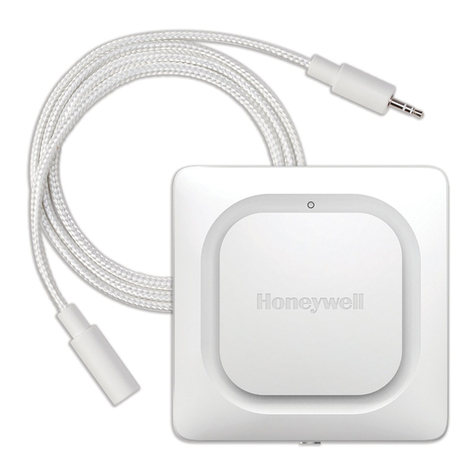

Refer to Installation Instructions and diagrams (next page) when installing this product

©2002 Honeywell International Inc. All rights reserved.

Honeywell, FlexGuard and IntelliSense are registered trademarks of

Honeywell International Inc. - All other brands mentioned are the

trademarks or registered trademarks of their respective owners.

Specifications subject to change without prior notice.

Ê5-051-737-00CaŠ

5-051-737-00 Rev C

FlexGuard®FG-1625F Glassbreak Detector Supplemental Information

1. General Information

The FG-1625F flush mount glassbreak detector senses

the sound of breaking plate, tempered, laminated, wired,

coated and sealed insulating glass.

This product is UL and ULC listed.

2. Choosing Mounting Location

The preferred mounting location for the device is on a

wall or ceiling, opposite the protected glass.

For the best detector performance, select a mounting

location that is:

•within 7.6 m (25 feet) of the protected glass;

•within clear view of the protected glass;

•at least 2 m (6.5 feet) from the floor;

•at least 1 m (3.3 feet) from forced air ducts;

•at least 1 m (3.3 feet) from sirens or bells greater

than 5 cm (2 inches) in diameter.

•between the protected glass and any heavy

window coverings that may be present.

Alternatively, when heavy window coverings are

present, the detector can be mounted on the frame

of the window.

Avoid mounting the detector on the same wall as the

protected glass, on free-standing posts or pillars, or in

rooms with noisy equipment (air compressors, bells,

power tools, etc.), if this equipment is operated when

the detector is armed.

3. Testing Mounting Location With 9V Battery

You may test the detector in the desired mounting

location before drilling/wiring. If the 9V battery cannot

supply sufficient power, the detector will not operate

and the red and green LEDs will flash on/off.

Follow the procedure described in “Testing the

Detector”(below) to confirm proper operation.

4. Configuring Sensitivity (Range)

DIP switches SENS1 and SENS2 set detector

sensitivity (range), as shown:

SENSITIVITY RANGE * SENS1 SENS2

MAX 7.6m (25 ft) OFF OFF

MEDIUM 4.6m (15 ft) ON OFF

LOW 3m (10 ft) OFF ON

LOWEST 1.5M (5 ft) ON ON

*Sensitivity must be set to match the distance between

the detector and the protected glass, as verified using

the FG-701 Glassbreak Simulator.

5. Configuring LED Switch

The LATCH and LED DIP switches determine LED

indicator operation.

SWITCH OFF ON

LATCH Red LED lights for 5

seconds during alarm Red LED latches ON when

detector goes into alarm 1, 2

LED LEDs disabled (except for

power up and test mode3) LEDs always enabled

1 Alarm relay timing is not affected by the latched Alarm LED.

2 Reset the Alarm LED by removing/restoring power, or by toggling the

detector in and out of Test Mode.

3 LEDs can be enabled/disabled using FG-701.

6. Preparing Mounting Location

The FG-1625F is designed for flush mounting using a

standard US or Canadian electrical junction box. Once

you have selected the appropriate mounting location,

install a junction box.

7. Wiring the Detector

Refer to the wiring diagrams (page 1) to select the

appropriate wiring configuration.

NOTE: This sensor must be connected to a UL Listed

power supply or UL Listed control unit capable of

supplying a minimum of four hours of standby power.

8. Mounting the Detector

Using appropriate screws (not supplied), mount the

detector to the junction box. When not using a

junction box, use wall anchors for mounting in sheet

rock.

9. Testing the Detector

The detector should be tested at least once each year.

Test the detector with the FG-701 Glassbreak Simulator.

The model FG-700 Glassbreak Simulator can also be

used if it is set for the TEMPered glass sound. Other

simulators will not give accurate indication of range.

Always test detector with cover in place.

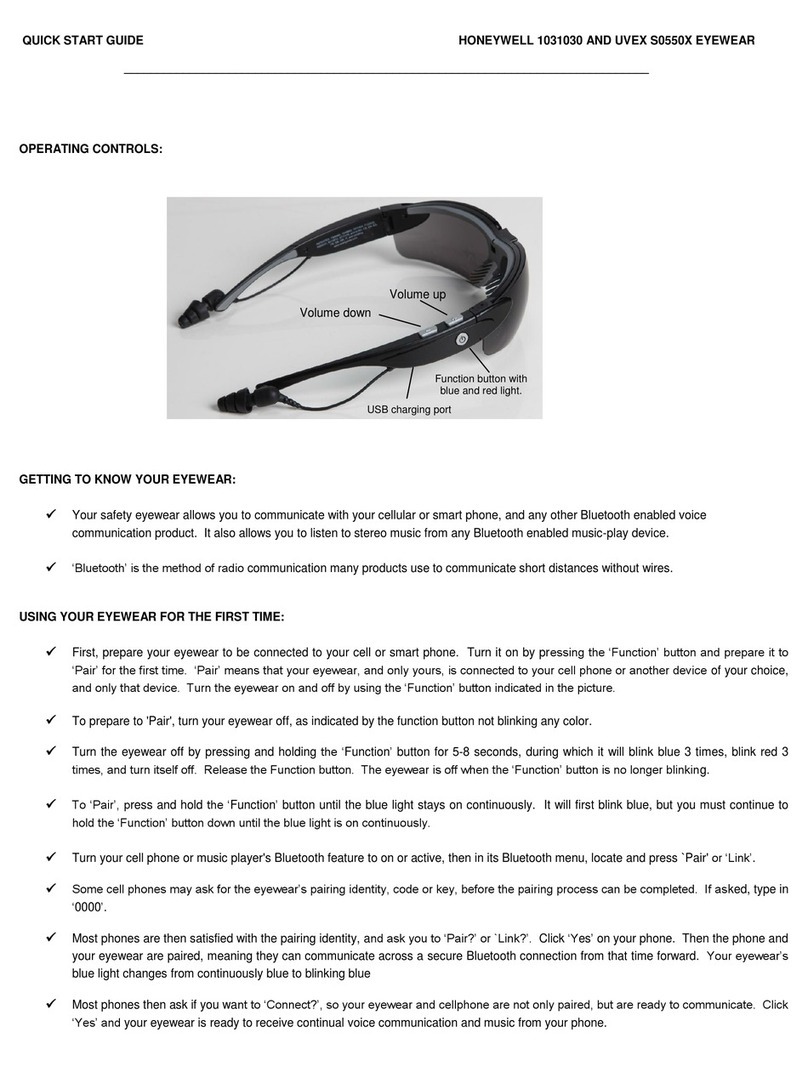

To enter Test Mode manually:

1. Remove the front cover.

2. Use a screwdriver to short the Test Mode

pads on the PC board (see diagram on next

page).

3. Close the front cover.

The detector’s green LED blinks approximately once per

second to indicate that it has entered Test Mode.

To enter the Test Mode with the FG-701:

1. Stand within 4.6 m (15 feet) of the detector.

2. Switch the FG-701 to ACTIVATE and MANual

modes.

3. Point the front [speaker] of the glassbreak

simulator towards the detector. Press the red

START button to send a short activation code.

When the detector enters Test Mode, the green LED

on the detector flashes about once per second. If the

green LED does not flash, move closer to the detector

and repeat the procedure.

Testing the Detector (flex and audio signals):

To test the detector using the FG-701:

1. Place the detector in Test Mode.

2. Set the FG-701 switches to the TEST and

FLEX positions.

3. Position the FG-701 near the farthest point of

the protected glass, and point the speaker

directly at the detector. If window coverings

are present, close them fully and hold the FG-

701 between the coverings and the protected

glass.

4. Press the red START button. The simulator

clicks on and starts an 8-second armed

period.

5. Generate a flex signal by carefully striking the

glass with a cushioned tool. The FG-701

responds with a burst of glassbreak audio.

If the detector receives both the flex and audio signals

properly, its red Alarm LED lights for five (5) seconds.

(Red Alarm LED does not latch in Test Mode).

Testing the Detector (audio signals only):

The FG-701 can also be used to test the detector’s

ability to receive audio signals only. See the FG-701

Operating Instructions for additional information. When

it receives the audio signal, the detector flickers its

green Event LED.

Exiting Test Mode:

When you have finished testing, exit Test Mode by

following the same procedure used to enter Test Mode.

The FG-1625F automatically exits Test Mode five

minutes after the last event is detected.

10. LED Indicators

The detector is equipped with two LEDs: a green Event

LED and a red Alarm LED. When the LEDs are

enabled, they light in a variety of patterns to indicate

the detector's status. The following table summarizes

the LED messages.

CONDITION GREEN LED RED LED

Normal OFF OFF

Normal, event detected Flicker OFF

Normal, break detected OFF ON 5 seconds

Normal, alarm latched OFF ON

Power up ON 1 second ON 1 second

Low Voltage Flash ON/OFF Flash ON/OFF

Test Mode Flash once per sec OFF

Test Mode, event detected Flicker OFF

Test Mode, alarm Flash once per sec ON 5 seconds

11. Remote LED Enable/Disable Mode

The detector’s Remote LED Enable/Disable Mode allows

you to enable or disable the detector’s LEDs with the

FG-701 Glassbreak Simulator.

To enable or disable the LEDs with the FG-701:

1. Set LED switch, S4 position 4, to off.

2. Enter Test Mode, and then exit Test Mode.

3. Within two (2) seconds, enter Test Mode

again; this changes LED enable/disable status.

4. Exit Test Mode again.

5. Clap your hands to test the LEDs. If enabled,

the green LED will flicker. If disabled, the

green LED will remain off.

12. Specifications

Range:

7.6 m (25 ft.) maximum, omni-

directional

No minimum range

Operating Temperature:

-10° to 50° C (14° to 122° F)

Storage: -20° to 50° C

(-4° to 122° F)

Alarm Duration:

5 seconds (unaffected by

alarm LED latching)

Alarm Relay:

FG-1625F Form A

125 mA maximum

25 VDC maximum

ON/closed 22Ω±1Ω

OFF/open >1MΩ

Tamper Switch:

Cover tamper

25 mA maximum

24 VDC maximum

RFI Immunity:

30 V/m,

10 MHz - 1000 MHz

ESD Immunity:

10 kV discharges of either

polarity to exposed surfaces

Power Requirements:

6 - 18 VDC; 12 mA typical at

12 VDC, 22 mA max, (Latched

LED) AC Ripple: 4 Volts

peak-to-peak at Nominal 12

VDC

Dimensions:

Face Plate

:

125 x 84 x 70mm

(4.9 in. H x 3.3 in. W x 0.53 in. D)

Rear Housing

:

70 x 42mm

(2.8 in. H x 1.6 in. W)

Weight:

98 g (3.5 oz.)

PackagedProduct:126 g(4.5oz.)

Approvals / Listings:

FCC and IC verified

UL Listed, ULC Listed

CE, C-Tick

EN 50131-1; Security Grade

2, Environmental Class II

Suitable for connection to an

EN60950 Class II Limited

Power Source

13. Nominal Glass Thickness Chart

Nominal Thickness

Glass Type* Minimum Maximum

Plate 3a, 3b, 4 2mm (3/32 in.) 10mm (3/8 in.)

Tempered 3mm (1/8 in.) 10mm (3/8 in.)

Laminated 3b 3mm (1/8 in.) 14mm (9/16 in.)

Wired 6mm (1/4 in.) 6mm (1/4 in.)

Coated 2,3b 3mm (1/8 in.) 6mm (1/4 in.)

Sealed Insulating1,5 3mm (1/8 in.)

[13mm (1/2 in.)

overall]

6mm (1/4 in.)

[19mm (3/4 in.)

overall]

* Minimum size for all types is 28cm (11 in.) square; glass must be

framed in the wall or mounted in a barrier at least 0.9m (36 in.) wide.

1 Protected only if both plates in the unit are broken

2 Coated glass with security films up to 0.35mm (14 mils) thick (including

films for solar protection) may be used. Evaluated with the these

products: 3M®SCOTCHSHIELD®SH14CLARL –0.35mm (14 mils), 4

ply film; Film Technologies International, Inc.’s GLASS-GARD GGLL

1200 has been evaluated with this product by Underwriters

Laboratories, Inc.

3 In compliance with Underwriters Laboratories of Canada’s Standard

for Intrusion Detection Units (CAN/ULC-S306-M89):

a. Plate glass 3mm (1/8 in.) to 10mm (3/8 in.) can be used.

b. ULC recognizes a maximum range for protecting coated, 3mm

(1/8 in.) laminated, and 2mm (3/32 in.) plate glass of 3.8m

(12.5 ft.); sensitivity should be set at maximum.

4Minimum of 3mm (1/8 in.) plate glass is to be used in UL installations.

5UL recognizes a maximum range for protecting sealed insulating

glass of 6.1m (20 ft.) with sensitivity set at maximum.

NOTICES

FCC NOTICE: This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) This deice may

not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired

operation.

The user is cautioned that changes or modifications not expressly

approved by Honeywell could void the user’s authority to operate this

equipment.

NOTE: This equipment as been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or

relocate the receiving antenna; 2) increase the separation between the

equipment and receiver; 3) connect the equipment into an outlet on a

circuit different from that to which the receiver is connected; 4) consult

the dealer or an experienced radio/television technician for help.

IC Notice: This Class B digital apparatus complies with the Canadian

ICES-003.

Cet appareil numérique de la Classe B est conforme àla norme NMB-

003 du Canada