Honeywell M6410C/L Operation manual

Other Honeywell Controllers manuals

Honeywell

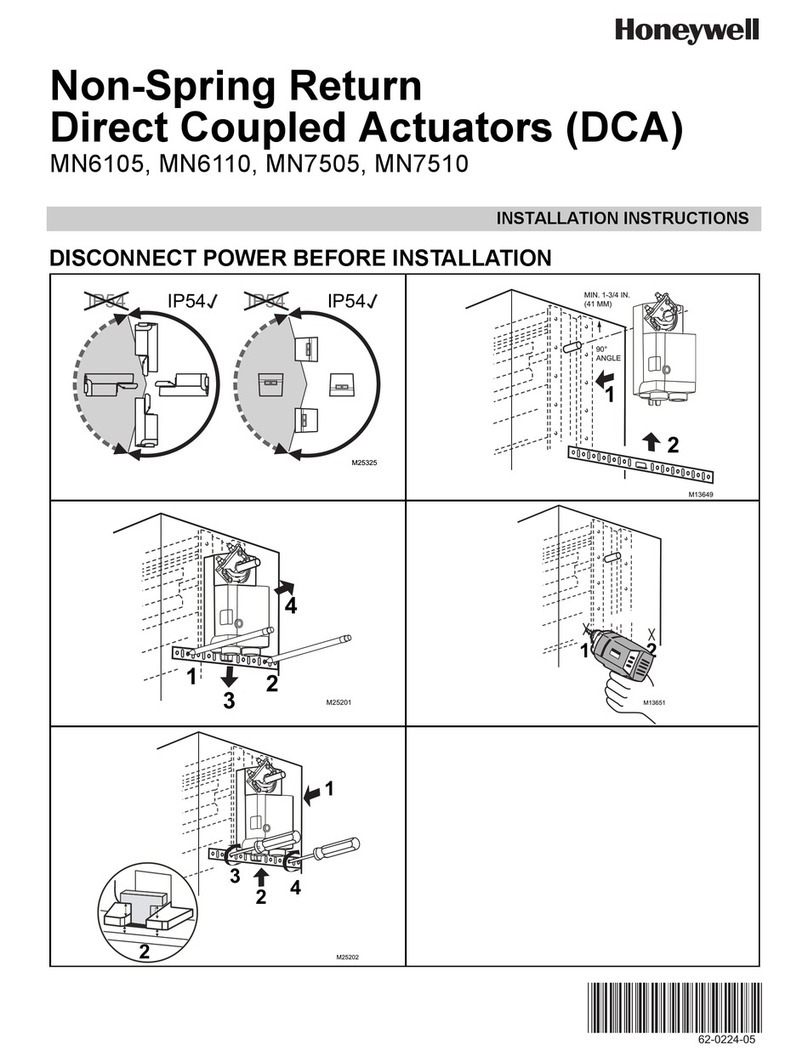

Honeywell MN7505 User manual

Honeywell

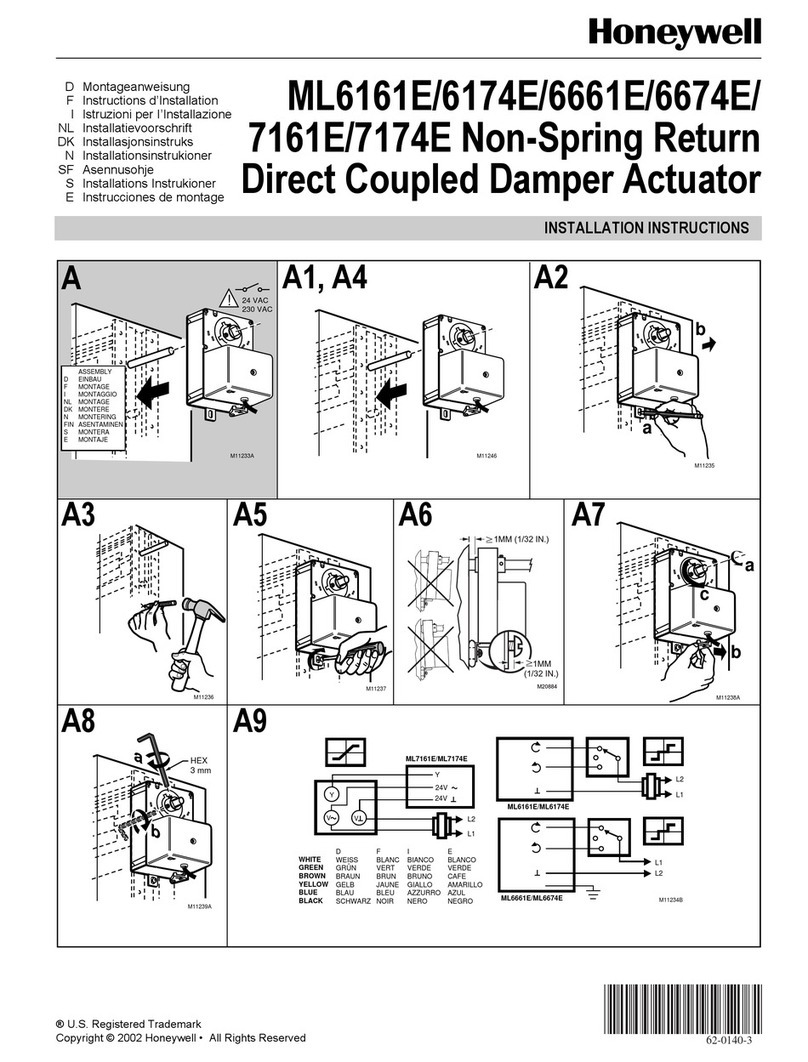

Honeywell ML6161E User manual

Honeywell

Honeywell DC33XB User manual

Honeywell

Honeywell ICON 100 SERIES User manual

Honeywell

Honeywell SmartValve SV9510 User manual

Honeywell

Honeywell CENTRA LINE LION CLLIONLC01 Installation and operation manual

Honeywell

Honeywell WEB-300E Series User manual

Honeywell

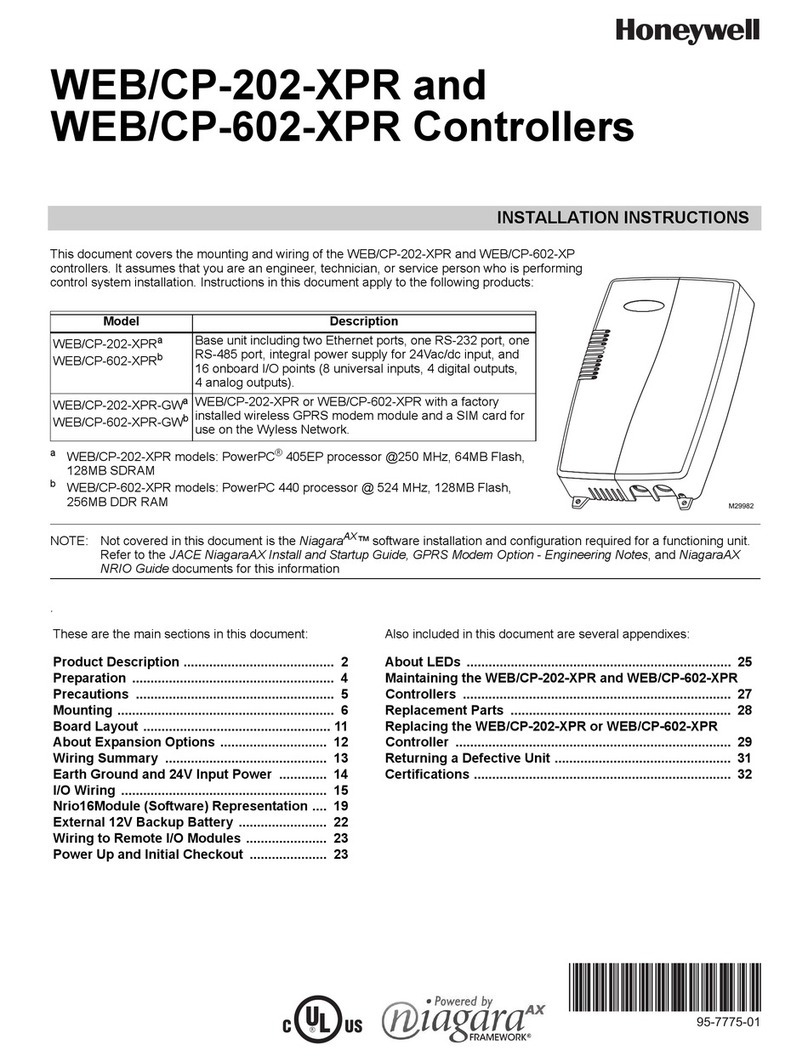

Honeywell WEB/CP-202-XPR User manual

Honeywell

Honeywell Ex-Or MLS Installation and operation manual

Honeywell

Honeywell CN100 Technical manual

Honeywell

Honeywell ML7295E User manual

Honeywell

Honeywell HON 5020 Operating instructions

Honeywell

Honeywell Pressuretrol P7810C User manual

Honeywell

Honeywell 4000 Series Operation manual

Honeywell

Honeywell Touchpoint Plus User guide

Honeywell

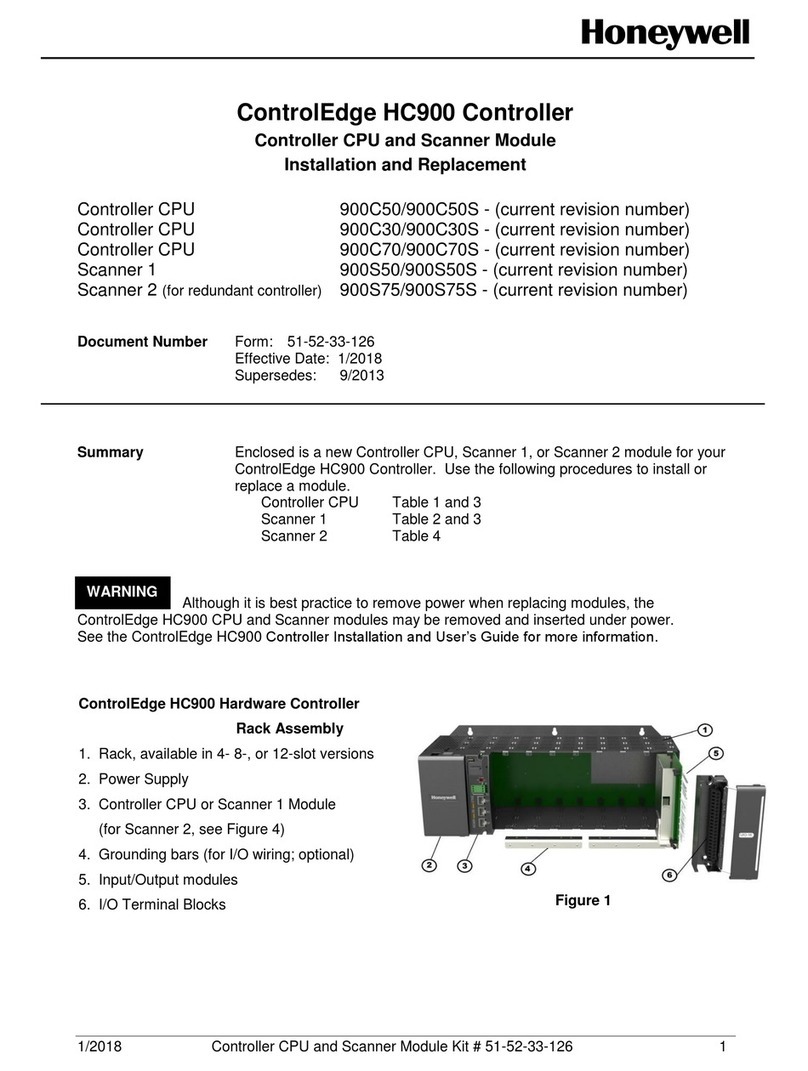

Honeywell HC900 Use and care manual

Honeywell

Honeywell ML6420 Operation manual

Honeywell

Honeywell MP909E Datasheet

Honeywell

Honeywell DBC2000 Series User manual

Honeywell

Honeywell Ex-Or MLSM2000A Installation and operation manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions