Adjust Knob

1. Rotate Adjust Knob to anti-clockwise direction for increase power, Rotate to

clockwise direction for decrease power.

2. If feel not work strong, could increase power, do not rotate more than 3 scales.

3. Judge Adjust Knob Locate at “Strong” or “Weak” site.

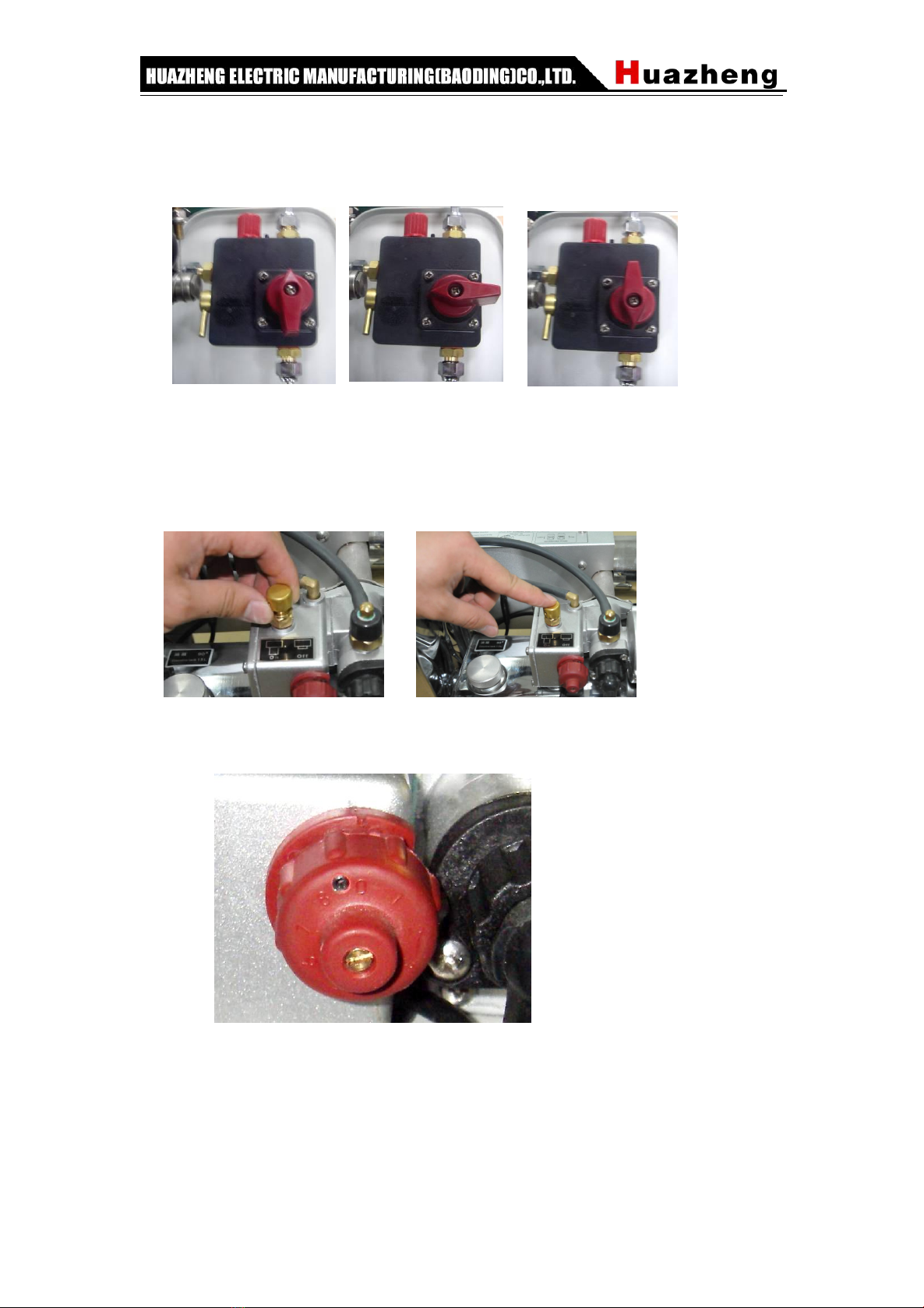

Listen engine working sound,

If runs normally, explosion should sounds clearly;

If sound like “PU, PU ,PU….”, or after start up, if have flame spray out, have been located

at “Strong” site, should reduce power;

If have explosion sound, but could not start up, have been located at “Weak” site, should

increase power;

Note: Check illustration below, take standard site as reference, divide one circle

into 8 parts, 1-3 parts will best position.

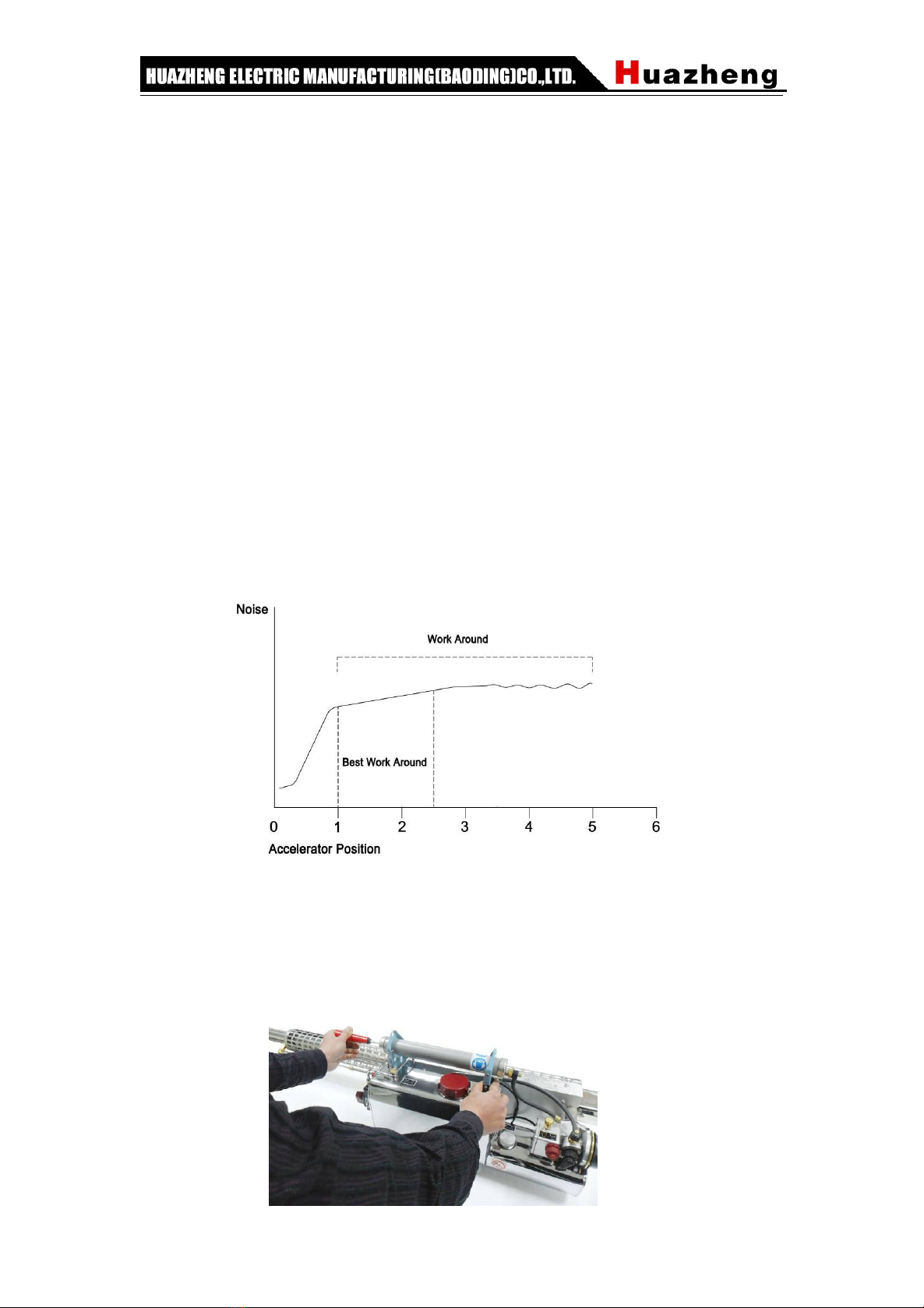

Start Up

As illustration showed, use left hand to hold air pump handle to press and retract it while

right hand to press down igniter button, actuate air pump slowly, evenly, gently (Will hear

ignition sounds, "Ta, Ta, Ta ..."), continually actuate air-pump will start up machine.