6

Safety

Important Safety Information

WARNING: To reduce the risk

of injury, read operating

instructions carefully before

using.

1. Read the owner's manual

thoroughly. Failure to follow

instructions could cause

malfunction of the machine

and result in death, serious

bodily injury and/or property

damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes.

Contact your electrician, plumber, utility company

or the selling dealer for specific details.

DANGER: Improper connection of the equipment-

grounding conductor can result in a risk of electro-

cution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug

provided with the product - if it will not fit the outlet,

have a proper outlet installed by a qualified electri-

cian. Do not use any type of adaptor with this

product

WARNING: Keep wand, hose,

and water spray away from

electric wiring or fatal electric

shock may result.

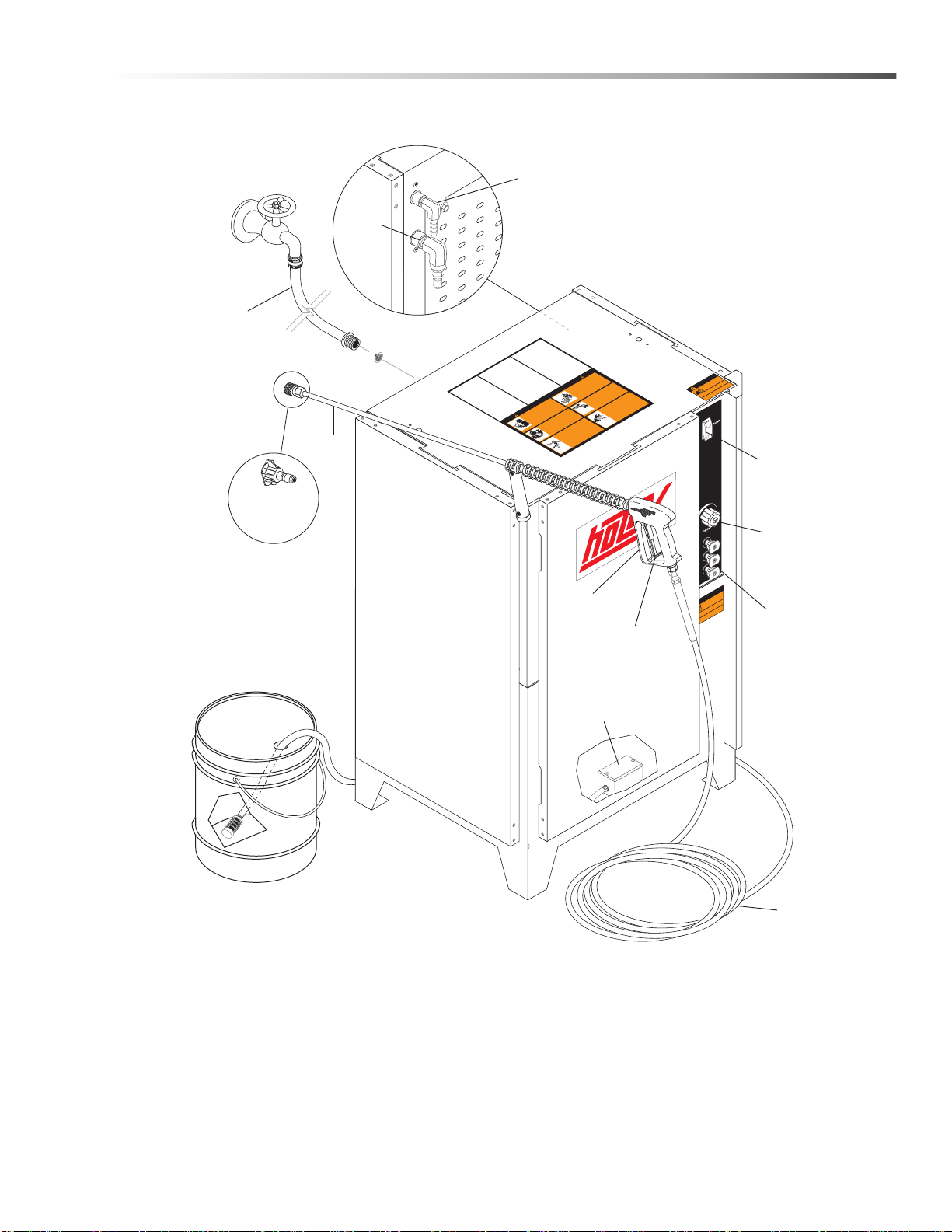

5. To protect the operator from

electrical shock, the machine

must be electrically grounded.

It is the responsibility of the

ownertoconnectthis machine

to a UL grounded receptacle

of proper voltage and

amperage ratings. Do not

spray water on or near electrical components. Do

not touch machine with wet hands or while

standing in water. Always disconnect power before

servicing.

WARNING: Flammable liquids

can create fumes which can

ignite, causing property

damage or severe injury.

WARNING: Risk of explosion

— Do not spray flammable

liquids.

6. Do not allow acids, caustic or abrasive fluids to

pass through the pump.

7. Never run pump dry or leave spray gun closed

longer than 1-2 minutes.

8. Keep operating area clear of all persons.

WARNING: High pressure

spray can cause paint chips or

other particles to become

airborne and fly at high

speeds. To avoid personal

injury, eye, hand and foot

safety devices must be worn.

9. Always wear properly rated

eye protection such as

safety goggles or face shield

while spraying. (Safety

glasses do not provide full

protection.)

WARNING: Grip cleaning wand

securely with both hands

before starting. Failure to do

this could result in injury from

a whipping wand.

WARNING: High pressure

developed by these machines

will cause personal injury or

equipment damage. Keep clear

of nozzle. Use caution when

operating. Do not direct

discharge stream at people, or

severe injury or death will

result.

HOTSY • CWC OPERATOR’S MANUAL • 9.801-695.0-B

WARNING

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

WARNING

WARNING

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE

LIQUIDS.

WARNING

TRIGGER GUN KICKS

BACK — HOLD WITH

BOTH HANDS

WARNING

USE PROTECTIVE

EYE WEAR

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

WARNING

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.