EXCEL 10 W7754K,P,Q,R,S,T,V FCU CONTROLLERS −INSTALLATION INSTRUCTIONS

EN1B-0304GE51 R0916M

5

Configuration of the Wall Module's LED / LCD

When either a T7460 or a T7560 Wall Module has been

hardwired to the W7754, the module's LED can be configured

(using Honeywell's LNS plug-in) to provide information about,

e.g., overrides or effective occupancy modes. The LCD of a

T7560 Wall Module can likewise be configured to display such

information.

Configuration of LED to Display Info on Overrides

The wall module's LED can be configured to indicate if an

override has been activated by either the wall module's over-

ride button being pushed or because the controller has re-

ceived a network command. Specifically:

If the wall module's LED is OFF, then no override (from

the wall module or the LONWORKS network) is currently in

effect.

If the wall module's LED is ON continuously, the override

button or a network command has placed the controller

into the "occupied" or "override" mode (but if the override

button is again pushed or if a cancellation network

command is received or if the override time expires, the

controller will return to its scheduled occupancy mode).

If the wall module's LED flashes once per second, the

override button or a network command has placed the

controller into the "unoccupied" mode (however, if the

override button is again pushed or if a cancellation net-

work command is received, the controller will return to its

scheduled occupancy mode).

If the wall module's LED flashes twice per second, a

network command has placed the controller into either the

"standby" or the "occupied" mode.

If the wall module's LED flashes four times per second, the

controller is responding to a network management "wink"

command.

Configuration of LED to Display Info on Occupancy Mode

The wall module's LED can also be configured to indicate the

effective occupancy mode of the W7754. Specifically:

If the wall module's LED is OFF, the controller is in the

"unoccupied" mode.

If the wall module's LED is ON, the controller is in the

"occupied" mode.

If the wall module's LED flashes once per second, the

controller is in the "standby" mode.

If the wall module's LED flashes four times per second, the

controller is responding to a network management "wink"

command.

Configuration of LCD to Display Info on Occupancy Mode

The T7560 Wall Module's LCD can be configured to display

various symbols to indicate the effective occupancy mode of

the W7754. Specifically:

If is displayed continuously, the controller is in the

"occupied" or "override" mode; if it flashes, the given mode

has been overridden.

If is displayed continuously, the controller is in the

"standby" mode; if it flashes, the "standby" mode has been

overridden.

If

is displayed continuously, the controller is in the

"unoccupied" mode; if it flashes, the "unoccupied" mode

has been overridden.

NOTE: If all three of these symbols are flashing simul-

taneously, the controller is responding to a network

management "wink" command.

means that the controller is OFF.

and mean that the controller is OFF, but that "frost

protection" has been enabled.

LonWorks Communications

General Information

The unit is equipped with a free-topology transceiver for

communication on LONWORKS® networks. The LONWORKS

network is insensitive to polarity, eliminating the possibility of

installation errors due to miswiring.

Different network configurations (daisy-chain, loop, and star

configurations, or any combination thereof) are possible (see

also Excel 50/500 LONWORKS Mechanisms Interface

Description, EN0B-0270GE51).

Connecting to the LONWORKS Network

IMPORTANT

Do not bundle wires carrying field device signals or

LONWORKS communications together with high-

voltage power supply or relay cables. Specifically,

maintain a min. separation of 3 inches (76 mm)

between such cables. Local wiring codes may take

precedence over this recommendation.

IMPORTANT

Try to avoid installing in areas of high electro-

magnetic noise (EMI).

The unit must be wired to the LONWORKS network using level

IV 22 AWG (Belden part number 9D220150) or plenum-rated

level IV 22 AWG (Belden part number 9H2201504) non-

shielded, twisted-pair, solid-conductor wire. When possible,

use Honeywell AK3781, AK3782, AK3791, or AK3792 cable

(US part numbers). See Excel 50/5000 LONWORKS

Mechanisms, EN0B-0270GE51, for details, including max.

lengths. Use wire with a min. size of 20 AWG (0.5 mm2) and a

max. size of 14 AWG (2.5 mm2).

D-71101 Schönaich

Made in Germany

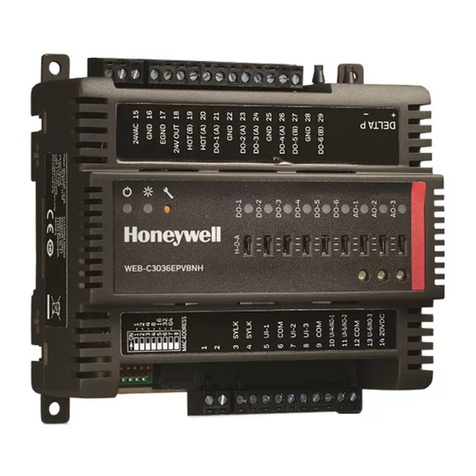

W7754K,P,Q,R,S,T,V

1 2 1 2

termination

module

D-71101 Schönaich

Made in Germany

W7754K,P,Q,R,S,T,V

Fig. 6. Connection to LonWorks network and termination

module (here: daisy-chain network configuration)

The unit is connected to the LONWORKS network via a

removable terminal plug (attached to terminals 1 and 2)

permitting individual units to be connected / disconnected

without disturbing the operation of other devices.