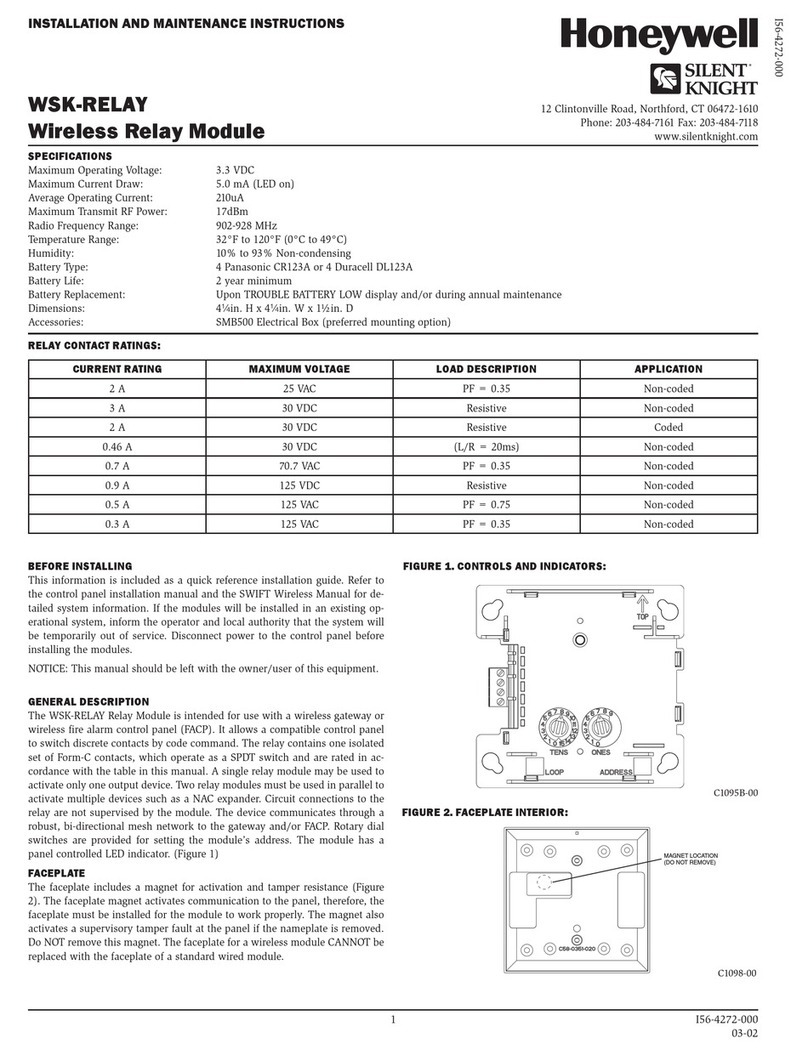

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a compatible

Notifier system control panel (list available from Notifier).

BATTERY REPLACEMENT

Low battery levels on the wireless devices are displayed as a trouble in the

FACP. Therefore when the message “TROUBLE BATTERY LOW” is displayed,

replace the battery in the device. This message is an indication that approxi-

mately one week of battery life remains.

To replace the batteries in a wireless device use the following steps:

1. Have 4 CR123A (or DL123A) batteries available

2. Remove the faceplate from the module.

3. Open the battery compartment. (See Figure 3.)

4. Remove the used batteries and replace with new batteries. The battery com-

partment is designed such that the batteries can only align in the appropri-

ate direction. Do not force the batteries into the openings.

5. Replace the battery compartment cover.

6. Replace the faceplace.

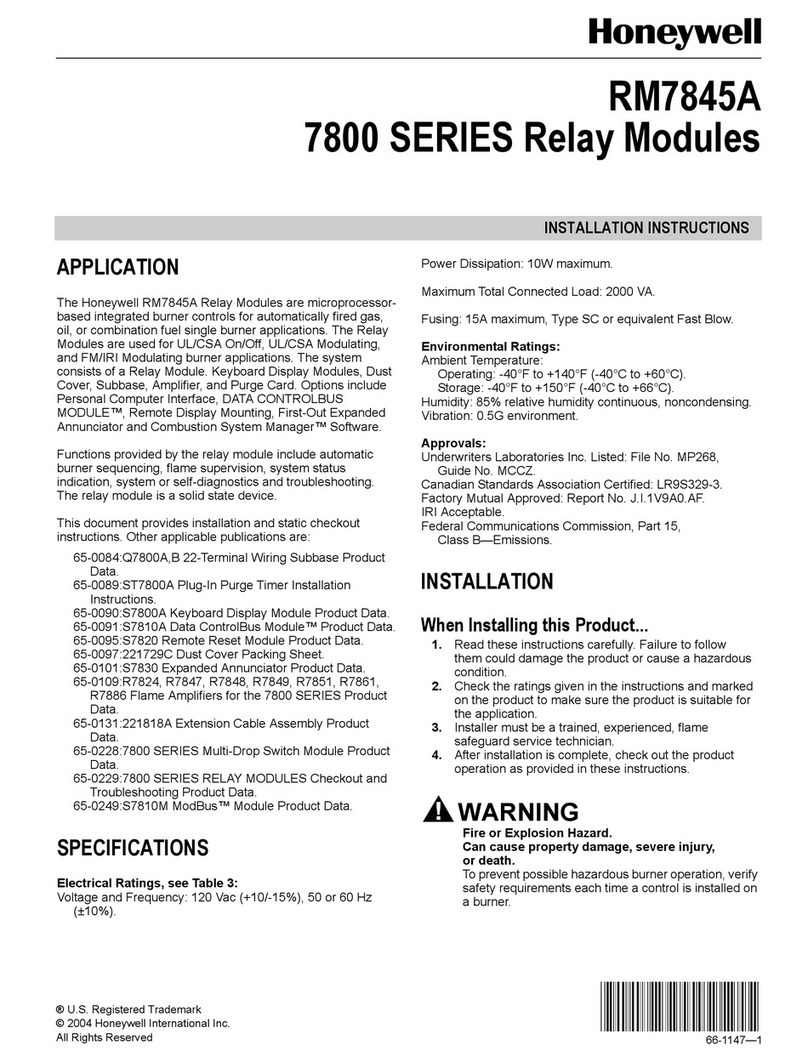

MOUNTING

The FW-RM(A) mounts directly to an SMB500(-WH) electrical box. (See

Figure 4.) To avoid interference with the wireless network metal elec-

trical boxes are NOT recommended. Non-metal surface mounted elec-

trical boxes (SMB500/SMB500-WH) are available from Notifier. If not

using an SMB500(-WH), the minimum mounting opening dimensions for the

FW-RM(A) are 4 in. X 3¾ in. x 1½ in. deep.

NOTE: Do not attach the module to temporary structures such that the place-

ment could be altered.

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations. For applications interfacing with Emergency Control Functions,

field wiring shall be limited to 3' or 20' in non-metallic conduit. In Canada,

wiring methods shall be in accordance with CSA C22.1 Safety Standard for

Electrical Installations, Canadian Electrical Code, Part 1, Section 32.

1. Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as shown in

Figure 4.

WARNING

All relay switch contacts are shipped in the standby state (open) state, but may

have transferred to the activated (closed) state during shipping. To ensure that

the switch contacts are in their correct state, modules must be made to com-

municate with the panel before connecting circuits controlled by the module.

When interfacing with an emergency control function, that function must re-

spond in 1 second or less.

2 I56-4068-002

©2021 Notifier. 10/7/2021

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

WARNING: Do not make changes to the equipment. Changes or modifications not expressly approved by the manufacturer could void the user’s authority to operate the equipment.

FCC STATEMENT

IC STATEMENT

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

RAPPORT D’IC

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes: (1) l’appareil ne doit pas produire de

brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

INSTITUTO FEDERAL DE TELECOMUNICACIONES

This device utilizes the Honeywell915 rev A radio module and complies with IFETEL standard(s). IFT: RCPHOSW14-1983

Use of these products in combination with non-Honeywell products in a wireless mesh

network, or to access, monitor or control devices in a wireless mesh nework via the

internet or another external wide area network, may require a separate license from

Sipco, LLC. For more information, contact Sipco, LLC or Ipco, LLC at 8215 Roswell Rd.,

Building 900, Suite 950, Atlanta, GA 30350, or at www.sipcollc.com or www.intusiq.com.

LICENSING STATEMENT

Notifier®and SWIFT ® are registered trademarks of Honeywell International, Inc.

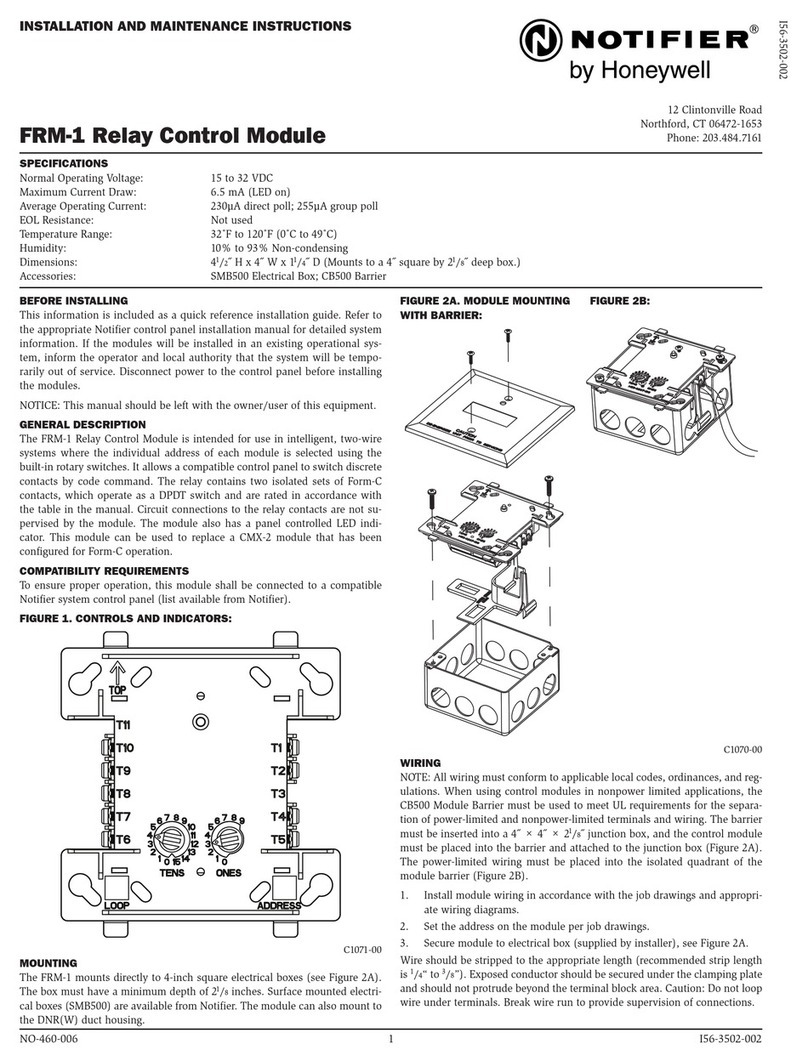

FIGURE 5. TYPICAL WIRING CONFIGURATION

MODULE DOES NOT SUPERVISE

CONTROLLED CIRCUITS

CONNECT THE SEPARATELY

ENERGIZED RELAY CONTACTS TO

CLASS 2 POWER-LIMITED OUTPUTS

FROM A POWER SOURCE LISTED TO

UL 864 OR ULC-S527.

INSTALL CONTACT CLOSURE DEVICES

PER MANUFACTURER’S INSTALLATION

INSTRUCTIONS.

T1: NOT USED

T2: NORMALLY OPEN

T3: COMMON

T4: NORMALLY CLOSED

NOTE: IN APPLICATIONS INTERFACING WITH EMERGENCY CONTROL FUNCTIONS, FIELD WIRING

SHALL BE LIMITED TO 3 FEET OR 20 FEET IN THE SAME ROOM IN NON-METALLIC CONDUIT.

C2019B-01

FIGURE 4. MODULE MOUNTING

C1096-01

FIGURE 3. BATTERY COMPARTMENT

BATTERY

COMPARTMENT

DOOR

BATTERY

COMPARTMENT

C2002-01