Page 2 of 3

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00911851 FORM NO. K0602 R03/04 ECO 8-030-017

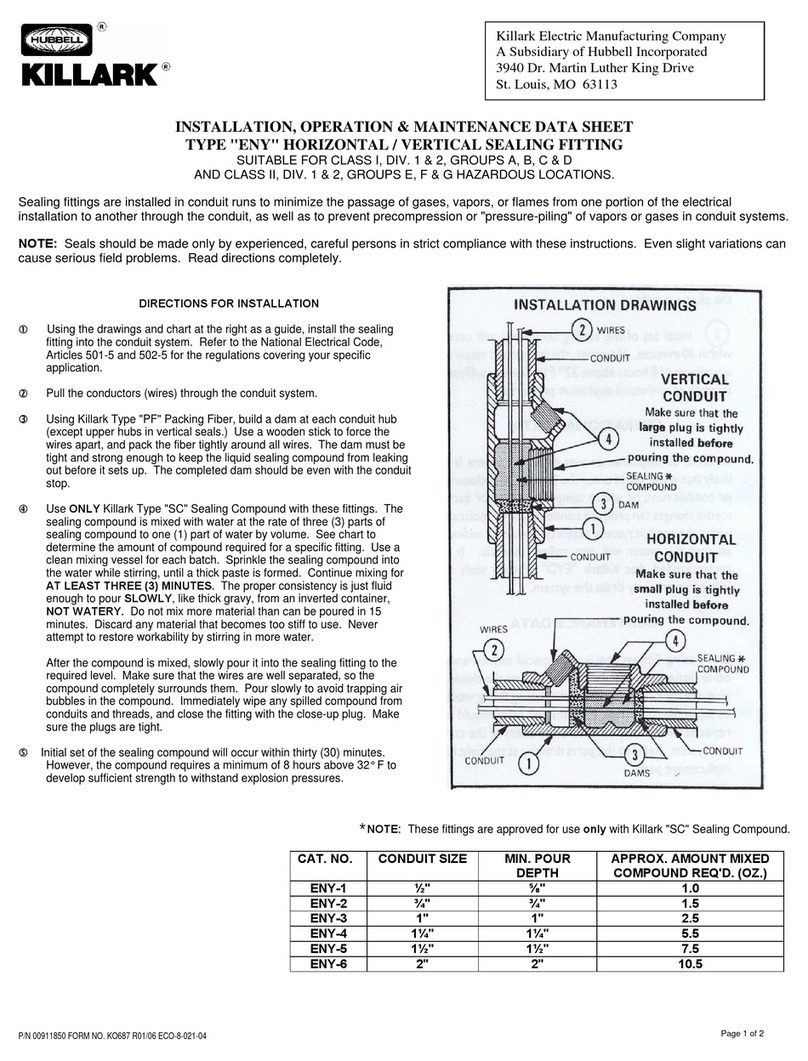

1. DIRECTIONS FOR INSTALLATION

Seals are installed in conduit runs to minimize the

passage of gases, vapours or ames from one

portion of the electrical installation to another through

the conduit; also, to prevent pre-compression or

“pressure-piling” of vapours or gases in conduit

systems.

Sealing ttings should be installed in the conduit

system in accordance with Articles 501-5 and 502-5

of the National Electrical Code.

Series EYS sealing ttings may be installed vertical

or horizontal in conduit runs. If used horizontal, the

tting must be positioned so that the cover is facing

upward. Remove cover and pour sealing compound

ush to the top of the cover opening.

Prepare the tting by separating the conductors and

making a dam to hold the uid sealing compound

with Killark type “PF” packing ber. Dams even with

the conduit stop are required in the lower hub vertical

ttings and both hubs of horizontal ttings. Pack the

packing ber tightly between the conductors and

between the conductors and the hubs. Use care so

as not to damage the conductor insulation. Be sure

to push any shreds of packing ber away from the

conductors to prevent leakage paths.

Use ONLY Killark Type “SC” sealing compound

with these ttings. The compound is mixed with

water at the rate of 3 parts of compound to 1 part

of water by volume. Chart A shows the amount of

compound required for your tting. Fittings with

fewer conductors will require more compound. Use

a clean mixing vessel for every batch. Sprinkle the

compound into the water while stirring, until a thick

paste is formed. Continue mixing for AT LEAST

3 MINUTES. The proper consistency is just uid

enough to pour SLOWLY, like thick gravy, from an

inverted container; NOT WATERY. Do not mix more

material than can be poured in 15 minutes. Discard

any material that becomes too stiff to use. Never

attempt to restore workability by stirring in more

water.

Slowly pour the uid compound into the sealing tting

to the level indicated in drawing. Be careful to pour

slowly so as not to trap air bubbles in the poured

seal. Immediately wipe off any spilled compound

and close the seal with the close-up plug or cover.

Initial set of the sealing compound will occur within

30 minutes, however, the compound requires a

minimum of 8 hours above 40o F to develop sealing

strength. Once fully cured, (min. 7 days) there is

no lower temperature limit to which “SC” could be

exposed.