General Information

These instructions are intended for the manufacturer of the end product and are not

designed for passing on to the operator of the end product. With regard to the specialist

information contained herein, these instructions can serve as a basis for drawing up the

instructions for the end products.

It is essential to note the information contained in these instructions! In doing so, you

can prevent mistakes being made in installing or connecting the system which could result

in…

Ÿinjury and accidents as well as

Ÿdamage to the drive system or the end product.

To supply the voltage, use only a DC power supply!DewertOkin

The DC power supply includes an earth-free electric circuit which is isolated DewertOkin

from the supply voltage via double or reinforced insulation.

DewertOkin accepts no liability for damage caused as a result of …

Ÿnon-observance of these instructions,

Ÿalterations to the product not approved by DewertOkin or

Ÿthe use of spare parts not manufactured or approved by DewertOkin - these may

not ensure adequate safety!

Due to the policy of ongoing product improvement, DewertOkin reserves the right to carry

out technical changes at any time without prior notification!

2

Contents page

General Information...................................................................................................... 2

Designated Use............................................................................................................. 3

Prerequisites................................................................................................................. 3

Getting to Know the System......................................................................................... 4

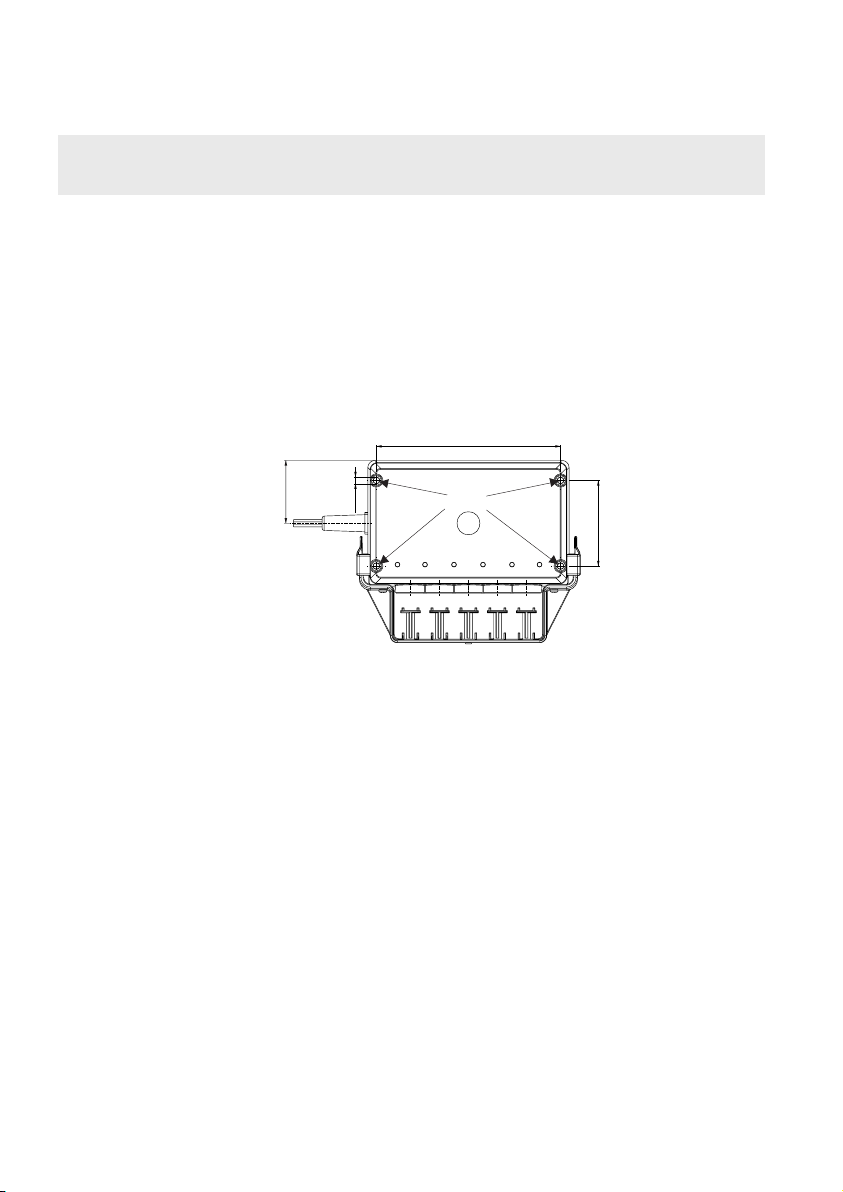

Fitting............................................................................................................................ 6

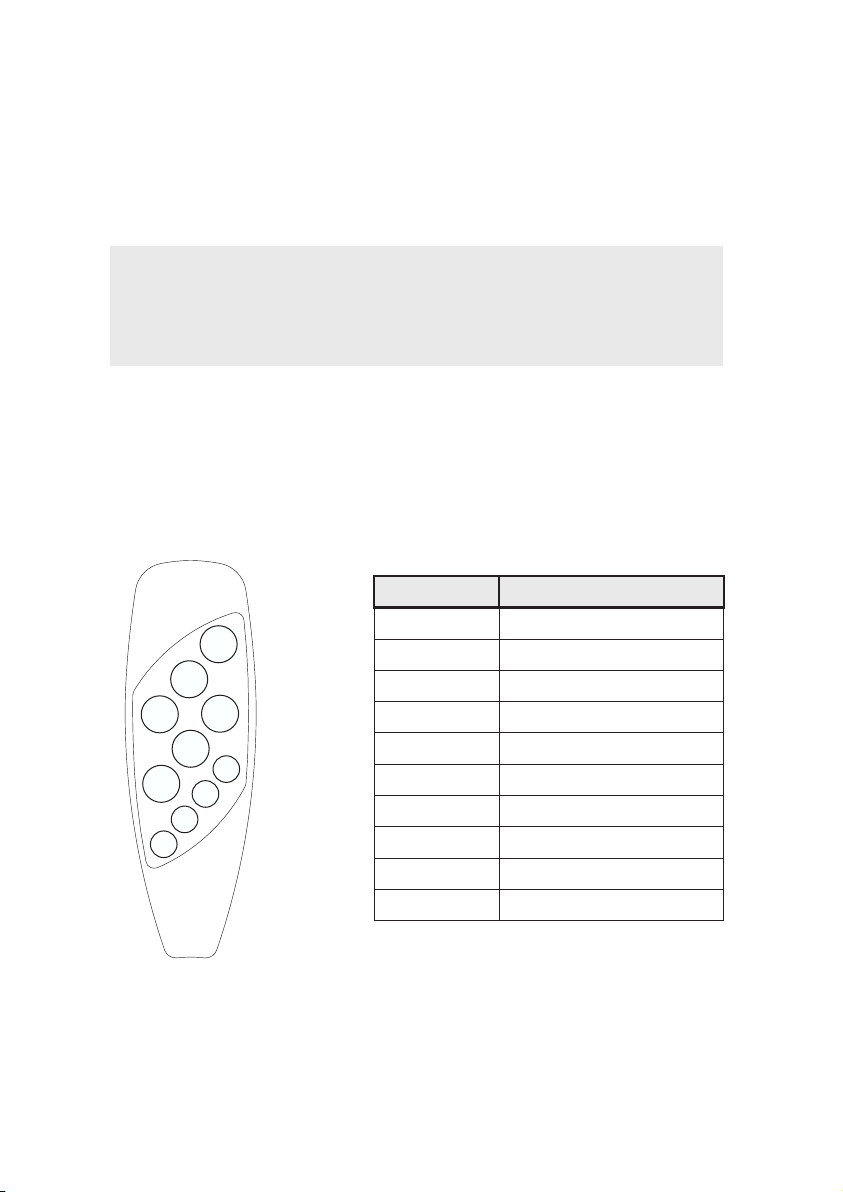

Operation..................... ................................................................................................ 8

Maintenance and Repairs............................................................................................. 9

T 10ype Label....................................................................................................................

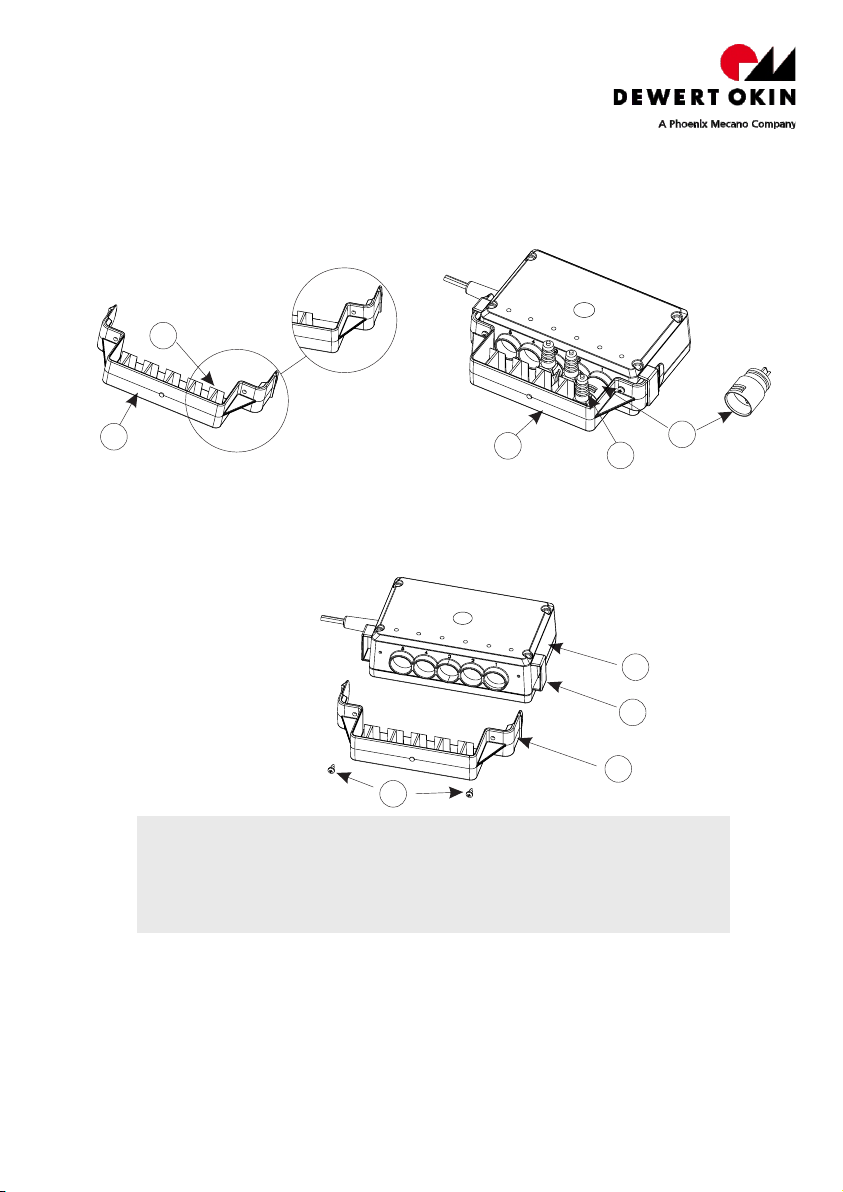

Design of the CU155 Drive Control Unit....................................................................... 11

Troubleshooting............................................................................................................ 12

Cleaning and Care........................................................................................................ 13

Declarations of Conformity ........................................................................................... 14

1. Designated Use

The CU155 drive control unit is designed for installing in end products...

Ÿto control motorised adjustment devices in movable furniture components (e.g.

beds, chairs...)

The CU155 drive control unit is not intended for use…

Ÿin an environment where inflammable or explosive gases or vapours (e.g.

anaesthetics) are likely to occur,

Ÿin a damp environment, i.e. outdoors

Ÿin beds intended for cleaning in wash tunnels

Ÿin applications in which inadvertent movements are not prevented by appropriate

technical measures.

2. Prerequisites

The installation steps described in these instructions must be performed by a fully trained

electrical engineer.

ŸThis being the case, you should never carry out this work yourself unless you are a

qualified electrical engineer or

Ÿyou should entrust this work to suitably qualified persons only.

Conformity according to EC Directives

The CU155 drive control unit is supplied ex factory as a machine not ready for use in

accordance with the EC "Machinery" Directive. In other words, you may not put the drive

control system into operation until you have met the safety objectives of the "Machinery"

Directive and issued a corresponding Declaration of Conformity!

The drive control unit with DewertOkin DC power supply meets the safety objectives of the

EC Directives concerning Low voltage and Electromagnetic Compatibility (EMC).

The CU155 drive control unit is not a medical product - for installing into same,

manufacture in conformity with the EC Directive for Medical Products or other regulations is

the responsibility of the manufacturer of the end product.

3

CU155

03/2020

ID 49623 3.0

03/2020

ID 49623 3.0