Honeywell HP970A Mounting instructions

Other Honeywell Humidistat manuals

Honeywell

Honeywell HumidiPRO H6062 User manual

Honeywell

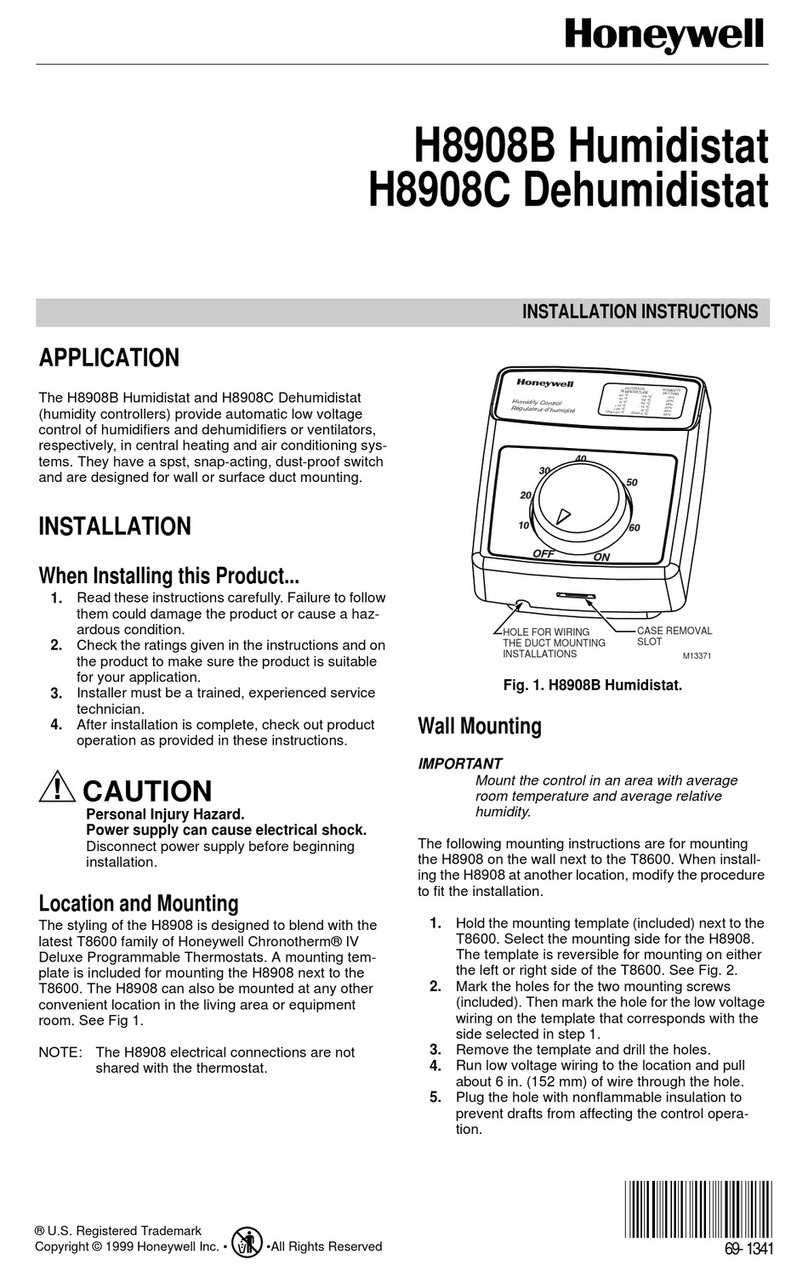

Honeywell H8908B Humidistat User manual

Honeywell

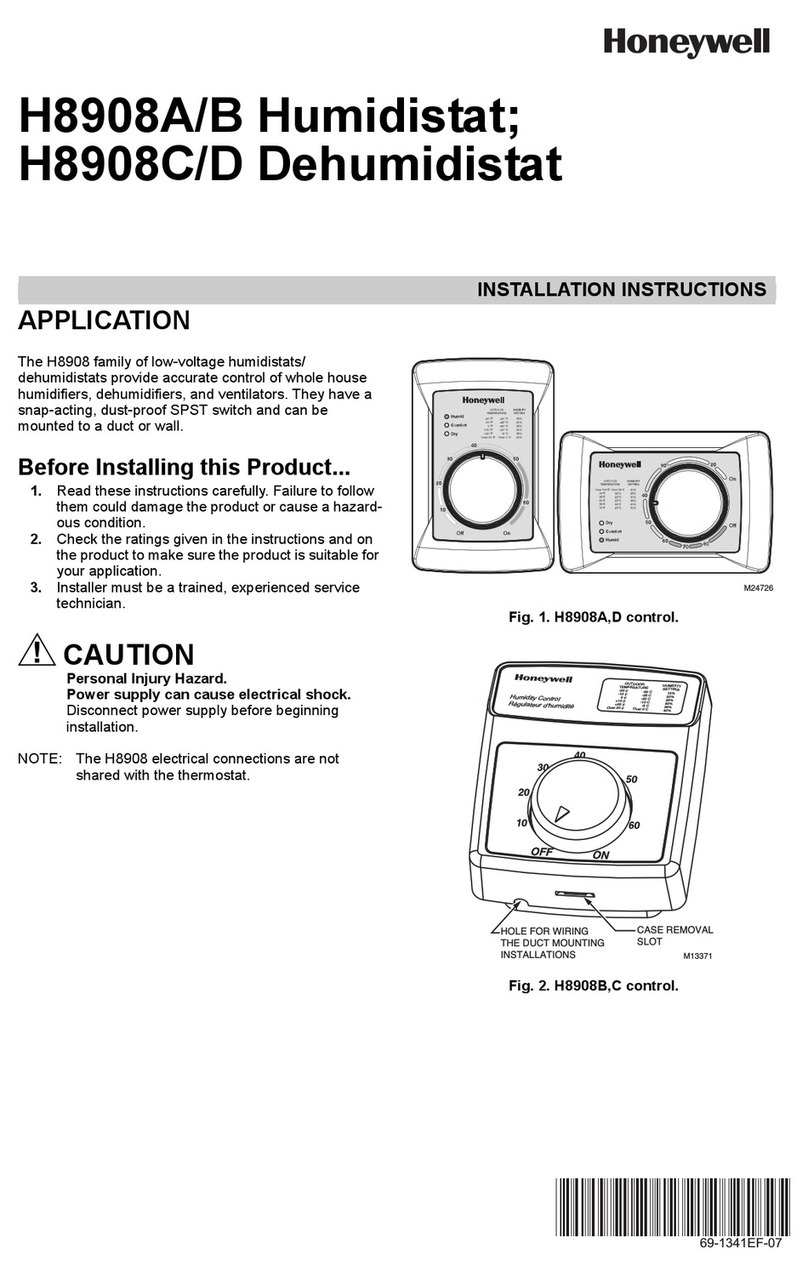

Honeywell H8908A/B User manual

Honeywell

Honeywell HumidiPRO H6062 User manual

Honeywell

Honeywell H8908ASPST - Humidistat Control User manual

Honeywell

Honeywell H8908B Humidistat User manual

Honeywell

Honeywell HumidiPRO H6062 User manual

Popular Humidistat manuals by other brands

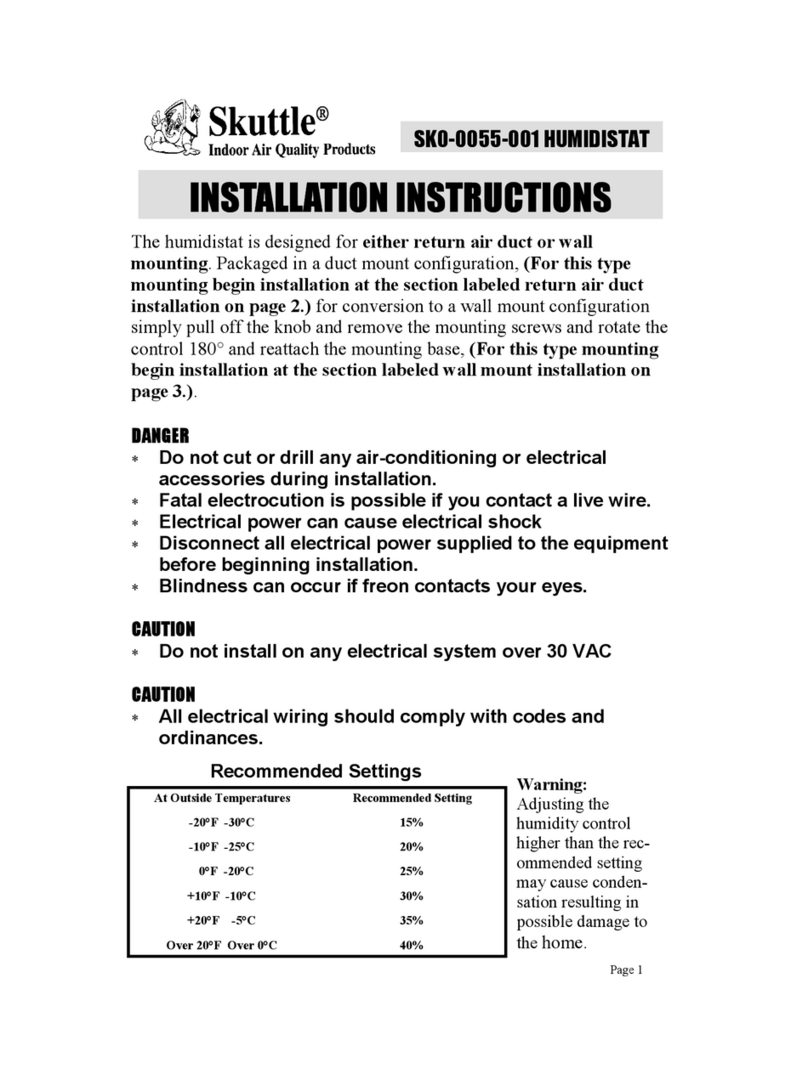

Skuttle Indoor Air Quality Products

Skuttle Indoor Air Quality Products SK0-0055-001 installation instructions

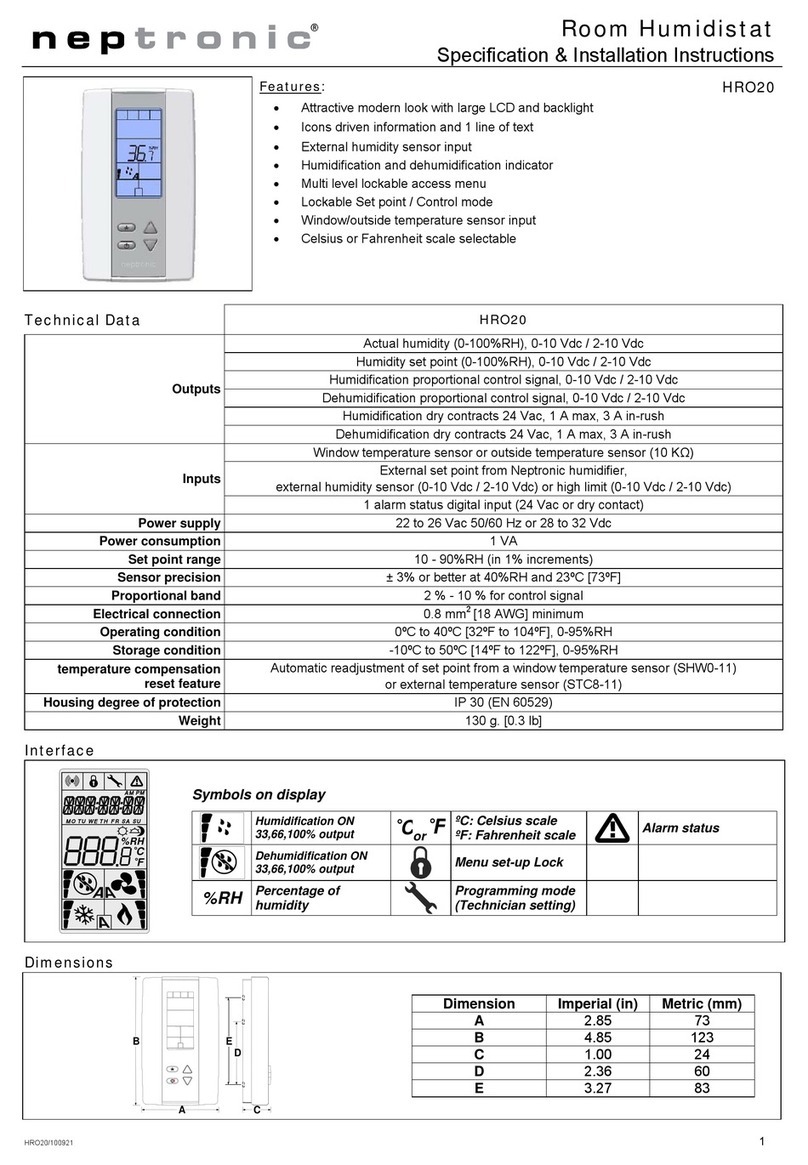

Neptronic

Neptronic HRO20 Specification & installation instructions

Lucky Reptile

Lucky Reptile Humidity Control II operating instructions

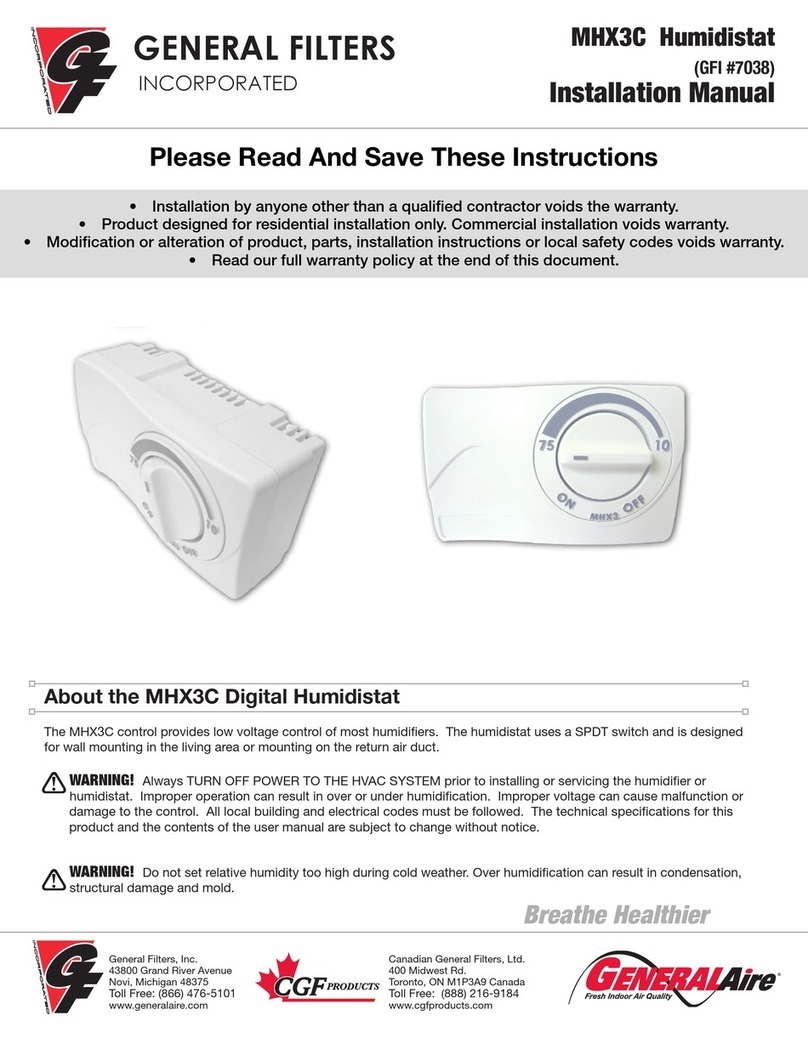

General Filters

General Filters MHX3C installation manual

TrolMaster

TrolMaster HS-1 manual

Skuttle Indoor Air Quality Products

Skuttle Indoor Air Quality Products Compustat SEH-7100-000 Safety and installation instructions

MS Electronics

MS Electronics E925 Product guide

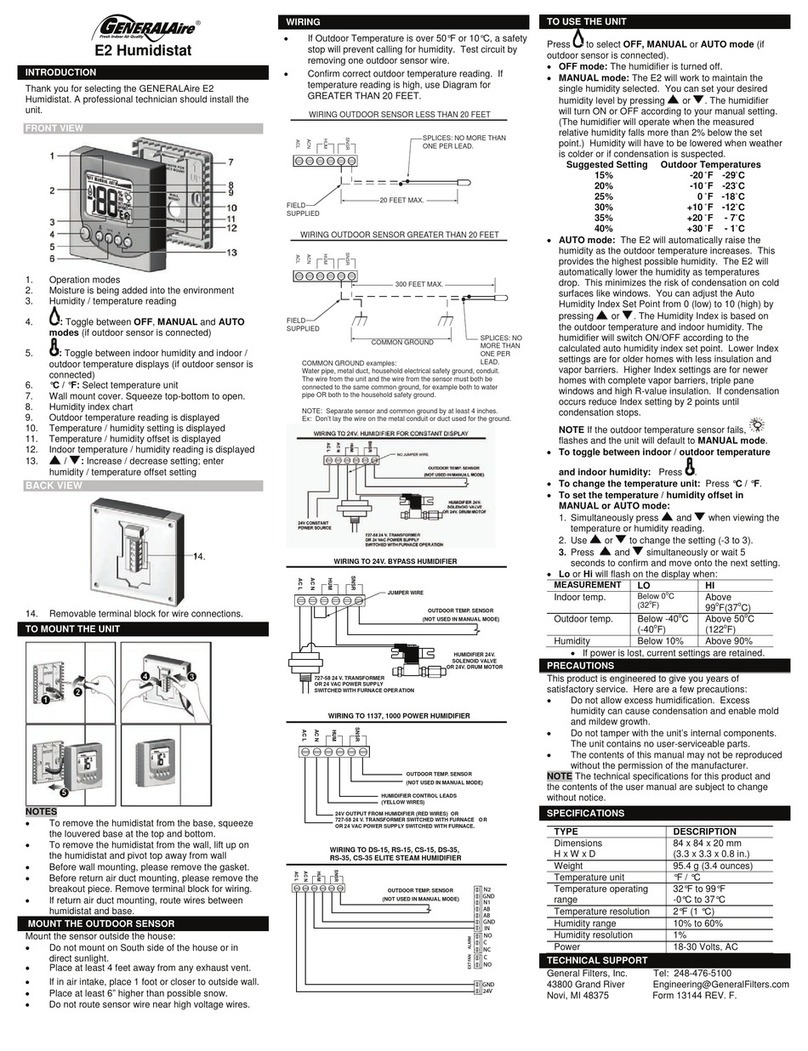

GeneralAire

GeneralAire GFX4 Installation and operating instructions

Azbil

Azbil Neostat HY9000Z Specifications and Instructions

DriSteem

DriSteem TCI-W11-U-H Safety, installation, and operation manual

COMFORTSTEAM

COMFORTSTEAM ELECTRONIC HUMIDISTAT quick start guide

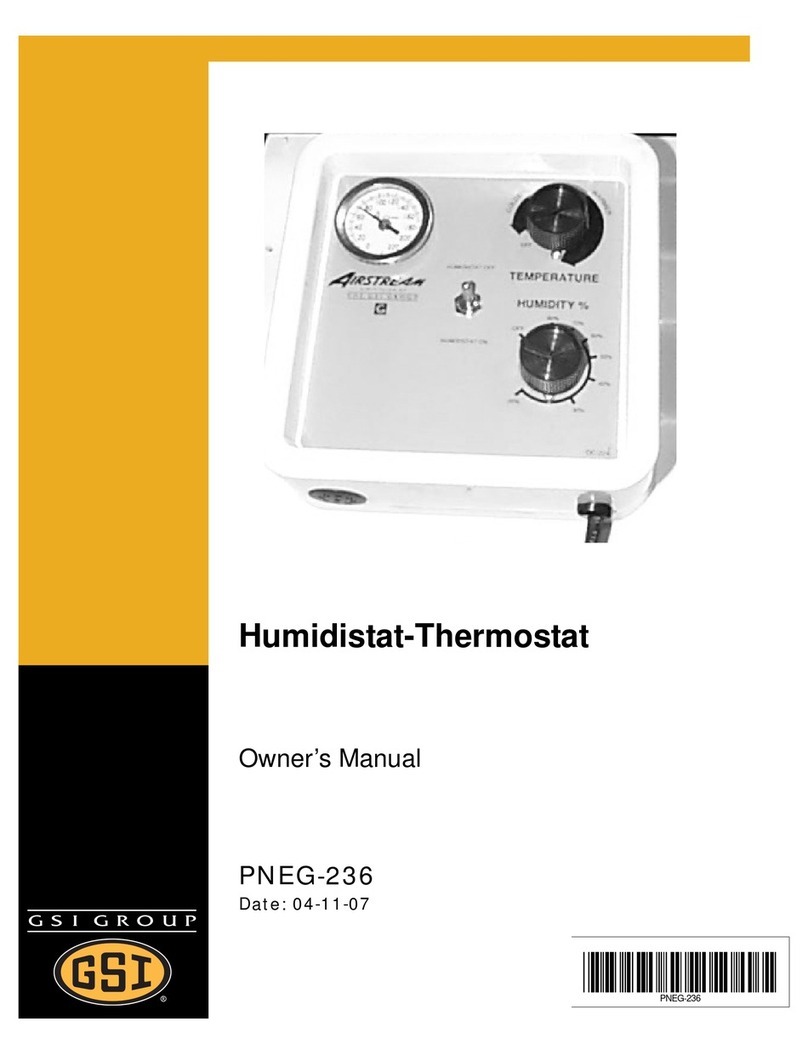

GSi

GSi PNEG-236 owner's manual