1-7

Before appl

in

power to the suppl

, check the label on the

heat sink to make certain that the suppl

's line volta

e option

a

rees with the line volta

e to be used. If the option does not

correspond to

our line volta

e, refer to para

raph "LINE

VOLTAGE OPTION CONVERSION" in the service section

before appl

in

power.

TURN -ON CHECKOUT PROCEDURE

a. Connect line cord to power source and turn LINE

switch on.

b. Push +6V METER switch and, with no load con-

nected, var

+6V VOLTAGE control over its ran

e

and check that the voltmeter responds to the control

settin

and the ammeter indicates zero.

c. Set the +6V VOLTAGE control to 6 volts and short the

+6V output terminal to COM (common) terminal

with an insulated test lead. The ammeter should

indicate a short-circuit output current of approximatel

1.0 A. Remove the short from the output terminals.

d. Push the +20V METER switch and turn Trackin

Ratio control full

clockwise to the Fixed position.

With no load connected, var

±20V VOLTAGE control

over its ran

e and check that the voltmeter

responds to the control settin

and the ammeter indi-

cates zero.

e. Set the ±20V VOLTAGE control to 20 volts and

short the +20V output terminal to the COM terminal

with an insulated test lead. The ammeter should

indicate a short-circuit output current of 0.55 A ± 5%.

Remove the short from the output terminals.

f. Repeat steps (d) and (e) for -20 V output.

. Adjust the +20V output to 20 volts. Then push -20V

METER switch and check the effect of the Trackin

Ratio control on the volta

e of the -20V output. The -

20V output should be adjustable from less than 0.5

volts to a maximum of 19 to 21 volts.

If this brief checkout procedure or later use of the suppl

reveals a possible malfunction, see the service information

section for detailed test, troubleshootin

, and adjustment pro-

cedures.

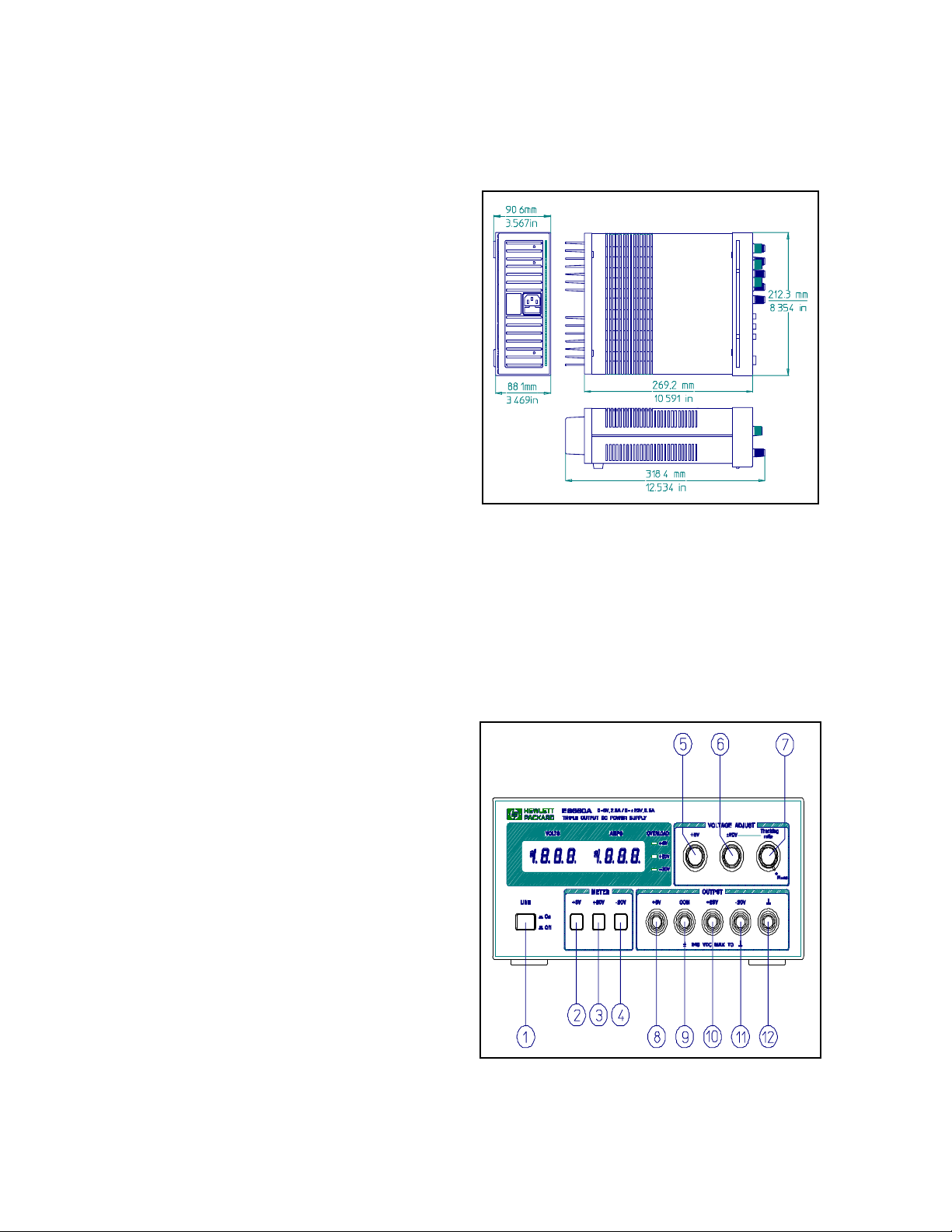

OPERATION

This power suppl

can be operated individuall

or in parallel

or series with another suppl

(see Parallel and Series Opera-

tion para

raphs). All output terminals are isolated from

round. The ±20V and +6V outputs use a sin

le common out-

put terminal. This common (COM) terminal or an

one of the

other output terminals ma

be

rounded to the chassis at the

front panel

round terminal ( in Fi

ure 2), or all outputs ma

be left floatin

. Loads can be connected separatel

between

each of the 0 to ±20V output terminals and the COM terminal,

or between the -20V and the +20V terminals for a 0 to 40V

output. Each output volta

e or current can be quickl

selected

for monitorin

with the push-button meter switches. To moni-

tor the 0 to 40V output volta

e, add the voltmeter readin

s of

the +20V and -20V output and use either the +20V or the -

20V meter to measure the current.

Tracking Ratio Control

With the Trackin

Ratio control in the Fixed position, the volt-

a

e of the -20V suppl

tracks that of the +20V suppl

within

1% for convenience in var

in

the s

mmetrical volta

es

needed b

operational amplifiers and other circuits usin

bal-

anced positive and ne

ative inputs.

Turn the Trackin

Ratio control counter clockwise out of the

Fixed position to set the volta

e of the -20V suppl

lower than

that of the +20V suppl

. The ne

ative suppl

can be set from

a minimum of less than 0.5 volts to a maximum within 5% of

the +20V suppl

's output. Once this is done, the ±20V volta

e

control still controls both outputs and maintains a constant

ratio between their volta

es.

Overload Protection Circuits

±20-Volt Current Limit. The +20V and -20V outputs are indi-

viduall

protected a

ainst overload or short circuit dama

e b

separate current limit circuits to limit the output current to 0.55

A ± 5%. (This is 110% of the maximum rated output.) If a sin-

le load is connected between the +20V and -20V outputs,

the circuit set for the lesser current limit will limit the output.

No deterioration of suppl

performance occurs if the output

current remains below the current limit settin

.

+6V Current Foldback. The overload and short-circuit pro-

tection circuit for the +6V output reduces the output current

limit as the output terminal volta

e decreases. (The operatin

re

ion of the +6V output is enclosed b

heav

lines in Fi

ure

4.) The maximum rated output current is 2.5 A and the current

limit is factor

-adjusted to operate at 2.75 A ± 5% when the

output is 6 volts. At lower output volta

es, the circuit reduces

the maximum obtainable output current linearl

until 1 A ±

15% flows when the output is shorted. The short-circuit cur-

rent can not be adjusted.

Durin

the actual operation of the ±20V and +6V outputs, if a

load chan

e causes the current limit to be exceeded, the OL

LED is li

hted. If overload conditions occur, the ±20V supplies

will protect the load b

limitin

the current to 0.55 A and the

+6V suppl

will protect the load b

reducin

both volta

e and

current simultaneousl

alon

the foldback locus as shown in

Fi

ure 4. The ±20V and +6V supplies are self restorin

; that

is, when the overload is removed or corrected, the output

volta

e is automaticall

restored to the previousl

set value.

Operation Beyond Rated Output

The suppl

ma

be able to provide volta

es and currents

reater than its rated maximum outputs if the line volta

e is at

or above its nominal value. Operation can be extended up to

5% over the rated output without dama

e to the suppl

, but

performance can not be

uaranteed to meet specifications in