Instructions

These installation instructions assume the damper is already

mounted in a duct or sleeve with the damper shaft extending

beyond the duct or sleeve a minimum of 6 inches (152mm).

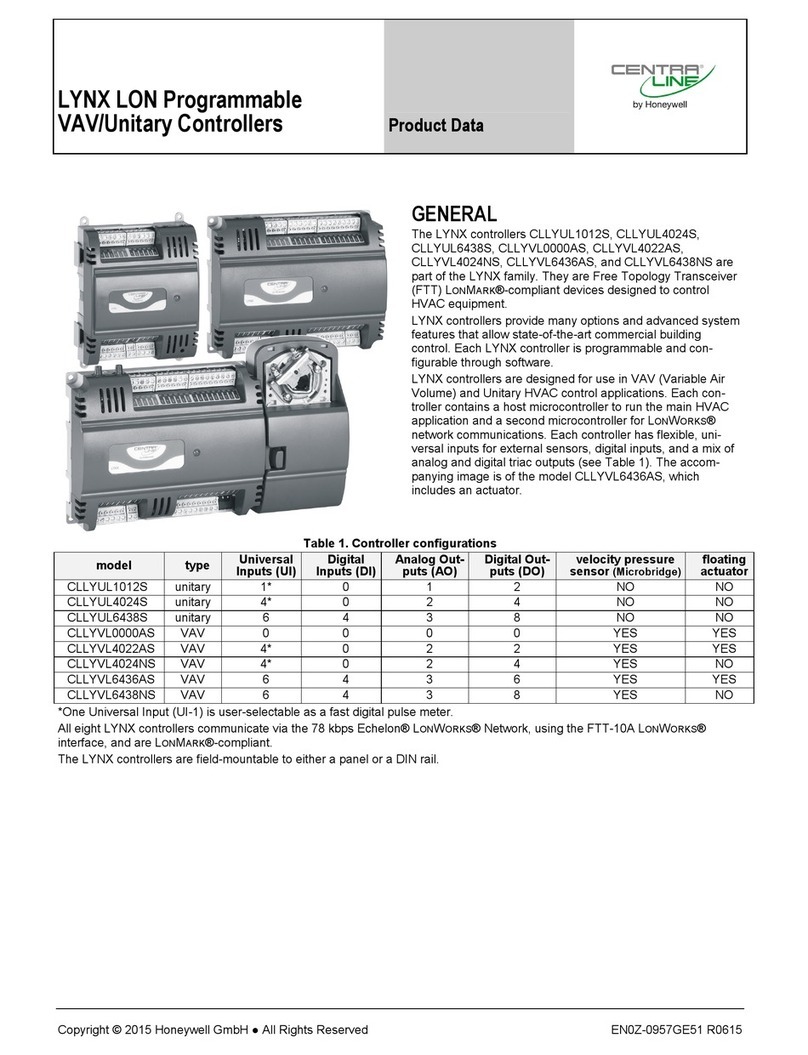

1. INSTALL THE STANDOFF BRACKET

Dampers with a jackshaft

Jackshaft supplied is typically 1 inch (25mm) diameter.

For these applications the bearing must be removed

from stand-off bracket (item #6). Mount the stand-off

bracket with [4] thread studs (item #8) and [4] 1⁄4-20

splinlock nut (item #2). Orient the stand-off bracket so

the hole is centered on the jackshaft.

Dampers without jackshaft (Shaft Extension)

Mount the stand-off bracket (item #6) spanning across

the damper frame flanges. Fasten to the damper frame

with [4] #14 x 3⁄4Tek screws (item #3). Be sure not to run

the screws into the damper linkage, which is between

the flanges.

2. MOUNT ACTUATOR BRACKET

Mount actuator bracket (item #7) using [4] thread studs

(item #8) and [4] 1⁄4- 20 nuts (item #2).

NOTE: The mounting bracket may be attached in three

positions: parallel with the duct, perpendicular up

from the duct, or perpendicular down from the duct.

Choose a position that offers the most clearance for the

application.

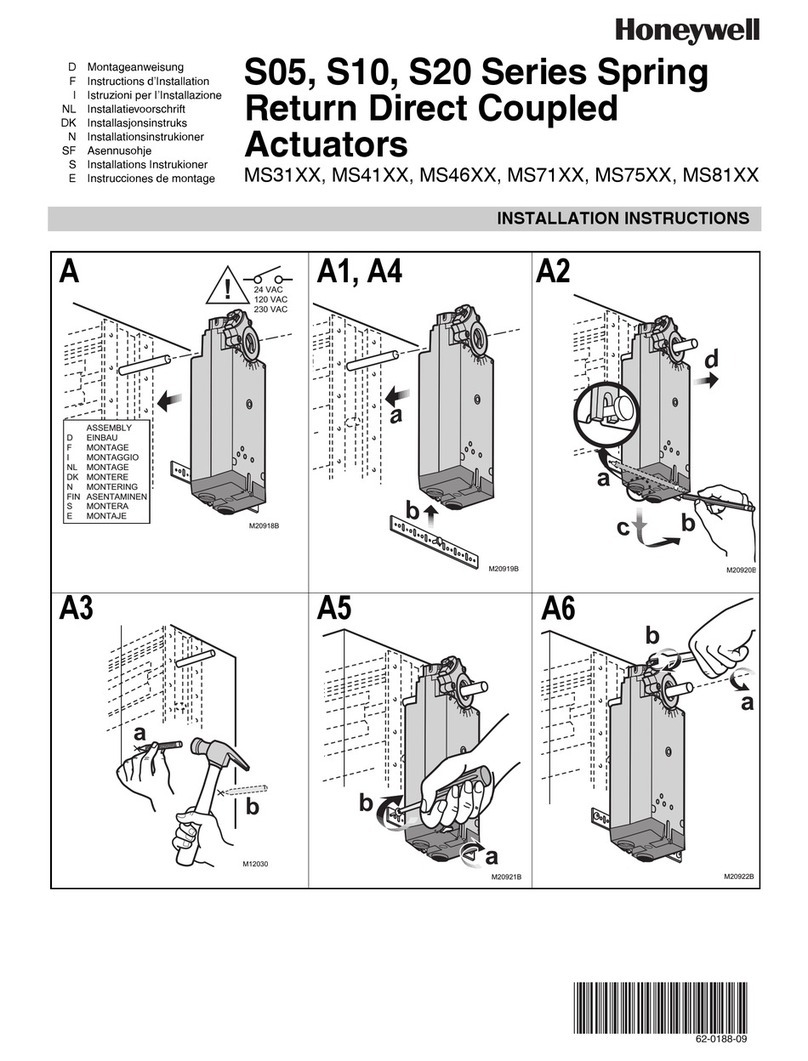

3. ACTUATOR ROTATION

If the fail rotation of the damper is counter clockwise the

universal clamp should be on the side of the actuator

showing the power direction as clockwise rotation

(usually shipped in this orientation).

To change the universal clamp to the other side, remove

the retaining clip and then the universal clamp from the

actuator. Move the universal clamp onto the actuator.

When the clamp is installed, then lock in place using the

retaining clip.

NOTE: All fail rotations refer to the damper shaft rotation

needed to achieve the desire blade fail position. If fail

position is closed, make sure damper blades are fully

close and ensure blade seals are compressed prior to

tightening the actuator clamp to the damper extension

pin or jackshaft. Inspect the damper blades and the

damper shaft to determine the proper damper shaft

rotation for the desired fail position.

4. MOUNTING ACTUATOR

Slide the actuator (item #1) over damper drive shaft.

Install thread stud through the mounting lug on the back

of the actuator and through the corresponding hole of

the actuator bracket (item #7).

Secure the thread stud to actuator bracket with #10-

24 nut. Verify that the damper is in its fail position.

Secure actuator to the damper shaft by torquing the

screw on the actuator universal clamp to 88 in. lbs. .

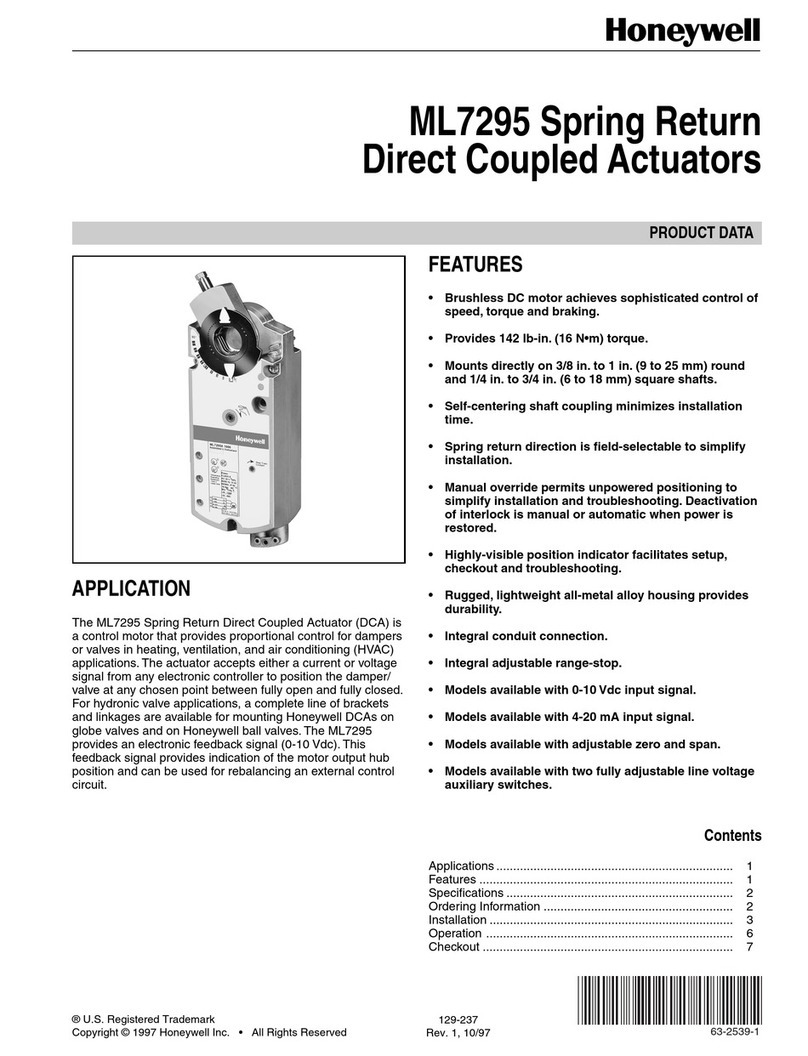

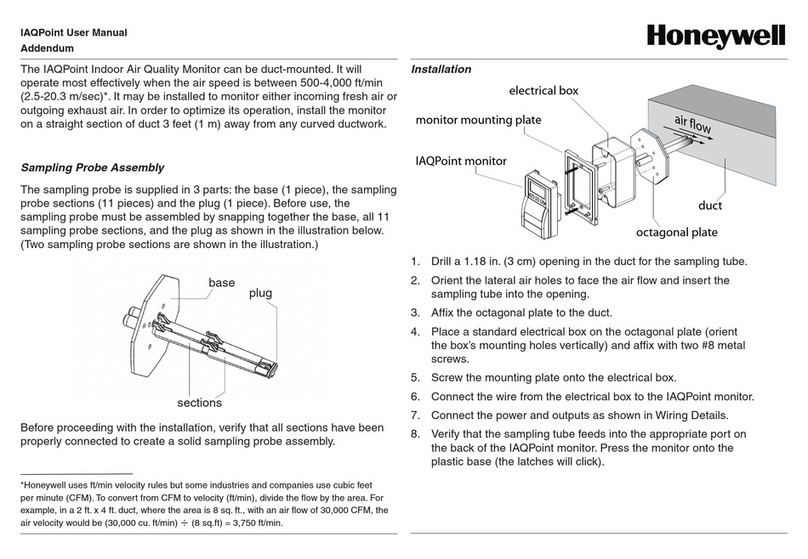

5. The wiring illustration below identifies actuator electrical

requirements and connections. Wiring must comply

with all applicable electrical codes.

6. Apply power to the actuator. The damper blades

should fully open or close and return to the fail

position when power is disconnected.

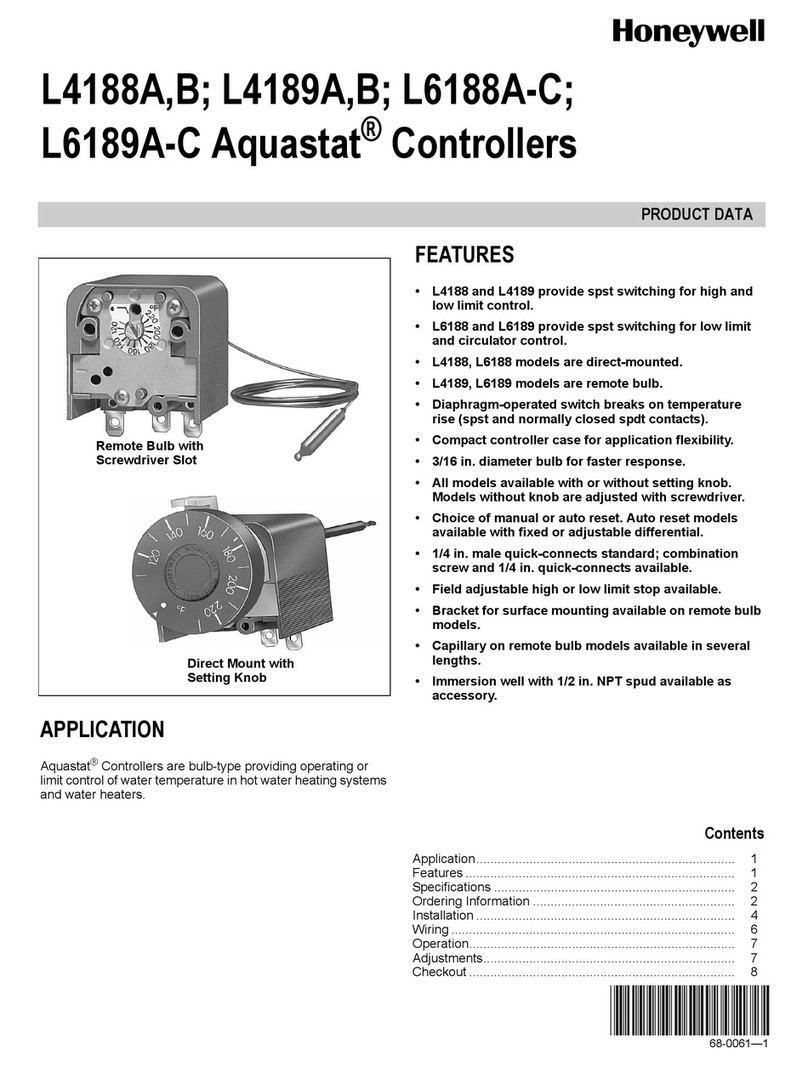

Orientation of Stand-off

Bracket for a jackshaft

driven dampers

Orientation of Stand-off

bracket for a directly

driven damper

24 volt

M

Wiring Illustration

Wiring Illustration

Important

A break in power of less than one second can cause the

actuator to spring-return 5 degrees or less and remain in

place until a break in power of longer duration.

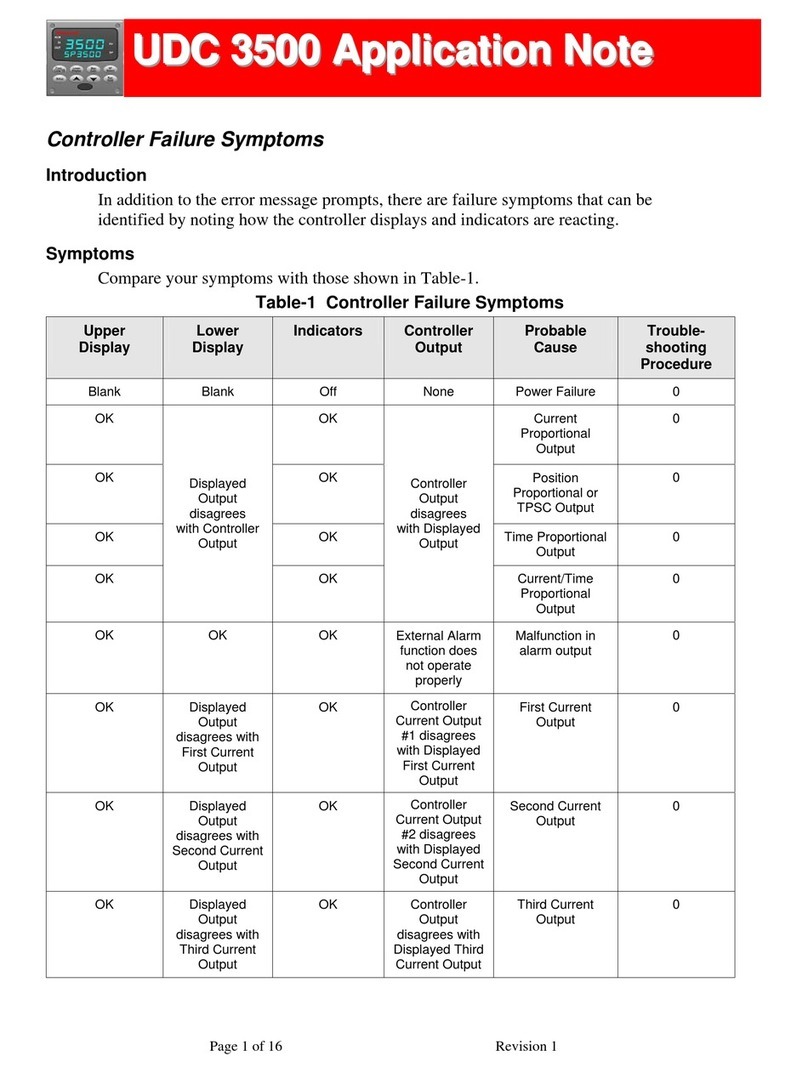

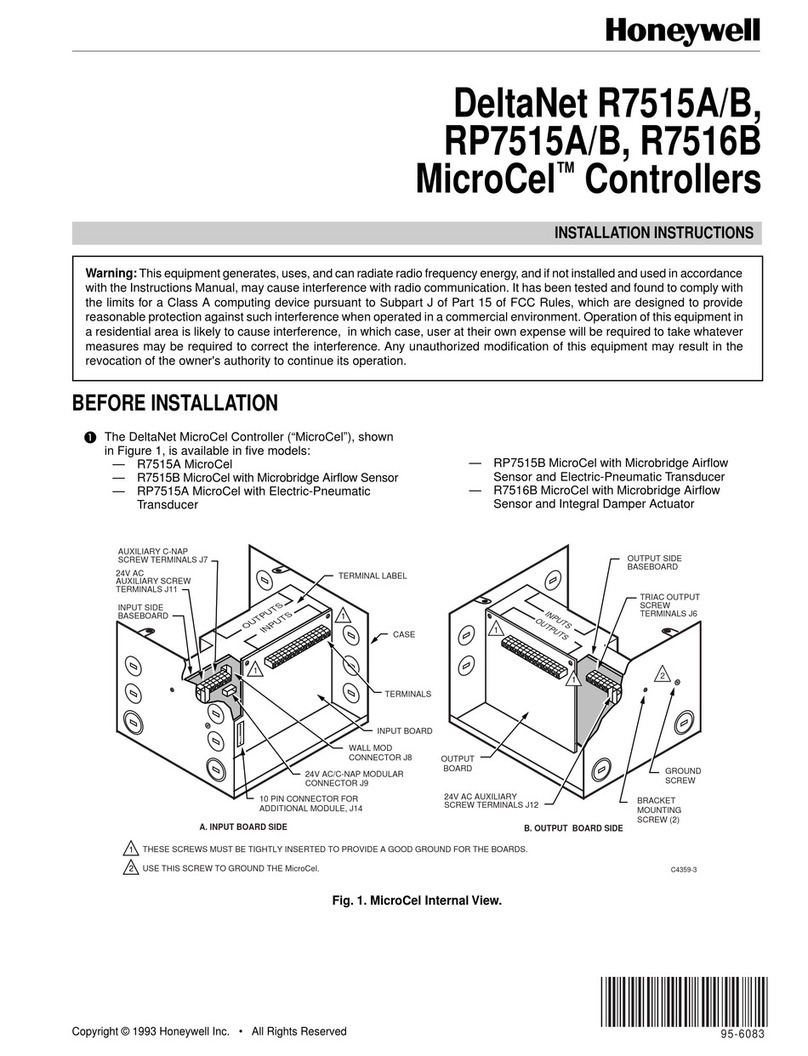

Model Volts Running Holding

MS4120F1006

120 VAC 35W 10W

MS4120F1204

MS4620F1005

230 VAC 35W 10W

MS4620F1203

MS7510A2008

24 VAC/VDC

14W

5W

MS7510A2206 14W

MS7520A2007 16W

MS7520A2015 22W

MS7520A2205 16W

MS7520A2213 22W

MS8110A1206 24 VAC/VDC 30W 8W

MS8120F1002

24 VAC 45W 10W

MS8120F1200

464287 • MS4120 MS4620 MS8120, Rev. 9, January 2019 Copyright 2019 © Greenheck Fan Corporation2

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Product warranties can be found online at Greenheck.com, either on the specific product page or in the literature

section of the website at Greenheck.com/Resources/Library/Literature.

®

Phone:

715.359.6171

•

Fax:

715.355.2399

•

Parts

:

800.355.5354

•

E-mail:

[email protected] •

W

ebsite:

www

.greenheck.com

Our Commitment