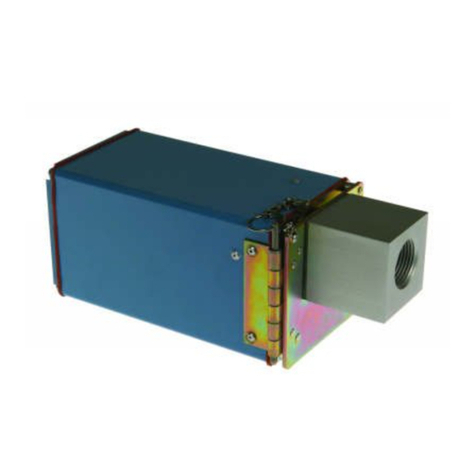

Honeywell SC105 Mini-Seismic Vibration Detector

Installation Guide

1. General Information

SC105 Mini-Seismic Vibration Detector is a seismic or structural vibration detector designed to detect selected vibrations from

burglary or intrusion attempts on mini-ATMs, Containers, Filing Cabinets and so on. The detector consists of a sensor to

convert mechanical vibrations to electrical signals, a signal conditioning block, signal analysis and alarm criteria blocks, output

alarm circuits, tamper protection, and a switching block for selecting detector settings, all in a miniature metal housing.

This Installation Guide provides general information about the mounting and configuring of SC105 Mini-Seismic Vibration

Detector. For more details, such as planning detector locations, please refer to “SC105 Mini-Seismic Vibration Detector

Planning and Installation Guide”.

2. Applications

SC105 Mini-Seismic Vibration Detector is designed to detect any known attack tool on:

Mini-ATMs

Filing Cabinets

Gates

Containers

Chests

Vending machines

Ticket machines

2.1 Application Settings

Sensitivity Settings Material Detection

Radius Applications Noise Level

Steel 3.0 m

Ghigh Concrete 2.0 m

Mini-ATMs (grade 3,4) and Containers Insignificant noise level

Steel 1.5 m

Gnormal Concrete 1.0 m

Mini-ATMs (grade 1,2) and Chests Moderate noise level

Glow Steel 1.0 m Filing Cabinets, Gates Considerable noise level

Gnoisy Sheet Steel <3.0 m Vending machines, Ticket machines Heavy noise level

Notes:

1. Sensitivity settings (Ghigh, Gnormal, Glow, Gnoisy) are defined in “4.2.1 DIP Switch Settings”.

2. The parameters in the table above are only for reference, and they may vary according to the quality of the material.

3. The detection range will be reduced if cracks and joints exist in the material.

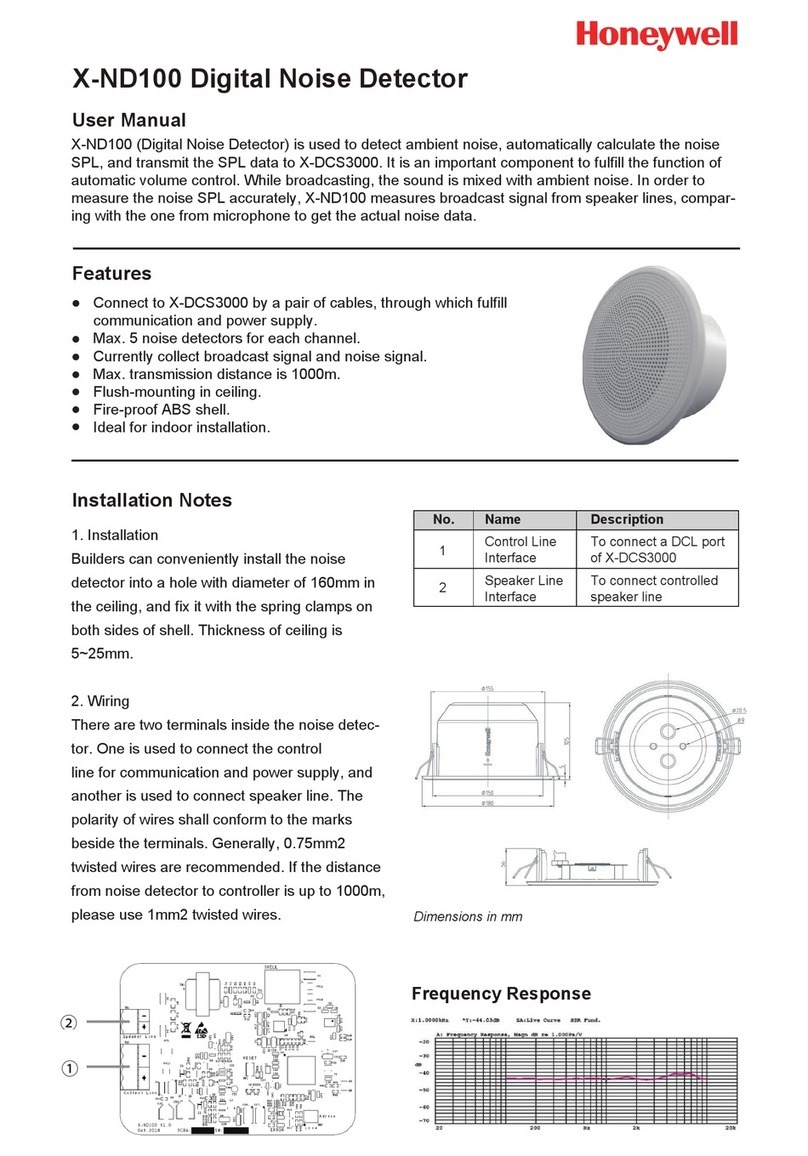

3. Mounting the Detector

SC105 Mini-Seismic Vibration Detector can be mounted on any solid surface, of which the most common surfaces are: Steel,

Stainless Steel, Hardened Steel and Concrete.

3.1 Opening the Detector

Before mounting the detector, separate the detector cover from the detector base first (by loosing the top screw, see Figure 1).

Figure 1 Open the detector

Detector Cover Detector Base

Figure 2 Drill Plan

Note Plea se remove the drill

:

plan after mounting holes

have been drille d

3.2 Mounting on Steel

When mounting the detector on a flat and smooth steel surface, both Drill Plan (see Figure 2) and Detector Base can be used

to mark the mounting holes.

1. Remove and clean paint from the mounting area.

2. Attach the detector base or drill plan on the mounting area, then mark the outline and center punch detector mounting

holes A, B and Test Transmitter SC113 mounting hole C.

A

B

Notes:

Detector base cannot be used to mark Test

Transmitter SC113 mounting hole C.

Skip marking hole C if Test Transmitter

SC113 is not used.

C

A

B

3. Drill detector mounting holes A, B (Ø 3.3 mm and

minimum 8 mm deep), and then thread the two holes

with a M4 Tap (6 mm at least).

4. Drill Test Transmitter SC113 mounting hole C (Ø 3.3

mm and minimum 8 mm deep), and then thread the

hole with a M4 Tap (6 mm at least).

5. Remove dill plan and all of the burrs.

Notes:

Cool the tools with oil while drilling and threading.

Skip step 4 if Test Transmitter SC113 is not used.

6. Attach Test Transmitter SC113 on the mounting area

(at C) and then use the M4×8 mm screw to fix it.

Note: Skip this step if Test Transmitter SC113 is not used.

C

7. Attach the detector base on the steel surface and then

use the two M4×8 mm screws provided to fix it.

8. Wire and configure the detector (see “4. Wirings and

Settings”), and then use the top screw to fix the detector

cover properly.

3.3 Mounting on Stainless Steel or Hardened Steel

When mounting on stainless steel or hardened steel, Mounting Plate SC110 (UPSIDE DOWN, see Figure 4) must be used

and should be welded on the mounting surface first.

Figure 3 Mounting Plate SC110

UPSIDE

F

G

C

D

E

A

B

H

J

I

This orientation is used for mounting

on concrete.

A, B– Detector SC105 mounting holes

C, D, – Test Transmitter SC113 locating holes

E– Mounting Plate SC110 Mounting hole

F, G– Welding Slots

H,I,J – Countersink screw hole (compatible with

other mounting plates)

Figure 4 Mounting Plate SC110

UPSIDE DOWN

FG

C

D

E

A

B

H

J

I

This orientation is used for mounting on

stainless steel or hardened steel.

24-hour surveillance of mini-ATMs, Filing Cabinets and so on

Flat frequency response sensor for genuine signal analysis

DIP switch sensitivity settings

Noise sensitivity settings using build-in diagnostic tool

Integrated EOL resistors

High detection capability

Low current consumption

Standard drill sheet protection

Miniature metal housing – easy to fit in restricted spaces

1. Remove paint from the mounting area

(especially welding area).

2. Attach

Mounting Plate SC110 on the mounting

area, and then mark the outline.

3. Fix Mounting Plate SC110 into the outline marked and ensure it

cannot move, and then along the INSIDE of the welding slots

weld Mounting Plate SC110 on the mounting surface.

Note: The welding must be done along the INSIDE of the welding

slots, otherwise Mounting Plate SC110 can be deformed.

4. Tap off slag and remove weld spatter and make sure the whole mounting surface is still flat.

5. Attach Test Transmitter SC113 on Mounting Plate SC110 (at C) and then use the M4×8 mm screw to fix it.

Note: Skip this step if Test Transmitter SC113 is not used.

C

6. Attach the detector base on Mounting Plate

SC110 and then use the two M4×8 mm screws

provided to fix it.

7. Wire and configure the detector (see “4. Wirings and

Settings”), and then use the top screw to fix the detector cover

properly.

3.4 Mounting on Concrete

When mounting on Concrete, Mounting Plate SC110 (UPSIDE, see Figure3) must be used.

Note: Mounting directly on a bare or plastered concrete surface may result in low detection sensitivity and cause damage to

the detector.

1. Attach

Mounting Plate SC110 on the mounting area and

then mark the outline and center hole E.

2. Drill the center hole E of Ø 10 mm and minimum 65 mm

deep, and then remove all drill residuals and plaster.

E

3. Insert M6 anchor into hole E and make sure the end

of the anchor can reach but not protrude the concrete

surface.

Note: Use a longer M6 anchor or a distance sleeve

between Mounting Plate SC110 and the anchor if the M6

anchor cannot reach the solid concrete.

4. Attach

Mounting Plate SC110 into the outline marked,

and then through the center hole insert M6×50 mm

screw into M6 anchor in the wall.

5. Tighten M6×50 mm screw but do not fix Mounting

Plate SC110 on the concrete surface, and make sure

Mounting Plate SC110 does not expand either.

Note: Mounting Plate SC110 can be rotated here.

Note: Skip step 6 to step 11 if Test Transmitter SC113 is not used.

6. Rotate Mounting Plate SC110 clockwise 180˚and mark

hole C.

7. Rotate

Mounting Plate SC110 anticlockwise until the

marked hole C can be seen through hole D.

Note: Tighten the center screw slightly to stabilize Mounting

Plate SC110 at this step.

8. Through hole D drill a hole of Ø 5.5 mm and minimum 25

mm deep and then remove all residuals.

180

°

Clockwise

CD

D

D

C

C

Anticlockwise

9. Release and turn Mounting Plate SC110 to the original

orientation (see the figure below).

10. Insert M4 anchor into the drilled hole and make sure

the end of the anchor cannot protrude the concrete

surface.

11. Attach Test Transmitter SC113 on M4 anchor, and

then use M4×14 mm screw to fix it permanently.

12. Tighten M6×50 mm screw (and knock on the screw head with a hammer when needed) until the mounting plate is

fixed on the concrete surface and cannot be rotated.

13. Attach the detector base on Mounting Plate SC110 and

then use the two M4×8 mm screws provided to fix it.

14. Wire and configure the detector (see “4. Wirings and

Settings”), and then use the top screw to fix the

detector cover properly.

Detector mounting hole ATest Transmitter SC113

mounting hole C

Note: The top screw is only

used to fix the cover, so do

not tighten it too much

when mounting the detector

Note: The drill plan shall be

removed after all of the mounting

holes have been drilled.

Detector mounting hole B