10

Operation

Stick one of IC tags provided on the grip top and such of the

soldering iron. Stick on a plastic surface and such since IC tags

stuck on metallic surfaces may not function normally.

Sticking an IC tag

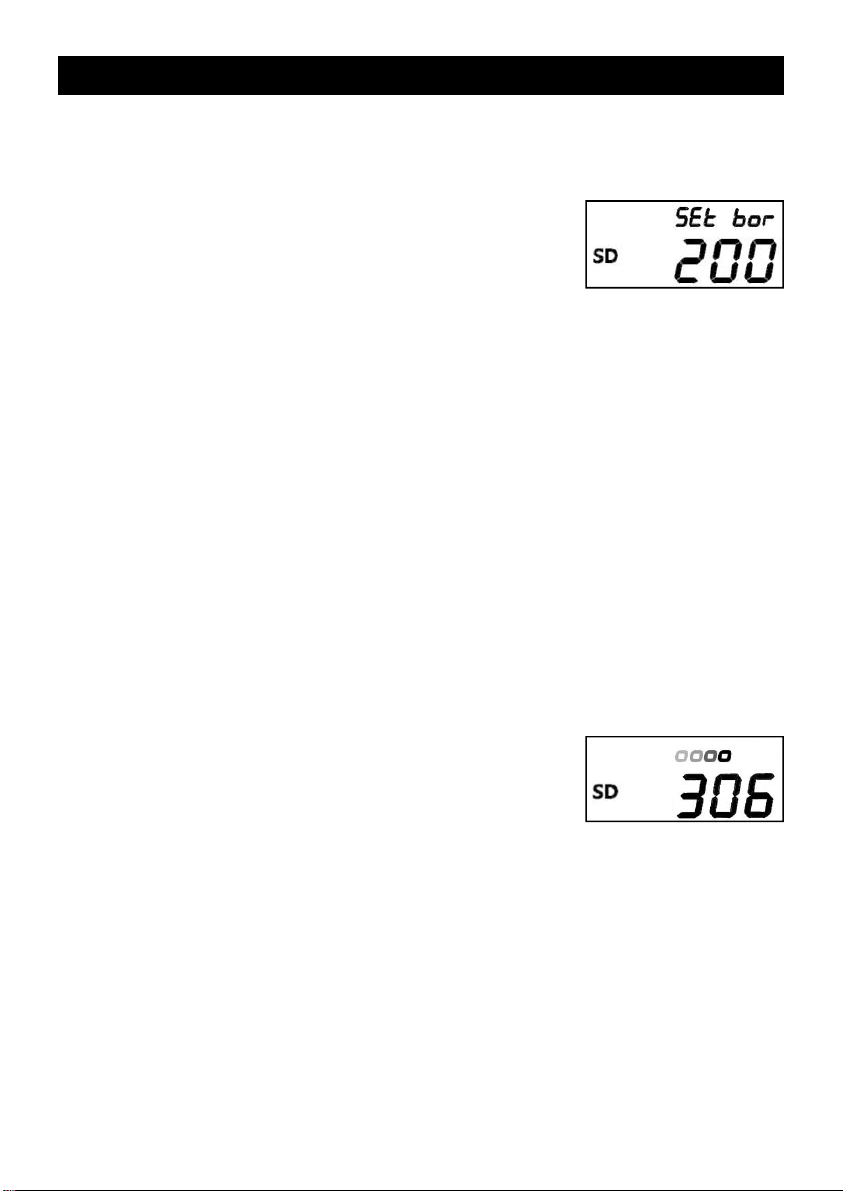

A new IC tag has no ID number.

When bring close the IC tag to the

antenna part of H-769, the

recorded contents are displayed

buzzing “Pi!”

Be careful not to burn by the

soldering iron.

An H-769 can administer 99 soldering irons correspond to ID

numbers 01 to 99.

On and after the 100th soldering irons can not recorded. Those

are displayed by under bars.

*Always hold IC tags up over the antenna one by one. Holding

plural IC tags up at a time could cause confusion and

malfunction.

*5 IC tags are provided with H-769. purchase H-769-1 IC tag (5/

pack) depending on increase of soldering irons to be

administered.

*See page 17 for procedures confirming recorded IDs of

soldering irons or deleting them.

The soldering irons/IC tags recorded by other H-769 already

can not be recorded. Those data are simply displayed.

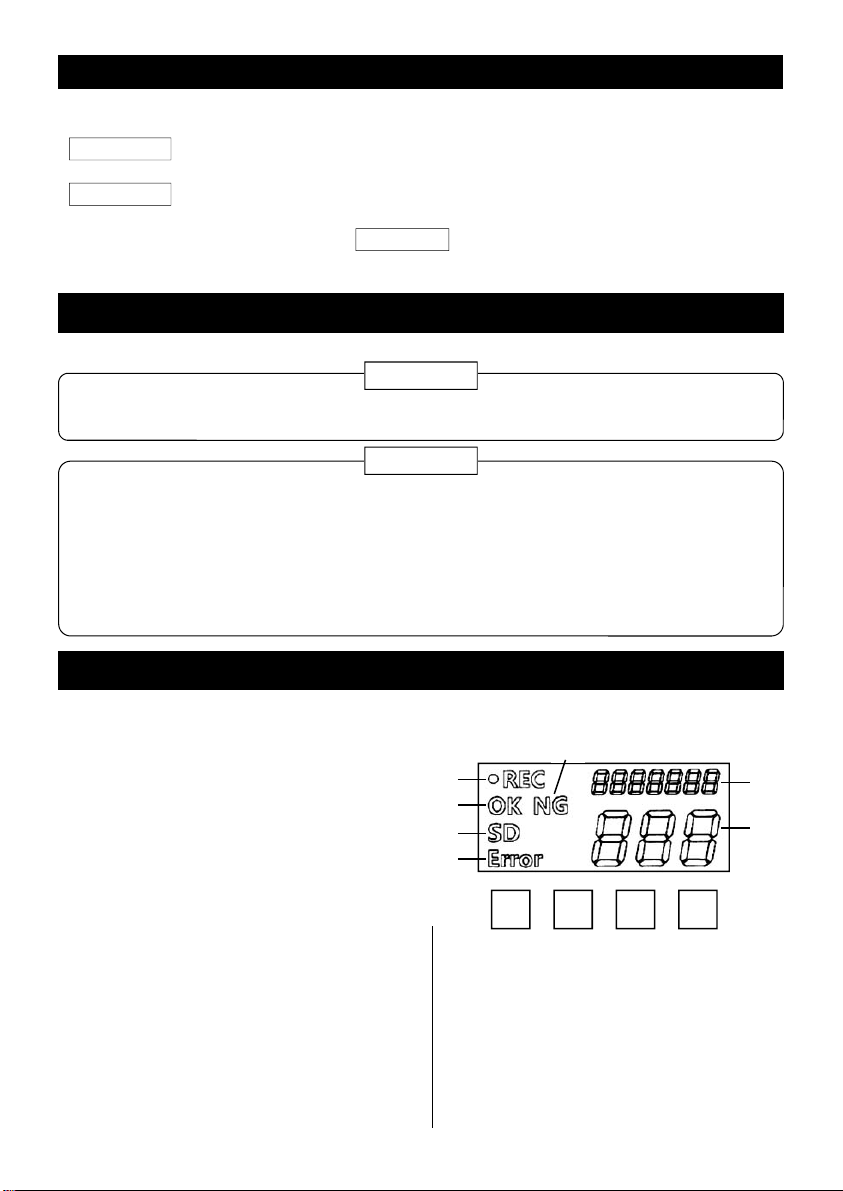

Serial number of this H-769

(seven-digit number)

ID number of soldering iron

(01 to 99)

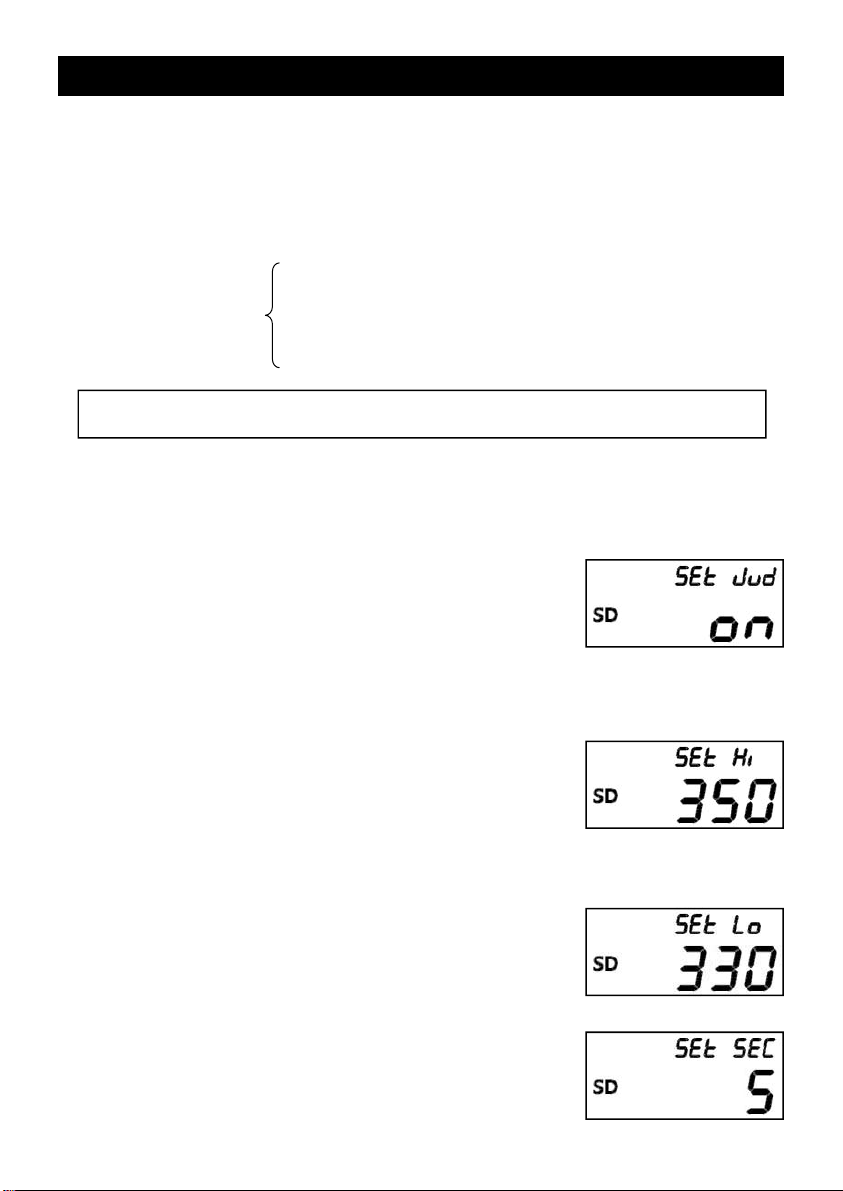

Soldering iron discrimination function

(Preparation)

This is the function to distinguish plural soldering irons.

The ID number given to each soldering iron and measured data of which are saved in the

SD card being combined.

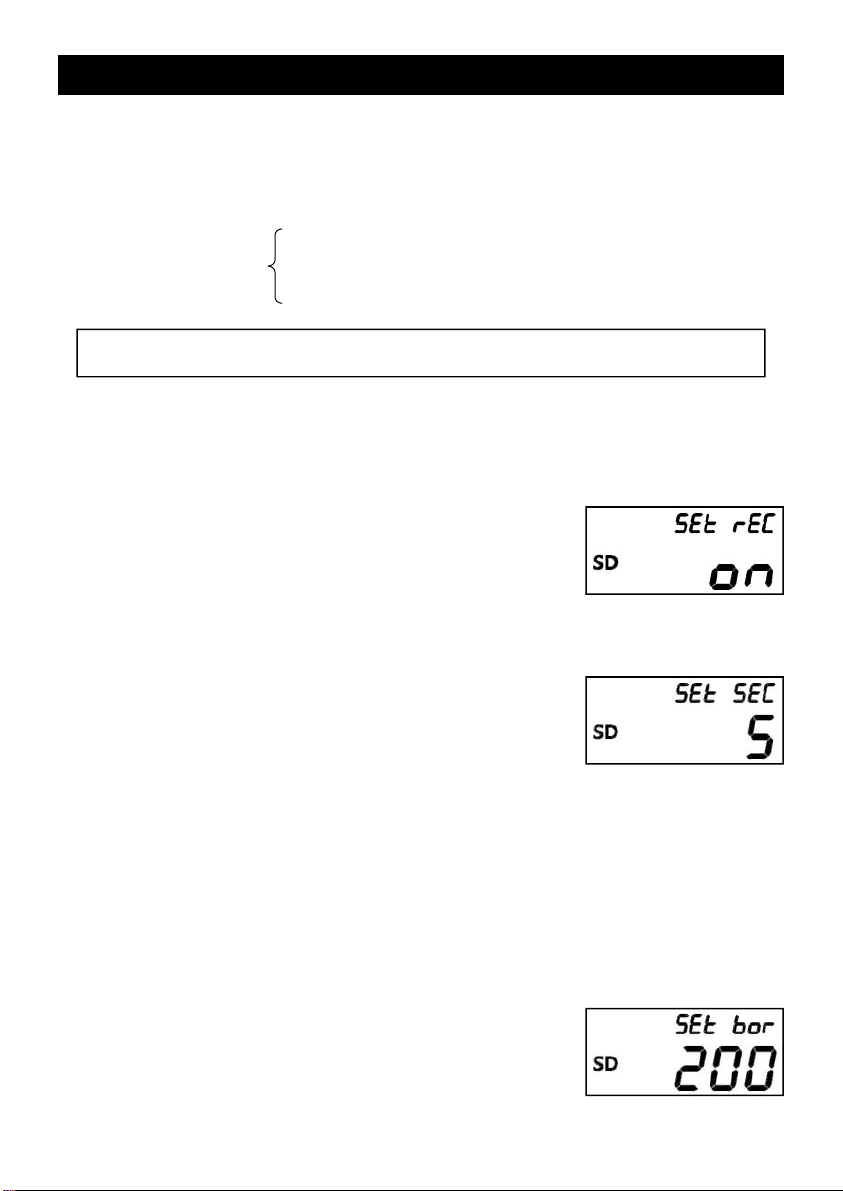

Inserting SD card When insert a SD card into the SD card slot, “SD” is displayed

on the LCD buzzing “Pi!”

*The bar will spin at the upper right corner of the LCD during

the SD card is accessing the CPU. Do not shut the power or

remove the SD card till this dynamic image goes out. This

could damage the data in the SD card.

*The soldering iron discrimination function does not work

without inserting SD cards.

Adding ID number