For advice on the safety and suitability of this

equipment contact your local HSS Hire.

Keep children, animals and bystanders away from the

work area.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or

drugs.

This equipment should only be used by a competent

person who has read and understood these

instructions.

Never let more than one person onto the steps at any

one time.

Wear sensible clothing and stout, comfortable

footwear offering good grip. If necessary,

wear goggles and gloves.

A hard hat must be worn by everyone in the work

area.

Don’t attempt to use access equipment unless you feel

comfortable working at heights.

Never use step ladders unless there is someone within

ear-shot to summon help, in the event of accident.

Alloy step ladders must not be used for work on

electrical installations.

Never carry equipment while climbing unless you can

do so leaving your hands free, by carrying the

equipment in a shoulder bag. Climb first then haul the

equipment up after you on a rope.

Never use access equipment near over-head or wall

mounted power cables and similar hazards.

Never use the steps in very windy or blustery

conditions.

Note that the steps are designed to provide access for

light maintenance work. Never use them as a work

platform.

Check the equipment’s condition before use. If it shows

signs of damage or excessive wear – notably to feet, rungs

hinged braces, return it to your local HSS Hire

immediately.

Keep your feet in the middle of the steps and climb

gripping the side firmly, with both hands.

Always climb on the outer face, never on the underside.

Never lean to far to one side to reach. Move the steps as

necessary.

Never do anything that involves applying a lot of force.

The steps could topple over.

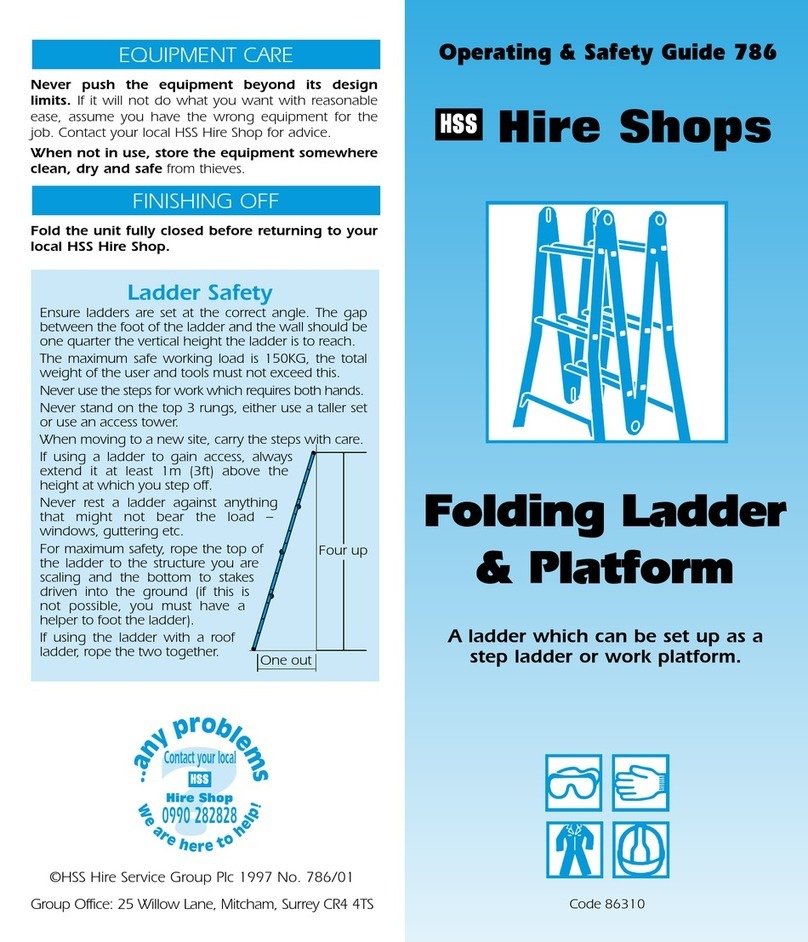

Always set the steps up on a firm, level, non-slip surface.

On soft ground, stand the steps on boards to stop it

sinking in.

GENERAL SAFETY

GETTING STARTED

Make sure they are fully open. Never use them partly

open.

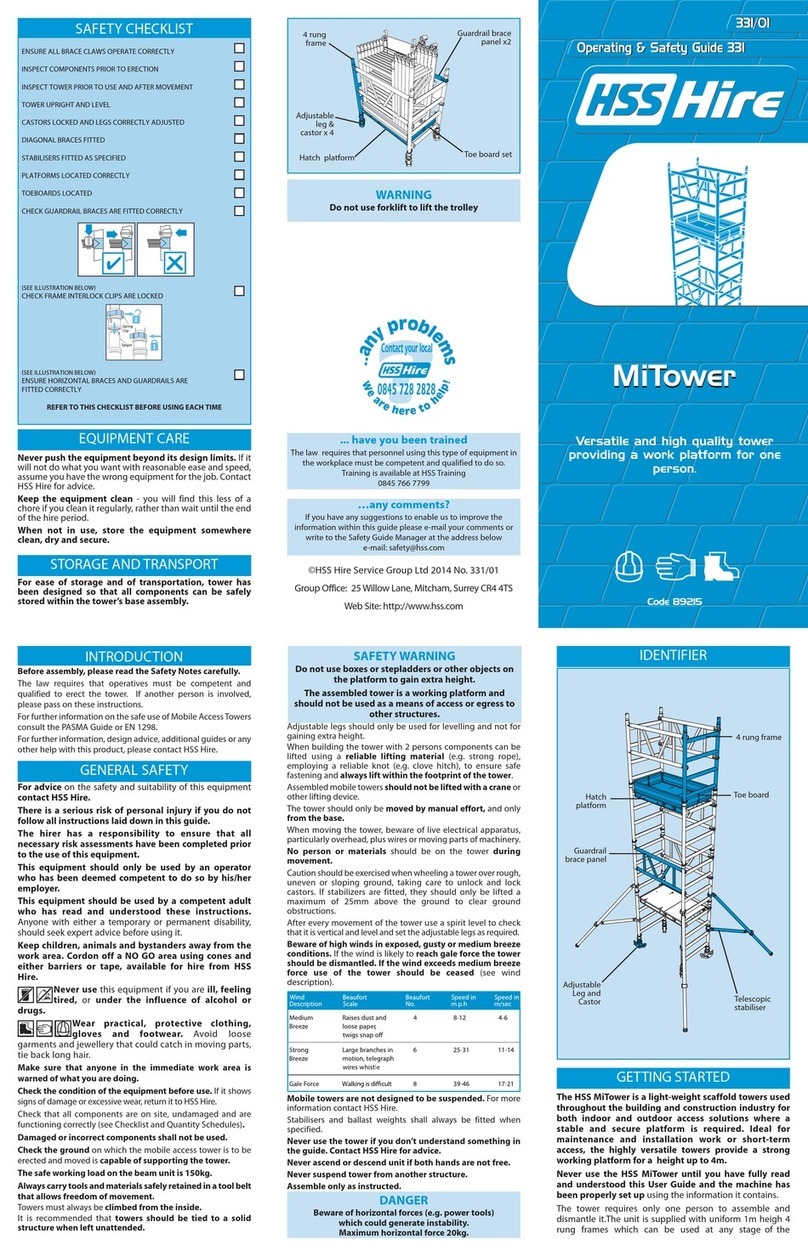

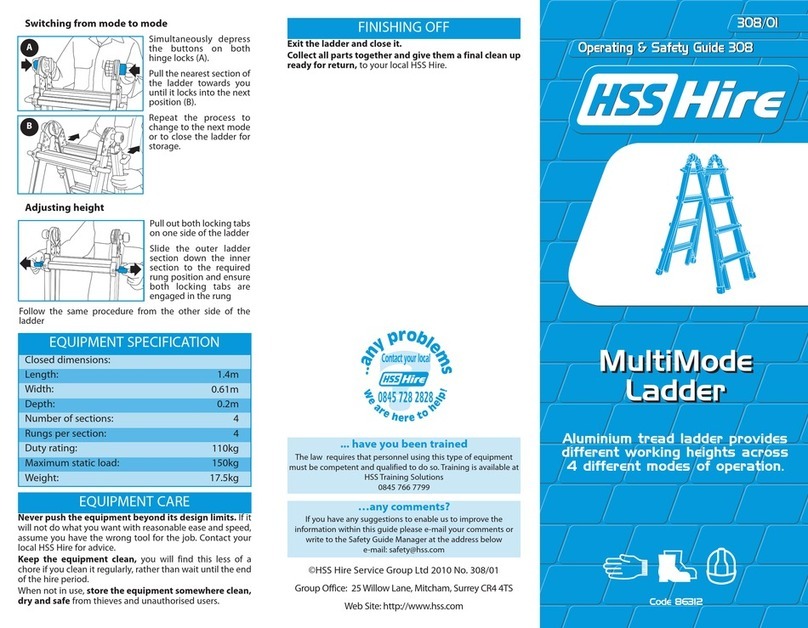

Alloy steps have a hinged brace fitted between the two

sections (see image) and must be pushed flat before use.

Never push the equipment beyond its design limits. If it

will not do what you with reasonable ease, assume you

have the wrong equipment for the job. Contact your local

HSS Hire for advice.

Keep the equipment clean, you will find it less of a chore

if you clean it regularly rather than at the end of the hire

period.

When not in use, store the equipment somewhere clean,

dry and safe from thieves.

Transport the steps in the closed position. If

transporting on a roof rack, tie down securely.

FINISHING OFF

EQUIPMENT CARE

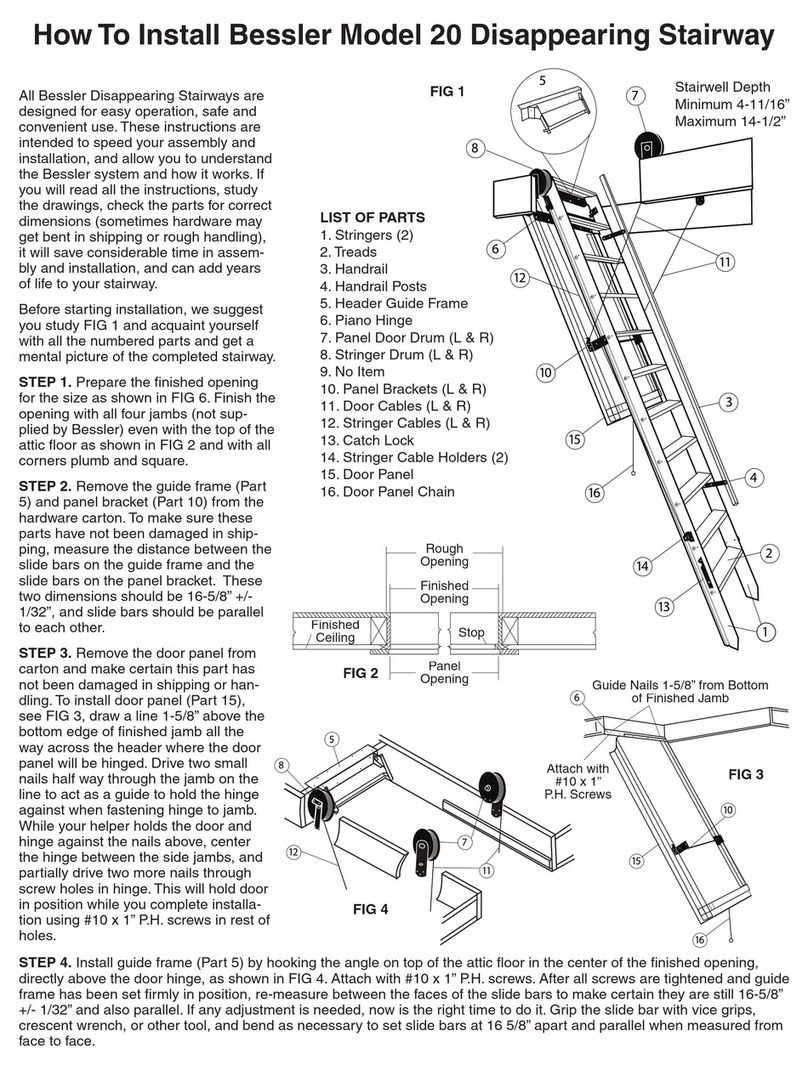

Ladder Safety

The maximum safe working load is 130KG, the total

weight of the user and tools must not exceed this.

Never use the steps in the closed position acting as a

ladder or as a ramp with boards. Never use the steps

for work which requires both hands.

Never stand on the top rung, either use a taller set or

use an access tower.

When moving to a new site, carry the steps with care.