Pub. 42004-194H

GAI-Tronics Corporation P.O. Box 1060, Reading, PA 19607-1060 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 234 Stanchion Assembly

Confidentiality Notice

This manual is provided solely as an installation, operation, and maintenance guide and contains sensitive

business and technical information that is confidential and proprietary to GAI-Tronics. GAI-Tronics

retains all intellectual property and other rights in or to the information contained herein, and such

information may only be used in connection with the operation of your GAI-Tronics product or system.

This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any third party.

Introduction

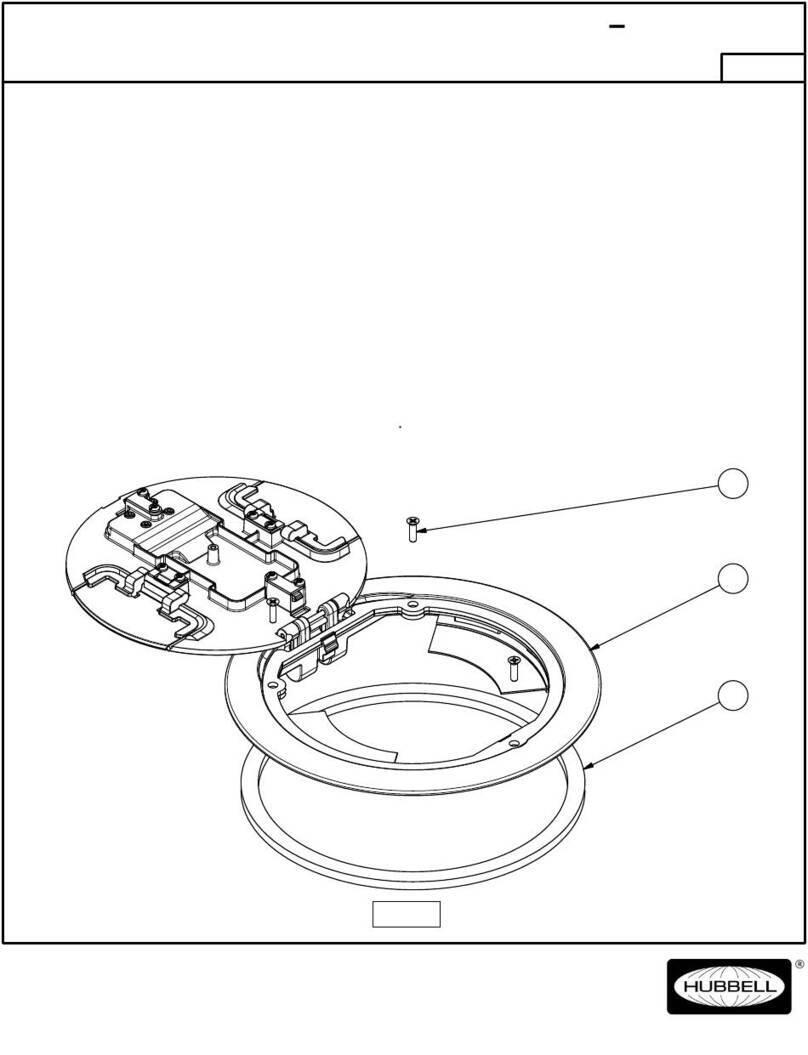

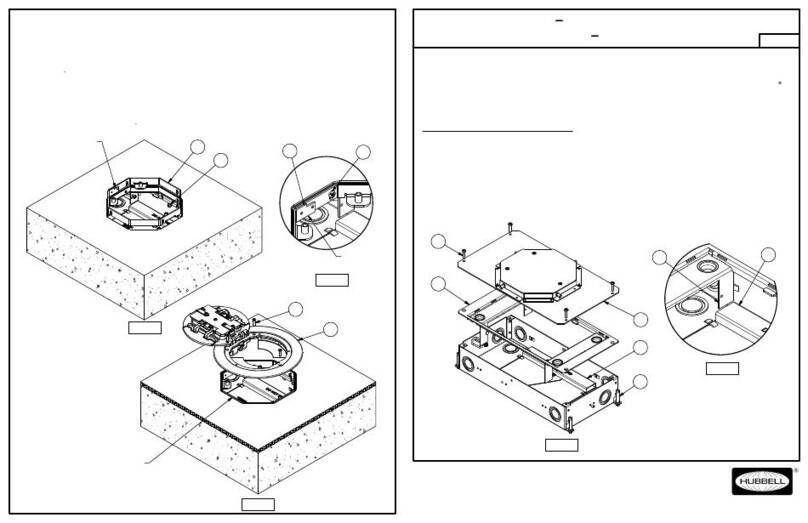

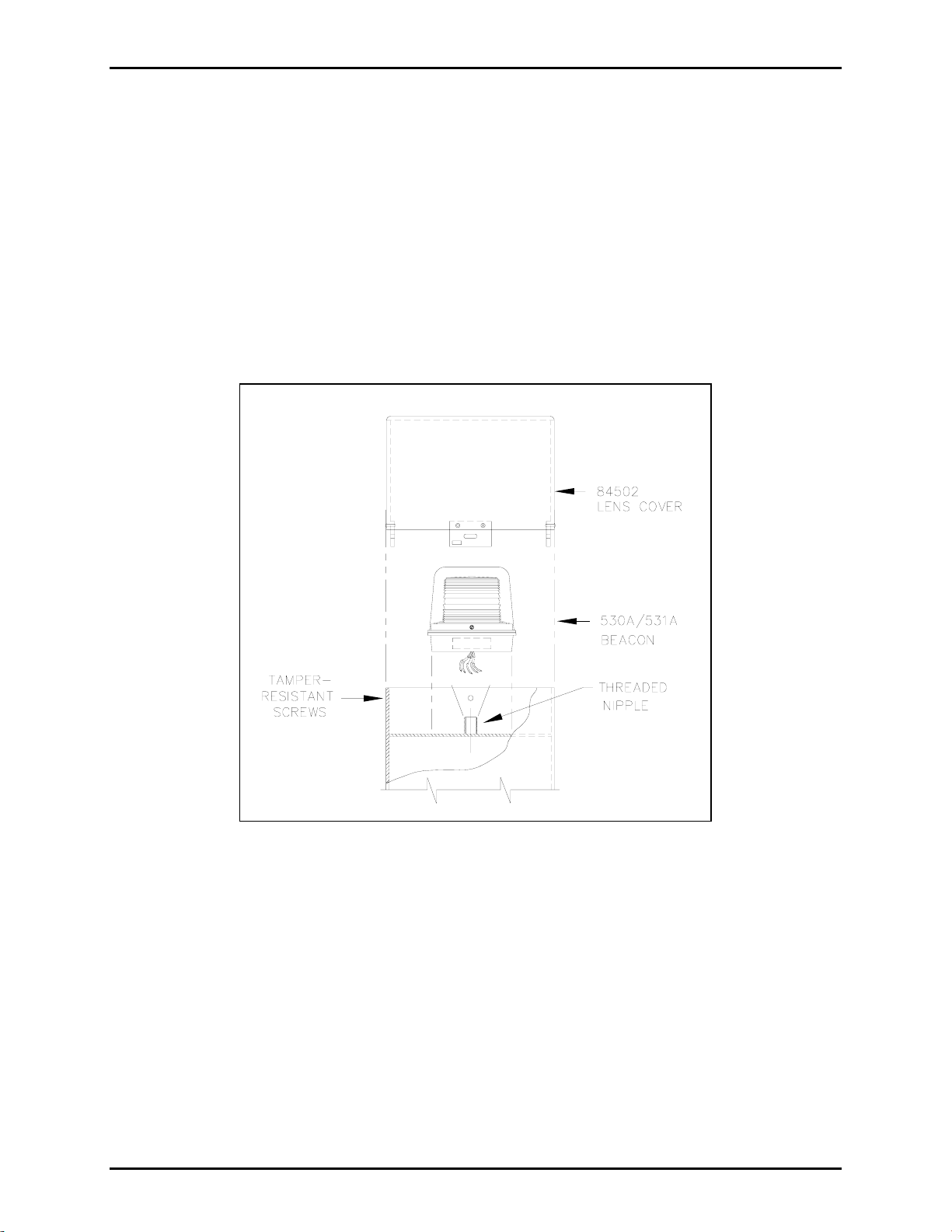

The complete emergency station is shipped in two stages. The Model 84504 Hardware Kit is usually

shipped in advance followed by the remaining assemblies (Model 84501, Model 84502, and Model

84503). In addition to this publication, refer to the following manuals to assist in properly installing a

complete station:

Pub. No. Emergency Phone Model

Pub. 42004-284 Model 530FB Strobe with Dual Constant-On Lamps

Pub. 42004-352 Model 297-001 Flush-Mount Emergency Phone

Pub. 42004-351 Model 297-003 S.M.A.R.T. Flush-Mount Emergency Phone

Pub. 42004-352 Model 298-001 Flush-Mount Emergency Phone with Keypad

Pub. 42004-351 Model 298-003 S.M.A.R.T. Flush-Mount Emergency Phone with Keypad

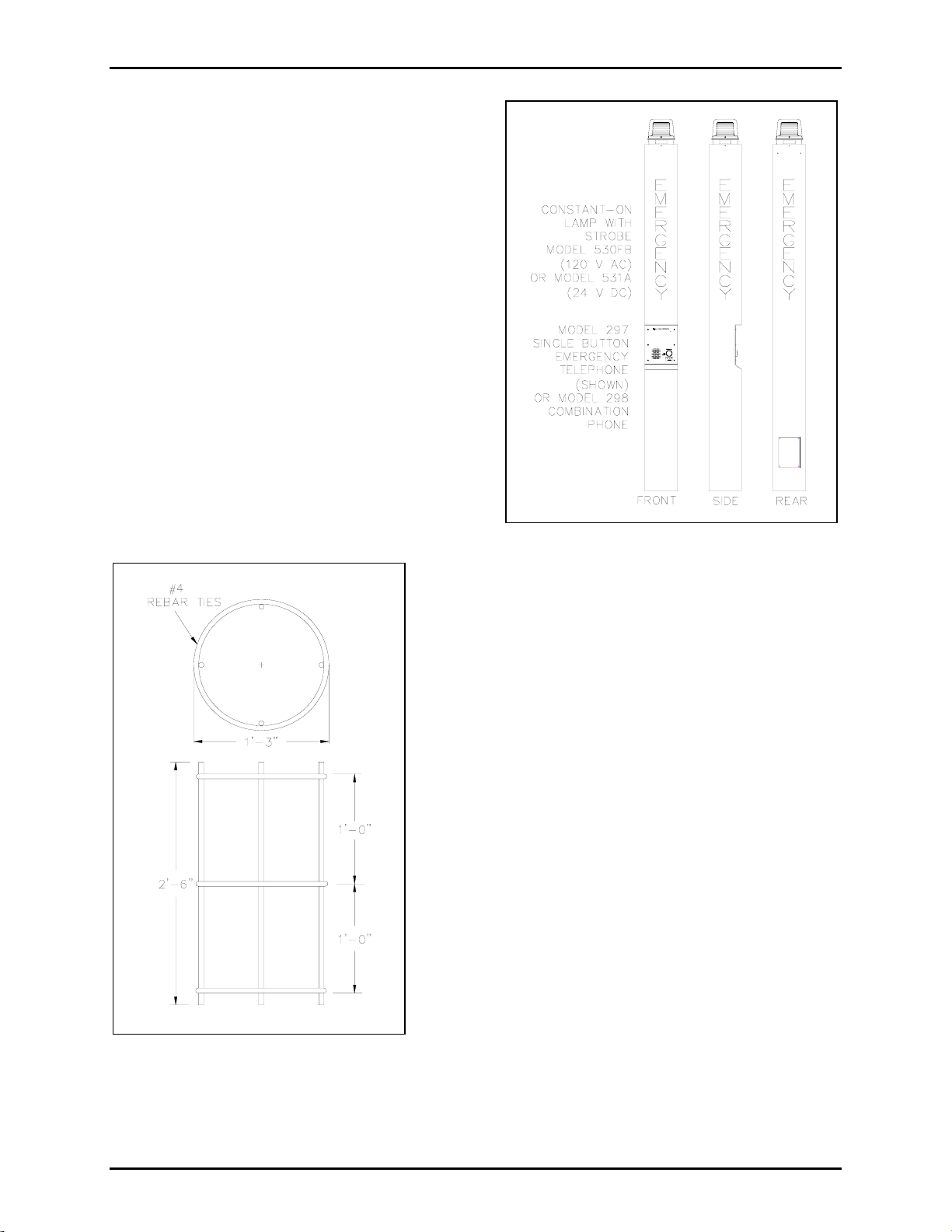

The Model 234 Stanchion Assembly is designed to house a Model 298 or 297 Emergency Telephone and

a Model 530FB or 531A Beacon. This aesthetically-pleasing stanchion is over 9 feet tall, making it easily

located by potential users.

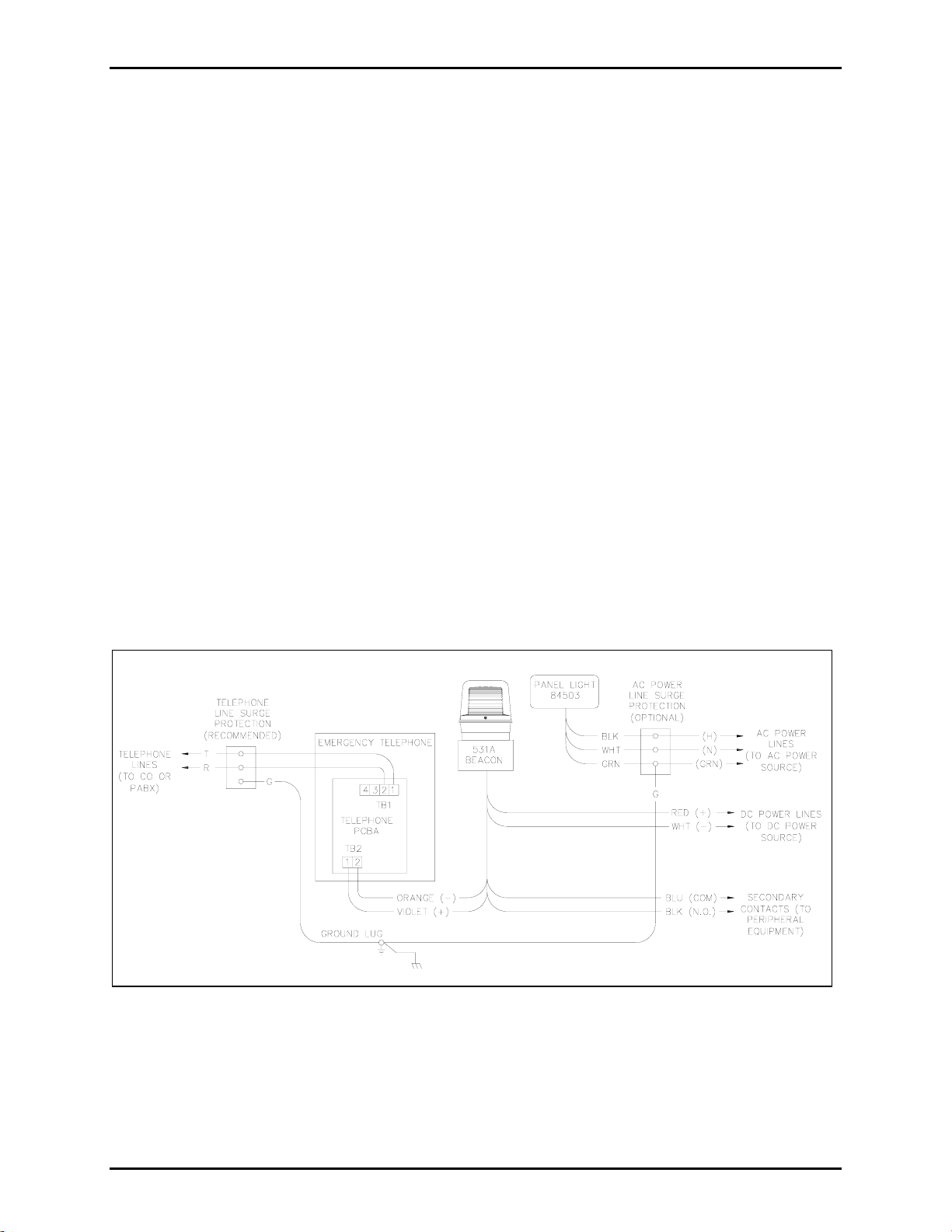

The beacon creates added noticeability to emergency telephone locations by providing a constant-on lamp

and a flashing strobe light is automatically engaged when the emergency button is pressed. The telephone

is also highly visible; a light mounted in the stanchion shines on the front panel of the telephone to

illuminate the phone for nighttime use.

GAI-Tronics enhanced emergency telephones are designed for isolated high-risk areas requiring

emergency communications equipment.

Emergency telephone users simply press the clearly labeled emergency push button for immediate

connection to a user-programmed central security telephone number.