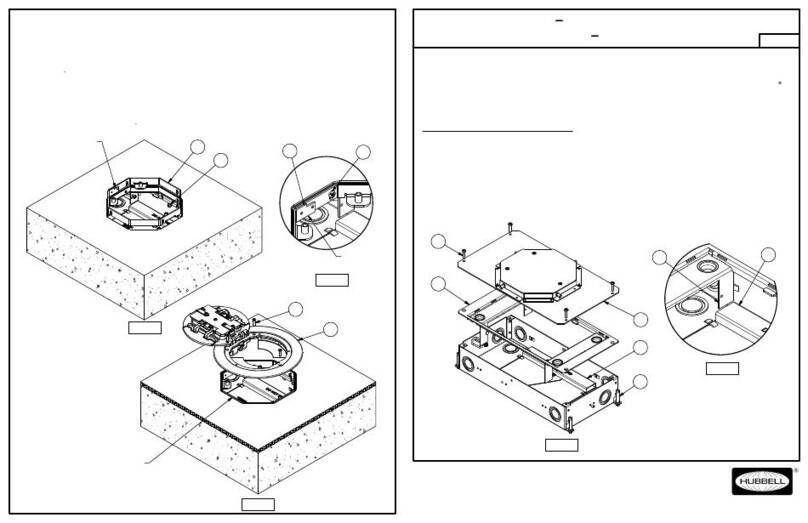

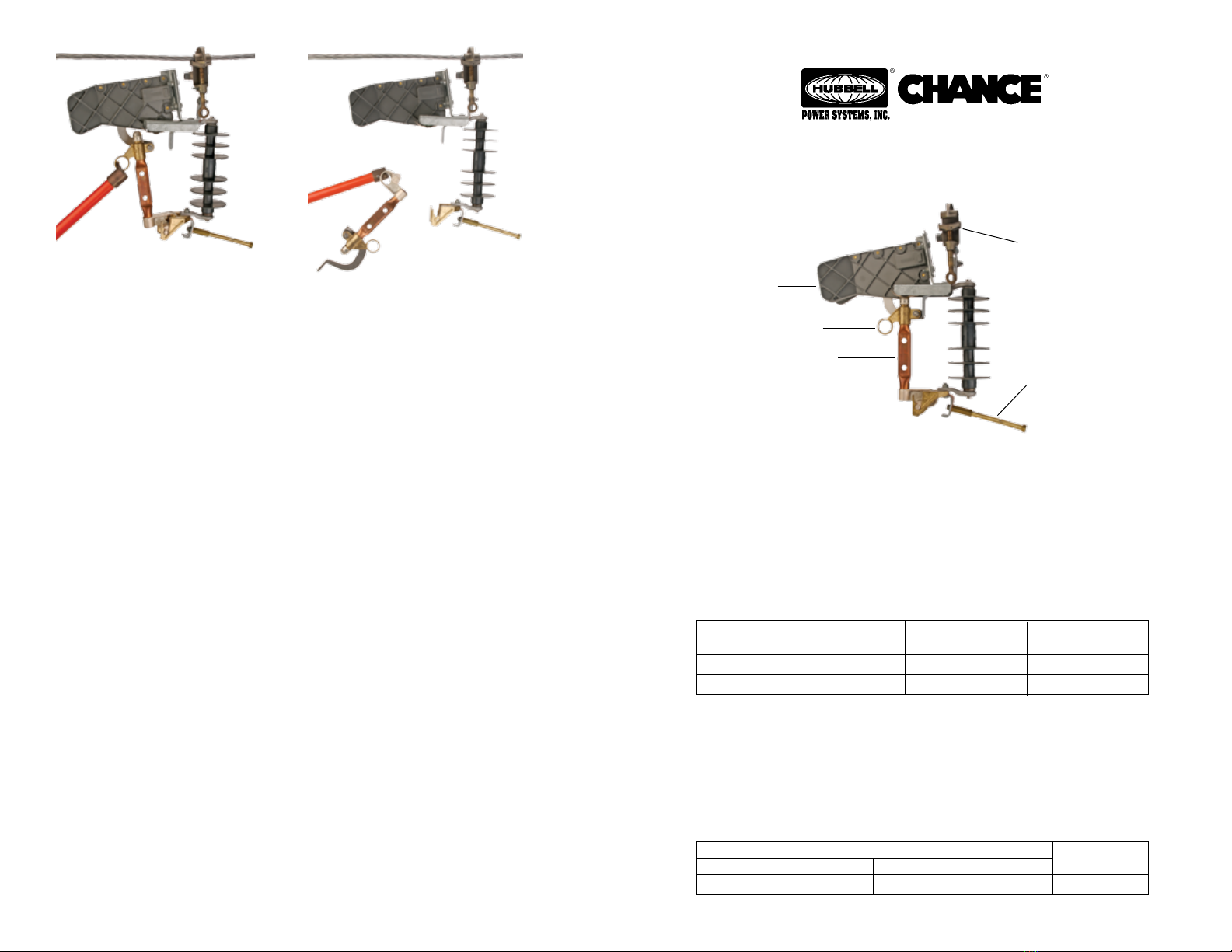

FIGURE 4 FIGURE 5

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to

change design and specications without notice.

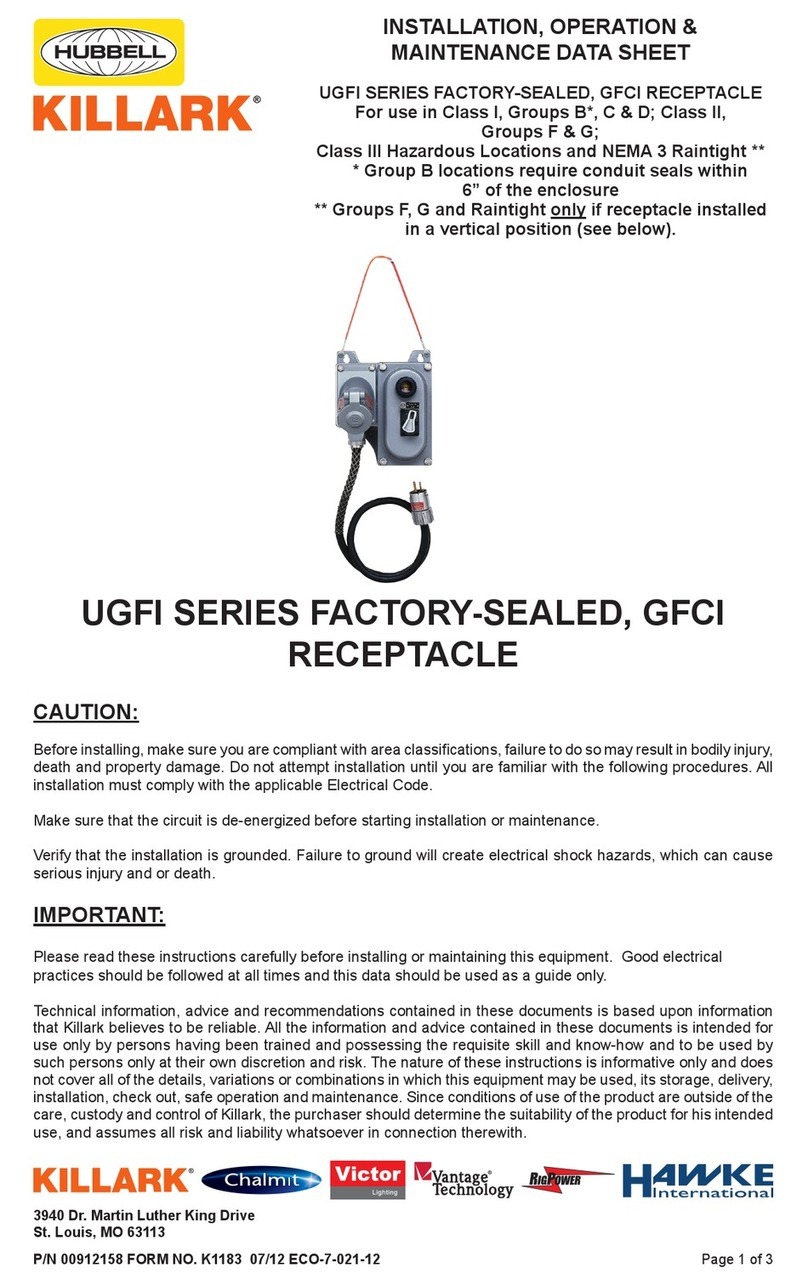

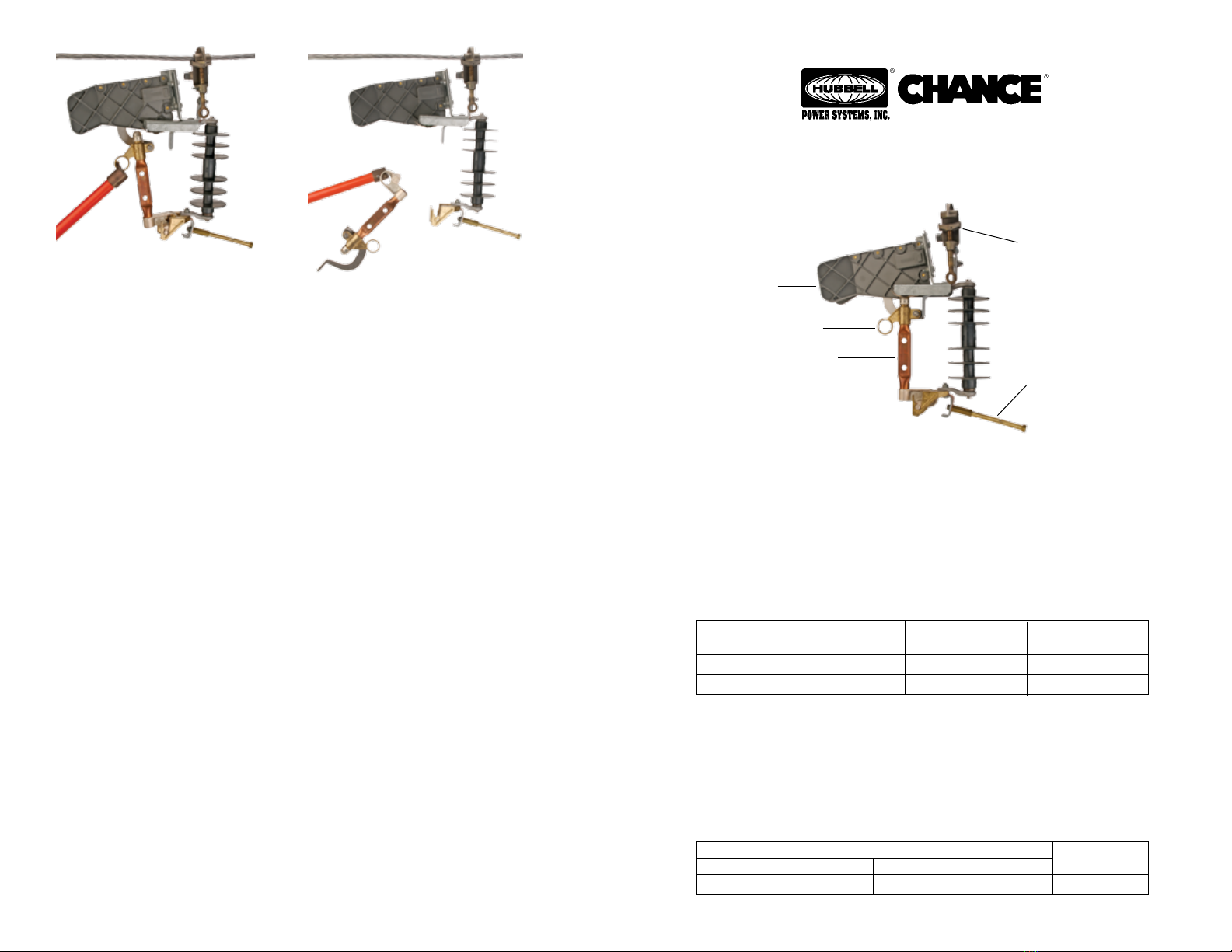

Both Models

Minimum

#6 solid copper (0.162")

Tap

Stud

1/2" diameter

Maximum

954 kcmil ACSR (1.20")

Main Line Range

Max. Momentary

Rating (Amps)

12,000†Asym

12,000†Asym

Epoxiglas®

Insulation Length

63/4" length

101/8" length

Max. Loadbreak

Current

300 Amps

300 Amps

System

Class

8.3/15kV*

15/27kV*

Ratings and Specifications

This unfused tool provides a temporary means of connecting and disconnecting

equipment or circuits under load conditions. This tool does not provide fault

or overcurrent protection. It has no fuse. It should never be closed into a fault

or opened during a fault. Unfused or unswitched loads can be disconnected by

first installing this tool with a temporary bypass jumper in parallel with the

permanent tap connection. After closing the blade of the tool, the permanent tap

can be disconnected. The load can then be dropped or reconnected by operating

the blade of the tool.

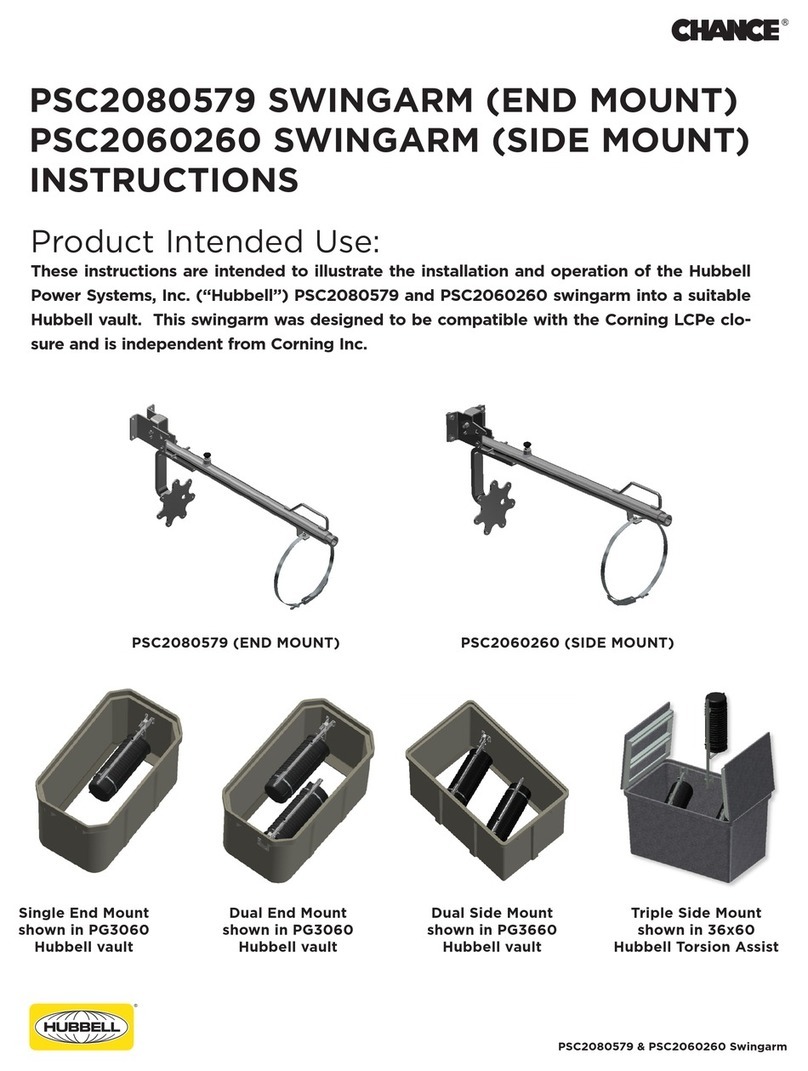

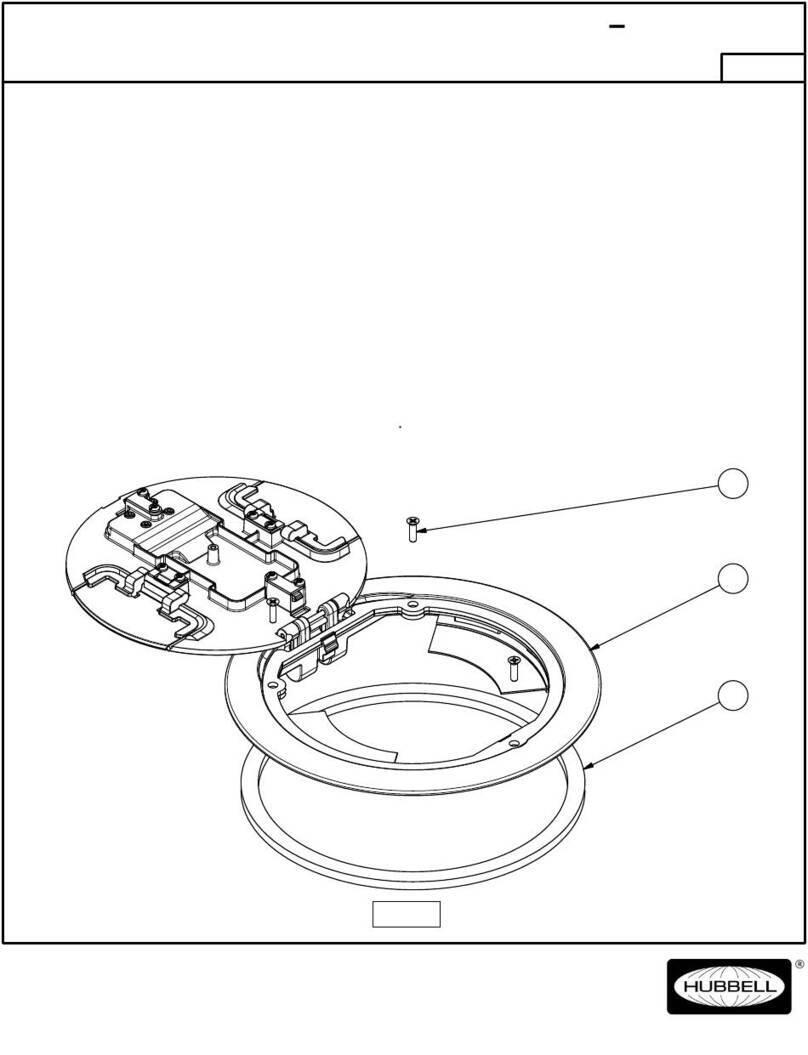

Load-Break

Arc Chute

Pulling Eye Insulator

Tap Stud for

Temporary Jumper

Line Conductor Clamp

* For application on single-phase-to-neutral or three-phase solidly-grounded-

wye connected circuits where recovery voltage does not exceed the maximum

design voltage of the device.

†This is a pass-through fault current rating only.

The tool should never be opened or closed when the current exceeds the

maximum continuous load current of 300 amps.

P6002400

Rev. A

Removal

To remove the Temporary Load Disconnect Tool, while maintaining a continuous

circuit connection, first make up a permanent connection or replace the previ-

ously removed permanent connection, in parallel with the tool. Now there are

two energizing paths.

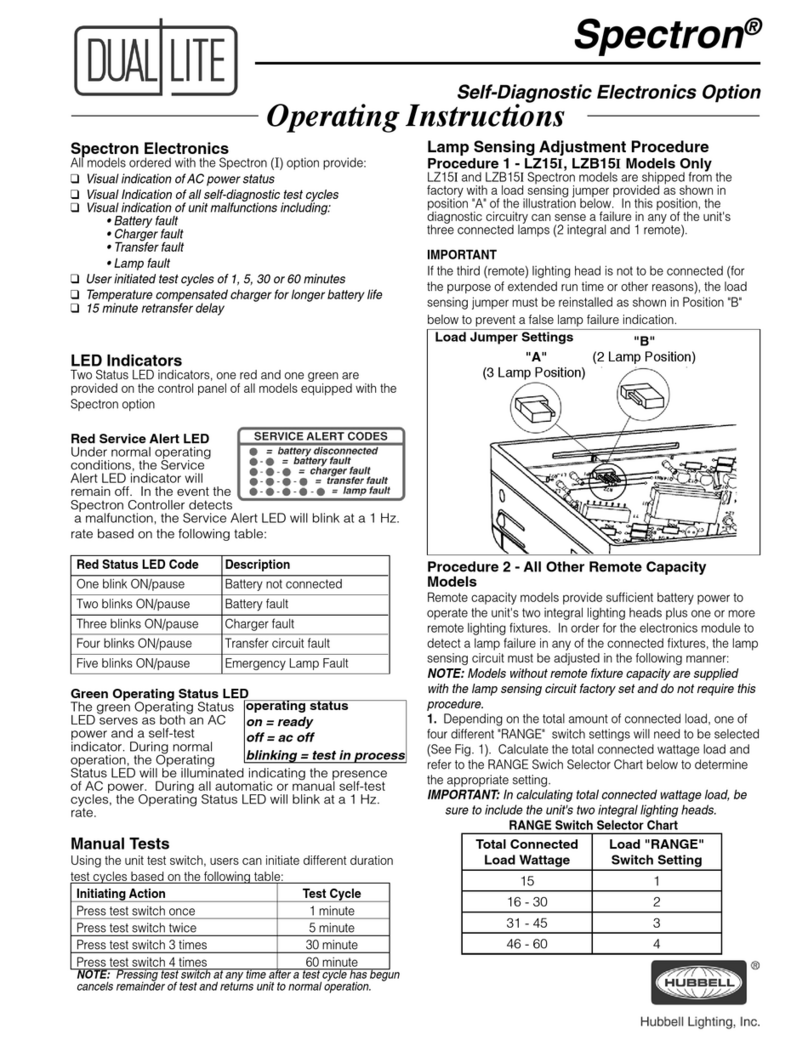

This tool is equipped with an arc-chute type interrupter. The arc chute enables

the tool to perform as a loadbreak device capable of interrupting load currents.

To operate this loadbreak device, place a disconnect stick in the pull ring on the

blade (see Figure 4). Position yourself approximately 2 feet to one side of the

tool. Look away from the tool and pull sharply on the disconnect stick without

hesitation.After opening blade, swing it into a full open position. Use a disconnect

stick to remove the blade from the lower hinge (see Figure 5). With a Grip-All

clampstick remove the temporary jumper from the energized conductor and

secure it on the stud at the lower hinge. With a Grip-All clampstick remove the

tool from the energized line conductor (see Figure 1).

Checklist

1. Check tool for proper closing and latching before each use.

2. This product should not be installed for extended periods. With the blade

removed, the insulator may permit excessive leakage depending upon sur-

face contamination and the extent of surface wetting. Wiping the insulator

with a clean Chance Wiping Cloth (Cat. No. M1904) or a silicone material

will help resist this condition.

3. To assure proper closing and opening operations, always close the blade in

line with the insulator.

4. When attaching jumper clamp to load, do not pull tool out of vertical posi-

tion.

5. Inspect contacts for excessive pitting or burning and replace as necessary.

Check blade for burrs or excessive erosion and replace if necessary. Check

arc chute for cracks and replace if broken.

6. When not in use or when in storage, always keep tool in the storage case

provided.

7. After approximately 50 operations, inspect the entire tool as described in

Item 5 above.

Catalog No. Application

PSC6010347 8.3/15kV

PSC6010348 15/27kV

Temporary Load Disconnect Tool

OPERATING INSTRUCTIONS FOR

©Copyright 2007 Hubbell Power Systems, Inc. Printed in USA

P6002400

Rev. A

Blade