1. PURPOSE

SECRA helmet protects upper head area against injuries from falling objects,

splashes of molten metal and electric shock by preventing electric current flow

through the head, as well as against electric arc hazards. It is particularly

recommended as personal protective equipment in live line working.

2. ADJUSTMENTS

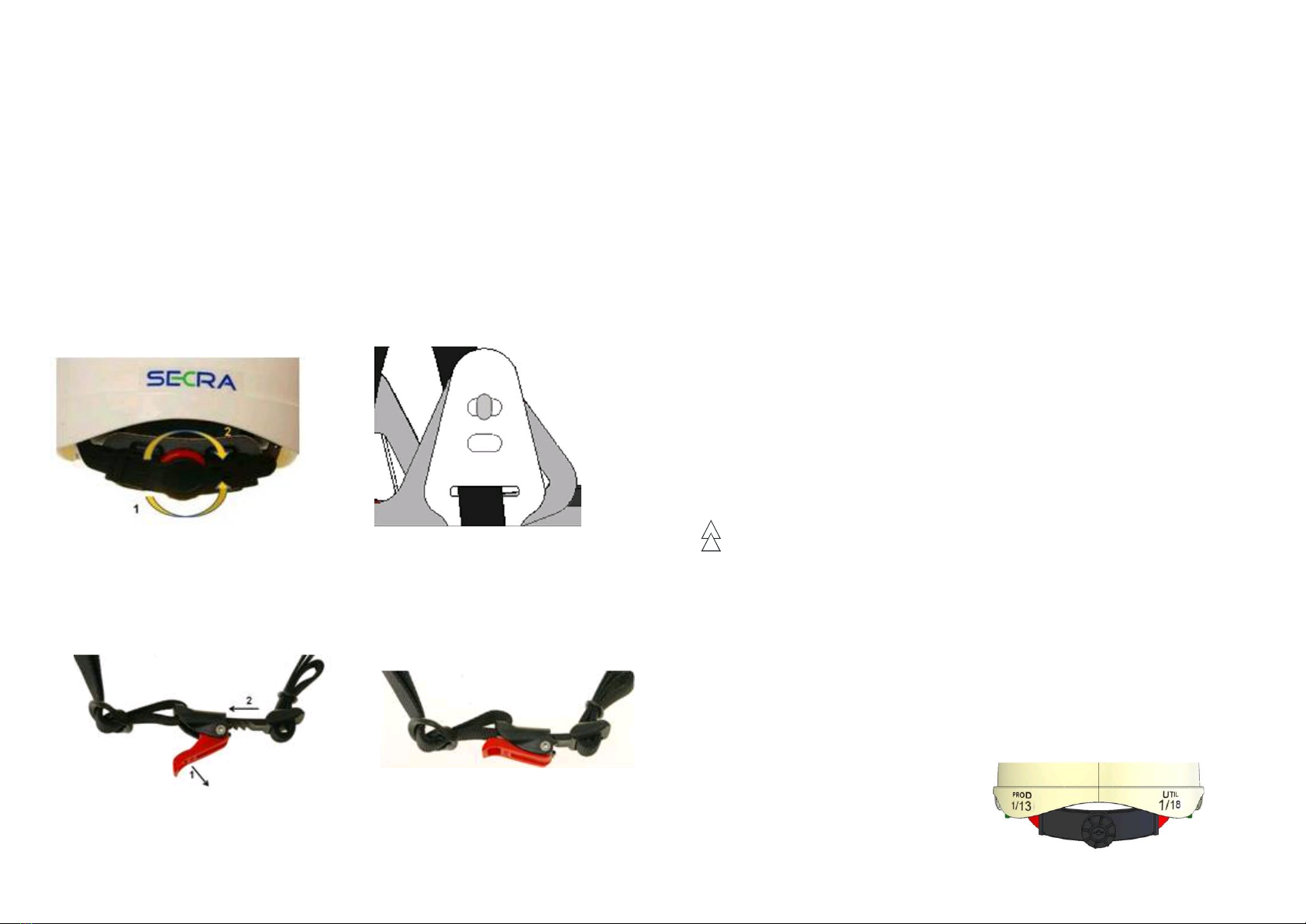

The helmet must properly fit the head. To adjust the helmet to the head

circumference, set the chinstrap length and the helmet height accordingly. The

helmet can be adjusted stepwise every 2 mm to fit the scalp within the range of

53 –63 cm, and is equipped with a two-step adjustment of the helmet height.

CHINSTRAP CLIP

Pull away the clip (1), insert the strap piece (2) into the snap fastener of the strap,

and release clip.

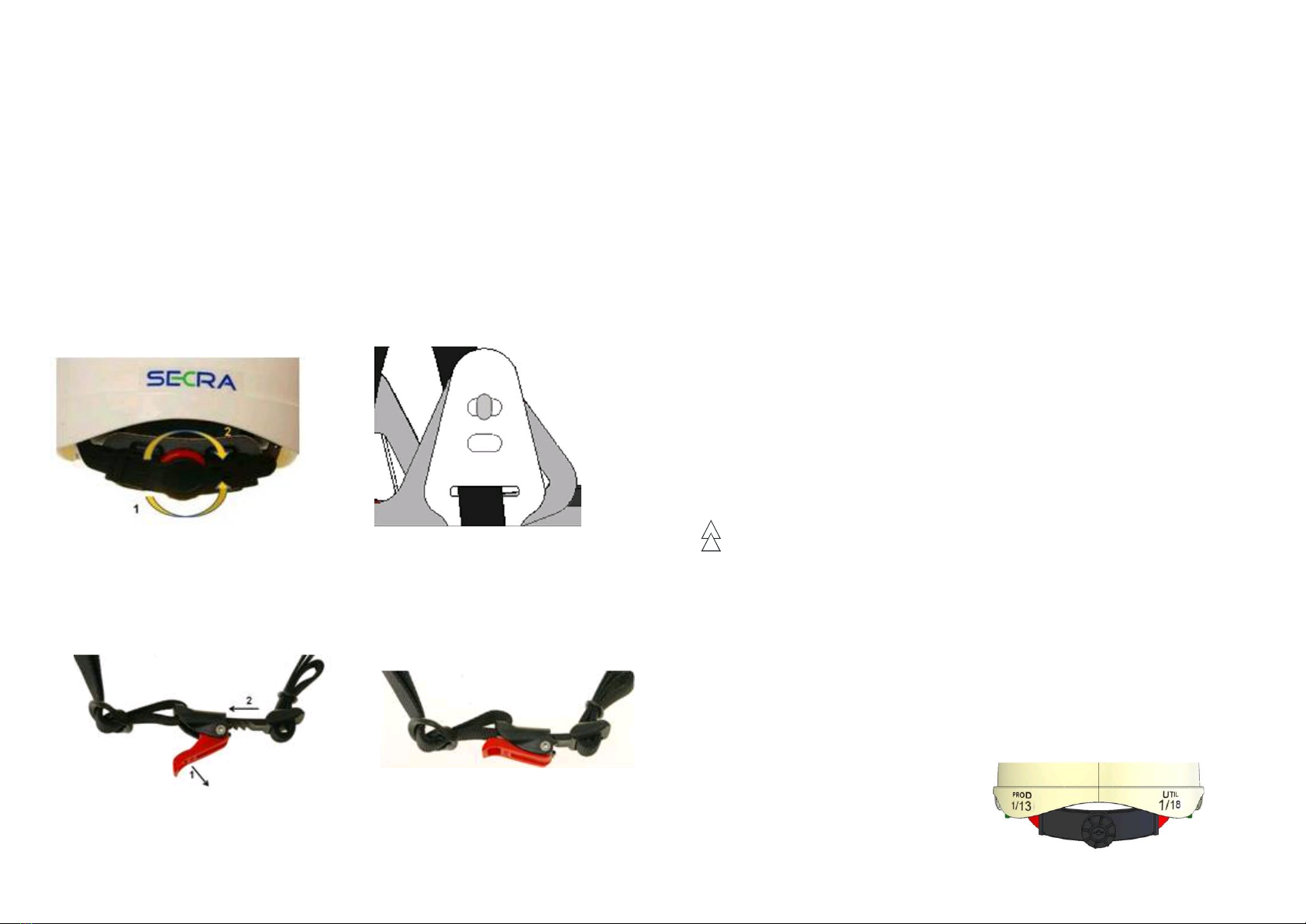

Working life of the helmet is 60 months from the date of manufacture. DISPOSE

OF THE HELMET IN CASE OF SURGE, CRACKS OR DAMAGE. None of the

helmet elements can be removed or tampered with. Do not use paints, acids or

any self-adhesive labels unauthorized by the manufacturer.

3. STORAGE & TRANSPORTATION: The helmet must be stored and shipped in

a separate transport bag. Store far from sources of heat. Protect against

mechanical damage and sunlight (UV). Do not place the helmet directly next to

room and vehicle windows.

4. CLEANING: Clean with water and soap. Dry after cleaning. Replace sweat

cloth if used up.

5. ROUTINE TESTS AND INSPECTION BEFORE USE:

The inspection should be done each time before commencement of work. The

inspection is aimed at checking:

olack of visible defects in the shell of a helmet

ocorrectness of operation of head girth regulation

ocorrectness of operation of under-chin fastening strap

oservice life

Damaged (mechanical damage of the shell or incorrect operation of head girth

regulation or under-chin fastening strap) or dirty helmet cannot be used for live

working. Dry thoroughly the wet helmet before use. Pay attention to the service

life of the helmet, which is 60 months from the date of production. After this period

the helmet should be taken out of service and utilized.

The helmet is executed according to EN 397:2012 and EN 50365:2002 standards.

6. MARKING:

label stamped on the helmet shell:

-live line working symbol.

EN 50365:2002: -reference standard „Electrically insulating helmets for use on low voltage

installations”

class 0: -electric class for systems with voltage rating up to 1,000V AC, and 1,500V DC

serial no. -for example 015

CE 1437: - conformity marking acc. to Directive 89 / 686 / EEC and notified body

no.

SECRA: - symbol (name) of the product

EN 397:2012+A1:2012 -reference standard „Industrial safety helmets”

53-63cm: - adjustment range - head circumference

HUBIX: - manufacturer

-30°C: - very low temperature (down to –30°C)

440 Vac: - electrical insulation

MM: - molten metal splash

LD: - lateral deformation

date of manufacture (quarter / year)

date of disposal (quarter / year)

loosen (1) or tighten (2)

Position of the clip: (1) shallow,

(2) deep,