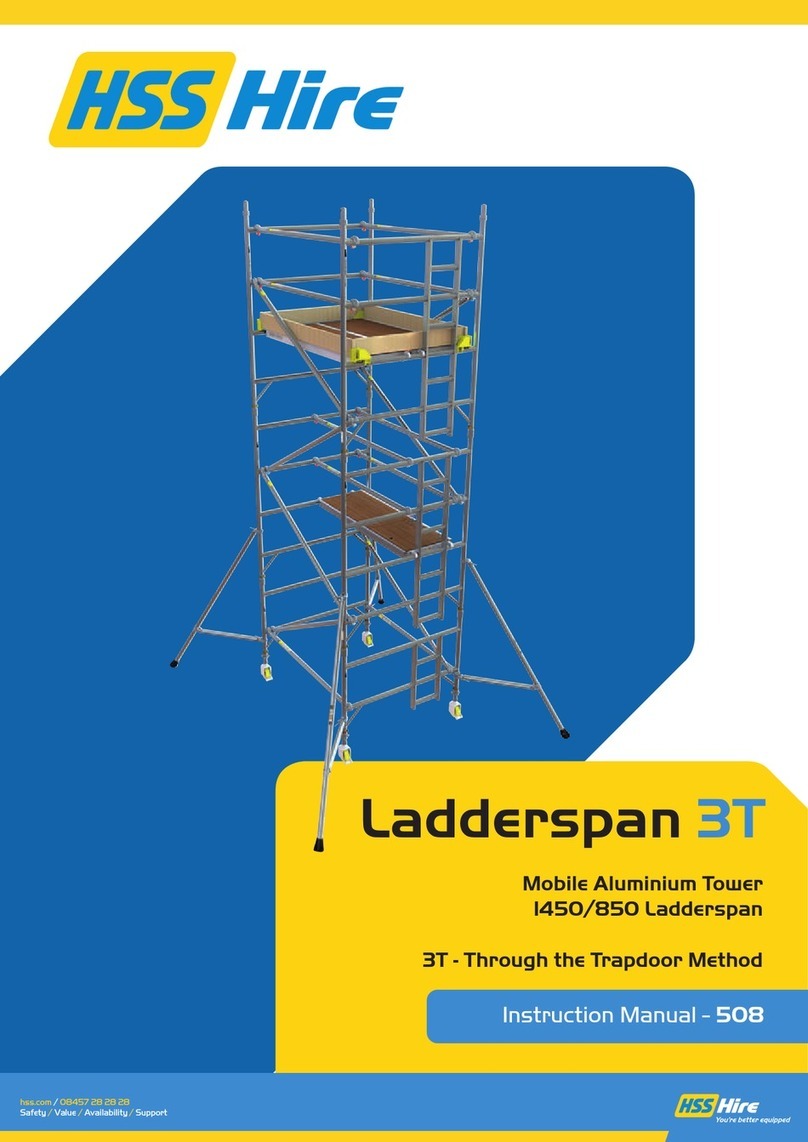

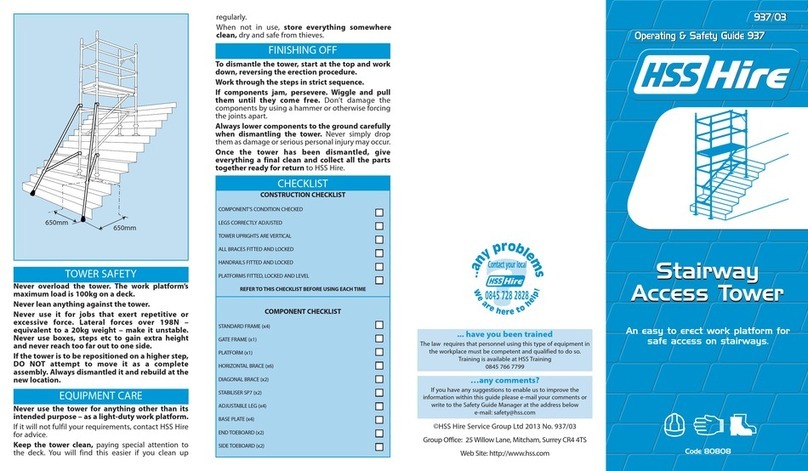

ASSEMBLY

THIS TYPE OF STRUCTURE MUST BE ERECTED BY

OPERATIVES WITH A PASMA CERTIFICATE &

PRODUCT SPECIFIC TRAINING

NEVER STAND OR WORK ON AN UNPROTECTED

PLATFORM

DO NOT EXCEED THE SAFE WORKING LOAD OF

150KG ON THE BEAM UNIT PLATFORM

Fully insert the adjustable

legs with castors into 2

frames, turning the leg’s

height adjustment collar to

bring each leg 25mm from the

lowest position.

1

Attach a guardrail brace

panel to the vertical tube

of one frame with the

upper claw positioned

above the fourth rung and with

all claws facing outward. Make

sure the claws are correctly

locked on the frame tube. Now

attach the second frame to the

guardrail brace panel to create

the base frame assembly. Lock all

four castors and using a spirit

level as a guide, adjust each leg

to bring the base square and

level.

2

Construct 2 sets of

conjoined frames, these

will give you two 2m

sections and will speed up

the erection process. Release the

frame clips on one four rung

frame and fit it on to a second

four rung frame. Apply the frame

clips and ensure they are

correctly locked. Repeat this

with the second set. Fit one set

of conjoined frame and apply

the frame clips. Repeat this with

the second set.

3

Next attach one guardrail

brace panel with its lower

jaw position above the

sixth frame rung. It must be

fitted on the opposite side to the

first guardrail brace panel to

ensure stability. Ensure all claws

are facing outward and correctly

locked on the frame tube.

4

Stand inside the tower and fit

the platform on the eighth

rung, making sure that the

wind-lock catches engage

5

Fit a stabiliser to each corner of

the tower. Position the lower

horizontal stabiliser coupler

clamp just above the frame’s

second rung, then secure the top

stabiliser coupler clamp just above

the frame’s fifth rung. Adjust the

stabilisers so that you create as

square a footprint as possible . Adjust

each stabiliser’s length so that they

are in contact with the ground. Make

sure all coupler clamps are correctly

secured. Extend and lock the four

component hangers located on

either sid of the platform

6

Place three guardrail brace

panels on to one set of hangers

and a pair of eight rung

conjoined frames to the other

side. Enter the tower framework and

climb the frame rungs until you are

half way through the platform trap

door. Now manoeuvre yourself so

that you are sitting on the platform,

with your legs through the trap door

and your feet on the frame rungs.

From this position, you should take a

guardrail brace panel, one at a time,

and attach so that the upper jaws are

positioned above the twelfth rung.

With both panels in position, you may

access the platform.

7

Fit one set of conjoined frames

to each end of the tower and

apply the frame clips. Next,

attach the guardrail brace panel

with its lower jaw positioned above

the fourteenth frame rung. Ensure all

claws are facing outward and

correctly locked on to the frame tube.

Descend the tower and from the

ground place two guardrail brace

panels onto the hangers on one side

of the platform then a set of toe

boards and a platform on the other

side.

8

Access the tower then carefully

fit the second platform on the

sixteenth rung, making sure

that the wind-lock catches

engage. Extend and lock the four

component hangers located on either

side of the platform. Transfer the two

guardrail brace panels and the set of

toe boards to the component hangers

on the second platform

9

Position yourself so that you are

half way though the second

platform’s trap door. Now

manoeuvre yourself so that you

are sitting on the platform, with your

legs through the trap door and your

feet on the frame rungs. From this

position, you should take each of the

guardrail brace panels, one at a time,

and attach so that the upper jaws are

positioned above the twentieth rung.

10

With both panels in position,

you may access the platform.

Unfold the toe board set and

position so that they sit on the

outer edge of the platform. Finally,

retract all hangers and the tower is

now complete and ready to use.

11

Any platform fitted to the tower at

any stage may be used as a work

platform, provided toe boards and

guardrail brace panels are fitted.

STABILISERS POSITIONING

Stabilisers are supplied and must be used in any

heights. For maximum effect arrange the stabilisers by

positioning at an angle of 45 degrees to give a footprint

as close to square as possible.

If the tower is to be positioned agains a wall, the

stabiliser footprint can be altered (see figure), but only

when the height of the wall is a minimum of two third

of the height of the top working platform.

Ensure that all four stabilisers’ feet are in contact with

the ground and that the ground can support the weight

of the tower and stabilisers.

DISMANTLING

The tower is easily dismantled by simply reversing the

erection procedure. Make sure that the component

hangers are evenly loaded to ensure the tower remains

balanced. You must, however, be protected by guardrail

brace panels when standing on any platform and

ensure that you use the 3T method when removing

guardrail brace panels.

4 rung Frame

Telescopic outrigger

Hatch platform

Guardrail brace panel

220mm adjustable leg

125mm locking castor

Toe board set

Tower weight

4

2

4

1

109 kg

QUANTITY SCHEDULE

Platform safe working load

10

150 kg

7

4

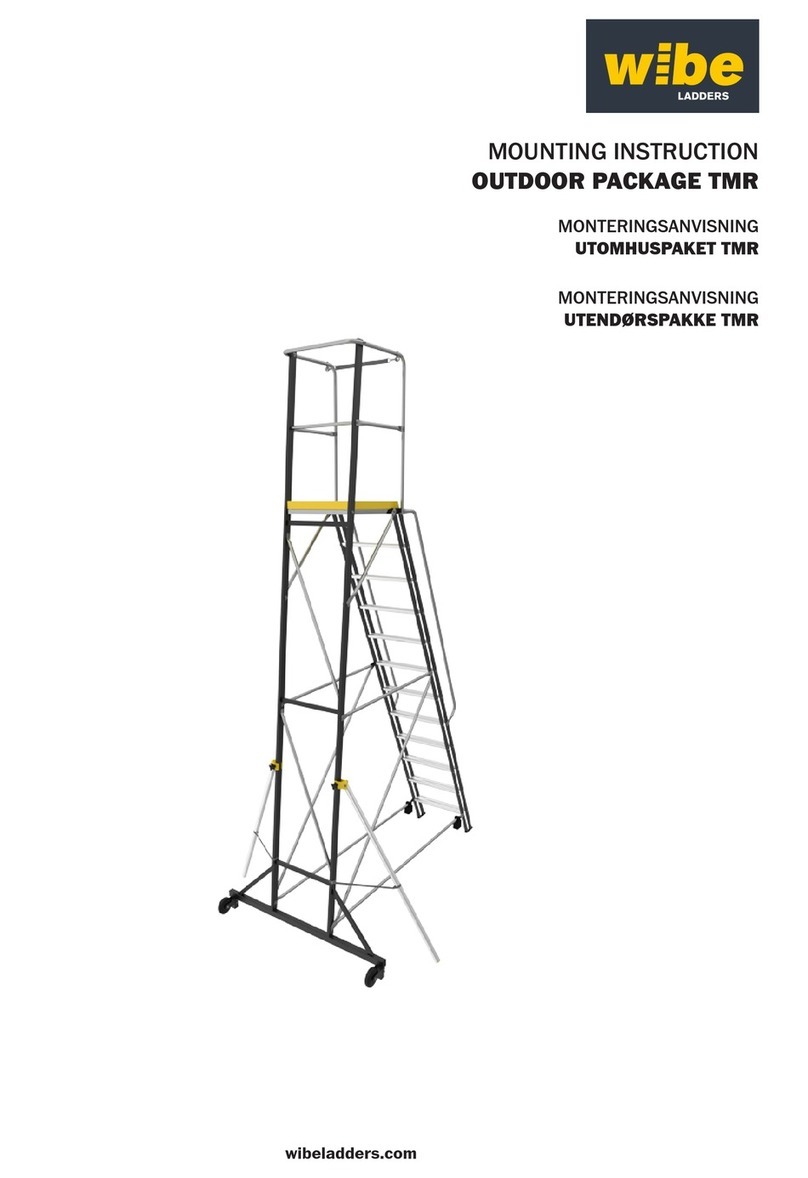

assembly. During erection, the frames may be connected

together to create 2m high frames which makes assembly

both quicker and easier.

THROUGH THE TRAPDOOR SYSTEM (3T)

The 3T method of construction has been developed to

reduce the risk of an erector falling from a tower during

construction. The erector must sit on the platform with legs

through the hatch and feet on the frame rungs when

attaching guardrail brace panels above the platform. This

ensures the erector is always protected be a set of guardrail

brace panels.

PREPARATION

The floor area must be clear of any obstructions

including materials and debris. Check that you have all

components necessary to construct the tower height

you require. Check also each component for condition

and correct function. If any part is missing or damaged /

not working correctly the tower should not be erected. In

this case return unit to HSS Hire.

You should consider tying in the tower to add stability, but

this may only be carried out by a suitable trained person.

Ballast must be used to stabilise against overturning. Only

use solid material as ballast (i.e. block of concrete) and

position to avoid overloading individual components.

Ballast should be supported by the base of the tower and

securely fastened to prevent removal.

COMPONENTS

Guardrail Brace Panel

Claws are fitted to the guardrail brace

panels and each has an automatic

locking jaw which is released by simply

moving the jaw’s trigger. The claw must

only be attached to the frame with the

opening facing outward. Attachment

with the jaw’s opening facing inward

will not fully protect the user if lent

upon and may cause serious injury or death. Always ensure

that each claw is positively locked in position before using

the tower.

Frame Clips

The frame clip’s pin locates into a

retaining hole in the frames to lock

tower sections together when

place one on top of the other. The

pin is locked in place by a red tab

to ensure that it remains in place.

From the disengaged position,

pivot the pin / tab to bring the pin

horizontal. Insert the pin fully through the retaining hole

with its tail pointing down. Next flip the tab vertically to

lock the pin in place. Removal is simply a reversal of the

fitting sequence.

Stabiliser Coupler Clamp

The coupler clamps are used to

secure the stabilisers to the tower’s

vertical tubing. With the clamp jaw

open, offer it to the tube. Bring the

jaw around the tube and set the

buckle on to the hook, then close the

clamp arm to lock the stabiliser in position. A similar clamp

is fitted to the stabiliser extension leg.

Wind-lock Catch

The wind-lock catch is drop down

jaw fitted to the side of the hatch

platform’s mounting hook and

prevents the platform from lifting in

windy conditions. It is attached to the

horizontal tube of the frame. To

disengaged, simply lift and hold the jaw as you rise the

platform clear.

Platform with built in Component Hangers

To enable one man to erect the

tower, each hatch platform is

fitted with four component

hangers which are stowed (two

either side) within the platform’s

frame. The hangers can be

extended when needed and

retracted when not. To extend

and lock a hanger, take a hold of

the hanger stop end and pull from the frame. Once the

stop rivet is clear of the slot, turn the hanger 45 degrees

anticlockwise then gently slide back in until it stops. To

retract the hunger, simply reverse the procedure.

Adjust Leg and Castor

The adjustable leg and castor

allows for accurate

positioning of your tower in

relation to your workplace.

The legs can be extended or

retracted to allow for

levelling and the brake must

be applied to prevent

movement.

Engaged Disengaged

Retract

Extend

Lock

Release

Retract

Extend

Off

On

Engagement

spring

SAFETY WARNING

Only use adjustable legs to level the tower

and not gain extra height.

When the tower needs to be moved a small distance to

enable you to continue your task, this can be achieved

provided the stabilisers can remain in pattern and all

tools, materials and personnel are removed from the

tower.

You will need to rise the stabilisers so that they are

no more than 25mm above the floor and properly

locked. However if the stabilisers need to be positioned

and this reduces the footprint, the tower must be

reduced in height to 2m.

You must only move the tower by manual effort at

the base at a slow pace and only after fully assessing

the risk.

Once moved, always check the tower before using.

If the unit is to be moved to new location, a new level or

over the rough terrain, it must be fully dismantled and

rebuild at the new location.

MOVING TOWER

WARNING

The hangers are intended for hanging of components

during the erection of the tower. Do not use the hangers

other than to their intended purpose.

DANGER

Do not exceed maximum weight of 20kg per hanger.