Temperature Ratings:

Boiler Design Temperature: 80°F to 210°F (26°C to

99°C)

Boiler Differential: 2°F to 41°F (1°C to 23°C), or Auto

Boiler (Supply) Minimum Control Temperature: OFF,

59°F to 180°F (OFF, 15°C to 82°C)

Boiler (Supply) Maximum Control Temperature: OFF,

120°F to 225°F (OFF, 49°C to 107°C)

Outdoor Low Design Control Temperature: -60°F to

32°F (-51°C to 0°C)

Return Minimum Control Temperature: OFF, 80°F to

180°F (OFF, 27°C to 82°C)

Secondary Loop Mixing (Supply) Design Temp

Range: 70°F to 210°F (21°C to 99°C)

Secondary Loop Mixing (Supply) Min. Control Temp

Range: OFF, 35°F to 150°F (OFF, 2°C to 66°C)

Secondary Loop Mixing (Supply) Max. Control Temp

Range: OFF, 80°F to 210°F (OFF, 27°C to 99°C)

Sensor Temperature Rating: -58°F to 230°F (-50°C to

110°C)

Warm Weather Shut Down (WWSD) Temperature: OFF,

35°F to 100°F (OFF, 1°C to 38°C)

Cold Weather Shut Down (CWSD) Temperature: OFF,

32°F to 100°F (OFF, 0°C to 38°C)

Inputs/Outputs:

Auxiliary (Demand) Input: External dry contacts

connection only

DHW Demand Input: External dry contacts connection

only

Heat Demand (Thermostat R-W) Input: External dry

contacts connection only

Modulating Output: )-10 or 2-10 Vdc for variable speed

pump or modulating boiler

Mixing Valve (Com, O, C): 324 Vac, 0.5A, 12VA

R–C Input (on Control and Zoning Modules): 24 Vac

Class II

R–C Output (on transformer): 38 VA, 24 Vac Class II

Interface and Timings:

User Interface (Setting, Programming): LCD Display

and a 7-button keypad

Setback Program: 7 day, up to 2 setback periods/day.

Boiler Heat Post Purge: Off, 10 seconds to 30 minutes

(factory default is 30 seconds)

Pump/Valve exercise: 30 seconds per 2 weeks of space

heating inactivity

Thermostat Compatibility: Digital non-communicating

thermostats and/or AQ1000 Series 2-wire communicating

thermostats

Supply/Return/Secondary (Mixed) Loop Sensor: 10K ohm

NTC thermistor at 77°F (25°C) ± 0.5°F (±0.3°C). Lead

length: 10 ft. (3.0 m); up to 500 ft. (150 m) using 18 AWG or

larger wire, beta=3892.

Outdoor Sensor: 10K ohm NTC thermistor at 77°F (25°C) ±

0.5°F (±0.3°C). Lead length: 15 ft. (4.6 m); up to 500 ft. (150

m) using 18 AWG or larger wire, beta=3892

Dimensions (HxWxD): 8 x 16 1/2 x 3 3/8 in. (20.3 x 42 x

8.5 cm) approximate

Weight: 4.9 lb. (2.3 kg)

Approvals: Canadian Standards Association: Certified, File

No. LR76030

1 INSTALLATION PREPARATION

NOTES: Throughout these instructions, the following

terminology conventions are used:

—AQ155 refers to the AQ15540B Zoning Module.

—AQ157 refers to the AQ15740B Zoning Module.

—AQ1520 refers to the AQ15200B Control Module within

an AQ252 Series Control Panel.

—AQ252 refers to the AQ25242B and AQ25244B

Control Panels. Where there are specific instructions or

details relating to the -42B or -44B Control Panels, the

full model number (i.e., AQ25244B) is used.

—AQ255 refers to all of the AQ25542B, AQ25582B and

AQ25742B Expansion Zoning Panels.

—AQ257 refers to the AQ25744B Expansion Zoning

Panel. Where there are specific instructions or details

relating to the -542B, -582B, -742B, or - 744B

Expansion Zoning Panels, the full model number (i.e.,

AQ25744B) is used.

—Control Module refers to the component within an

AQ252 Series Control Panel that performs the master

control operations. See Table 1 on page 2 for specific

models.

—Control Panel refers to an assembled product,

consisting of a transformer, Control Module and Zoning

Module, all contained within an AQ2000 panel

enclosure.

—Expansion Zoning Panel refers to an assembled

product, consisting of a Zoning Module and (if

applicable) a transformer, contained within an AQ2000

panel enclosure. Expansion Zoning Panels are

available in either 4-zone or 8-zone configurations.

—Zoning Module refers to the component within the

AQ252 Series Control Panel that controls zoning

operations.

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

the application.

3. Installers must be trained, experienced, and licensed

service technicians.

4. Follow local codes for installation and application.

5. After installation is complete, check out the product

operation as printed in these instructions.