Model 8754A

INSTRUMENT DESCRIPTION

Introduction

The 8754A Network Analyzer consists

of

an internally leveled 4to 1300 MHz swept source with crystal

markers, athree input tuned receiver with two independent measurement channels,

and

a

CRT

display with

rectangular

and

polar graticules. Together with appropriate signal separation accessories,the 8754Aisa

complete stimulus/response test system

that

measures magnitude

and

phase characteristics

of

linear net-

works by comparing the incident signal with the signal transmitted by the device

or

reflected from its input.

The basic transmission measurements described here are: insertion loss

or

gain, insertion phase, and trans-

mission coefficient,

S21

or

S12.

Basic reflection measurements are: return loss, from which SWR can be

calculated, and reflection coefficient, SII

or

S22'

from which impedance can be calculated

or

read from a

Smith

Chart

overlay.

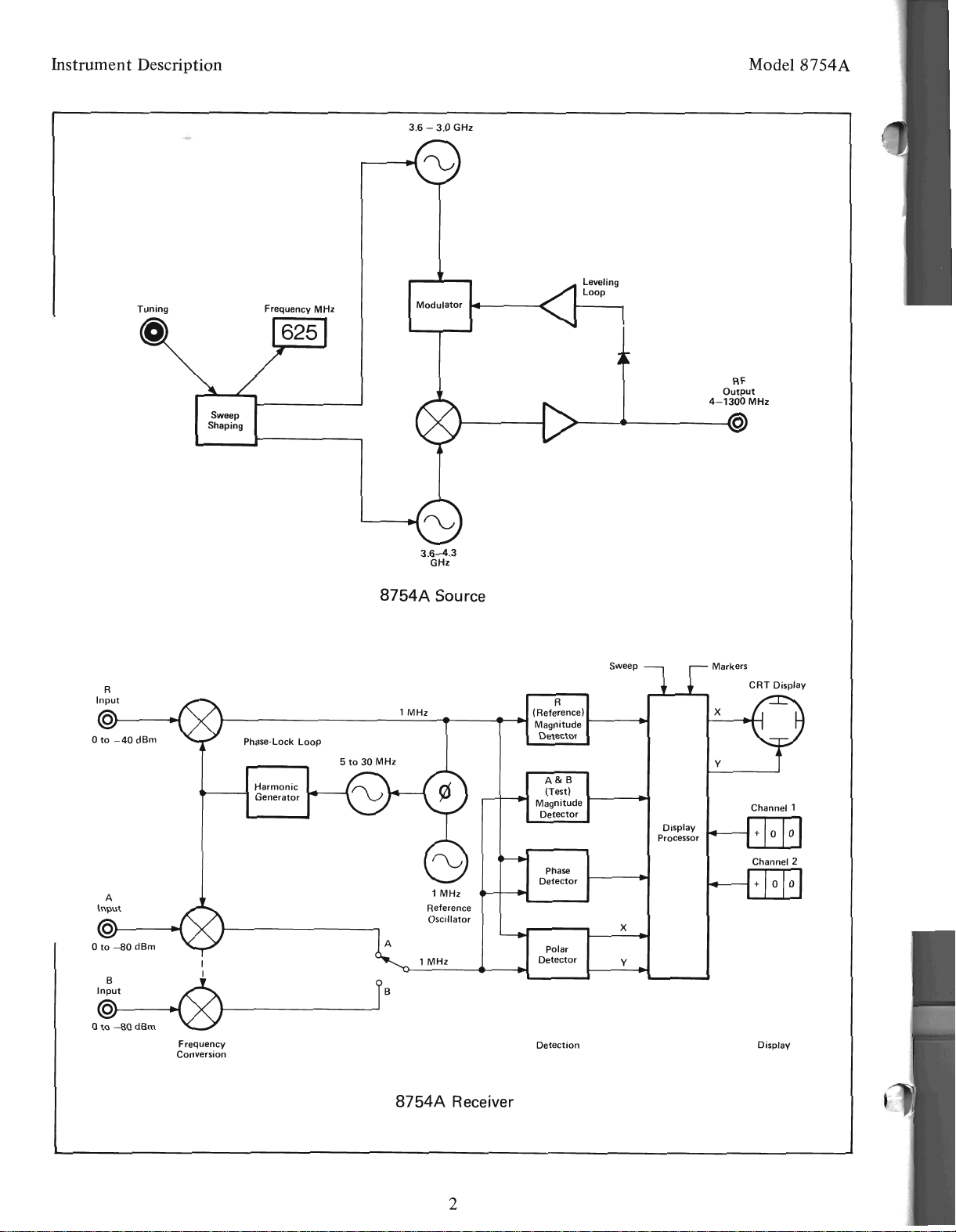

Block Diagram Description

The source provides RF to the test device. It uses two varactor tuned microwave oscillators, one swept up

in frequency from 3.6

to

4.3

GHz

and

one swept down in frequency from 3.6 to 3.0 GHz, in a

"see-saw"

configuration. The oscillator outputs are mixed and the difference frequency

is

amplified to provide the 4

to

1300

MHz

RF output.

An

internal leveling loop maintains constant RF

output

powerlevel over the sweep.

The receiver provides signal processing

to

convert incident (R)

and

test (A

and

B)

inputs

to

dc levels for

display. Signal separation accessories route the signal incident

at

the test device

to

the Rinput

and

the

reflected and transmitted signals

to

the A

or

Binputs. The receiver uses the sampling technique to convert

the three input signals

to

1

MHz

IF

for detection while maintaining theirmagnitude andphase relationships.

An

automatic phase lock loop tunes the receiver

to

the frequency

of

the Rinput signal; the A

and

Binputs

are used as full range test inputs. Two measurement channels allow measurement

of

any two parameters

using asingle test setup.

For

simultaneous transmission and reflection measurements

the

A

or

B

IF

is switched

to

the detectors on alternate sweeps. Absolute magnitude

of

the three inputs as well as the magnitude

ratio

and

phase angle difference between the Rinput

and

either

of

the test inputs are processed for display

on

the built-in CRT.

3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com