10/00 UDC2300 Indicator Product Manual v

Contents

1 INTRODUCTION................................................................................................... 1

1.1 Overview........................................................................................................................................ 1

1.2 CE Conformity (Europe)................................................................................................................ 2

2 INSTALLATION .................................................................................................... 3

2.1 Overview........................................................................................................................................ 3

2.2 Model Number Interpretation ........................................................................................................ 5

2.3 Preliminary Checks........................................................................................................................ 6

2.4 Alarm Relay Contact Information.................................................................................................. 8

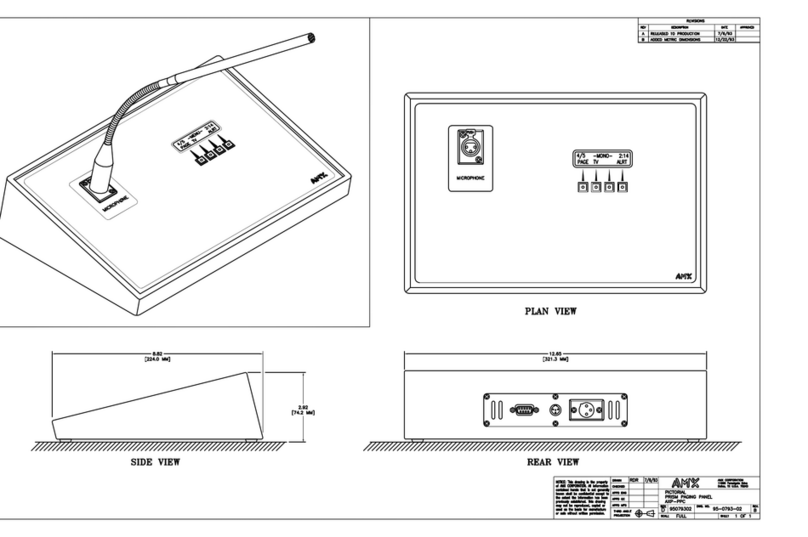

2.5 Mounting........................................................................................................................................ 9

2.6 Wiring .......................................................................................................................................... 11

2.7 Wiring Diagrams.......................................................................................................................... 12

3 INITIAL START-UP............................................................................................. 17

3.1 Overview...................................................................................................................................... 17

3.2 Powering Up the Indicator........................................................................................................... 17

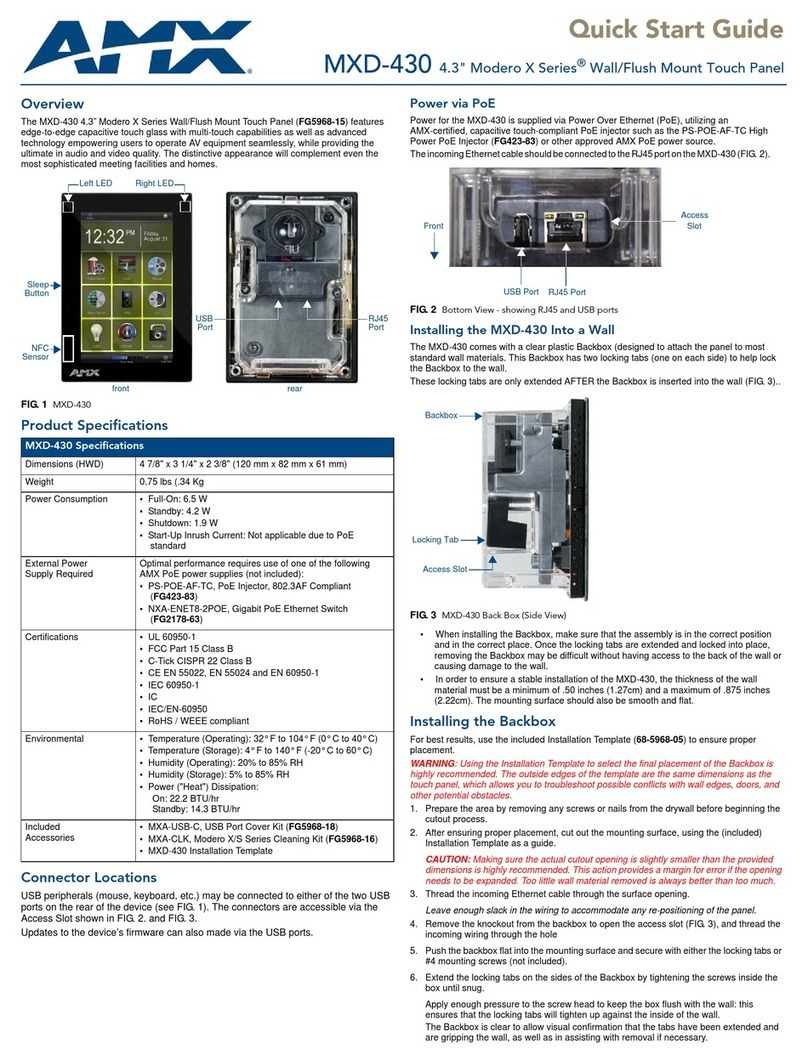

3.3 Operator Interface and Key Functions.........................................................................................18

3.4 Key Error Message....................................................................................................................... 18

4 CONFIGURATION .............................................................................................. 19

4.1 Overview...................................................................................................................................... 19

4.2 Configuration Prompt Hierarchy ................................................................................................. 20

4.3 Configuration Procedure.............................................................................................................. 21

4.4 Lock Set Up Group ...................................................................................................................... 22

4.5 Input Set Up Group..................................................................................................................... 23

4.6 Communications Set Up Group................................................................................................... 27

4.7 Alarms Set Up Group................................................................................................................... 30

4.8 Configuration Record Sheet......................................................................................................... 32

5 MONITORING THE INDICATOR........................................................................ 33

5.1 Overview...................................................................................................................................... 33

5.2 Operator Interface........................................................................................................................ 34

5.3 Entering a Security Code ............................................................................................................. 34

5.4 Lockout Feature ........................................................................................................................... 35

5.5 Monitoring Your Indicator........................................................................................................... 36

5.6 Alarm Setpoints............................................................................................................................ 37