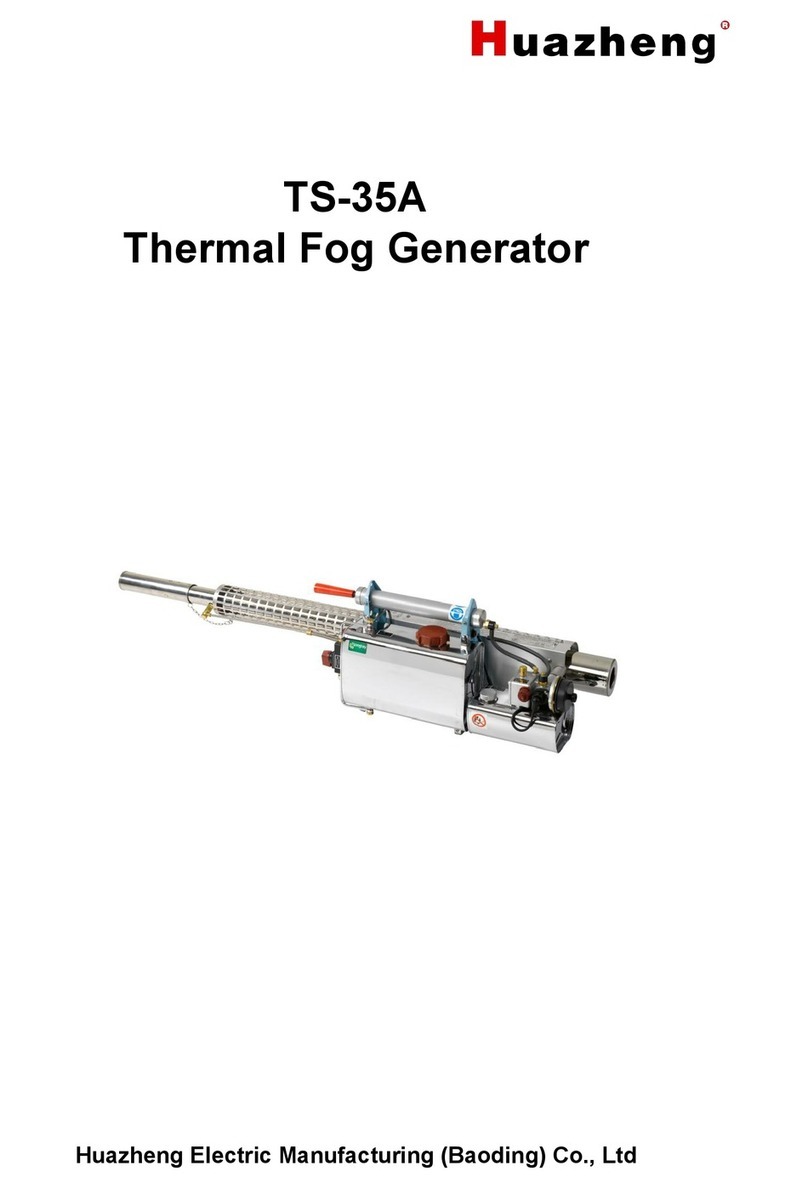

If there is no sound from the fire, replace the solenoid valve. If there is still no air

intake sound after replacing the solenoid valve, the circuit board is faulty.The most

problematic in the actual work of the gas gun is that the gas gun inlet nozzle is blocked.

Because impurities in the gas (such as condensate, tar, etc.), these impurities will

accumulate the moving parts, it is necessary to clean regularly to keep the equipment

working properly. Otherwise, the inlet nozzle may be stuck by the oily substance in the

cylinder, which affects the flow and mixing ratio control, which affects the gas gun

sounding effect.Liquefied petroleum gas will cause rubber and some plastics to age. Use

hoses specially designed for LPG. The hose should not exceed 2 meters. The hoses

should be equipped at both ends. The hose should be replaced every six months to

prevent aging and update Pressure valve once a year.

In the winter, attention should also be paid to the heat preservation treatment of gas

cylinders, pressure reducing valves, hoses and other components to prevent gas

condensation and freezing from reducing the gasification of liquefied petroleum gas and

affecting the normal operation of the gas gun.

In summer, due to the excessive external temperature, the gas volume of the gas

tank should be strictly controlled. The maximum amount should not exceed two-thirds of

the total storage gas to avoid danger.

After a long period of use, impurities in liquefied petroleum gas (such as condensate,

tar, etc.), especially when the gas volume in the liquefied gas tank is less than one-third,

will accumulate in the moving parts and the combustion chamber wall. In the above, when

the gas cannon is working, it is very likely to ignite it, causing unsafe factors and damage

to the gas cannon. The following points are emphasized here:

1. In summer, the amount of liquefied gas should be between one-third and

two-thirds; in winter, it should be kept at one-third to full.

2, regularly wipe the burning warehouse wall every month. That is, open the

high-pressure ignition head behind the combustion chamber, and wipe the wall with cotton

yarn. Note that cotton yarn and so on are not allowed to remain in the combustion

chamber.

3. When using for one year, it should be cleaned by a professional.

4. When using, the operator should pay attention to observe whether the

combustion chamber and other components are ignited, find them in time, and reflect and

solve them in time.