44 Operator's manual M 824

ELECTRICAL

AND PNEUMATIC

HOOK-UPS

WARNING

All operations required for the elec-

trical hook-up of the machine to the

power supply must be carried out ex-

clusively by qualied personnel.

The electrical hook-up must be per-

formed according to:

- the electric power consumption of the

machine specied on the relative ma-

chine data plate.

- the distance between the machine and

the power supply hook-up point, to en-

sure that voltage drops under full load

do not exceed 4% (10% during start-up)

relative to the rated voltage indicated on

the specications plate.

The operator must:

- t a power plug onto the power cable in

compliance with applicable legislation.

- connect the machine to its own dedi-

cated power supply outlet equipped with

a specic type A or B differential circuit-

breaker (with sensitivity of 30 mA).

IMPORTANT: only the specied type A

and B security breakers will be tripped

correctly in response to all the failure cur-

rents which may occur on the machine.

- install protection fuses on the power

line that are suitably sized in accordance

with the indications given in the general

electrical layout diagram included in this

manual.

- ensure that the workshop electrical

system includes a functional grounding

circuit.

- prevent unauthorised use of the ma-

chine, always disconnect the power

supply plug when the machine is not

used (switched off) for extended peri-

ods of time.

- if the machine is connected directly to

the power supply by means of the main

electrical panel and without the use of

a plug, install a key-operated switch

or suitable lock-out device to restrict

machine use exclusively to qualied

personnel.

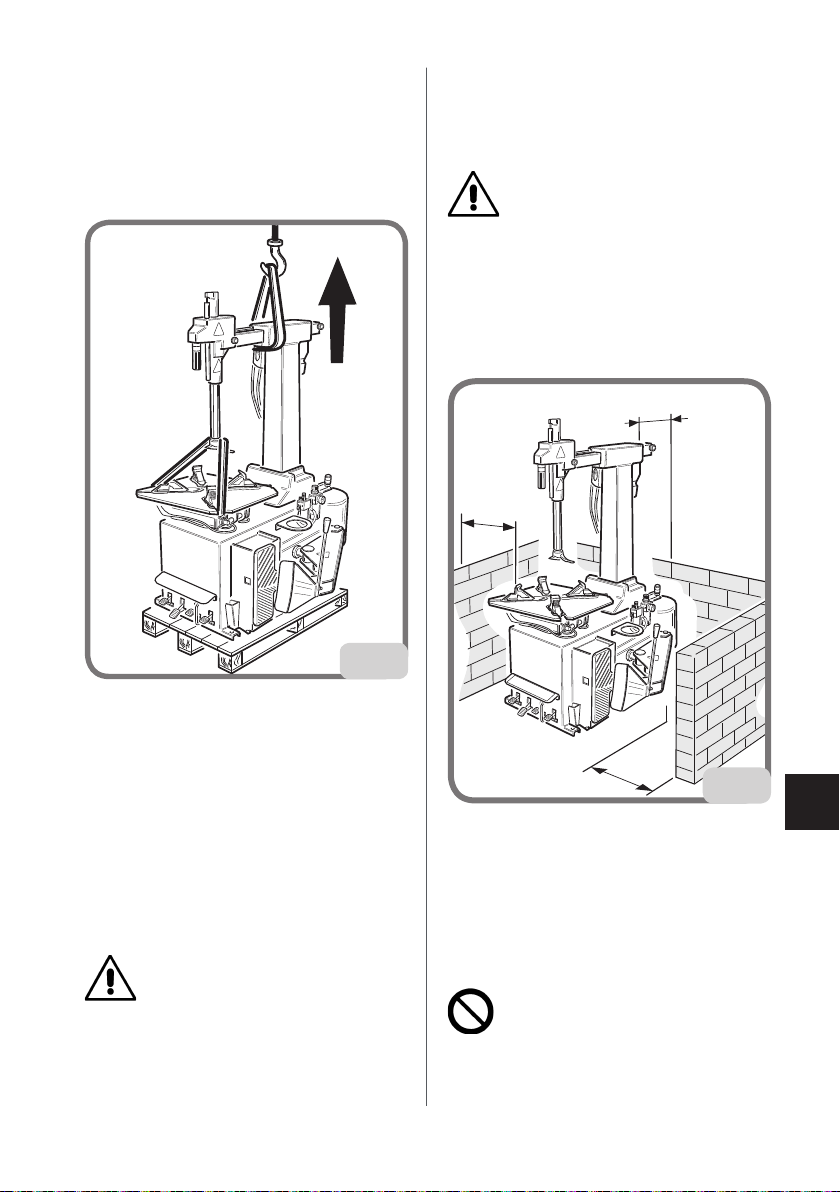

For correct machine operation the com-

pressed air supply line must provide a

pressure range from no less than 8 bar

to no more than 16 bar.

NOTE

The machine is equipped with a pres-

sure regulator set at 10 bar (standard

machine operation). When working with

easily deformable rims (such as vintage

car wheels, for example) we recommend

temporarily lowering the pressure to

7 - 8 bar.

WARNING

For the correct functioning of the ma-

chine it is essential to have a good

ground connection.

NEVER connect the ground wire to a

gas pipe, water pipe, telephone line

or other makeshift system.

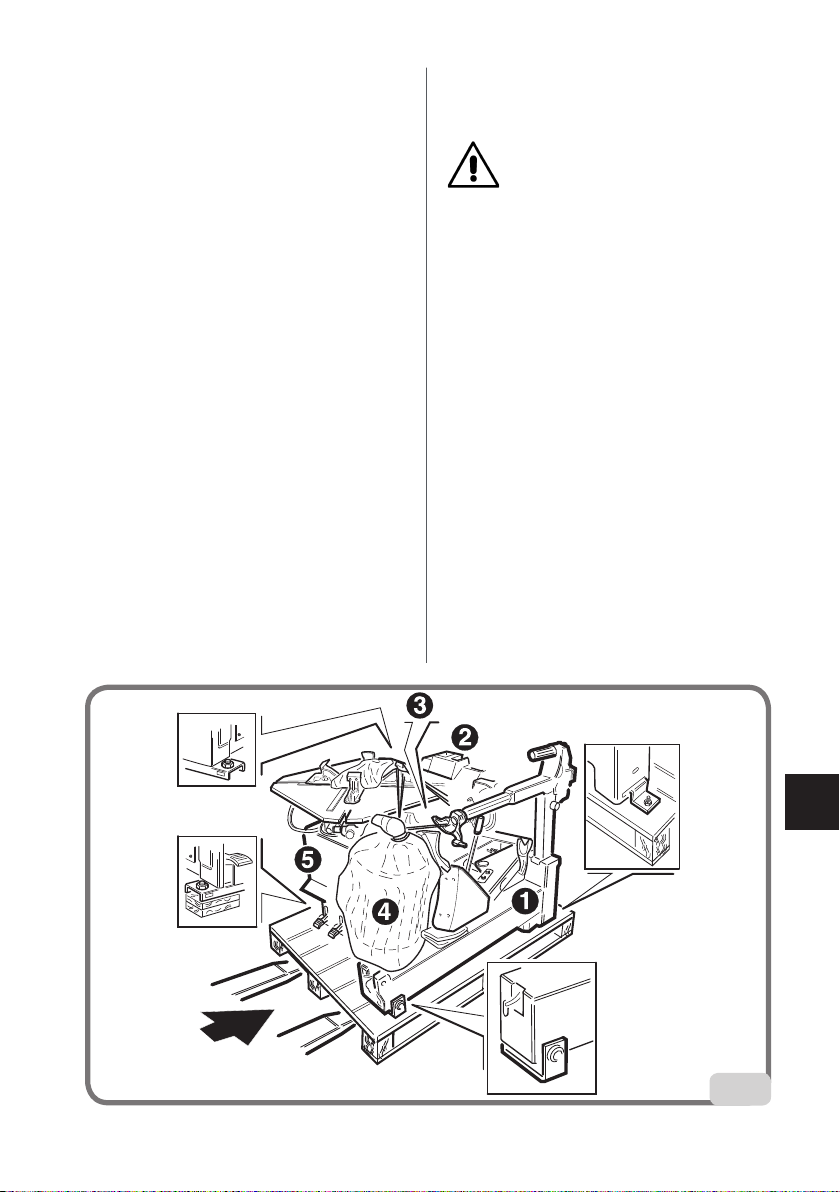

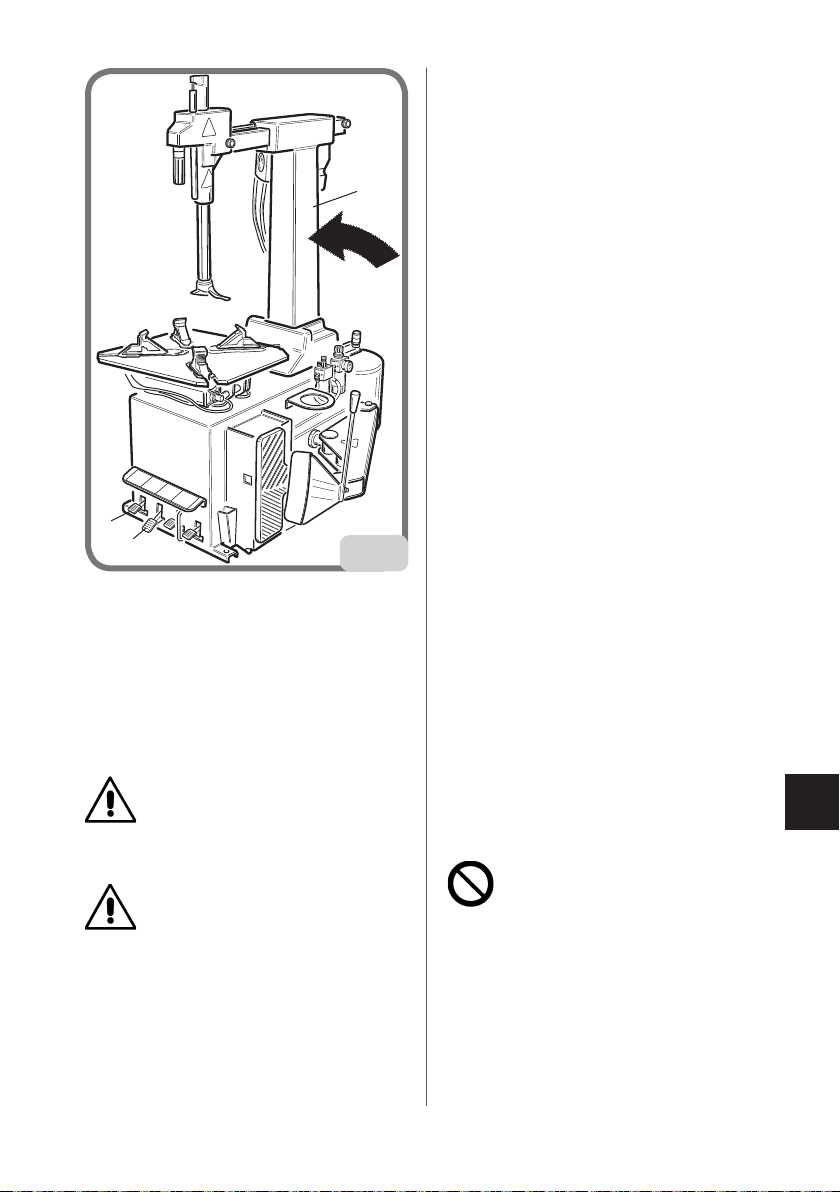

Before making the electrical and pneu-

matic hook-ups, make sure that the ma-

chine is congured as described below

(g.5):

- pedals A and B (if present) in fully de-

pressed position.

- column C vertical (not tilted).