For advice on the safety and suitability of this

equipment contact HSS Hire.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

This equipment should only be used by an

operator who has been deemed competent to do

so by his/her employer.

This equipment should be used by a competent

adult who has read and understood these

instructions. Anyone with either a temporary or

permanent disability, should seek expert advice

before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for

hire from HSS Hire.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Wear sensible, protective clothing and

footwear offering good grip, plus gloves

and a hard hat. Tie back long hair and avoid loose

garments and jewellery that could get in your way.

Never work on the tower if you suffer from vertigo.

Never suspend the tower from another structure.

Always climb onto the tower from the upper end,

entering through the gate in the handrail frame.

Keep your feet in the middle of the rungs and grip

the frame sides firmly with both hands.

Never carry anything when climbing, unless you

can do so leaving both hands free. Haul things up

after you, using a stout rope and secure knots.

Always check the condition of components before

use – and at regular intervals thereafter. If any

show signs of damage or excessive wear, do not

use them. Return them to HSS Hire.

Always ensure the tower is correctly built and

level before use – and check regularly thereafter.

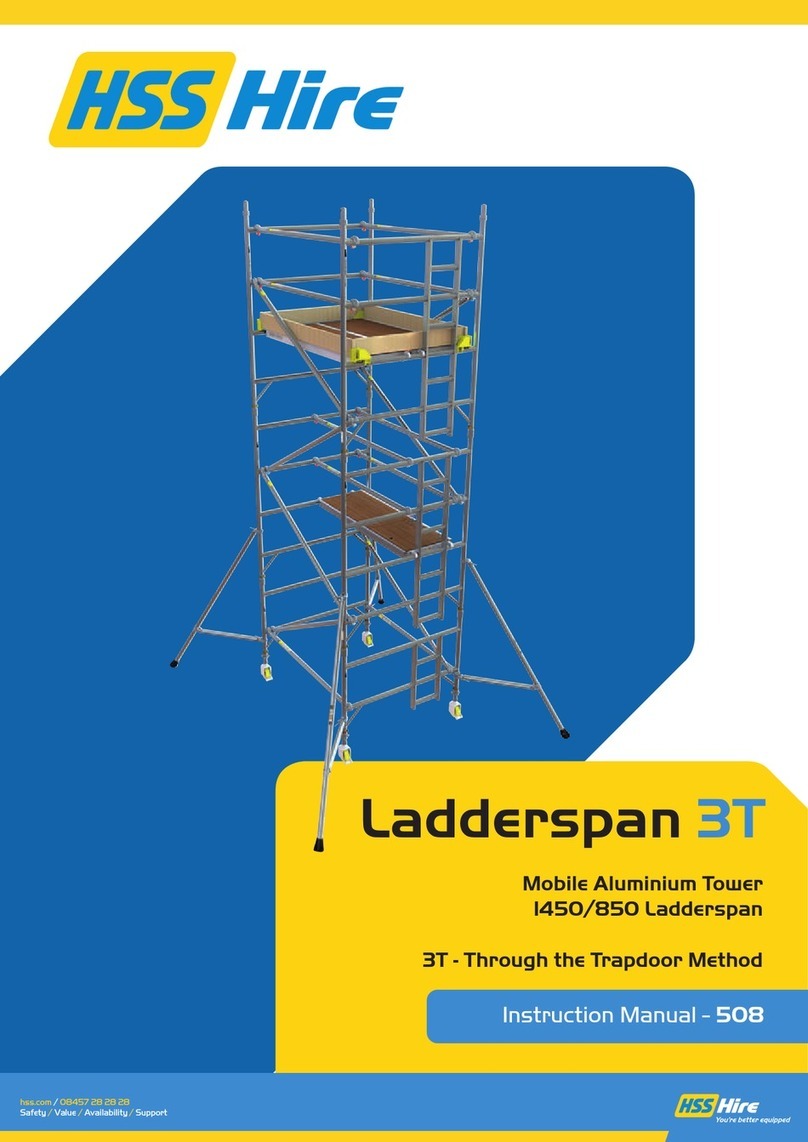

GENERAL SAFETY

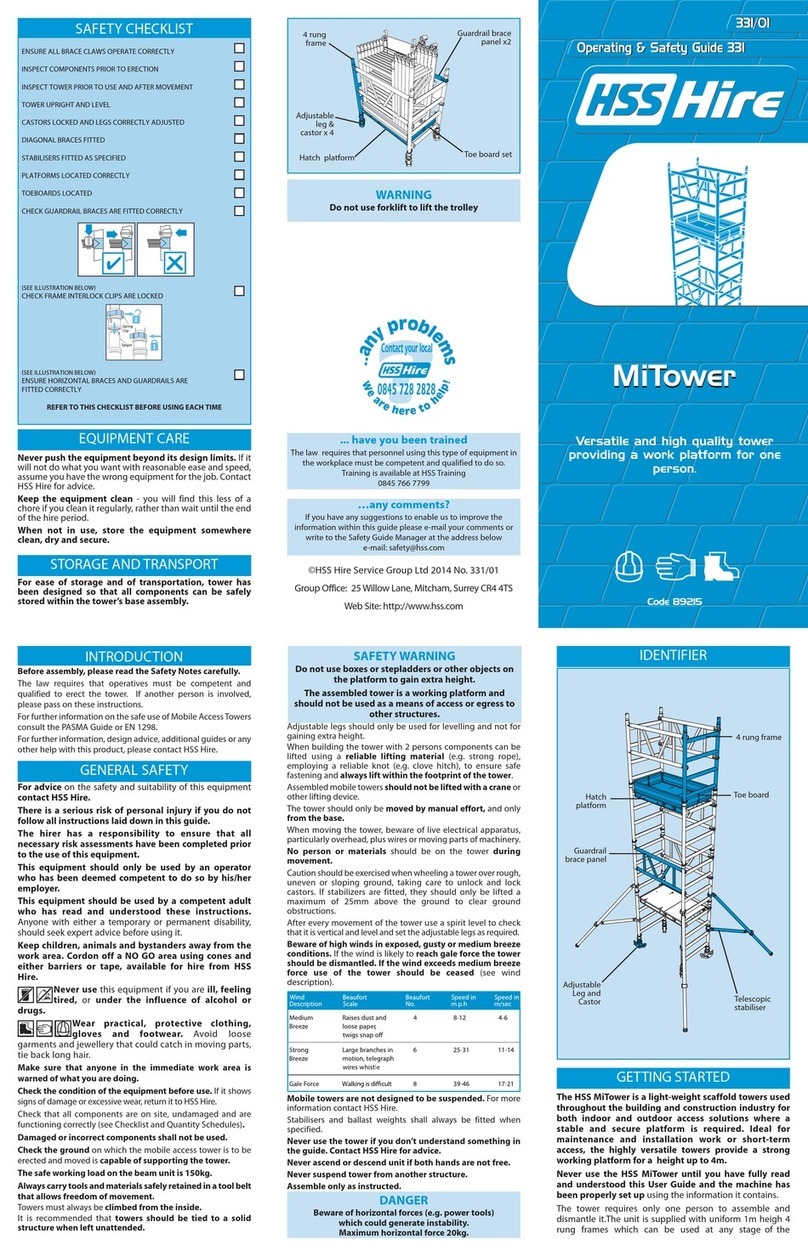

GETTING STARTED

The tower must be constructed on the stairwell,

therefore ensure that you are not contravening

any health and safety law (blocking a fire exit for

example) before proceeding.

Make sure that you understand these instructions

and are familiar with the tower’s components

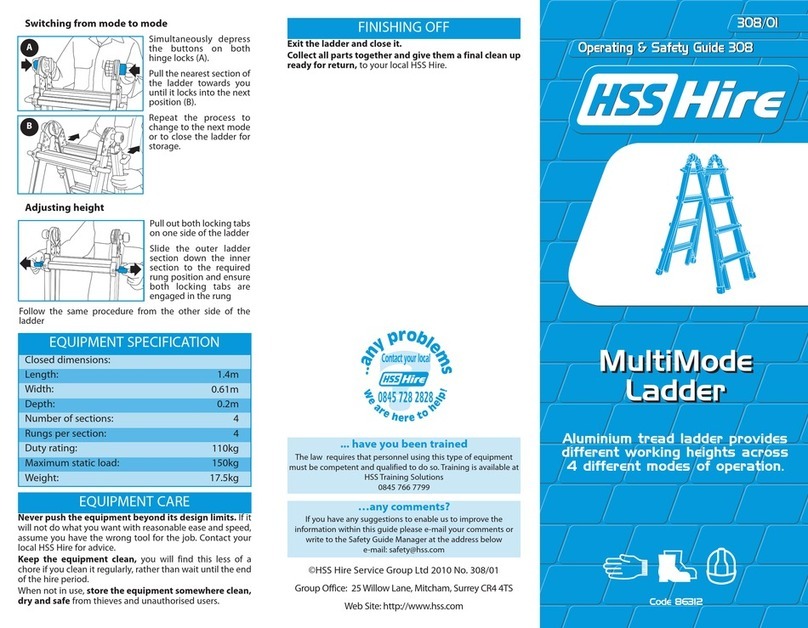

CLIPS & CLAWS

Components are linked using two kinds of fitting...

INTERLOCK CLIPS join frame

uprights. Unlock those on the

frame to be added, fit its

sockets over the spigots of the

lower frame and re-lock the

clips.

LOCKING CLAWS join braces to

frames. Pull back the trigger to

open the jaws, then snap the

claw onto the rail or upright,

ensuring the open side faces

down or out. The jaws should

lock automatically.

Whichever fitting you are using, though, always

double-check that it is locked and secure

before continuing.

before you begin.

Make sure too, that you have everything you need

to hand and refer to the illustrations for

construction. Unlock the interlock clips on all

frames, fit base plate legs securely to two standard

frames. These will now be referred to as the base

frames.

Fit an additional frame to one of the base frames

and engage the interlock clips.

Place the base frame, fitted with an extra frame, on

the lower stair and the singular base frame on the

upper stair, allowing the correct distance between the

frames for the platform to fit (1.6 metres).

Link these frames with two horizontal and two

diagonal braces as shown in the illustration, to form

the tower base – easiest if you start by clipping the

horizontal brace to the frame uprights.

Now adjust the feet as necessary to leave the

tower absolutely level – check this using a builder’s

level on the uprights and horizontal braces.

Fit the platform to the top rungs of the two end

frames. Make sure all four platform end hooks are in

contact with the top rungs, then secure in place by

engaging the locking claws.

Fit a standard frame to the top of the frame that is

at the lower step, securing it in place with the

interlock clips.

Fit the gate frame to the top of the frame that is

resting on the upper step. Make sure that the

access bar is positioned so that it opens in towards

the tower.

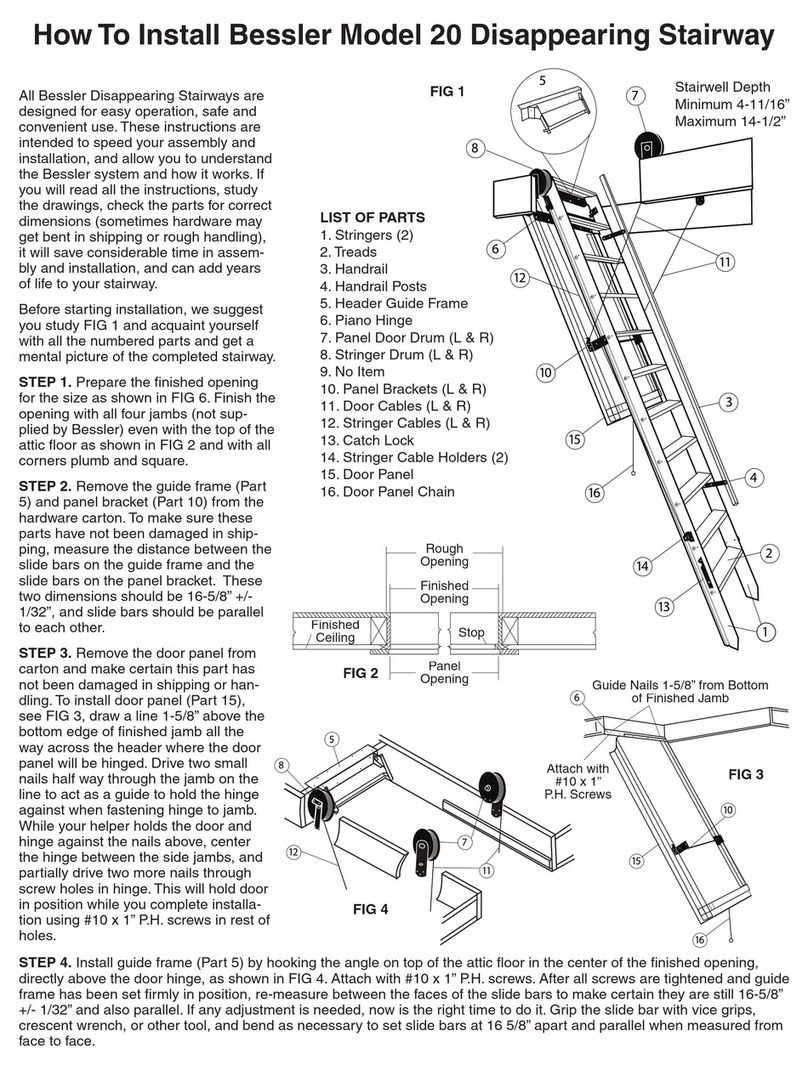

STABILISATION

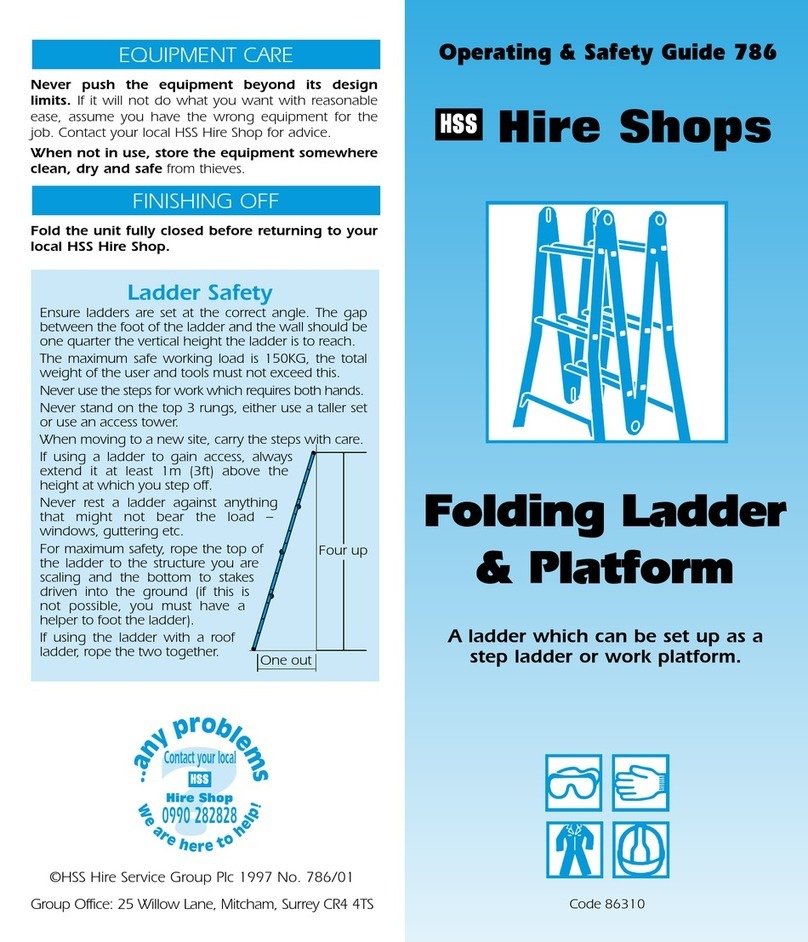

Refer to the table below for the correct method(s) of

stabilising the tower for the stairwell in which you

intend to erect it:

For additional stability more than one stabilisation

method may be used. The HSS Hire strongly

recommends that ballast be used in all applications

in addition to the alternative methods indicated by

this guide.

METHODS OF STABILISATION

A- Strongly recommended: The tower is fitted with

150kg of ballast uniformly spread along the bottom

rung of each base frame (i.e. 75kg at each end).

Please contact your supplier or hire shop for details.

B - The tower is positioned up against a wall on one

side, and a stabiliser is fitted on the other, to the end

frame on the lower step. The stabiliser must have a

minimum sideways extension of 650mm, and reach

down the stairs for a minimum distance of 650mm.

C - The tower is fitted with a stabiliser on both sides,

each with a minimum sideways extension of

650mm, and reaching down the stairs for a

minimum distance of 650mm. Additional stabiliser

available from your supplier or hire shop.

D - The tower is fixed solidly to a wall on one side

with ties. They should be rigid, two-way ties

fastened to both uprights of the frame with load

bearing right-angled or swivel couplers. Only

couplers suitable for the 50.8mm diameter tube of

the tower should be used. Ideally ties should secure

to either the face of a solid structure or by means of

anchorages. Tying in with rope or non-rigid

members is not acceptable.

Position of

tower in

Stairwell

0.8 to 1.4m 1.4 to 2.0m 2.0m or

greater

Free-Standing

(No walls on

either side of

staircase)

A A A or C

Up against a wall

on one side of

the staircase A or D A or B or D A or B or D

Mid-way

between walls

on each side of

staircase

A or D A or D A or C

To complete the tower, attach the four guard rails

(see illustration) ensuring that the claws face

outward.